Take the First Step For Estimate!

- Accurancy

- Efficiency

- Transparency

- Customization

- Time Saving

- Professionalism

- Cost Control

Estimate Florida Consulting specializes in providing accurate cost estimates for rubber roof repair in warehouse buildings. The cost of repairing or replacing a rubber roof on warehouse buildings with minor repairs ranging between $3.90 to $10.40 per square foot for tasks like fixing seams or patching holes. Moderate repairs, addressing larger damages or resealing, could cost between $6.50 to $15.60 per square foot. Extensive repairs, involving significant membrane replacement or damage remediation, are estimated between $10.40 to $19.50 per square foot.

For complete roof replacements, necessary when repairs are insufficient or the roof is beyond its life, costs are anticipated between $9.10 to $15.60 per square foot, depending on the specifics of the roofing system and project requirements.

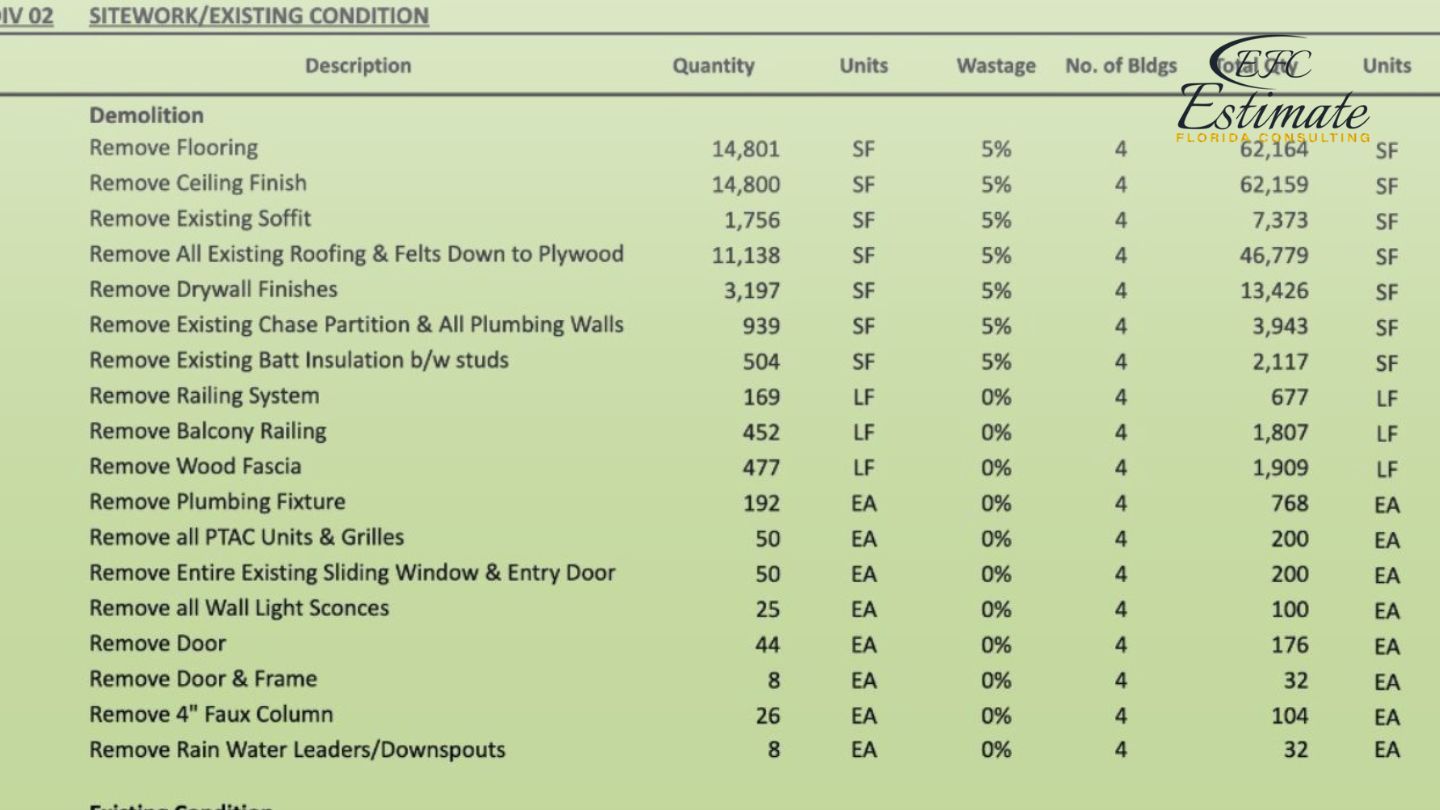

Here’s the information presented in a table format for easier reference:

Repair Category | Cost Range | Description |

Basic Repairs | $200 – $500 | Addressing minor issues like small punctures, seam resealing, or fixing isolated areas of damage. |

Moderate Repairs | $500 – $2,000 | More extensive work, including repairing larger areas of damage, multiple seams, or water intrusion. |

Major Repairs | $2,000 – $10,000+ | Comprehensive repairs, such as replacing insulation, large roof sections, and addressing structural issues if found. |

These cost ranges are approximate and can vary depending on various factors, as mentioned in the original information.

Rubber roofing materials, notably EPDM and TPO, are popular choices for warehouse buildings due to their long lifespan, resistance to extreme weather, and relatively low installation and maintenance costs. EPDM roofs are known for their durability and flexibility, while TPO roofs offer energy efficiency benefits due to their reflective properties.

Despite their durability, rubber roofs can encounter several issues, including punctures and tears from foot traffic or debris, seam failures due to adhesive breakdown, water ponding, and damage from UV exposure and shrinkage. Addressing these issues promptly can prevent more significant damage and extend the roof’s lifespan.

The extent of damage to a rubber roof is a critical factor influencing repair costs. Minor repairs, such as sealing a few seams or patching a small area, are generally less costly compared to addressing widespread water damage or structural issues. When damage is limited and localized, repairs can often be conducted with minimal material and labor expenses. However, extensive damage that compromises a significant portion of the roof may require more extensive repairs, leading to higher costs.

The size of the rubber roof and its accessibility play a significant role in determining repair costs. Larger roofs naturally require more time, materials, and labor to complete repairs. Additionally, the accessibility of the roof can impact costs. Roofs that are difficult to reach or have limited access for equipment and personnel may necessitate specialized tools or scaffolding, which can result in higher repair expenses. Contractors may also need to factor in safety measures and additional time for navigating challenging roof layouts.

Labor rates vary significantly depending on the geographic location of the roofing project. In regions with higher living costs and greater demand for skilled labor, labor rates are generally higher. The availability of experienced roofing contractors can also influence labor costs. Roof repair projects in areas with a competitive roofing industry may benefit from lower labor rates due to increased availability of skilled professionals. Conversely, in regions with a shortage of qualified roofers, labor rates may be higher, affecting the overall repair budget.

The price of rubber roofing materials and necessary accessories is a crucial factor in determining repair costs. The cost of rubber membrane sheets, adhesives, sealants, and insulation can vary based on factors such as material quality, brand, and market demand. High-quality rubber roofing materials may command a premium price but offer enhanced durability and longevity. Contractors often consider the specific requirements of the repair project and choose materials that align with the budget while ensuring the long-term integrity of the roof.

Several additional factors can impact rubber roof repair costs. The need to remove waterlogged insulation or damaged roofing materials can add to the overall expenses. Insulation replacement, in particular, can increase costs, especially if it has been affected by moisture and must be replaced to prevent further damage. Repairing underlying structural issues, such as damaged decking or trusses, can also significantly affect the final repair bill. Contractors will assess these factors during the initial inspection to provide a comprehensive estimate that accounts for all necessary repairs.

ZIP Code Based Estimate

Highly Accurate

Fully Insured License Hire Sub-Contractor for Warehouse Rubber Roof Repair

Hire Contractor

Make Informed Design Decisions Showcase Your Design Ideas

Get RenderingInvesting in regular maintenance, such as annual inspections and immediate repair of minor issues, can significantly reduce long-term repair costs. Additionally, ensuring a high-quality initial installation and using premium materials can prevent many common roofing issues.

Investing in regular maintenance, such as annual inspections and immediate repair of minor issues, can significantly reduce long-term repair costs. Additionally, ensuring a high-quality initial installation and using premium materials can prevent many common roofing issues.

Ensuring the longevity of a rubber roof on a warehouse requires a proactive approach to maintenance and care. Regular maintenance not only extends the life of the roof but also helps avoid costly repairs down the line. This section outlines effective strategies and preventative measures that warehouse owners and facility managers can adopt to maintain the integrity of their rubber roofs.

Ready to raise the roof on your bids? Take your construction projects to new heights by inquiring about our top-notch estimating services.

Selecting the right contractor is crucial for effective and lasting roof repairs. Look for contractors with specific experience in rubber roofing, proper licensing and insurance, and a solid warranty on their work. It’s also advisable to obtain detailed cost estimates and project timelines from several providers for comparison.

Maintaining the integrity of a rubber roof for warehouse buildings is essential for protecting valuable assets and ensuring the long-term structural soundness of the facility. Understanding the factors that affect rubber roof repair costs, such as the extent of damage, roof size, labor rates, material costs, and additional factors, can help warehouse owners budget and plan for maintenance effectively. Regular inspections, cleanliness, prompt repairs, and proactive maintenance measures can go a long way in reducing long-term repair expenses and extending the life of a rubber roof. Selecting the right contractor with expertise in rubber roofing is vital for successful and lasting repairs. By prioritizing roof care and investing in preventative measures, warehouse owners can ensure the continued reliability and resilience of their rubber roofs.

Signs of potential issues include visible punctures, tears, or water leaks in the building. Regular inspections, especially after severe weather events, can help identify the need for repairs.

Common causes include foot traffic, debris accumulation, adhesive breakdown, UV exposure, weather events, and the natural aging of the roofing material.

Preventative measures such as regular inspections, prompt repair of minor issues, and proper maintenance can help reduce long-term repair costs. Investing in high-quality materials during the initial installation can also extend the roof’s lifespan.

While minor repairs like sealing seams or small punctures can be DIY projects, larger repairs and those requiring specialized equipment are best handled by professional roofing contractors with experience in rubber roof repair.

When choosing a contractor, consider their experience with rubber roofing, licensing, insurance coverage, and warranties on their work. Obtaining multiple cost estimates and project timelines is advisable to make an informed decision.

It’s recommended to have a professional roofing contractor inspect your rubber roof annually. Additional inspections should be conducted after significant weather events to ensure the roof’s integrity.

Here I am going to share some steps to get your rubber roof repair cost for warehouse buildings estimate report.

You can send us your plan on info@estimatorflorida.com

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

All copyright © Reserved | Designed By V Marketing Media | Disclaimer