Boost Your Warehouse Construction Bids – Request a Precision Estimate!

- Accurancy

- Efficiency

- Transparency

- Customization

- Time Saving

- Professionalism

- Cost Control

Determining the cost of a metal warehouse roofing system in Florida involves considering several factors outlined in the preceding section. To provide a general overview, industry estimates suggest that the installation of a metal roof in Florida typically falls within a broad price range. On average, businesses and property owners can expect to invest anywhere from $4,000 to $18,000 or more for a metal roofing system. The fluctuation in cost is influenced by variables such as the size of the warehouse, the type of metal roofing material selected, and the intricacy of the installation process.

At Estimate Florida Consulting, we understand the importance of accurate cost projections for your projects. We specialize in providing detailed estimates tailored to your specific needs.

The selection of roofing materials plays a pivotal role in determining overall costs. Common choices for metal warehouse roofing include metal panels, standing seam roofs, and insulated metal panels. The cost variations arise from factors such as the type of material, its thickness, and insulation properties. While basic metal panels may offer cost-effectiveness, standing seam roofs and insulated metal panels may come with higher initial investments due to enhanced durability and energy-efficient features.

Fully Insured Licensed

Hire Contractor For Warehouse Construction

Make Informed Design Decisions Showcase Your Design Ideas

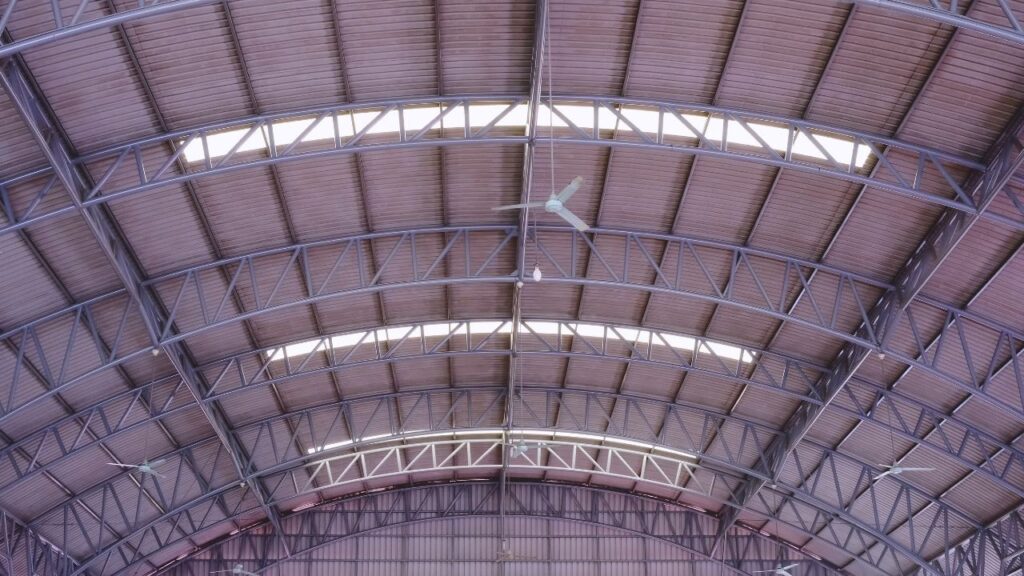

Get RenderingMetal roofs have gained popularity in warehouse construction due to their durability, energy efficiency, and cost-effectiveness. With proper maintenance and safeguards, metal roofs can boast an impressive lifespan ranging from 40 to 80 years, making them a durable and long-lasting roofing option. Typically applied to sloped or pitched roofs, metal roofing offers a robust solution for varied architectural needs.

Steel is the most prevalent and cost-effective type of metal roofing used in warehouse construction. Renowned for its durability, steel roofs are often coated with aluminum or zinc, providing an additional layer of protection against corrosion. The affordability of steel makes it a popular choice for various projects, and its robustness ensures a long lifespan, contributing to its cost-effectiveness. Typically, the cost for steel metal roofing installation ranges from $7 to $12 or more per square foot, making it a budget-friendly option for those seeking a durable and reliable roofing solution.

Aluminum metal roofing is recognized for its lightweight nature and corrosion resistance, making it an ideal choice for areas prone to extreme weather conditions. Although more expensive than steel, the ease of working with aluminum contributes to its popularity in construction projects. The cost for aluminum metal roofing installation typically ranges from $10 to $15 or more per square foot. While the initial investment is higher, the durability and low-maintenance characteristics of aluminum make it a cost-effective choice over the long term, especially in regions where weather resistance is a critical consideration.

Zinc metal roofing stands out as an excellent choice for high-risk exposure areas due to its exceptional corrosion resistance. With a history dating back to the 16th century, zinc roofs offer reliability and longevity with proper maintenance. Additionally, zinc roofs provide excellent energy efficiency and reflectivity, contributing to reduced cooling costs in the summer. The cost for zinc metal roofing installation is typically higher, ranging from $12 to $20 or more per square foot. While the upfront cost may be more substantial, the long lifespan, durability, and energy-efficient qualities make zinc a cost-effective investment for those prioritizing longevity and sustainability in warehouse roofing projects.

The thickness of the roofing material influences both its durability and cost. Thicker roofing materials generally come at a higher price but may offer increased resilience against environmental factors. Additionally, the structural design of the roof, including considerations for snow loads and wind resistance, can impact material specifications and costs. Structural engineering assessments to meet local building codes may add an extra layer of expense.

Insulating the warehouse roof is a crucial aspect of energy efficiency and climate control. While opting for insulated metal panels can contribute to significant energy savings over time, the upfront costs may be higher compared to basic metal panels. The thickness and type of insulation material also play a role in determining costs. The strategic decision to invest in insulation should consider long-term operational benefits against initial expenditures.

The choice of coatings for metal warehouse roofing is another factor influencing costs. Galvanized coatings offer corrosion resistance, while painted finishes provide aesthetic appeal. Each option comes with its own price considerations. Balancing the need for protection against the desire for a specific aesthetic can impact material expenses. Additionally, the geographical location of the warehouse may influence the choice of coatings based on climate and environmental factors.

The size and complexity of the metal warehouse roofing design directly impact material costs. Larger warehouses require more roofing material, contributing to higher expenses. Additionally, warehouses with intricate designs or architectural nuances may involve custom engineering and fabrication, adding complexity and cost to the roofing structure. Striking a balance between the spatial expanse of the roof and design intricacies is crucial in managing costs effectively.

While the focus is often on upfront expenses, considering the long-term maintenance costs is essential. Investing in high-quality roofing materials and coatings may incur higher initial costs but can lead to reduced maintenance expenses over the warehouse’s operational life. Evaluating the trade-offs between upfront investments and long-term maintenance savings is a strategic aspect of cost-conscious decision-making.

Strategic material selection and sourcing are foundational in optimizing metal warehouse roofing costs. It involves a meticulous balance between choosing roofing materials that offer durability and performance while being mindful of cost implications. Exploring local sourcing options not only supports the regional economy but also minimizes transportation costs. Bulk purchasing of materials can further leverage discounts, contributing to overall cost-effectiveness. This approach ensures that the selected materials align with both budget constraints and the long-term resilience of the roofing system.

Investing in energy-efficient roofing systems is a forward-thinking strategy that can lead to substantial long-term operational savings. Energy-efficient materials, such as cool roofing options that reflect sunlight and heat, contribute to enhanced thermal performance. While there might be a slightly higher initial investment, the subsequent reduction in energy consumption and utility expenses can outweigh these upfront costs. This approach not only aligns with sustainability goals but positions the metal warehouse as a modern and environmentally conscious entity in the industrial landscape.

Proactive maintenance planning is a critical element in optimizing metal warehouse roofing costs over time. By implementing a systematic maintenance plan, potential issues can be identified and addressed early, preventing more extensive and expensive repairs. Regular inspections, timely repairs, and adherence to a maintenance schedule contribute to the longevity of the roofing system. The upfront investment in proactive maintenance significantly reduces the risk of unforeseen and costly roofing-related issues.

The integration of technology into metal warehouse roofing design and installation processes is a key strategy for optimizing costs. Technological advancements allow for precise and efficient roofing solutions. Utilizing innovative technologies during the design phase enhances accuracy and reduces the likelihood of errors, leading to cost savings. Whether through advanced modeling software or automated installation processes, technology integration ensures that the roofing project is executed with efficiency and precision.

Designing the roofing system to be weather-adaptive is essential for optimizing costs in the face of varying climate conditions. Different regions experience different weather patterns, and the roofing design should be tailored to withstand these challenges. Considering climate-specific factors during the design phase, such as wind resistance and water drainage, contributes to the resilience and longevity of the roofing system. This approach minimizes the need for frequent repairs and replacements, ultimately reducing long-term costs.

Collaborating with experienced roofing contractors is a fundamental aspect of optimizing costs. Seasoned contractors bring valuable expertise and insights to the project, ensuring that cost-effective solutions are implemented without compromising quality. Recommendations and reviews play a crucial role in verifying the reliability and efficiency of a contractor. Choosing a contractor with a proven track record in metal roofing projects instills confidence in the project’s success and cost-effectiveness.

Implementing waste reduction and recycling practices during metal warehouse roofing installation aligns with both cost optimization and environmental sustainability. Minimizing material wastage through precise measurements, cutting, and responsible disposal practices contributes to economic efficiency. Establishing recycling protocols for metal scraps ensures that reusable materials are redirected back into the supply chain. This dual-focus approach addresses both financial and environmental considerations, making it an integral part of a comprehensive cost optimization strategy.

The roofing of a metal warehouse is a multifaceted aspect that demands careful consideration of material choices, design factors, and long-term maintenance strategies. Balancing durability, aesthetics, and energy efficiency with cost-effectiveness is pivotal. The selection of metal roofing materials, such as steel, aluminum, and zinc, introduces various cost dynamics. Strategic planning, proactive maintenance, and technological integration emerge as key players in optimizing costs over the operational life of the warehouse. Collaborating with experienced contractors and implementing waste reduction practices further contribute to the overall cost-effectiveness and sustainability of metal warehouse roofing projects. As businesses navigate the complexities of construction, a comprehensive approach that embraces both immediate and long-term considerations ensures the success of metal warehouse roofing endeavors.

The cost of metal warehouse roofing is influenced by factors such as the choice of roofing material, its type and thickness, insulation properties, roof coatings, the size and complexity of the warehouse, and the region’s climate.

Common types include steel (coated with aluminum or zinc), aluminum, and zinc. Each material has its own cost considerations and specific advantages, such as durability, affordability, and resistance to corrosion.

Insulation is a significant factor affecting costs. While opting for insulated metal panels can lead to long-term energy savings, the initial costs may be higher compared to basic metal panels. The type and thickness of insulation material also contribute to overall expenses.

Thicker roofing materials often come at a higher price but may provide increased resilience. The structural design, including considerations for snow loads and wind resistance, can impact material specifications and costs. Structural engineering assessments may add additional expenses.

Yes, the geographical location plays a role in determining costs due to regional pricing differences, variations in climate, and specific environmental factors that may influence the choice of coatings and materials.

Cost optimization strategies include strategic material selection and sourcing, investing in energy-efficient roofing systems, proactive maintenance planning, technology integration, designing the roofing system to be weather-adaptive, collaborating with experienced contractors, and implementing waste reduction and recycling practices.

Here I am going to share some steps to get your metal warehouse roofing cost estimate report.

You can send us your plan on info@estimatorflorida.com

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

All copyright © Reserved | Designed By V Marketing Media | Disclaimer