Estimate Florida Consulting offers precision metal estimation for construction projects of all sizes, encompassing both residential and commercial scopes. Our seasoned metal estimators deliver meticulously detailed reports to enhance your project-winning potential.

We cater to contractors, fabricators, manufacturers, installers, and distributors with our expert metal estimating services.

Bid smarter, win bigger!

Question Answer

Frequently Asked Question

Ensuring the accuracy of steel estimating services involves several key practices:

Experienced Estimators: Employ skilled and experienced estimators who understand steel materials, fabrication processes, and industry standards. Their expertise helps in making precise assessments.

Detailed Specifications: Provide comprehensive project specifications, including design drawings, dimensions, material requirements, and any special considerations. Clear and detailed information reduces ambiguity in estimates.

Accurate Material Data: Use up-to-date material data, including current market prices and availability. This prevents miscalculations due to outdated information.

Advanced Software: Utilize advanced estimating software that accounts for various factors, such as material wastage, fabrication methods, and labor requirements. This software can perform complex calculations quickly and accurately.

Reference Projects: Refer to past similar projects as benchmarks. These references can help in predicting potential challenges and accurately estimating resources needed.

Collaboration: Foster effective collaboration between estimators, project managers, engineers, and designers. Regular communication ensures that estimations align with project goals and scope.

Supplier Engagement: Collaborate closely with steel suppliers to obtain accurate pricing and availability information. Supplier partnerships can lead to more precise cost estimates.

Feedback Loop: Establish a feedback loop to review completed projects against initial estimates. Analyzing any discrepancies can identify areas for improvement and refinement in future estimates.

Contingency Planning: Incorporate a contingency factor into estimates to account for unforeseen changes, market fluctuations, or project uncertainties.

Continuous Learning: Stay updated on industry trends, materials, and methodologies. Continuous learning helps estimators refine their skills and adapt to changing conditions.

Double-Check Calculations: Implement a system of double-checking calculations to catch any errors or oversights in the estimation process.

Independent Reviews: Have estimations reviewed by a separate team member or department to ensure an additional layer of accuracy validation.

By combining these practices, steel estimating services can significantly enhance their accuracy, leading to more reliable project budgets and successful project execution.

Call Now: +1(561)530-2845

Estimate Florida Consulting provides the best metal estimating service in Florida. We work with years of experience in the field of construction estimating.

Call Now: +1(561)530-2845

Structural metal framing refers to the construction technique of using metal materials, typically steel, to create the framework or skeletal structure of a building or structure. This framing system provides the underlying support for walls, floors, roofs, and other components of a building. It is commonly used in both commercial and residential construction due to its durability, strength, and versatility.

Key features of structural metal framing include:

Steel Components: Structural metal framing involves the use of steel beams, columns, and other steel members to form the framework of the building. Steel is chosen for its high strength-to-weight ratio and ability to withstand heavy loads.

Load-Bearing: The main purpose of structural metal framing is to carry and distribute the loads of the building, including dead loads (permanent loads like the weight of the structure itself) and live loads (temporary loads like occupants, furniture, and equipment).

Design Flexibility: Steel framing allows for flexible design options. It can accommodate large spans, varying shapes, and intricate architectural designs while maintaining structural integrity.

Fast Construction: Steel framing is prefabricated off-site, which can expedite construction. On-site assembly is typically faster compared to traditional construction methods, resulting in shorter project timelines.

Durability: Steel is resistant to fire, rot, insects, and other common building hazards. This leads to a longer lifespan for the structure and reduced maintenance needs.

Space Efficiency: Steel members can have smaller cross-sections while maintaining strength, resulting in more usable interior space compared to bulkier materials.

Economic Advantages: Despite potentially higher upfront costs for materials, steel framing can lead to cost savings in the long run due to reduced maintenance, quicker construction, and adaptability to changes.

Seismic and Wind Resistance: Steel framing is known for its ability to withstand seismic forces and high winds, making it a popular choice in areas prone to earthquakes or hurricanes.

Sustainability: Steel is recyclable and can be reused, making it an environmentally friendly choice for construction.

Structural metal framing can take various forms, including steel beams and columns, steel trusses, and steel studs for walls. It's a versatile and widely used method that contributes to the stability and longevity of modern buildings and structures.

Call Now: +1(561)530-2845

Indeed, utilizing metal studs for house framing is entirely feasible. Metal stud framing serves as a prevalent substitute for conventional wood framing. The advantages of metal studs encompass their longevity, immunity to decay, pests, and fire. These studs are lightweight, maintain their straightness, and can be pre-cut with precision. However, it's essential to recognize that the approach to design and construction might contrast with wood framing methods. Seeking guidance from a proficient architect or contractor experienced in metal stud framing is advisable to guarantee accurate design and installation practices. Moreover, adherence to local building codes and regulations is imperative.

Call Now: +1(561)530-2845

To obtain an accurate metal cost estimate for a project, you should provide comprehensive and detailed information to the estimator. The more precise the information, the more accurate the estimate will be. Here's the key information you should provide:

Project Scope and Drawings: Detailed project plans, blueprints, and drawings are essential. They should include dimensions, specifications, and any specific design requirements.

Material Specifications: Clearly define the type of metal you intend to use, including its grade, thickness, finish, and any special attributes or coatings.

Quantities: Provide accurate quantities of each type of metal required for the project, including lengths, widths, and quantities of various components.

Design Complexity: Describe any intricate or custom designs that might impact fabrication and installation processes.

Finishing Requirements: If the metal needs surface treatments, coatings, or finishes, specify these details.

Fabrication Details: If any components need special fabrication processes (welding, cutting, bending), provide specifics.

Site Conditions: Share information about the project location, accessibility, and any challenges that might affect installation.

Timeline: Clearly communicate the project timeline and any deadlines that need to be met.

Additional Components: List any additional elements required for installation, such as fasteners, brackets, or connectors.

Labor Considerations: If you have specific labor requirements or constraints, communicate them. This could include factors like union labor, specific skill sets, or special safety measures.

Budget Constraints: If you have a budget limitation, provide this information upfront. It can help the estimator tailor their recommendations to fit within your financial parameters.

Regulatory and Code Requirements: Inform the estimator of any local building codes, regulations, or industry standards that need to be adhered to.

Changes and Revisions: If there have been any design changes or revisions, provide updated information to reflect the most current project details.

Consultation: Consider having a discussion with the estimator to ensure they have a clear understanding of your project and its unique requirements.

Remember, the accuracy of the estimate depends on the accuracy of the information you provide. Providing as much detail as possible will lead to a more precise and reliable estimate.

Call Now: +1(561)530-2845

Estimate Florida Consulting offers precise, affordable, and timely primary steel, rebar, and miscellaneous metal estimating solutions.

Our team of skilled metal estimators is prepared to tackle your projects.

Receive a precise estimate report utilizing ZIP code tracking, ensuring a high degree of accuracy in your estimation.

Get Acquainted with Metal Installation

Metal Roofing

Rebar Installing

Steel Construction

Metal Estimating Service

Residential Metal Estimating

- Homes Metal Estimator

- Studio Flats Metal Estimator

- Mixed used facilities Metal Estimator

- Home additions Metal Estimator

- Custom Homes Metal Estimator

- Apartments Metal Estimator

- Condominium Metal Estimator

- Home Improvements Metal Estimator

Commercial Metal Estimating

- Arenas Metal Estimator

- Hospitals Metal Estimator

- Schools Metal Estimator

- Restaurants Metal Estimator

- Offices Metal Estimator

- Shopping Malls Metal Estimator

- Multi Family Properties Metal Estimator

- Hotels Metal Estimator

Industrial Metal Estimating

- Petrochemical Metal Estimator

- Marine Metal Estimator

- Wastewater plants Metal Estimator

- Drilling Metal Estimator

- Food Processing Metal Estimator

- Oil & Gas Metal Estimator

- Mining and Metals Cost Estimator

- Pharmaceutical Plants Metal Estimator

Win More Projects With Us

Metal House Construction Cost

- Public

- Commercial

- Industrial

- Institutional

- Recreation Centers

- Manufacturing Units

- High Rise Buildings

- Power Plants

- Monuments

- Multiplexes

- Condominiums

- Parking

- Culverts

- Sports Clubs

- Bridges & Flyovers

- Health Centers

- Renovation

- Dams

- Additions

- Hotels

- Water Treatment Plants

Our estimates encompass a comprehensive breakdown of metals and steel, encompassing materials, plates, connectors, accessories, and erection costs. These details aid in project planning, procurement, cost management, and minimizing on-site storage requirements. Our goal is to enhance productivity and cost-efficiency for your projects.

We Quantify in Our Metal Estimating Service

- Fasteners

- Fastenings

- Metal Decking

- Stick Framing

- Rebar

- Steel Framing

- Access Ramps

- Metal Joists

- Stud Framing

- Dome Structures

- Stairs

- Load-bearing wall framing

- Canopy

- Lintels

- Ladders

- Railings

- Gratings

- Decking

- Bollards

- Treads and Noising

- Ironwork

- Trench Drains

- Roof Steel

- Column Steel

- Castings

- Trusses

- Floor Steel

- Cooper Flashing

- Fireproofing

- Gusset Plates

- Ornametal Ironwork

- Base Plates

- Steel Girders

- Steel Anchors

- Noising Strips

- Corner Beads

Fasteners Cost Estimate

In construction and fabrication projects, fasteners play a vital role in securely joining materials together. Precisely estimating the cost of fasteners is crucial for accurate budgeting and project planning. Fastener costs can fluctuate based on variables like the fastener type, required quantity, and project-specific needs.

Fasteners encompass a range of items, including screws, bolts, nuts, washers, rivets, and more. Their cost is influenced by factors like material composition, size, and quality. Different materials, such as stainless steel or galvanized steel, can result in varying costs. Furthermore, the size and strength specifications of the fasteners can impact their price.

To arrive at an accurate estimate for fastener costs, it’s imperative to account for the required quantity. This depends on the number of joints or connections needed, as well as any additional factors like reinforcements or structural considerations. Precisely determining the necessary quantity of fasteners guarantees a comprehensive cost estimate.

Here’s a table summarizing estimated costs for common fasteners:

| Fastener Type | Size | Estimated Cost (per piece) |

|---|---|---|

| Screws | #8 | $0.10 – $1.00 |

| Bolts | 1/4″ | $0.50 – $5.00 |

| Nuts | 1/4″ | $0.05 – $0.50 |

| Washers | 1/2″ | $0.02 – $0.20 |

| Rivets | 3/16″ | $0.10 – $0.50 |

The chosen supplier or vendor can also impact the cost of fasteners. Various suppliers might present different prices, making it advantageous to conduct research and compare quotes from multiple sources. Moreover, when selecting a supplier, it’s essential to factor in elements like shipping expenses, lead times, and quality assurance.

For precise estimates tailored to a specific project, seeking advice from a fastener specialist or supplier is advised. They can offer recommendations for suitable fasteners based on project specifics and suggest cost-efficient alternatives. Consulting with these experts ensures well-informed decisions and accurate cost projections.

Get Financing For Metal Construction Business

Maximize your metal construction business’s potential with our competitive financing options

Rebar Cost Estimate

Rebar, also recognized as reinforcement bar or reinforcing steel, holds pivotal significance in concrete construction by imparting strength and stability to structures. The precise estimation of rebar costs is imperative for effective project budgeting and planning in construction endeavors. The expenses linked to rebar can vary, contingent on aspects such as size, grade, quantity requirements, and prevalent market conditions.

The dimensions and grade of rebar stand as primary factors influencing its cost. Rebar is available in an array of sizes, generally ranging from #3 to #18, with larger numbers indicating increased diameter and strength. Meanwhile, rebar’s grade signifies its tensile strength, denoted by designations like Grade 40, Grade 60, or Grade 80. Generally, higher-grade rebar comes with a higher price tag.

| Rebar Size | Rebar Grade | Estimated Cost per Ton |

|---|---|---|

| #3 | Grade 40 | $500 – $800 |

| #4 | Grade 60 | $600 – $900 |

| #5 | Grade 60 | $700 – $1,000 |

| #6 | Grade 60 | $800 – $1,200 |

| #8 | Grade 60 | $1,000 – $1,400 |

| #10 | Grade 60 | $1,200 – $1,600 |

| #12 | Grade 60 | $1,400 – $1,800 |

| #14 | Grade 60 | $1,600 – $2,000 |

| #18 | Grade 60 | $2,000 – $2,500 |

The cost of rebar is frequently gauged per ton. The cost per ton can fluctuate based on variables such as prevailing market dynamics, project location, and purchase volume. It is prudent to engage local suppliers or explore online marketplaces to access current rebar pricing.

To compute the rebar expense for a project, the initial step involves calculating the necessary quantity aligned with the project’s structural and engineering stipulations. This entails accounting for aspects like concrete element dimensions, rebar spacing and arrangement, and any supplementary reinforcement prerequisites.

Once the rebar quantity is ascertained, it can be multiplied by the cost per ton to derive the total expense. It is advisable to factor in a margin for wastage and additional requisites to ensure an accurate cost projection.

Keep in mind that rebar costs can be subject to market fluctuations, varying across time. It is wise to procure quotes from multiple suppliers and take into account attributes such as product quality, delivery choices, and customer service when finalizing a supplier.

Steel Framing Cost Estimate

Steel framing presents an array of benefits in construction undertakings, encompassing endurance, robustness, and adaptability. Precisely calculating the cost of steel framing holds paramount importance in the precision of project budgeting and planning. The expenditure can fluctuate contingent upon aspects like structure size, intricacy, design prerequisites, and the prevailing market milieu.

In approximating the cost of steel framing, several pivotal elements warrant consideration. These entail the dimensions of the structure, the design delineations, the composition and gauge of the steel framing components, and the outlay related to labor and installation.

| Structure Size | Estimated Cost per Square Foot |

|---|---|

| Small (<1,000 sq. ft.) | $8 – $12 |

| Medium (1,000 – 5,000 sq. ft.) | $7 – $10 |

| Large (>5,000 sq. ft.) | $6 – $9 |

The cost of steel framing is significantly influenced by the structure’s size. Larger structures necessitate more steel material, leading to elevated expenses. Moreover, the specifics of the design, encompassing height, width, and overall intricacy of the edifice, can also wield an influence on the cost.

The composition and thickness of the steel framing components hold substantial sway in cost assessment. Varied steel types, like hot-rolled or cold-formed, entail distinct costs. Similarly, the thickness or gauge of steel framing elements can yield cost disparities, with thicker steel generally incurring greater expenses.

Incorporating labor and installation expenses into the estimation is imperative. The intricacy of the project, the demanded expertise, and local labor rates collectively mold labor costs. Merging these expenses with the project’s dimensions and intricacy is key to garnering a precise projection.

The dynamic steel market and its price fluctuations can exert an impact on steel framing costs. Engaging steel suppliers, contractors, or industry experts to gather current pricing details and trends is prudent.

Why Choose Us?

In this context, I’d like to highlight several advantages associated with having a skilled estimator for your project. Before enlisting the services of an estimator, it’s essential to familiarize yourself with their attributes. If your chosen estimator provides these benefits, it’s a strong indicator that they are a suitable fit for your project.

- You'll receive a precise and comprehensive project estimate report covering labor, materials, and more.

- With an estimator at your disposal, you'll significantly reduce the risk of missing out on any job opportunities.

- No need to invest in costly software or assemble a dedicated team to generate estimating reports.

- Access a remarkably accurate project database with the assistance of an estimator.

- By having an estimator on board, you'll free up time to enhance your other endeavors, potentially managing multiple projects concurrently.

- Reviewing the report will only require a brief 10 to 20 minutes of your time.

A Wining Cost Estimate That Helps You To Win More Construction Projects

Metal House Construction Cost

The typical expense for constructing a metal home averages around $380,000, encompassing construction expenses, land acquisition, and finishing touches.

Should you possess the land beforehand and select a more compact 40 x 60 square foot structure, the expenditures for the basic structure alone can range between $6,000 and $35,000.

| Basic component | Cost | Description |

| Site Work | $15,903 | Building permit fees, Impact fees, Design & Planning, Inspections |

| Foundations | $25,671 | Excavation, Concrete Foundations, Backfill, Wall Retaining |

| Framing | $41,123 | Framing, Trusses, Sheathing, Metal Beams |

| Exterior Finishes | $33,066 | Exterior Wall Finishing, Roofing, Windows, Doors |

| Major Systems | $32,746 | Plumbing, Electrical, HVAC |

| Interior Finishes | $67,939 | Insulation, Drywall, Interior Accessories, Lighting, Appliances, Flooring, Painting |

| Exterior Amenities | $16,591 | Landscaping, Clean-Up, Outdoor Structures, Driveways, Finishing Touches |

| Misc. | $4,722 | Other unforeseeable costs |

Estimate Florida Consulting provides metal house construction cost estimating service for residential and commercial construction projects.

Benefits of Constructing Your Own Metal Home

-

Customizable

You wield full control over every detail and facet of your home, granting you ultimate authority over its outcome. Moreover, suppliers often collaborate to devise solutions that cater to your requirements while adhering to your budget.

-

Seamless Upgrades

Embarking on construction from scratch empowers you to seamlessly incorporate new additions or modify existing ones according to your preferences, such as integrating an office space.

-

Enhanced Longevity

With novel structures, foundations, and appliances, the lifespan of your assets outlasts those found in pre-existing homes.

-

Reduced Insurance Costs

Steel homes, renowned for their robust structural integrity, garner favor from insurers due to their attributes such as weather resistance and durability.

-

New Home Warranty

Steel home providers extend a minimum 20-year warranty for newly built homes, underscoring the confidence they possess in the caliber of their constructions.

Commercial Metal Estimating

Our expertise encompasses commercial metal estimating services catering to projects of varying scales. We meticulously assess the expenses associated with commercial metal endeavors. In contemporary commercial construction, the adoption of prefabricated steel structures is on the rise. This contemporary approach boasts cost efficiency, environmental consciousness, and versatility across an array of commercial sectors. The applications for commercial metal buildings span from commonplace and familiar to distinct and extraordinary purposes.

Our portfolio extends to residential electrical estimate ventures spanning arenas, schools, hospitals, shopping malls, multi-family properties, office roofing, hotel roofing, and more.

Commercial Metal Estimator

We help Residential & Commercial Contractors to win more projects with higher accuracy.

Residential Metal Estimating

Our offerings encompass residential metal estimating services tailored to projects of varying scopes. We meticulously evaluate the expenditures linked to residential metal undertakings. The pricing of structural steel and metal exhibits considerable variance, often fluctuating even within a single day. This aspect becomes particularly pertinent given that substantial construction projects span several months or years. Failing to factor in potential price shifts across the envisaged project timeline can precipitate substantial budgetary and project disruptions.

Our experience extends to residential metal estimation endeavors spanning arenas, schools, hospitals, shopping malls, multi-family properties, office roofing, hotel roofing, and more.

Residential Metal Estimator

We help Residential & Commercial Contractors to win more projects with higher accuracy.

Metal Siding Cost per Square Foot

Metal siding encompasses a wide array of materials and design options. The spectrum of metal siding materials spans from tin to copper, with costs spanning from $2 to $35 per square foot. Among the prevalent metal siding varieties, aluminum and steel stand out, falling within the price range of $4 to $8 per square foot.

| Square Footage | Average Cost (Material Only) |

|---|---|

| 500 sq.ft. | $1,000 – $19,000 |

| 1,000 sq.ft. | $2,000 – $35,000 |

| 1,500 sq.ft. | $2,500 – $55,000 |

| 2,000 sq.ft. | $3,000 – $65,000 |

| 2,500 sq.ft. | $4,000 – $80,000 |

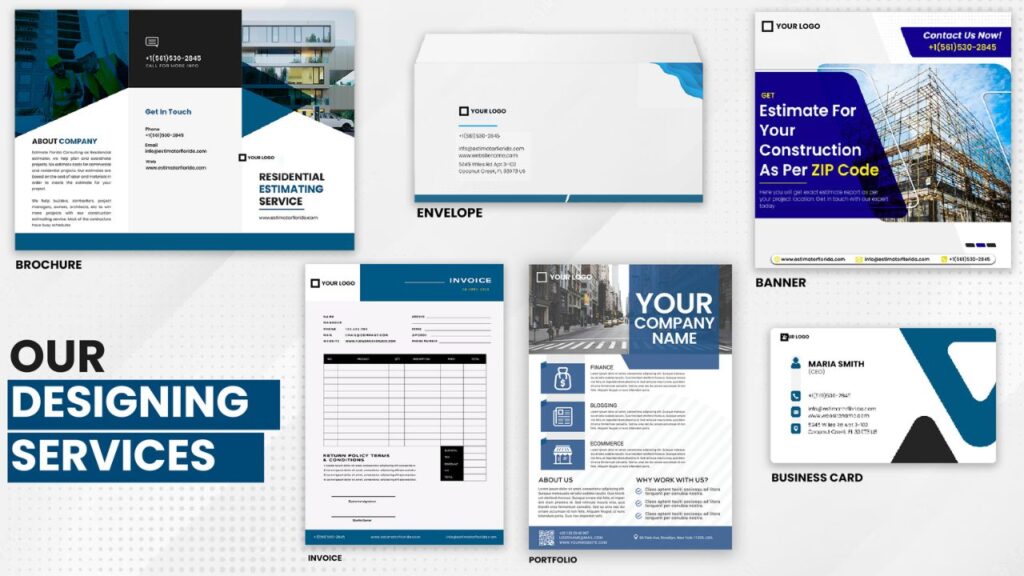

Need Templates for Portfolio, Brochure, Banner, Business Card, Envelope, Invoice, etc?

Metal Siding Cost by Material

Numerous metals are suitable for siding applications, each varying in availability and style options. With distinct costs and characteristics, careful consideration is warranted for each metal choice:

| Material | Average Costs per Square Foot (Material Only) |

|---|---|

| Tin | $2 – $5 |

| Aluminum | $3 – $5 |

| Steel | $5 – $8 |

| Insulated Steel | $6 – $8 |

| Vinyl-Wrapped Aluminum | $6 – $9 |

| Corrugated Steel | $6 – $10 |

| Zinc | $17 – $22 |

| Copper | $22 – $35 |

Comprehensive Trade-Specific Estimates

At Estimate Florida Consulting, we offer detailed cost estimates across all major trades, ensuring no part of your project is overlooked. From the foundation to the finishing touches, our trade-specific estimates provide you with a complete and accurate breakdown of costs for any type of construction project.

Construction Metal Contractors in Florida

Florida Metal Building Services LLC

Concrete Reflections Inc. has established itself as a frontrunner in the field, specializing in concrete staining, grinding, and polishing processes. The outcome is a durable flooring product capable of withstanding substantial wear and tear. This polished solution not only enhances aesthetics but also imparts a highly reflective, vivid, and immaculate appearance to floor maintenance endeavors.

Hoopers Concrete

Hoopers Concrete is a construction firm collaborating closely with architects and designers to craft exquisite and functional structures.

Uhire

Uhire facilitates the process of locating licensed and fully insured mechanical contractors, ensuring peace of mind for clients. Their service spectrum extends beyond this to encompass painting, drywall, bathroom remodeling, flooring, HVAC, plumbing, and ductwork services, providing a comprehensive array of solutions.

Structural Steel Estimating

Check out The Video About Structural Steel Estimating of SPC Group.

Types of Structural Steels

Exhibiting robust strength, favorable machinability, and exceptional ductility, a structural steel plate emerges as a secure and economically viable building material, forming the core of structural steel edifices.

Varied categories of structural steel, as well as distinct metal grades, come with their individual properties and attributes.

Check out The Video About Structural Steel Estimating of Weld.com.

Construction Estimating Tips For Submitting Bids

Check out The Video About Construction Estimating – Tips For Submitting Bids of Weld.com.

Building Estimation Methods and Process

Check out The Video About “Building Estimation Methods and Process” of Masters in Building Training.

Metal Building Innovations

Check out The Video About “Metal Building Innovations” of MBMA MEDIA.

Steel Warehouse Construction

Steel structures consistently exhibit lower weight compared to other building types while retaining equivalent strength. Moreover, expansive long-span warehouses and steel constructions are ideally suited for projects requiring considerable spans, such as factories and stadiums.

Furthermore, the demand for warehouses is becoming increasingly pressing.

Check out The Video About “Metal Building Innovations” of MBMA MEDIA.

Why Choose Estimate Florida Consulting

- Significant cost savings can be achieved on your project.

- Our estimate reports boast remarkable accuracy.

- Labor and material estimates can be provided within one or two days.

- Estimate Florida Consulting offers round-the-clock customer support.

- Our experience encompasses collaboration with General Contractors, Subcontractors, Developers, Architects, and Owners.

- Our pricing is exceptionally budget-friendly.

Steps to Obtain an Metal Estimate Report

Below, I will outline the steps to acquire your metal estimate report.

-

Kindly forward your plan to us.

Please forward your plan to info@estimatorflorida.com.

-

A project quote will be provided to you.

Prior to commencing your project, we will furnish you with a comprehensive service quote. This quote will encompass intricate project details, including size, complexity, level of difficulty, and the bid date for pricing determination.

-

Get Estimate Report

We undertake metal estimating and compile an exhaustive report for your project. Upon review and approval, the report is finalized, marking the completion of the project.

Steps to Follow

Our Simple Process to Get Your Estimate

01

Upload Plans

Submit your project plans, blueprints, or relevant documents through our online form or via email.

02

Receive Quotation

We’ll review your project details and send you a quote based on your scope and requirements.

03

Confirmation

Confirm the details and finalize any adjustments to ensure the estimate meets your project needs.

04

Get Estimate

Receive your detailed, trade-specific estimate within 1-2 business days, ready for your project execution.

Testimonials

What Our Clients Say

We take pride in delivering accurate, timely, and reliable estimates that help contractors and builders win more projects. Our clients consistently praise our attention to detail, fast turnaround times, and the positive impact our estimates have on their businesses.

Estimate Florida Consulting has helped us win more bids with their fast and accurate estimates. We trust them for every project!