Bid Confidently, Win Consistently – Zip Code Estimates Made Easy!

- Accurancy

- Efficiency

- Transparency

- Customization

- Time Saving

- Professionalism

- Cost Control

Pharmaceutical plants, critical for producing life-saving medications, face the challenge of balancing operational efficiency with cost-effectiveness. One significant aspect of this challenge is estimating and optimizing electrical costs. In this article, we’ll delve into the importance of effective electrical estimation in pharmaceutical plants, factors influencing costs, and strategies for optimizing expenses.

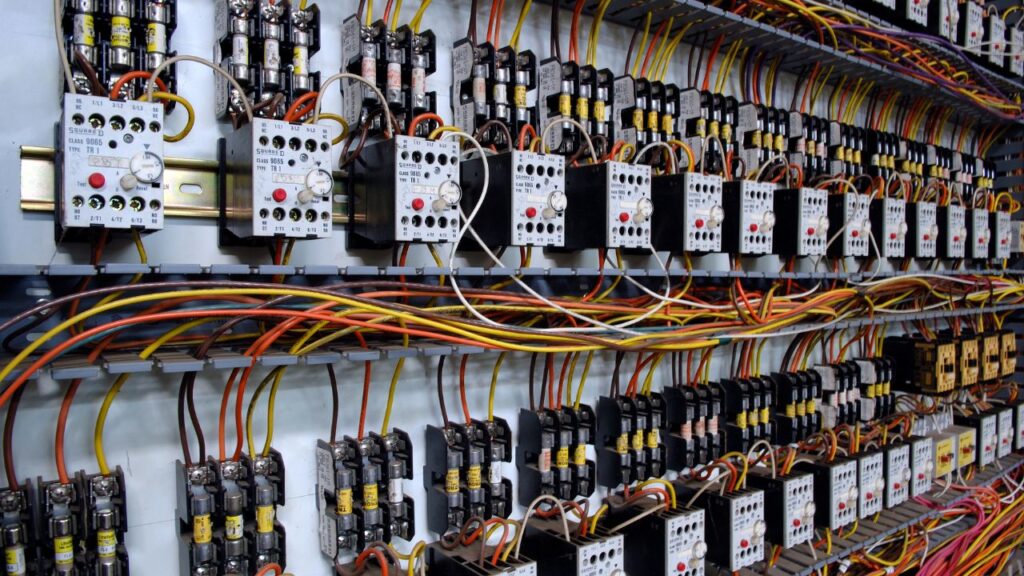

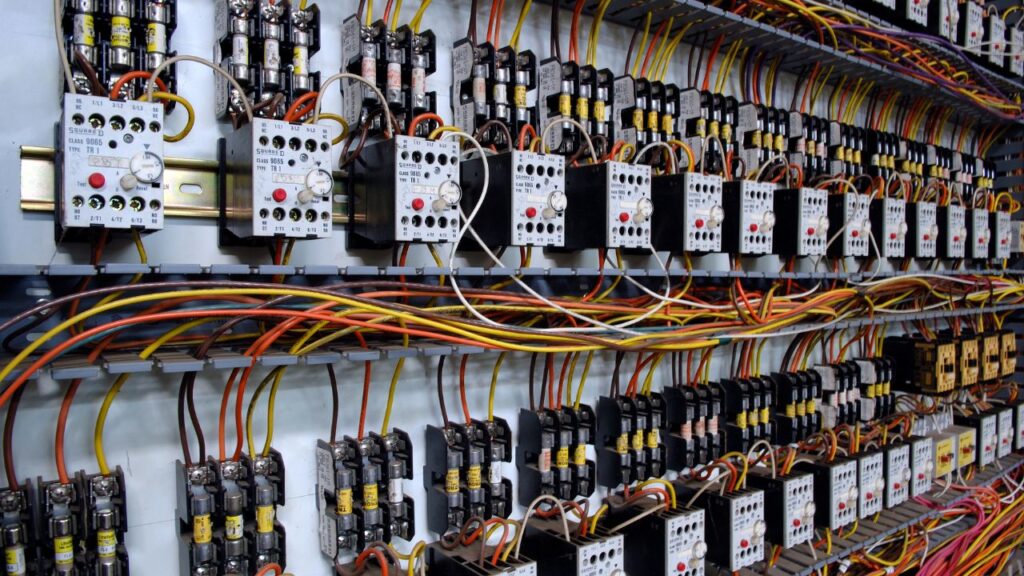

Electrical systems are the backbone of pharmaceutical plants, powering crucial processes and maintaining a controlled environment necessary for drug manufacturing. Accurate electrical estimation is essential for budgeting, project planning, and ensuring that the facility operates efficiently. It not only prevents budget overruns but also contributes to sustainable operations and regulatory compliance.

Pharmaceutical plants house a myriad of specialized equipment and machinery critical to the drug manufacturing process. Each piece of equipment demands a unique electrical load, and accurately estimating their power requirements is paramount. This estimation not only prevents the risk of electrical overload but also aids in reducing downtime due to unexpected power issues. Additionally, optimizing energy usage based on precise estimations contributes to overall operational efficiency, ensuring that the electrical infrastructure adequately supports the diverse needs of the pharmaceutical production line.

Fully Insured Licensed Hire a Contractor For Electrical

Hire Contractor

Make Informed Design Decisions Showcase Your Design Ideas

Get RenderingThe controlled environment of cleanrooms is fundamental to pharmaceutical production, demanding meticulous attention to temperature, humidity, and air quality management. These stringent environmental controls significantly influence electrical costs. Accurate estimation is vital for planning energy-efficient Heating, Ventilation, and Air Conditioning (HVAC) systems tailored to the unique demands of cleanroom operations. By incorporating precise estimations, pharmaceutical plants can implement targeted environmental control measures, ensuring both compliance with industry standards and cost-effective energy usage.

Adequate and strategic lighting is essential for pharmaceutical plant operations, particularly in areas like laboratories and manufacturing facilities. Estimating the lighting requirements involves a careful consideration of factors such as workspace illumination needs and regulatory compliance. Introducing energy-efficient lighting solutions, such as LED technology, not only addresses these requirements but also contributes to significant cost savings over time. Furthermore, exploring automation in lighting control enhances efficiency, allowing for dynamic adjustments based on specific operational needs and schedules.

Pharmaceutical manufacturing relies heavily on the integration of sophisticated automation and control systems. Estimating the electrical needs for these systems encompasses a wide range of components, including sensors, controllers, actuators, and communication devices. Accurate estimation ensures that the electrical infrastructure can support the seamless functionality of these systems, avoiding operational disruptions. The investment in precise electrical estimation for automation contributes not only to the efficiency of manufacturing processes but also to long-term cost-effectiveness, as it allows for strategic planning and resource allocation.

Pharmaceutical plants operate in a highly regulated environment, necessitating strict adherence to safety and regulatory standards. Estimating electrical costs involves accounting for various safety features, emergency systems, and compliance measures essential to maintaining a secure working environment. The financial investment in ensuring compliance is integral to risk mitigation, preventing potential fines, shutdowns, or safety incidents. Accurate cost estimation in this context is not only a financial consideration but a critical aspect of pharmaceutical plant operations that prioritizes both employee safety and regulatory integrity.

Pharmaceutical plants can significantly enhance their operational efficiency by investing in energy-efficient machinery and lighting systems. A prime example is the adoption of LED lighting, known for its lower energy consumption and extended lifespan. By making such investments, pharmaceutical facilities not only contribute to their sustainability objectives but also pave the way for substantial long-term savings. The reduction in energy consumption, particularly in critical areas like laboratories and manufacturing floors, translates directly into lowered operational costs, making it a strategic and cost-effective decision.

As part of a broader sustainability strategy, pharmaceutical plants can explore the integration of renewable energy sources into their electrical infrastructure. Solar and wind power, for instance, offer sustainable alternatives that can help offset traditional electricity costs. Beyond aligning with environmental goals, this integration of renewable energy sources positions pharmaceutical plants to capitalize on potential long-term savings. By harnessing natural resources, these facilities contribute to a greener footprint while simultaneously mitigating the impact of fluctuating electricity prices.

Implementing power factor correction measures is a proactive step toward optimizing the efficiency of electrical systems in pharmaceutical plants. This technique ensures that the power drawn from the grid is utilized more effectively, reducing energy consumption and, consequently, lowering costs. Power factor correction measures are particularly relevant in facilities with a mix of machinery and equipment, where variations in power requirements can occur. By improving power factor, pharmaceutical plants not only enhance their energy efficiency but also gain financial benefits through reduced electricity expenses.

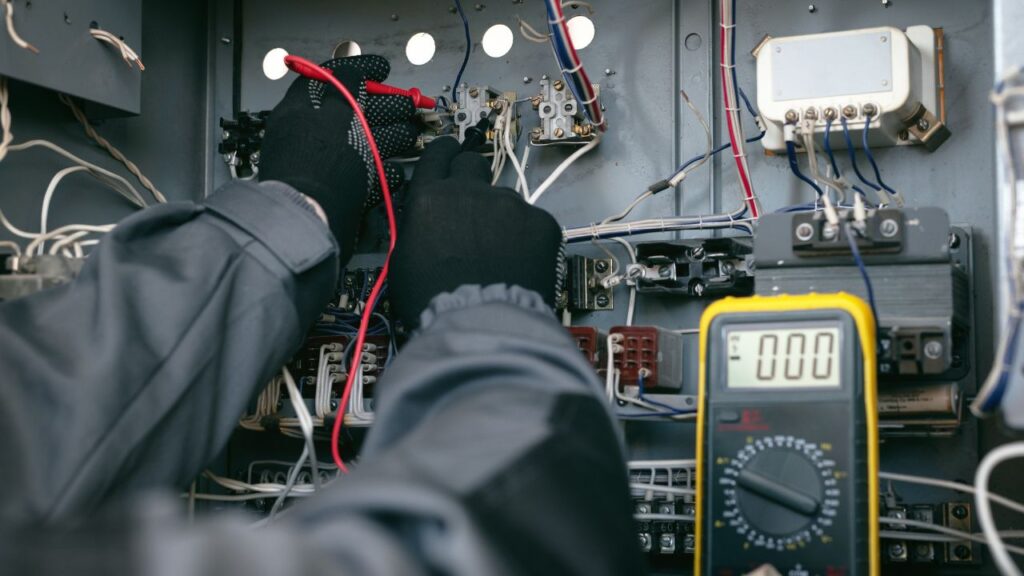

The installation of advanced energy management systems represents a technological leap for pharmaceutical plants in optimizing their energy usage. These systems provide real-time monitoring, analysis, and optimization of energy consumption throughout the facility. By leveraging data-driven insights, pharmaceutical facilities can make informed decisions to minimize energy costs. The proactive nature of energy management systems enables quick responses to fluctuations in energy demand, contributing to both operational efficiency and cost-effectiveness. This investment in technology aligns with the industry’s commitment to innovation and sustainability.

Conducting regular audits and maintenance checks on electrical systems is a fundamental practice for pharmaceutical plants. This proactive approach serves to identify inefficiencies, potential risks, and areas for improvement. Addressing electrical issues promptly not only ensures uninterrupted operations but also prevents unexpected costs associated with downtime and emergency repairs. Regular maintenance is an integral aspect of risk management, promoting the reliability and longevity of electrical systems. This commitment to proactive upkeep reflects the pharmaceutical industry’s dedication to ensuring the highest standards of operational efficiency and cost-effectiveness in their facilities.

Accurate electrical estimation is a cornerstone for ensuring the efficient and cost-effective operation of pharmaceutical plants. The diverse factors influencing electrical costs, ranging from specialized equipment and cleanroom requirements to lighting systems and automation, underscore the importance of precise estimation in budgeting and planning. Pharmaceutical facilities can further optimize their electrical costs through strategic investments in energy-efficient equipment, renewable energy integration, power factor correction, and advanced energy management systems. Emphasizing compliance and safety measures alongside regular maintenance and audits is not just a financial consideration but a commitment to operational excellence and regulatory integrity. By navigating the complexities of electrical estimation and embracing innovative strategies, pharmaceutical plants can strike a balance between operational efficiency, cost-effectiveness, and sustainability in their critical mission of producing life-saving medications.

Accurate electrical estimation is crucial for pharmaceutical plants as it forms the basis for budgeting, project planning, and efficient facility operation. It prevents budget overruns, aids in sustainable operations, and ensures compliance with regulatory standards.

Pharmaceutical plants house a range of specialized equipment, each with unique electrical requirements. Accurately estimating the power needs of this machinery is essential to prevent electrical overload, reduce downtime, and optimize energy usage.

Cleanrooms in pharmaceutical plants demand precise temperature, humidity, and air quality control. Accurate estimation ensures the planning of energy-efficient HVAC systems, contributing to compliance with industry standards and cost-effective energy usage.

Adequate and strategic lighting is crucial for pharmaceutical operations. Estimating lighting requirements, incorporating energy-efficient solutions like LED technology, and exploring automation contribute to significant cost savings over time.

Pharmaceutical manufacturing relies on sophisticated automation and control systems. Accurate electrical estimation for these systems, including sensors, controllers, and communication devices, ensures seamless functionality, avoiding operational disruptions and promoting long-term cost-effectiveness.

Pharmaceutical plants must adhere to strict safety and regulatory standards. Estimating electrical costs includes accounting for safety features, emergency systems, and compliance measures, ensuring a secure working environment and mitigating the risk of fines or shutdowns.

Investing in energy-efficient equipment, such as LED lighting, and exploring renewable energy integration, power factor correction, and advanced energy management systems are strategies that contribute to operational efficiency and long-term cost savings.

Regular audits and maintenance checks help identify inefficiencies, potential risks, and areas for improvement in electrical systems. Addressing issues promptly ensures uninterrupted operations, prevents unexpected costs, and promotes the reliability and longevity of electrical systems in pharmaceutical plants.

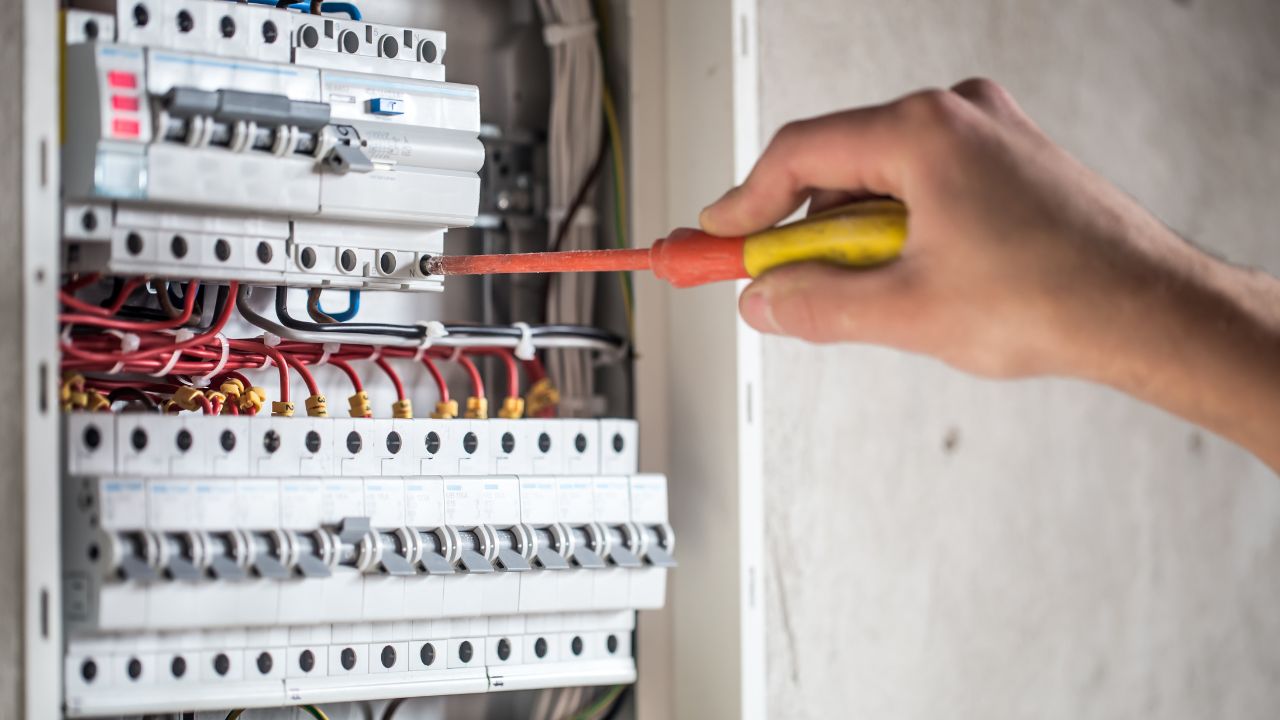

Here I am going to share some steps to get your pharmaceutical plants electrical estimate report.

You can send us your plan on info@estimatorflorida.com

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

All copyright © Reserved | Designed By V Marketing Media | Disclaimer