Quantity Takeoff And Cost Estimating

If you’re involved in architecture, engineering, or construction (AEC), you’re likely familiar with the concept of quantity takeoffs. This term has been a staple in the building industry for a long time, playing a crucial role in the planning process. Quantity takeoff requires a specialized skill set to manage data effectively.

This early stage of a project is pivotal for its success. Improper quantity takeoffs can lead to underestimating or overestimating construction costs, causing inefficiencies throughout the entire construction process. Overlooking or duplicating required material amounts and realistic pricing values can be detrimental to any job.

The key to effective construction data collection lies in thoroughness and accuracy. It’s essential to ensure that all necessary materials are accounted for and priced accurately to avoid costly mistakes down the line.

Quantity Takeoff in Construction

Let’s talk about what a quantity takeoff means in the building industry. Essentially, it’s the process of estimating the materials, resources, and labor required for a construction project. To do this, you carefully review the project plans and identify the specific materials outlined by the architect, engineer, or draftsperson.

- Estimating takeoffs

- Construction takeoffs

- Earthwork takeoffs

- Material takeoffs

- Material estimating

- Material counts

- Quantity surveying

It’s worth noting that quantity takeoffs are limited to material-specific details. Typically, quantity surveyors or takeoff specialists don’t consider other project needs like labor, overheads, permits, insurance, equipment, or incidentals. Their main goal is to pinpoint material requirements and translate that information into cost-based estimates.

New Approaches to Quantity Takeoff: Technology and Tools

The construction industry has witnessed a transformation in quantity takeoff methods, driven by advancements in technology and the adoption of sophisticated tools. Particularly for larger construction firms, the integration of computerization has become indispensable, revolutionizing traditional estimation processes. Today, processes like Building Information Modeling (BIM) and Computer-Aided Design (CAD) play a pivotal role in enhancing the accuracy and efficiency of quantity takeoffs. These innovations address longstanding challenges such as low productivity and excessive waste, as highlighted in a report by the Economist Intelligence Unit, by streamlining the construction takeoff process and minimizing errors.

The Impact of Building Information Modeling (BIM) on Takeoffs

Building Information Modeling (BIM) represents a comprehensive suite of 3D design and modeling software tools that have redefined how construction projects are visualized and managed. BIM software enables stakeholders to create detailed virtual representations of structures from multiple perspectives, facilitating a deeper understanding of the project before physical construction begins. One of the most significant advantages of BIM is its ability to enhance collaboration among project teams. Through features like clash detection and coordination tools, BIM fosters communication and coordination, ultimately leading to more accurate construction takeoffs. Moreover, BIM enables stakeholders to anticipate and resolve design conflicts early in the process, thereby minimizing costly changes during construction.

The Role of Computer-Aided Design (CAD) in Quantity Takeoffs

CAD programs have revolutionized the building industry by enabling companies to digitally construct their projects prior to breaking ground. Structures are meticulously designed in a virtual environment through 2D drawings and 3D models, allowing teams to iron out any issues and proceed with reduced-risk structures in the real world.

CAD offers several benefits:

- Optimized Designs: Operators can test designs under various real-world conditions to identify the one that best aligns with project specifications and budget constraints. These 2D and 3D models facilitate the optimization of material usage.

- Improved Quality: CAD enables greater precision and attention to detail by providing comprehensive construction visualization. More accurate representations lead to more precise quantity takeoffs, ultimately enhancing the overall quality of the project.

- Decreased Time: CAD facilitates efficient workflows, saving time on project design and takeoff estimations. Operators can swiftly make adjustments and seamlessly collaborate with other team members, resulting in faster project completion.

Exploring Various Quantity Takeoff Methods

While advancements in computerization have undoubtedly improved the accuracy and speed of takeoffs, it’s important to acknowledge the indispensable role of human expertise in ensuring quality. Even with digital takeoffs, human operators and interpreters play a crucial role, much like in manual takeoff methods. Today, construction projects still rely on two primary quantity takeoff methods: manual and digital.

Traditional Manual Material Takeoffs

The traditional manual material takeoff method remains a fundamental approach in the construction industry. It involves estimators meticulously examining physical plans or blueprints and meticulously recording every material type and quantity specified in the construction drawings. This process is time-consuming and susceptible to human error. The accuracy of manual takeoffs relies heavily on the estimator’s knowledge of materials, experience in estimating, and skill in quantifying material quantities. Attention to detail is paramount in manual methods, as there is no substitute for thoroughness.

Advancements in Digital Material Takeoffs

Digital material takeoffs, facilitated by computer analysis and database applications, represent a relatively newer approach in construction. The advent of CAD-based programs in the late ’80s and ’90s marked the beginning of sophisticated digital takeoff methods. These programs quickly evolved to integrate computerized building models with digital takeoff capabilities. Digital takeoffs offer significant advantages over manual methods, particularly for large and complex projects, due to their speed and comprehensive nature. However, the effectiveness of digital takeoffs hinges on the proficiency and training of the takeoff technician in using the software application, as well as their attentiveness to accurately translating takeoff information into cost-based results.

Quantity takeoffs may involve complex processes, but they ultimately serve a singular purpose: accurate data management. Whether employing manual takeoff personnel or utilizing the latest digital takeoff programs, the goal remains the same — to generate a precise list of all materials required for the project and develop a meaningful pricing structure accordingly.

Download Template For Lumber Project Breakdown

- Materials list updated to the zip code

- Fast delivery

- Data base of general contractors and sub-contractors

- Local estimators

Who's Involved in Quantity Takeoff?

Quantity takeoff isn’t just a task for the tail end of a building project—it’s a crucial step right from the start. It sets the stage for accurate cost estimates and informs the bidding process, ensuring realistic contracts based on precise material and financial data.

Whether you’re tackling a small residential unit or a sprawling subdivision project with complex earthworks and infrastructure, you need to crunch the numbers to understand the costs and materials required. This process kicks off with material takeoffs, where you assess what’s needed and forecast the eventual expenses.

While architects, engineers, and construction managers are key players in this process, they’re not the only ones. Regardless of the industry, anyone involved in construction needs to do material calculations and price estimates. Here’s a rundown of the professionals who typically handle material takeoffs:

- Urban planners and smart city designers

- Tunneling and subway architects

- Residential builders and renovators

- Rail and metro transportation engineers

- Offshore and marine architects

- Landscapers and landscape architects

- Highway and road engineers

- General contractors and construction managers

- Energy and utility contractors

- Civil, mechanical, and structural engineers

- Architects and building designers

Performing a quantity takeoff requires skill, patience, and keen observation. It’s a task that demands experience, as it’s a critical component in proposing and managing projects. In fact, many project managers enlist specialized independent professionals to handle quantity takeoffs due to its importance in the construction process.

Comprehensive Steps to Conduct a Quantity Takeoff

Quantity takeoffs serve as the backbone of building construction projects, ensuring accurate estimations of materials and resources required for successful completion. Mastering this process requires a systematic approach and a blend of technical expertise and practical experience.

Input Considerations

The initial phase of a quantity takeoff involves meticulous data input, laying the foundation for accurate estimations. Whether working with traditional blueprints or sophisticated CAD models, takeoff technicians play a critical role in managing and interpreting project data. While they may not be directly involved in the design phase, skilled technicians possess the ability to identify discrepancies and inconsistencies in the plans, ensuring that the input data is precise and reliable. This attention to detail is paramount in minimizing errors and discrepancies in the subsequent phases of the takeoff process.

Output Specifications

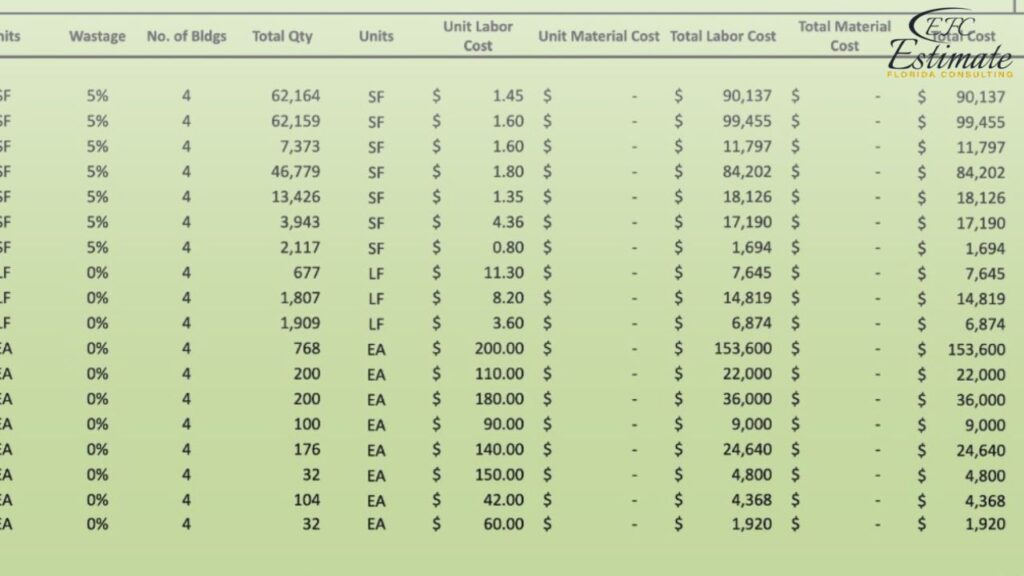

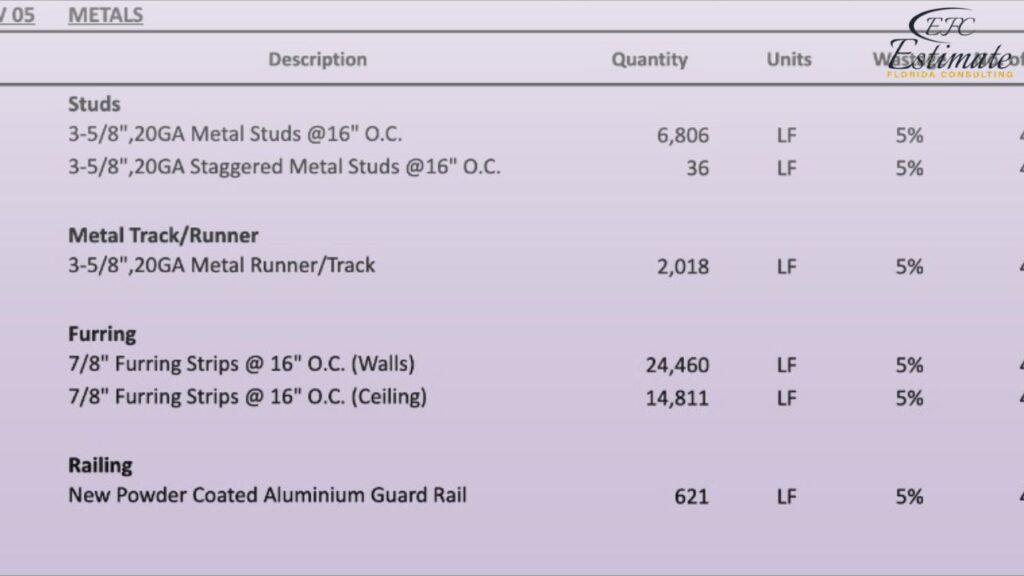

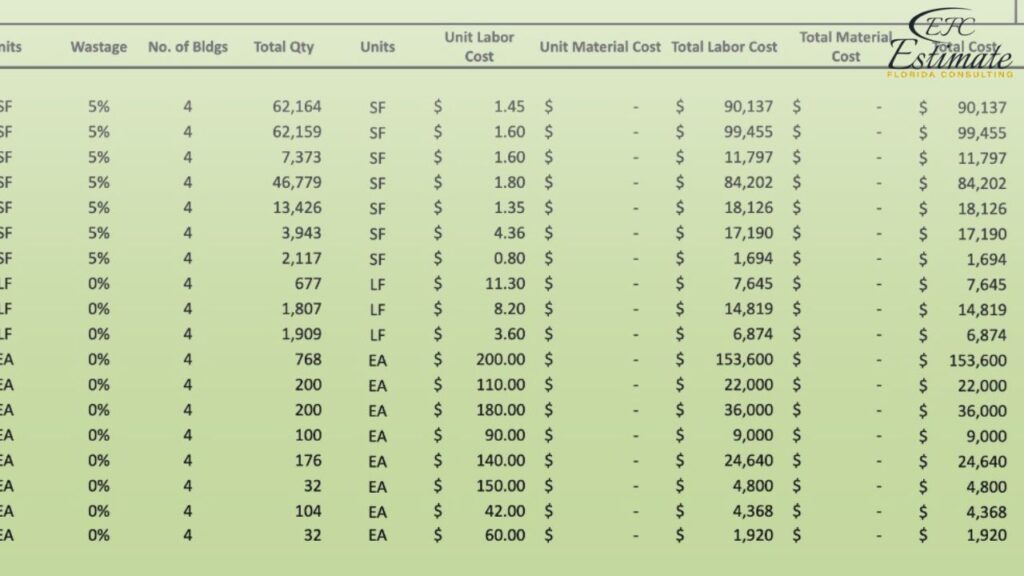

The final phase of a quantity takeoff revolves around generating comprehensive output specifications that form the basis of project estimates and proposals. This involves translating the input data into actionable material quantities and cost estimates. Whether utilizing software-generated reports or manual calculations, takeoff teams must ensure the accuracy and reliability of the output. By meticulously quantifying materials and attaching corresponding cost data, practitioners create a solid foundation for project planning and budgeting, laying the groundwork for successful bids and project execution.

Data Management and Pricing

Effective data management and pricing play a pivotal role in the accuracy and reliability of quantity takeoffs. Construction data management professionals are tasked with sourcing and validating pricing information to inform material estimates. Depending on the scale and scope of the project, estimators may rely on a combination of local and national pricing data to ensure accuracy. By leveraging quality data and industry expertise, practitioners can produce estimates that are not only precise but also aligned with project requirements and budgetary constraints.

Evaluating a Quantity Takeoff

Performing a quantity takeoff is essentially a mathematical process, involving the extraction and extrapolation of material figures from input data and referencing them to corresponding values on the output end. This forms the basis of a comprehensive project estimate, which incorporates additional costs for labor, equipment, and overhead.

In the realm of material takeoffs, the term “quantity” refers to the identification and quantification of various materials essential for construction. This includes earthwork materials such as cut and fill requirements, as well as materials like pipes, steel, or lumber necessary for structural components.

Quantity surveyors and material takeoff professionals face the challenge of translating two-dimensional plans into three-dimensional representations for accurate quantification. While manual takeoff methods require spatial visualization skills, digital methods streamline the process by managing data electronically.

Here are some fundamental formulas used by takeoff professionals to quantify construction materials:

- Unit count: This involves counting individual items such as light fixtures, pipe fittings, or door knobs. Estimators calculate the total unit figures and multiply them by the unit price to obtain a gross total.

- Linear length: Total lengths or runs of materials like lumber, steel, or piping are quantified by adding up their combined linear lengths and assigning a gross value to them.

- Surface area: Estimating surface area materials involves calculating the length times width for materials like flatwork stones, floor coverings, or roofing materials, and quantifying the total to a value.

- Cubic volume: Three-dimensional materials such as earthworks, concrete pours, or insulation are quantified using cubic volume calculations (length × width × height), which are then applied as unitized numbers in the value column.

- Physical weight: Calculating construction materials by weight is essential for accounting for transportation costs. This involves determining pounds of steel or tons of backfill, among other materials.

While meticulous attention is paid to two and three-dimensional calculations, quantity takeoff professionals recognize that their figures ultimately impact two additional dimensions of construction: time and cost. Therefore, ensuring accurate material takeoffs is crucial for project success, as inaccuracies can have significant implications for both the timeline and budget of a construction project.

The Benefits of Accurate Quantity Takeoffs

Quantity takeoffs play a pivotal role in various stages of a construction project, influencing everything from initial design to project execution. Precision in quantity takeoffs is paramount as it sets the foundation for project success. Accurate quantity takeoffs provide a detailed breakdown of required materials, allowing estimators to calculate costs effectively and enhance project components such as:

- Project Estimation: Quantity takeoffs form the cornerstone of project estimations. The accuracy of these takeoffs directly impacts the accuracy of project estimates, determining the project’s feasibility within budget constraints and ensuring alignment with client needs and expectations.

- Bidding: Accurate quantity takeoffs empower construction companies to submit competitive bids. By providing precise calculations for material quantities, companies can avoid overestimation or underestimation, showcasing their efficiency and professionalism to secure successful bids.

- Budgeting: Precision in quantity takeoffs leads to accurate budgeting. By meticulously calculating material needs, construction companies can estimate expenses with confidence, enabling them to deliver projects within budgetary constraints.

With precise quantity takeoffs, construction companies can further benefit by:

- Minimizing Material Waste: Accurate quantity takeoffs determine the exact amount of materials required, reducing overestimations. This optimization allows companies to streamline orders, minimize waste, and increase profitability.

- Improving Time Management: Accurate quantity takeoffs mitigate project delays caused by inadequate or incorrect material supplies. They also expedite project planning, speeding up design stages and project execution.

- Preventing Costly Rework: Precision in quantity takeoffs helps prevent expensive errors throughout the project duration, ensuring accuracy from the outset and minimizing the need for rework.

- Enhancing Collaboration: Clear material requirements derived from accurate quantity takeoffs facilitate effective communication and coordination among project teams. Transparent estimations foster positive relationships with clients, enhancing satisfaction and loyalty.

- Performing Cost Tracking: Accurate quantity takeoffs support effective cost tracking by providing a clear overview of realistic expenses. This enables informed decision-making, helping teams anticipate costs, avoid budget overruns, and address unexpected expenses.

- Managing Documentation: Accurate quantity takeoffs serve as a valuable reference point for documentation and record-keeping. They provide a comprehensive record of estimated quantities and costs, aiding in change management, progress evaluation, and post-project analysis.

The Importance Of Accuracy In Quantity Takeoffs

Accurate quantity takeoffs are crucial in the construction industry, particularly in the United States, where projects involve significant costs and timelines, impacting billions of dollars and employing millions of workers. Given the magnitude of these projects, precision in material takeoffs is paramount.

When it comes to material takeoffs, you typically have two main options: the traditional manual method or the more modern digital approach. Choosing between them often involves weighing factors like time and cost. While manual methods may be familiar and cost-effective, they can be time-consuming and prone to errors. On the other hand, digital takeoff systems offer greater accuracy and efficiency but may require an initial investment.

However, there’s a third option that combines the best of both worlds: hiring a professional material takeoff specialist. These experienced professionals are adept at delivering accurate and thorough takeoffs, ensuring reliability and precision in your estimates. By entrusting this task to experts, you can confidently support your bids and business endeavors, even under tight time constraints.

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- High-Rise Building

- Shopping Complex

Conclusion

Quantity takeoff and cost estimating are integral aspects of architecture, engineering, and construction (AEC) projects. Effective quantity takeoffs are essential for accurate project planning, ensuring that materials, resources, and labor are appropriately accounted for. Traditional manual methods, though time-tested, can be prone to errors and inefficiencies. However, advancements in technology, such as Building Information Modeling (BIM) and Computer-Aided Design (CAD), have revolutionized the process, enhancing accuracy and efficiency. Accurate quantity takeoffs not only facilitate precise cost estimations but also contribute to minimizing material waste, improving time management, and enhancing collaboration among project teams. Whether utilizing manual or digital methods, or leveraging the expertise of professional material takeoff specialists, the goal remains consistent: to achieve precise data management and cost-based estimations, ultimately ensuring the success of construction projects.

FAQs

A quantity takeoff is the process of estimating the materials, resources, and labor required for a construction project. It involves reviewing project plans to identify specific materials outlined by architects, engineers, or draftspersons.

Accuracy in quantity takeoffs is crucial as it forms the foundation for project success. Inaccurate estimations can lead to underestimating or overestimating construction costs, causing inefficiencies throughout the construction process.

Traditional methods involve manual examination of physical plans or blueprints, while digital methods utilize computer analysis and database applications for more efficient estimations.

Advancements in technology, such as Building Information Modeling (BIM) and Computer-Aided Design (CAD), have revolutionized quantity takeoff methods by enhancing accuracy, efficiency, and collaboration among project teams.

Quantity takeoffs are typically performed by architects, engineers, construction managers, and specialized professionals known as quantity surveyors or takeoff specialists.

Accurate quantity takeoffs enable precise project estimation, competitive bidding, and effective budgeting. They also help minimize material waste, improve time management, prevent costly rework, enhance collaboration, enable cost tracking, and facilitate documentation management.

Google Reviews

Process To Get Lumber Estimate Report

Here I am going to share some steps to get lumber estimate report.

-

You need to send your plan to us.

You can send us your plan on info@estimatorflorida.com

-

You receive a quote for your project.

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

-

Get Estimate Report

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.