Our Experience

- We provide estimates without any hassle.

- We have 30+ years of experience.

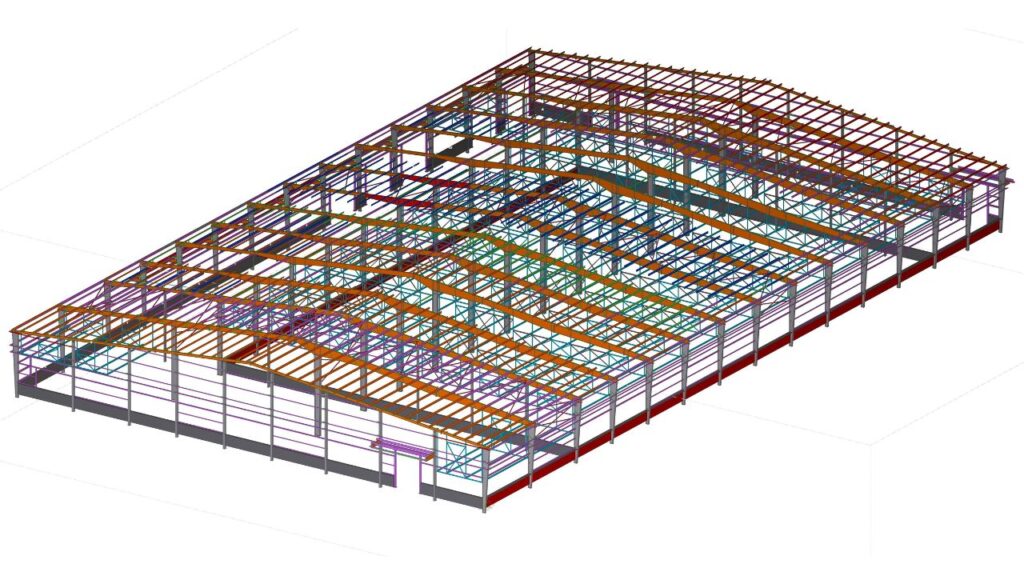

Are you on the hunt for a comprehensive and accurate metal cost estimator in the bustling heart of Daytona Beach? Your search ends here! At our esteemed establishment, we take pride in offering a specialized suite of services tailored to meet the distinct needs of both commercial and residential projects. Whether you’re a forward-thinking business owner looking to enhance your commercial space or a discerning homeowner with an eye for detail, our expert metal cost estimation services are designed to provide you with the insights you need for effective project planning.

Our dedicated team of seasoned professionals brings a wealth of experience to the table, ensuring that every facet of your metal fabrication project is meticulously evaluated. From selecting the ideal metal type that harmonizes with your project’s specific requirements to analyzing the intricacies of design that impact labor costs, we leave no stone unturned. With our proprietary metal cost estimator tool, which marries cutting-edge technology with industry-leading knowledge, you can expect nothing short of accurate and reliable cost estimates.

For commercial projects, we understand the importance of efficiency, durability, and aesthetics. Whether you’re envisioning a contemporary office space, a sleek retail storefront, or an industrial warehouse, our cost estimation takes into account factors like material quantity, specialized finishes for branding, and project timeline constraints. Our goal is to equip you with the information you need to make strategic decisions that align with your commercial objectives.

For residential projects, we recognize that personalization, style, and budget-consciousness are paramount. Whether you’re conceptualizing a modern kitchen with custom metal accents, a stunning backyard oasis with intricate metalwork, or even a complete residential renovation, our meticulous cost estimation considers elements such as material choices, design complexity, and potential finishing options. Our mission is to empower you to bring your residential visions to life without compromising on quality or financial prudence.

Metal fabrication costs can vary significantly based on a variety of factors that influence every step of the process. Understanding these factors is crucial for accurate cost estimation and effective project planning. Here’s an in-depth look at how each element can impact your expenses:

The choice of metal is a fundamental determinant of your project’s overall cost. Different metals have distinct price points due to availability, sourcing, and production methods. Common metals used in fabrication include:

The type of metal you select sets the foundation for your project’s expenses.

Intricate and complex designs introduce additional layers of craftsmanship, time, and expertise. Fabricating intricate shapes, patterns, or structures demands meticulous attention to detail. Skilled artisans may need more time to bring such designs to life, leading to higher labor costs. Moreover, intricate designs often require specialized tools and equipment, which contribute to overall expenses.

Unsurprisingly, the quantity of metal required for your project is a direct cost driver. Larger projects demand more material, translating to higher material expenses. It’s crucial to accurately assess the quantity needed to prevent overestimating or underestimating costs.

Skilled labor is a cornerstone of successful metal fabrication. The expertise, experience, and specialization of fabricators influence labor costs. Complex projects that require intricate welding, precision cutting, or artistic detailing demand a higher skill level, leading to increased expenses. The craftsmanship and attention to detail directly contribute to the final cost.

Beyond functionality, finishes and coatings enhance aesthetics and provide essential protection. Different finishing options, such as powder coating, plating, or anodizing, come with varying costs. Premium finishes not only add to material expenses but also reflect the skill and expertise required for application.

Time is money, and project timelines play a significant role in cost determination. Urgent projects that necessitate accelerated work schedules, overtime labor, or expedited processes can result in higher costs. Properly managing your project timeline ensures efficient resource allocation and cost control.

Navigating the complexities of metal fabrication cost estimation can be a daunting task, especially when considering the multitude of variables at play. Fortunately, modern technology offers a valuable solution – online metal cost estimator tools. These innovative tools have revolutionized the way projects are planned and budgets are allocated. Let’s delve deeper into how utilizing a metal cost estimator tool can streamline your project planning process:

Gone are the days of manual calculations and painstaking guesswork. Metal cost estimator tools provide a streamlined and efficient way to estimate project expenses. By inputting specific parameters such as metal type, design intricacy, quantity, and required services, you’re able to receive a comprehensive cost estimate within minutes. This not only saves valuable time but also ensures accuracy in your budgeting.

Metal fabrication costs encompass a plethora of factors, each contributing to the final tally. These tools are meticulously designed to take into account a wide array of variables, ranging from material costs and labor expenses to overhead allocations and additional services. The algorithms powering these tools integrate these factors seamlessly, providing you with a holistic and detailed cost breakdown that leaves no aspect unaddressed.

As project parameters evolve and specifications change, so can your cost estimates. Online metal cost estimator tools offer the flexibility of real-time adaptability. Adjustments to quantities, design complexity, or material preferences are instantly reflected in the updated cost projections. This invaluable feature empowers you to make informed decisions on the fly, ensuring that your budget aligns with the dynamic nature of your project.

Accurate cost estimation is the cornerstone of informed decision-making. By utilizing a metal cost estimator tool, you’re equipped with the knowledge needed to evaluate various scenarios and options. This informed approach enables you to explore alternatives, assess feasibility, and prioritize aspects of your project without compromising on quality or financial prudence.

Modern metal cost estimator tools are designed with user-friendliness in mind. Intuitive interfaces and easy-to-follow steps ensure that even those without extensive technical expertise can navigate the tool with confidence. This accessibility democratizes the process, allowing individuals from various backgrounds to benefit from precise cost estimation.

Estimating the cost of metal fabrication involves a multifaceted analysis that delves into various components. A thorough understanding of these components is essential for precise cost estimation and informed decision-making. Here’s a detailed exploration of each factor that contributes to calculating metal fabrication costs:

Material costs serve as the foundational building blocks of your metal fabrication project. It involves the price of the chosen metal per unit. While this aspect might seem straightforward, there are nuances to consider. Factors such as the type of metal, its grade, size, and any special attributes required for your project can influence material costs. Additionally, fluctuations in the market can impact the price of metals, making accurate sourcing and estimation vital.

The skilled artisans and technicians who transform raw materials into intricate designs are at the heart of metal fabrication. Labor costs encompass wages, benefits, and any additional compensation for the individuals involved in your project. The complexity of the design, the intricacy of the work, and the skill level required all contribute to labor costs. Highly intricate or specialized projects may demand a team of experts, impacting the overall expenses.

Beyond the direct costs of materials and labor, overhead expenses play a significant role in cost calculation. These are indirect costs that support the fabrication process but are distributed across multiple projects. Overhead expenses include utilities, rent for the fabrication facility, administrative fees, equipment maintenance, and other operational costs. Allocating a portion of these expenses to each project ensures a comprehensive understanding of the true cost of fabrication.

Metal fabrication projects often involve a range of supplementary services that enhance the final product. Design consultations, engineering support, and assembly assistance contribute to the overall cost. These services ensure that your project not only meets your specifications but also adheres to industry standards and best practices. The expertise and collaboration required for these services can influence your budget.

Maximize your Metal business’s potential with our competitive financing options

Here is the Metal Materials cost table with cost details:

Metal Materials | Cost Details |

Structural Steel | $1,200 – $1,800 per ton |

Steel Beams | $180 – $360 per linear foot |

Steel Columns | $120 – $240 per linear foot |

Steel Plates | $960 – $1,440 per ton |

Steel Tubes | $60 – $120 per linear foot |

Steel Sheets | $960 – $1,440 per ton |

Aluminum Sheets | $1.80 – $3.60 per square foot |

Aluminum Extrusions | $2.40 – $4.80 per linear foot |

Stainless Steel | $2,400 – $3,000 per ton |

Metal Fasteners | $0.12 – $0.60 per piece |

Metal Fabrication | Prices Vary |

Metal Finishing | Prices Vary |

The cost details provided in the table are estimates and can vary based on factors such as material type, size, and supplier. For Metal Fabrication and Metal Finishing, prices can vary widely based on specific requirements and services.

Looking for a reliable construction equipment rental company? Look no further. Rent from us today.

Efficiently navigating the intricate realm of metal fabrication cost estimation is no longer a formidable challenge, thanks to the advent of online metal cost estimator tools. These digital marvels have redefined the landscape of project planning and budgeting, offering an array of benefits that significantly enhance your decision-making process. Let’s delve deeper into the multitude of advantages that embracing a metal cost estimator tool can bring to your metal fabrication endeavors:

Gone are the days of relying on ballpark figures or rough estimates. Online metal cost estimator tools provide an unprecedented level of precision, allowing you to arrive at accurate cost projections with just a few clicks. By inputting crucial project parameters such as metal type, dimensions, complexity, and finishing preferences, you can rest assured that the generated cost estimate aligns with the intricacies of your vision.

Metal fabrication costs encompass a myriad of variables, each playing a pivotal role in shaping the financial landscape of your project. These innovative tools excel at comprehensively considering these variables, ranging from material costs and labor expenditures to overhead allocations and supplementary services. By seamlessly integrating these factors, a metal cost estimator tool provides you with a comprehensive breakdown that encapsulates the entirety of your project’s financial journey.

Time is of the essence in any project, and metal fabrication is no exception. One of the most compelling advantages of a metal cost estimator tool is its ability to facilitate swift decision-making. As you explore different design iterations, adjust quantities, or experiment with varying materials, the tool provides real-time feedback on how each adjustment influences costs. This empowers you to make informed decisions promptly, ensuring that your project remains on track without any unwelcome financial surprises.

In the realm of metal fabrication, budget optimization is a paramount consideration. A metal cost estimator tool empowers you to fine-tune your budget with unparalleled flexibility. You can experiment with different scenarios, evaluate the financial implications of design alterations, and even explore cost-saving measures without sacrificing quality. This dynamic budget optimization ensures that your financial resources are allocated in a manner that maximizes efficiency and value.

Accurate cost estimation stands as a fundamental pillar in the realm of project management, wielding a profound influence that extends far beyond mere financial considerations. It functions as a guiding beacon, illuminating the intricate pathway to project success with a clarity that transcends budgetary constraints. By meticulously gauging the potential financial outlays, accurate cost estimation serves as a shield against the adversities of unexpected expenses, fostering an environment of fiscal prudence and stability.

However, its significance stretches even further. Beyond the fiscal realm, precise cost estimation plays a pivotal role in ascertaining the overall feasibility of your project. It empowers you to embark on your endeavor with a comprehensive understanding of the resources required, enabling you to align your aspirations with the practical constraints of reality. This alignment, in turn, lays the foundation for setting realistic expectations, both for your team and stakeholders, fostering a culture of transparency and accountability.

In the dynamic landscape of project execution, accurate cost estimation operates as a compass, steering your decisions and actions with unwavering accuracy. It empowers you to allocate resources judiciously, optimize your strategies, and navigate unforeseen challenges with resilience. Moreover, the ripple effects of meticulous cost estimation extend to fostering efficient timelines, as informed budgeting allows for the timely procurement of materials, the allocation of skilled labor, and the orchestration of intricate processes.

Misconceptions can cast a shadow over even the most well-informed decisions. In the realm of metal fabrication costs, debunking these myths is essential for fostering a clear understanding of the financial landscape. Let’s unravel a couple of common misconceptions that often obscure the true nature of metal fabrication expenses:

While the allure of cost savings is undeniable, the notion that opting for cheaper metals invariably leads to superior outcomes is a fallacy that can have far-reaching consequences. Lower-quality metals may indeed offer initial savings, but this frugality can quickly unravel in the face of long-term maintenance and replacement costs. Inferior metals are often more susceptible to corrosion, wear, and structural compromise, necessitating frequent repairs or premature replacements. In contrast, investing in higher-quality metals upfront may involve a slightly higher initial cost but can result in substantial savings over the product’s lifecycle, thanks to enhanced durability and reduced maintenance expenses.

The belief that labor costs are a static, unalterable element in the metal fabrication equation is a misperception that fails to acknowledge the nuanced interplay between project intricacy and skill demand. In reality, labor costs are intricately linked to the complexity of the design and the level of skill required for execution. Highly intricate projects with intricate detailing, precision welding, or specialized techniques demand a higher skill set, often leading to increased labor costs. Skilled artisans bring a level of craftsmanship and expertise that directly influences the final product’s quality and intricacy. Understanding the dynamic nature of labor costs empowers you to make informed decisions, ensuring that your project’s budget aligns with its unique demands.

The art of estimating metal fabrication costs stands as a pivotal cornerstone in the intricate edifice of project planning and execution. Within this multifaceted realm, a nuanced comprehension of the myriad factors that converge to shape these costs emerges as a beacon of strategic wisdom. As you embark on the journey from concept to creation, a profound awareness of material intricacies, design complexities, labor dynamics, and the broader spectrum of overhead considerations empowers you to chart a course that transcends mere budgeting. It becomes a voyage of foresight, where each decision is underpinned by the orchestration of resources with surgical precision. This grasp not only shields your endeavors from the specter of unexpected financial burdens but also cultivates an environment where aspirations are tethered to reality through a tapestry of meticulous planning. With every informed judgment and strategic allocation, you lay the groundwork for the triumphant success of your metal fabrication projects, where innovation and financial prudence intertwine in harmonious unison, and where the symphony of your creative vision resonates with the resounding notes of accomplished execution.

Request a free quote or call us at: +1(561)530-2845 to start working with us

Here I am going to share some steps to get your residential and commercial metal cost estimate report.

You can send us your plan on info@estimatorflorida.com

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

We do residential and commercial metal cost estimating and prepare a detailed report for your project. At last, you finalize the report and finish the project.

Daytona International Speedway

Known as the “World Center of Racing,” this iconic racetrack hosts various motorsports events, including the famous Daytona 500. Visitors can take guided tours of the track and explore the Motorsports Hall of Fame of America to learn about legendary drivers and vehicles.

A historic baseball stadium, it’s the home of the Daytona Tortugas, a minor league baseball team. Baseball enthusiasts can enjoy games in a classic ballpark setting while learning about Jackie Robinson’s legacy and breaking the color barrier in Major League Baseball.

Daytona Beach Boardwalk and Pier

The boardwalk stretches along the beach and offers a nostalgic coastal experience. You’ll find amusement rides, arcades, souvenir shops, and a variety of eateries serving beachside treats like funnel cakes and ice cream.

This family-friendly water park and entertainment center offer a variety of water attractions, including water slides, wave pools, and a lazy river. It’s a great place to cool off and have fun on a hot day.

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

All copyright © Reserved | Designed By V Marketing Media | Disclaimer

IMPORTANT: Make sure the email and cell phone number you enter are correct. We will email and text you a link to get started.

By clicking “I Agree” above you give Estimate Florida Consultin express written consent to deliver or cause to be delivered calls and messages to you by email, telephone, pre-recorded message, autodialer, and text. Message and data rates may apply. You are able to opt-out at any time. You can text STOP to cancel future text messages.