Take the First Step For Estimate!

- Accurancy

- Efficiency

- Transparency

- Customization

- Time Saving

- Professionalism

- Cost Control

At Estimate Florida Consulting, your premier partner for precise and reliable water line installation estimates for warehouse buildings. Typically, simpler layouts or smaller buildings may see estimates ranging from $5,000 to $15,000, while moderate complexity or medium-sized warehouses could fall between $15,000 and $30,000. For larger buildings or those with intricate plumbing needs, estimates might reach the high range, spanning from $30,000 to $50,000 or beyond. These estimations are approximate and can vary based on project specifics and current market conditions.

Whether your project is big or small, our expertise ensures that your infrastructure needs are met with the highest standards of efficiency and professionalism.

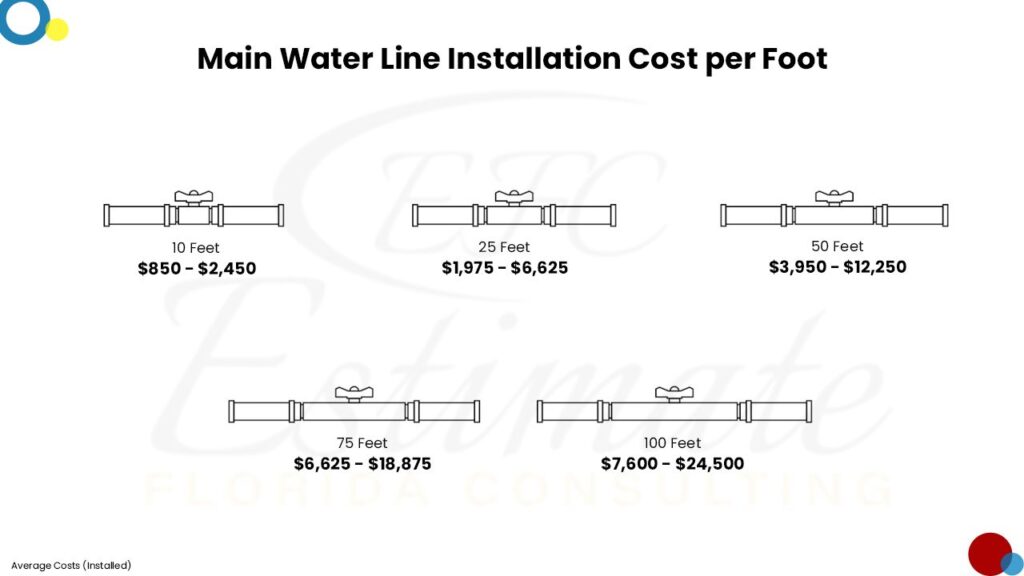

In warehouses, the main water line extends from the municipal main line to the facility’s water meter. It typically runs underground through various sections of the property. The connection point to the warehouse plumbing system is crucial and may occur in the basement or above ground. Costs are assessed per linear foot, ranging from $75 to $225, with an average of $100 to $200. Distance from the municipal road can affect project costs due to increased complexities in installation.

Length | Cost Range (Installed) |

10 Feet | $850 – $2,450 |

25 Feet | $1,975 – $6,625 |

50 Feet | $3,950 – $12,250 |

75 Feet | $6,625 – $18,875 |

100 Feet | $7,600 – $24,500 |

When considering the installation or replacement of a main water line in a warehouse setting, the primary cost consideration lies in the labor involved. While the choice of material for the line does impact the overall expenses, the bulk of the costs is attributed to labor. There are typically two methods for undertaking this project: digging and backfilling or trenchless installation.

The first method involves digging a trench in the warehouse premises to access, lay, or replace the pipes.

This traditional approach can be more disruptive and costly as it requires extensive excavation work.The second method, trenchless installation, is often preferred in warehouse environments. This method involves digging only two holes—one near the municipal street line and the other near the warehouse’s water meter. The pipe is then installed underground, threaded between these points. Trenchless installation tends to be less expensive and minimizes disruption to the warehouse property.

While trenchless installation is the preferred choice for its cost-effectiveness and reduced property disturbance, certain factors or issues may necessitate the use of the traditional digging and backfilling method.

Installation Type | Cost per Linear Foot (Labor Included) |

Trenchless | $75 – $150 |

Digging and Backfilling | $175 – $250 |

ZIP Code Based Estimate

Highly Accurate

Fully Insured License

Hire Contractor for Warehouse

Make Informed Design Decisions Showcase Your Design Ideas

Get RenderingWhen considering the materials for the main water line in a warehouse setting, various factors come into play, including cost, city regulations, climate conditions, and soil type. City regulations may dictate specific pipe types and sizes, while soil type and water needs also influence the selection.

For warehouses, main water lines typically range from ¾” to 2” in diameter, with 1” being the preferred size for most installations. The diameter is determined by factors such as distance from the water supply and elevation differences. Narrower diameters can increase water pressure, particularly for properties situated above the main supply.

Several materials are commonly used for main water lines in warehouses. PVC is cost-effective and unaffected by soil type but should be buried below the frost line in cold climates and avoided in hot climates. Polyethylene is resistant to heat and cold but may be more challenging to work with. Cast iron, once standard, is durable but prone to corrosion. Brass and copper are more expensive options that corrode in high-pH soil. Fiberglass, although durable, is best suited for short runs due to limitations in section length.

Pipe Material | Cost per Linear Foot (Materials Only) |

PVC | $0.50 – $5 |

Polyethylene | $2 – $5 |

Cast Iron | $2 – $10 |

Fiberglass | $6 – $10 |

Brass | $10 – $15 |

Copper | $20 – $30 |

PVC pipes are affordable and versatile, making them a popular choice. They are not affected by soil type but should be buried below the frost line in cold climates and avoided in hot climates due to potential degradation.

Polyethylene pipes are resistant to both heat and cold, making them suitable for various climates. However, they may be slightly more challenging to work with compared to other materials.

Cast iron pipes are durable and not affected by heat, cold, or soil conditions. However, they can be prone to corrosion over time, which has led to a decrease in their popularity compared to other materials.

Fiberglass pipes are durable and resistant to corrosion, making them suitable for long-term use. However, they are best suited for shorter runs due to limitations in section length.

Brass pipes are durable and resistant to corrosion in most soil conditions. However, they are more expensive compared to other materials, which may impact their suitability for larger installations.

Copper pipes are known for their longevity and resistance to corrosion. However, they are the most expensive option and may not be cost-effective for all projects.

Selecting the appropriate materials for water line installation in warehouse buildings is a multifaceted process that demands meticulous consideration of various factors. Copper, PVC, CPVC, and PEX are among the most commonly utilized materials, each offering distinct advantages and drawbacks. Copper, revered for its durability and resistance to corrosion, is often preferred for its long lifespan and reliability, albeit at a higher cost.

Conversely, PVC and CPVC present cost-effective alternatives, prized for their affordability and ease of installation. While PVC is suitable for cold-water applications, CPVC’s higher temperature tolerance renders it ideal for hot-water distribution. Meanwhile, PEX, known for its flexibility and freeze resistance, offers versatility in installation, particularly in challenging environments. The decision on material selection hinges on a nuanced assessment of factors such as budgetary constraints, anticipated water demand, temperature requirements, and compatibility with local building codes and regulations.

Efficient water distribution within warehouse buildings hinges on meticulous planning and optimization of pipe sizing and layout. The design process necessitates a comprehensive analysis of several variables, including anticipated water demand, pressure requirements, building layout, and plumbing fixture locations. Pipe sizing, in particular, plays a pivotal role in ensuring adequate water flow while minimizing pressure drops and energy consumption. A judicious selection of pipe diameters, informed by hydraulic calculations and industry standards, is imperative to prevent issues such as low water pressure and flow restrictions. Furthermore, the layout design must prioritize the minimization of pipe runs and the avoidance of sharp bends or obstructions to facilitate optimal water flow. By employing advanced modeling techniques and leveraging insights from experienced hydraulic engineers, designers can devise layouts that optimize efficiency, mitigate potential bottlenecks, and enhance the overall performance of the water distribution system.

Water line installation in warehouse buildings presents a myriad of challenges, owing to the diverse nature of these structures and the intricacies of their internal configurations. The installation process must contend with factors such as varying floor levels, expansive floor areas, structural impediments, and the presence of heavy machinery or equipment. Moreover, the incorporation of ancillary systems, such as fire suppression or process water distribution, further complicates the installation endeavor. Ensuring seamless integration with existing infrastructure and adherence to stringent safety protocols is paramount to mitigate potential disruptions and safety hazards. Additionally, the installation of water lines necessitates meticulous coordination with other trades, such as electrical and mechanical contractors, to ensure harmonious execution and prevent conflicts in routing or access. By anticipating these challenges and implementing proactive mitigation strategies, project stakeholders can streamline the installation process, minimize costly delays, and uphold the project’s timeline and budgetary constraints.

New projects are waiting for you.

Connect with more construction leads!

Navigating the labyrinthine landscape of local building codes and regulations is imperative for ensuring compliance and safeguarding the integrity of water line installation in warehouse buildings. Building codes dictate stringent requirements pertaining to pipe material selection, sizing, insulation, backflow prevention, and accessibility for maintenance and repairs. Failure to adhere to these regulations can precipitate a litany of legal and financial repercussions, ranging from costly fines to project delays and potential liabilities. Furthermore, compliance with regulatory mandates extends beyond mere box-checking; it encompasses a commitment to upholding the highest standards of safety, reliability, and environmental sustainability. As such, stakeholders must engage with knowledgeable professionals well-versed in local building codes and regulations to navigate the regulatory landscape adeptly. By fostering a culture of regulatory diligence and proactively addressing compliance issues, project teams can mitigate risks, instill confidence among stakeholders, and uphold the project’s reputation for excellence and integrity.

Strategizing cost-effective solutions for water line installation in warehouse buildings necessitates a judicious balancing act between quality, efficiency, and fiscal prudence. The financial outlay for water line installation encompasses various components, including material procurement, labor costs, equipment rentals, permitting fees, and contingencies for unforeseen expenses. As such, meticulous budget planning and accurate cost estimation are indispensable to prevent cost overruns and ensure financial viability. Value engineering, a systematic approach to optimizing project costs without compromising performance or quality, offers a potent tool for identifying cost-saving opportunities and maximizing return on investment. This entails scrutinizing every aspect of the project, from material selection and construction methodologies to operational efficiencies and lifecycle costs. Moreover, fostering collaborative partnerships with suppliers, subcontractors, and other project stakeholders can yield favorable pricing agreements and unlock synergies that drive down costs. By adopting a holistic approach to cost management and embracing innovation and efficiency, project teams can realize substantial savings while delivering exceptional value and performance.

Ensuring quality assurance through thorough testing and inspection of water lines in warehouse buildings is indispensable to safeguarding performance, reliability, and regulatory compliance. Rigorous testing protocols, including pressure testing, leak detection, and flow rate verification, are instrumental in identifying potential defects, vulnerabilities, or deficiencies in the installation. These tests serve as a litmus test for the integrity and functionality of the water distribution system, providing stakeholders with invaluable insights into its performance under operational conditions.

Moreover, periodic inspections throughout the construction process, conducted by qualified professionals and regulatory authorities, help identify deviations from design specifications and facilitate prompt corrective action. By adhering to a robust quality assurance regimen and proactively addressing any discrepancies or non-conformities, project teams can mitigate risks, uphold regulatory compliance, and deliver a water distribution system that exceeds expectations for reliability, efficiency, and longevity.

Securing skilled professionals for water line installation in warehouse buildings is paramount to the project’s success, safety, and longevity. The intricate nature of plumbing systems demands a high level of expertise and proficiency in hydraulic principles, material science, and construction methodologies. Moreover, navigating the complexities of local building codes and regulations requires a thorough understanding of regulatory mandates and compliance requirements. As such, selecting reputable contractors with a proven track record of excellence, reliability, and integrity is imperative. A rigorous vetting process that evaluates qualifications, experience, licensure, insurance coverage, and references can help mitigate risks and ensure the selection of contractors who possess the requisite expertise and professionalism. Additionally, fostering open lines of communication and cultivating a collaborative working relationship with contractors fosters transparency, accountability, and alignment of project objectives. By entrusting water line installation to seasoned professionals who prioritize quality, safety, and client satisfaction, stakeholders can instill confidence in the project’s outcomes and uphold the highest standards of excellence.

Before embarking on the journey of installing new water lines in a warehouse, it’s essential to navigate through a series of preparatory steps to ensure the project’s success. This segment delves into the crucial pre-installation considerations, including the evaluation of need, legal and environmental compliance, and the importance of thorough site assessment and preparation.

The decision to install new water lines should be driven by a clear understanding of the warehouse’s current and future needs. Factors such as increased water demand due to business expansion, outdated or inefficient existing systems, and compliance with updated health and safety regulations can all signify the necessity for new installations. It’s advisable for warehouse owners to consult with professionals to assess their specific needs and make informed decisions.

Adhering to legal and environmental regulations is paramount in any construction or installation project. Warehouse owners must be well-informed about local codes, permits required, and specific environmental protections in place, such as measures to prevent contamination of local water sources. Engaging with local authorities early in the planning process can streamline compliance and avoid costly delays or fines.

A comprehensive site assessment lays the foundation for a smooth installation process. This assessment should include:

Involving all relevant stakeholders, including local authorities, environmental agencies, contractors, and possibly neighboring businesses, in the planning phase can foster collaboration and ensure that all concerns and requirements are addressed upfront.

With all considerations addressed, finalizing a detailed installation plan that encompasses the project scope, timeline, budget, and contingency measures is crucial. This plan should serve as a blueprint guiding all phases of the installation process.

Regular maintenance and prompt repairs are indispensable for preserving the integrity and functionality of water lines in warehouse buildings.

A well-defined maintenance schedule, coupled with an awareness of common issues and their solutions, can significantly extend the lifespan of your water infrastructure and prevent costly downtime. This section outlines key strategies for effective water line maintenance and upkeep.

Creating a routine maintenance schedule is crucial for early detection of potential issues and ensuring the water lines remain in optimal condition. Consider the following aspects when developing your schedule:

Being vigilant about the following common issues and implementing timely solutions can prevent minor problems from escalating into major disruptions:

Let us take your project to the next level! Send us your plans, and we’ll provide a detailed estimate with competitive pricing. Our ZIP Code-based approach means better accuracy and a 90% higher chance of winning bids. Get personalized, no-shortcut service every time.

In addition to regular maintenance, implementing preventive measures can further safeguard your water lines:

Several factors can affect the cost of water line installation, including the size and complexity of the building, local labor and material costs, regulatory requirements, and any site-specific challenges. Additionally, the choice of materials and installation techniques can also impact the overall project cost.

Our estimates are meticulously crafted based on a thorough analysis of local regulations, labor costs, material prices, and prevailing market conditions specific to each project’s zip code. While we strive to provide accurate projections, it’s important to note that actual costs may vary depending on various factors and unforeseen circumstances.

Yes, we specialize in handling water line installation projects of all sizes, ranging from small-scale installations to large, complex systems. Our scalable solutions are tailored to meet the unique requirements of each warehouse, ensuring that every client receives personalized attention and exceptional service quality.

We prioritize efficiency and effectiveness to minimize disruptions during the installation process. Our team meticulously plans the project execution, coordinates logistics, and communicates proactively to anticipate and address any potential challenges or obstacles. By prioritizing minimal disruption, we aim to ensure a smooth project flow and uninterrupted operations for our clients.

At Estimate Florida Consulting, we pride ourselves on our expertise in providing accurate and comprehensive water line installation estimates tailored to the specific needs of warehouse projects. Our zip code-based estimation approach ensures that each project is evaluated with a keen eye on local specifics, leading to more reliable cost projections. Additionally, our commitment to excellence, professionalism, and customer satisfaction sets us apart in the industry.

Here I am going to share some steps to get your water line installation for warehouse buildings estimate report.

You can send us your plan on info@estimatorflorida.com

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

All copyright © Reserved | Designed By V Marketing Media | Disclaimer