Metal Cost Estimator in Indialantic, FL

At Estimate Florida Consulting, our expertise lies in delivering accurate estimates tailored to your specific needs for metal projects.the approximate cost range for metal in the construction of a 20,000 sq. ft. building could be between $45,000 and $90,000+, assuming basic metal applications and not including advanced or specialized metal work. Metal plays a pivotal role in construction and manufacturing industries across the globe. Its importance is equally recognized in Indialantic, where accurate cost estimation can significantly impact the feasibility and success of a project.

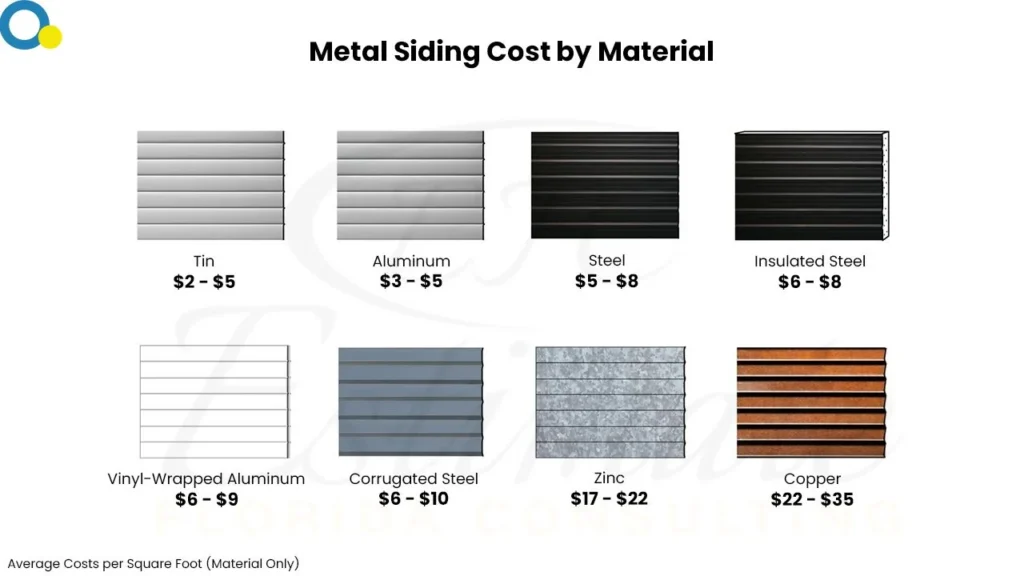

Metal Siding Cost by Material

Numerous metals are suitable for siding applications, each varying in availability and style options. With distinct costs and characteristics, careful consideration is warranted for each metal choice:

| Material | Average Costs per Square Foot (Material Only) |

|---|---|

| Tin | $2 – $5 |

| Aluminum | $3 – $5 |

| Steel | $5 – $8 |

| Insulated Steel | $6 – $8 |

| Vinyl-Wrapped Aluminum | $6 – $9 |

| Corrugated Steel | $6 – $10 |

| Zinc | $17 – $22 |

| Copper | $22 – $35 |

90% More Chances to Win Projects With Our Estimate!

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- School & University Building

- High-Rise Building

- Shopping Complex

- Data Center Building

Cost by Type of Metal in sq.ft

Metal prices have experienced a notable increase, leading to higher costs per square foot in USD. This surge affects various metals used in construction and manufacturing processes. Aluminum, copper, zinc, iron, steel, tin, and nickel have all seen upticks in pricing, influencing project budgets and procurement decisions.

Metal | Cost per Sq. Ft. (USD) |

Aluminum | $1.40 – $4.20 |

Copper | $5.60 – $11.20 |

Zinc | $2.80 – $8.40 |

Iron | $0.14 – $0.42 |

Steel | $0.70 – $3.50 |

Tin | $4.20 – $9.80 |

Nickel | $7.00 – $14.00 |

Get 5 New Leads in the Next 7 Days With Our System

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- High-Rise Building

- Shopping Complex

Factors Influencing Metal Cost

Global Economic Trends

Economic growth or recession plays a pivotal role in shaping the demand for metals globally. During periods of robust economic expansion, there’s typically an uptick in construction, manufacturing, and infrastructure development projects, all of which require significant amounts of metals like steel, copper, and aluminum. Strong economic activity not only stimulates domestic demand but also fuels global trade, further boosting the need for metals in various industries. Conversely, during economic downturns, such as recessions, demand for metals tends to soften as construction projects are delayed or canceled, manufacturing activities slow down, and infrastructure investments decrease. This decrease in demand can exert downward pressure on metal prices. Therefore, monitoring key economic indicators such as GDP growth, industrial production, and consumer spending is crucial for understanding the direction of metal prices and anticipating market trends.

Supply and Demand Dynamics

The intricate interplay between supply and demand dynamics is fundamental in determining metal prices. Supply disruptions, such as mine closures due to labor strikes, technical issues, or regulatory challenges, can quickly tighten supply and cause prices to spike. Conversely, new mining projects coming online or increased production from existing mines can alleviate supply constraints and exert downward pressure on prices. Demand dynamics are equally influential, with factors such as industrial activity, population growth, and urbanization patterns driving the need for metals across various sectors.

For instance, rapid urbanization in emerging economies often leads to increased demand for metals in construction and infrastructure development. Additionally, shifts in consumer preferences, technological advancements, and government policies can also impact demand for specific metals, further complicating the supply-demand equation.

Currency Fluctuations

Metal prices are intricately linked to currency fluctuations, particularly the value of the U.S. dollar (USD) since metals are priced and traded in USD on global commodity exchanges. A strengthening USD can make metals more expensive for buyers using other currencies, thereby dampening demand and exerting downward pressure on prices. Conversely, a weakening USD can make metals more affordable for international buyers, potentially increasing demand and driving prices higher. Moreover, currency movements can impact the competitiveness of metal producers located in different regions, as fluctuations in exchange rates affect their cost structures, profit margins, and export competitiveness. Therefore, monitoring currency trends and their potential impact on metal prices is essential for market participants, investors, and policymakers.

Government Policies and Regulations

Government policies and regulations wield significant influence over metal prices by shaping the operating environment for metal producers and consumers. Trade policies, such as tariffs and export restrictions, can disrupt supply chains and lead to supply shortages or excess inventory, thereby affecting prices. Environmental regulations aimed at reducing emissions or promoting sustainable practices can impact production costs for metal producers, potentially leading to higher prices for consumers. Moreover, fiscal stimulus measures, such as infrastructure spending or tax incentives for specific industries, can bolster demand for metals and support higher prices. Political instability, geopolitical tensions, and trade disputes can also introduce uncertainties into the market, influencing investor sentiment and price volatility.

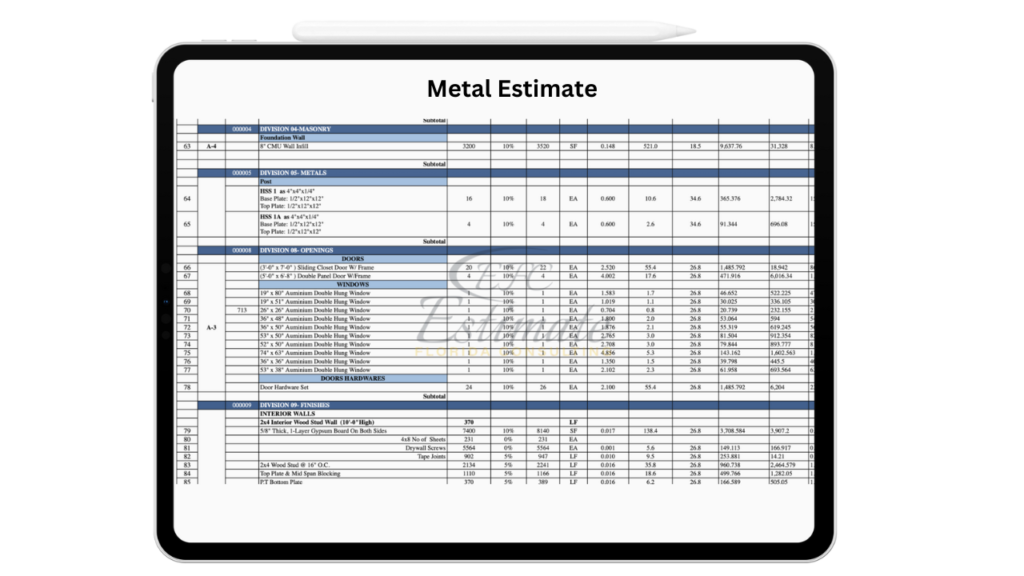

Download Template For Metal Project Breakdown

- Materials list updated to the zip code

- Fast delivery

- Data base of general contractors and sub-contractors

- Local estimators

Technological Advances

Technological innovations drive changes in metal consumption patterns and production methods, thereby influencing metal prices. For instance, the growing demand for electric vehicles (EVs) has spurred increased consumption of metals like lithium, cobalt, and nickel for battery production. Similarly, advancements in mining technologies, such as automation and remote sensing, have the potential to increase efficiency, reduce production costs, and unlock new sources of supply. However, technological disruptions can also pose challenges for traditional metal producers, as they may need to adapt their operations to remain competitive in a rapidly evolving landscape. Therefore, staying abreast of technological developments and their implications for metal markets is essential for industry participants and investors seeking to navigate the complexities of the market.

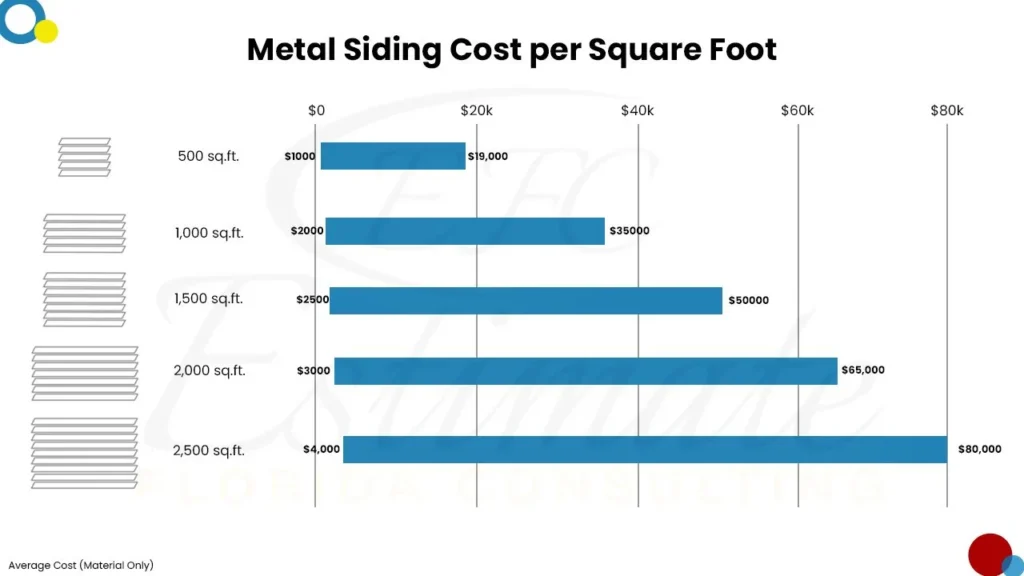

Metal Siding Cost per Square Foot

Metal siding encompasses a wide array of materials and design options. The spectrum of metal siding materials spans from tin to copper, with costs spanning from $2 to $35 per square foot. Among the prevalent metal siding varieties, aluminum and steel stand out, falling within the price range of $4 to $8 per square foot.

| Square Footage | Average Cost (Material Only) |

|---|---|

| 500 sq.ft. | $1,000 – $19,000 |

| 1,000 sq.ft. | $2,000 – $35,000 |

| 1,500 sq.ft. | $2,500 – $55,000 |

| 2,000 sq.ft. | $3,000 – $65,000 |

| 2,500 sq.ft. | $4,000 – $80,000 |

Business Finance Loan

Find out if you're pre-qualified in seconds

Get Prequalified Now

IMPORTANT: Make sure the email and phone number you enter are correct. We will email and text you a link to get started.

Cost of Metal by USD per Ton

The provided table lists the prices of various metals in terms of USD per ton. Each metal, including Aluminum, Lead, Iron Ore, Copper, Nickel, Zinc, and Tin, has its respective price per ton indicated. These prices serve as crucial reference points for industries and businesses involved in metal trading, manufacturing, construction, and infrastructure development. Metal prices are subject to fluctuations influenced by factors such as global economic trends, supply and demand dynamics, currency fluctuations, and geopolitical events.

NAME | PRICE | UNIT |

Aluminum | 2,273.40 | USD per Ton |

Lead | 2,106.65 | USD per Ton |

Iron Ore | 109.61 | USD per Dry Metric Ton |

Copper | 8,968.35 | USD per Ton |

Nickel | 17,987.50 | USD per Ton |

Zinc | 2,523.65 | USD per Ton |

Tin | 28,400.00 | USD per Ton |

Common Challenges in Metal Cost Estimation

Metal cost estimation is a critical aspect of planning and budgeting in industries such as construction, manufacturing, and various engineering sectors. However, despite technological advancements and improved methodologies, estimators face several challenges that can impact the accuracy and reliability of their estimates. Understanding these challenges is the first step towards developing strategies to overcome them.

Dealing with Price Volatility

One of the most significant challenges in metal cost estimation is the volatility of metal prices. Prices for metals like aluminum, copper, zinc, and steel can fluctuate widely due to a variety of factors, including changes in supply and demand, geopolitical events, economic conditions, and market speculation.

Strategies to Overcome Price Volatility

- Stay Informed: Regularly monitor metal markets and news to stay updated on current and forecasted prices.

- Flexible Contracts: Negotiate contracts that allow for price adjustments in response to significant market fluctuations.

- Hedging: Consider financial instruments or contracts that lock in metal prices for a future date, reducing the risk of adverse price movements.

Estimate Your Project With Us

Ensuring Accuracy in Measurements

Accurate measurements are foundational to precise cost estimation. Errors in measuring the quantity or dimensions of metal required can lead to significant discrepancies in the estimated versus actual costs.

Strategies to Enhance Measurement Accuracy

- Use Advanced Measuring Tools: Employ the latest technology in measurement tools and software for precise calculations.

- Training: Ensure that staff are adequately trained in measurement techniques and the use of any specialized equipment.

- Double-Check Measurements: Implement a process for reviewing and verifying measurements to catch and correct errors early.

Navigating Supply Chain Complexities

The complexity of the metal supply chain can also pose challenges, affecting the availability, delivery times, and cost of metals. Issues such as transportation delays, tariffs, and supplier reliability can all impact cost estimations.

Strategies to Navigate Supply Chain Complexities

- Diversify Suppliers: Avoid reliance on a single supplier by establishing relationships with multiple sources to ensure more consistent availability and competitive pricing.

- Understand Import/Export Conditions: Stay informed about tariffs and other trade regulations that may affect metal costs and availability.

- Incorporate Buffer Time and Costs: Build extra time and contingency funds into your estimates to accommodate unforeseen delays or price increases.

Need Template For Your Metal Business

We provide services for Brochure, Banner, Business Card, Envelope, Invoice, etc.

Adapting to Technological Changes

As new technologies emerge, there’s a continuous need to adapt and learn new tools and software for cost estimation. Keeping up with these changes can be challenging but is essential for improving accuracy and efficiency.

Strategies to Adapt to Technological Changes

- Continuous Learning: Encourage ongoing education and training for estimators to stay current with new technologies and methodologies.

- Invest in Technology: Allocate resources to acquire and implement the latest software and tools that can enhance estimation processes.

What is the role of metal ?

Metals play a vital role in modern society due to their unique properties, including strength, ductility, conductivity, and resistance to corrosion. These characteristics make metals indispensable in a wide range of applications. Here’s an overview of the key roles metals play across various industries and aspects of daily life:

Construction and Infrastructure

- Strength and Durability: Metals such as steel and aluminum are crucial in construction due to their strength and durability. They are used in building frameworks, bridges, highways, and tunnels, offering long-term stability and resistance to environmental impacts.

- Flexibility: Metals can be molded into various shapes, which is essential for architectural designs and infrastructural projects.

Transportation

- Vehicles: From cars and bicycles to airplanes and ships, metals are fundamental in manufacturing transportation vehicles. Their strength-to-weight ratio, especially in the case of aluminum and titanium, is critical for fuel efficiency and safety.

- Infrastructure: Metals are used in the construction of railways, airports, and ports, supporting the global transportation network.

Energy

- Renewable Energy: Metals are key components of renewable energy systems. For instance, copper and aluminum are used in solar panels and wind turbines for their conductivity and lightweight properties, respectively.

- Batteries: Metals like lithium, nickel, and cobalt are crucial for battery technology, powering everything from mobile devices to electric vehicles.

Are You Looking For?

Make Informed Design Decisions Showcase Your Design Ideas

Get RenderingCall Us To Discuss More at 561-530-2845

Conclusion

Accurate cost estimation is crucial for metal projects in the construction and manufacturing sectors, particularly in areas like Indialantic, where precise budgeting is essential for project feasibility. Understanding factors such as global economic trends, supply and demand dynamics, currency fluctuations, government policies, and technological advances is vital for obtaining reliable cost projections. Despite challenges such as price volatility, measurement accuracy, supply chain complexities, and technological changes, strategies can be implemented to mitigate these obstacles and improve the accuracy of estimates. Metals play indispensable roles across various industries, including construction, transportation, electronics, technology, and energy, highlighting their importance in modern society. At Estimate Florida Consulting, we specialize in delivering accurate estimates tailored to your specific needs, ensuring informed decision-making and successful project outcomes.

We Provide Services for Other Trades in Indialantic

FAQs

In Indialantic, the approximate cost range for using basic metal applications in the construction of a 20,000 square foot building can vary between $45,000 and $90,000 or more. These estimates cover materials such as aluminum, copper, zinc, iron, steel, tin, and nickel, but exclude advanced or specialized metal work.

Economic trends play a crucial role in shaping metal prices globally, including in Indialantic. Strong economic growth typically leads to increased demand for metals in construction, manufacturing, and infrastructure projects, thus driving prices upwards. Conversely, during economic downturns, demand softens, exerting downward pressure on metal prices.

The balance between supply and demand heavily impacts metal prices in Indialantic. Factors such as supply disruptions, population growth, industrial activity, and urbanization patterns can cause fluctuations in metal prices. Tightened supply due to mine closures or increased demand from emerging economies can lead to price spikes, while oversupply or decreased demand can result in price declines.

Government policies and regulations have a significant impact on metal prices in Indialantic. Policies such as tariffs, trade restrictions, and environmental regulations can disrupt supply chains and production processes, affecting prices. Additionally, fiscal stimulus measures and infrastructure spending initiatives can influence demand for metals, thereby impacting prices.

Technological innovations drive changes in metal consumption patterns and production methods, influencing metal prices in Indialantic. For instance, the growing demand for electric vehicles (EVs) has increased the need for metals like lithium, cobalt, and nickel, impacting their prices. Similarly, advancements in mining technologies can affect production costs and supply dynamics, thereby influencing metal prices in Indialantic.

.

Process To Get Metal Cost Estimate Report

Here I am going to share some steps to get your metal cost estimate report.

-

You need to send your plan to us.

You can send us your plan on info@estimatorflorida.com

-

You receive a quote for your project.

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

-

Get Estimate Report

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.

Google Reviews

Reach Out To Us

Places to visit if you new in Indialantic

Indialantic Beach and Boardwalk

This beautiful stretch of beach is perfect for swimming, sunbathing, surfing, or just relaxing and enjoying the view. The boardwalk is a great place to take a walk, have a picnic, or people-watch.

Sea Turtle Preservation Society

Learn about the sea turtles that nest on Indialantic’s beaches and how you can help protect them. The society offers tours, educational programs, and volunteer opportunities.

This hands-on aquarium is a great place to learn about the marine life of the Indian River Lagoon. You can touch stingrays, feed sharks, and see a variety of other fish and invertebrates.

There are many beach shops and boutiques located along A1A in Indialantic. You can find everything from souvenirs and beach gear to unique gifts and artwork.