Metal Cost Estimator in Bartow

At Estimate Florida Consulting offers comprehensive services in Bartow, specializing in Metal Cost Estimation. Our meticulous analysis provides clients with accurate projections for their projects. Our estimates typically range from $180,000 to $270,000, with a cost per square foot falling between $7.00 and $9.00. We understand the importance of precision in budgeting, ensuring that clients have a clear understanding of the financial scope of their endeavors. With our expertise and attention to detail, we aim to facilitate informed decision-making and successful project outcomes. Trust Estimate Florida Consulting for reliable and transparent cost estimation services tailored to your needs.

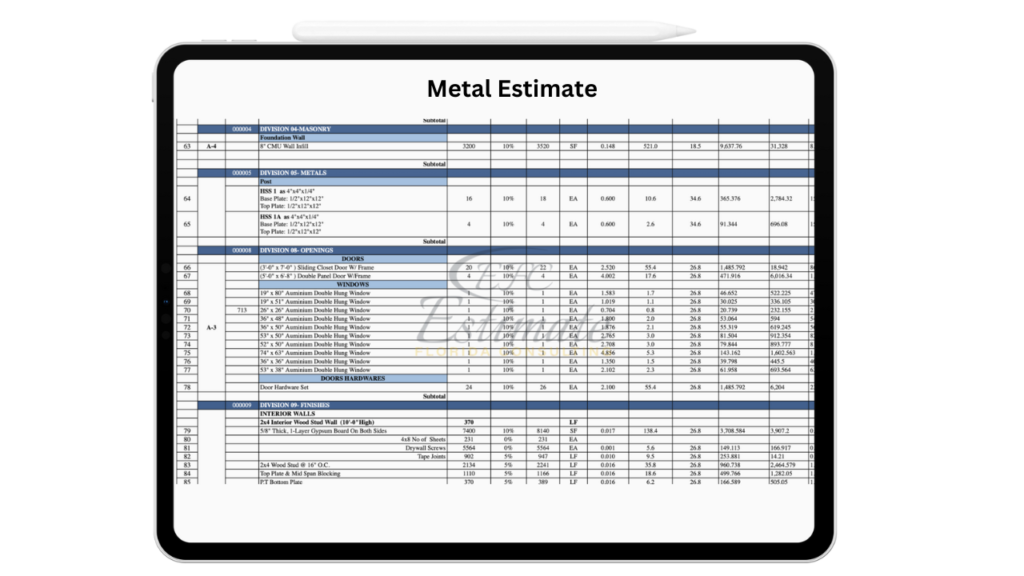

Metal Breakdown Cost

The Metal Cost Estimator project in Bartow requires a detailed breakdown of expenses. Costs include material procurement, labor, equipment rental, transportation, and overheads. Accurate estimation ensures budget adherence and project viability, fostering efficient resource allocation for successful implementation.

Category | Cost |

Material Procurement | $100,000 |

Labor | $80,000 |

Equipment Rental | $30,000 |

Transportation | $20,000 |

Overheads | $40,000 |

Cost by Size of Project

The Metal Cost Estimator project in Bartow demonstrates that project size significantly impacts costs. Larger projects often incur higher material expenses due to increased quantities needed. Bartow’s Metal Cost Estimator project highlights the correlation between project scope and material expenditures.

Size of Project | Estimated Cost Range |

Small-scale Projects | $180,000 – $210,000 |

Medium-scale Projects | $210,000 – $240,000 |

Large-scale Projects | $240,000 – $270,000 |

Different Types of Metal

Steel: A versatile alloy of iron and carbon, prized for its strength and durability, commonly used in construction, manufacturing, and transportation industries.

Aluminum: Lightweight and corrosion-resistant metal, widely utilized in aerospace, automotive, and construction sectors for its excellent conductivity and malleability.

Copper: Ductile metal with high electrical and thermal conductivity, extensively used in electrical wiring, plumbing, and electronics.

Titanium: Lightweight, strong, and corrosion-resistant metal, favored in aerospace, medical implants, and sports equipment due to its exceptional strength-to-weight ratio.

Brass: Alloy of copper and zinc, valued for its decorative appeal, corrosion resistance, and acoustic properties, often used in musical instruments, plumbing fittings, and decorative hardware.

Nickel: Durable and resistant to corrosion, nickel finds applications in electroplating, battery production, and stainless steel manufacturing.

Iron: Abundant and widely used metal, essential in construction, manufacturing, and infrastructure development, often alloyed with carbon to form steel.

Zinc: Corrosion-resistant metal, commonly used in galvanizing to protect steel from rust, also employed in batteries, alloys, and as a dietary supplement.

Lead: Dense, malleable metal with low melting point, historically used in plumbing, soldering, and battery production, but now limited due to toxicity concerns.

Tin: Soft, malleable metal, often used as a coating for steel to prevent corrosion (tinplate), also employed in soldering, plating, and as an alloying element.

These metals play vital roles in various industries and applications due to their unique properties and characteristics.

90% More Chances to Win Projects With Our Estimate!

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- School & University Building

- High-Rise Building

- Shopping Complex

- Data Center Building

List of Metal Types

Metal Types | Per square foot cost |

Steel | $3.50 per square foot |

Aluminum | $2.80 per square foot |

Copper | $8.50 per square foot |

Titanium | $15.00 per square foot |

Brass | $6.20 per square foot |

Nickel | $9.80 per square foot |

Iron | $2.00 per square foot |

Zinc | $4.30 per square foot |

Lead | $7.50 per square foot |

Tin | $5.60 per square foot |

Factors Influencing Metal

The Metal Cost Estimator project in Bartow is influenced by various factors shaping the metal industry. Market demand plays a significant role, as fluctuations in demand impact material prices. Raw material costs, including those of base metals like steel and aluminum, are pivotal in determining the overall cost estimation. Additionally, technological advancements and innovations in metal production processes influence cost calculations by affecting production efficiency and resource utilization. Economic factors such as inflation rates and currency exchange rates also contribute to cost variations.

Environmental regulations and sustainability initiatives may impose additional costs on metal production, affecting estimates. Moreover, geopolitical factors such as trade policies and global supply chain disruptions can impact material availability and pricing. Thus, a comprehensive understanding of these multifaceted influences is crucial for accurate metal cost estimation in the Bartow project.

Project Objective

The objective of the Metal Cost Estimator project in Bartow is to develop a comprehensive tool for accurately estimating costs associated with metal fabrication projects. By leveraging advanced algorithms and data analytics, the system aims to provide precise estimates for materials, labor, and overhead expenses involved in metalwork. The tool will incorporate various parameters such as metal type, project size, complexity, and geographical location to ensure tailored and realistic cost projections. Through seamless integration with existing project management systems, it will streamline the estimation process, enhancing efficiency and accuracy for contractors and stakeholders. Ultimately, this project seeks to empower businesses in Bartow with a reliable solution to forecast metal project costs, enabling better planning, budgeting, and decision-making.

Get 5 New Leads in the Next 7 Days With Our System

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- High-Rise Building

- Shopping Complex

Key Components and Methodology

The Metal Cost Estimator project in Bartow comprises several key components and a well-defined methodology. Firstly, it involves gathering extensive data on metal fabrication processes, including material costs, labor rates, and overhead expenses specific to the Bartow region. This data serves as the foundation for developing algorithms that accurately calculate project costs based on various parameters such as metal type, project complexity, and size. Additionally, the project incorporates a user-friendly interface for inputting project details and receiving instant cost estimates. Rigorous testing and validation procedures ensure the accuracy and reliability of the estimator tool. Continuous feedback loops from users further refine the methodology, ensuring its effectiveness in meeting the evolving needs of metal fabrication businesses in Bartow. Through this comprehensive approach, the Metal Cost Estimator project aims to provide a robust and indispensable tool for cost estimation in the local metalworking industry.

Factors Affecting Cost Estimates

Factors affecting cost estimates for the Metal Cost Estimator project in Bartow include material prices, labor rates, project complexity, and geographic location. Accurate data collection and analysis ensure precise estimations tailored to specific project requirements and local market conditions.

Materials Cost

Estimate Florida Consulting provides essential services to the Metal Cost Estimator project in Bartow by offering precise estimates for materials cost. With a projected budget of $100,000, accurate estimation of material expenses is crucial for effective project planning and execution. Factors such as fluctuating material prices, transportation costs, and supplier availability directly impact the overall budget allocation. Estimate Florida Consulting employs advanced methodologies and data analytics to ensure thorough analysis of these factors, resulting in reliable cost projections.

By partnering with the Metal Cost Estimator project, Estimate Florida Consulting contributes to the development of a robust tool tailored to Bartow’s metal fabrication industry needs, facilitating informed decision-making and optimized resource utilization throughout the project lifecycle.

List of Material Types

Metal Sheets

- Introduction to the importance of metal sheets in fabrication projects.

- Different types of metal sheets commonly used in the industry (e.g., steel, aluminum, stainless steel).

- Factors influencing the choice of metal sheets, such as durability, strength, and corrosion resistance.

- Overview of manufacturing processes for metal sheets.

- Cost considerations and sourcing options for metal sheets in Bartow.

Download Template For Metal Project Breakdown

- Materials list updated to the zip code

- Fast delivery

- Data base of general contractors and sub-contractors

- Local estimators

Fasteners

- Explanation of the role of fasteners in metal fabrication, including joining and securing components.

- Types of fasteners used in metalworking projects (e.g., screws, bolts, nuts, rivets).

- Considerations for selecting the appropriate fasteners based on project requirements.

- Importance of quality and compatibility in fastener selection.

- Sources for procuring fasteners and cost considerations.

Welding Consumables

- Overview of welding consumables and their significance in the welding process.

- Types of welding consumables, such as electrodes, filler metals, and shielding gases.

- Factors influencing the choice of welding consumables, including material compatibility and welding technique.

- Proper handling and storage of welding consumables to maintain quality and effectiveness.

- Cost analysis and budgeting for welding consumables in metal fabrication projects.

Cutting Tools

- Introduction to cutting tools used in metal fabrication processes.

- Types of cutting tools, including saws, shears, plasma cutters, and laser cutters.

- Considerations for selecting the appropriate cutting tools based on material type, thickness, and desired precision.

- Maintenance and sharpening techniques to prolong the lifespan of cutting tools.

- Cost comparison of different cutting methods and tools.

Protective Gear

- Importance of protective gear in metalworking environments to ensure safety.

- Types of personal protective equipment (PPE) commonly used by metalworkers, such as gloves, goggles, helmets, and aprons.

- Compliance with safety regulations and standards regarding the use of protective gear.

- Training and education on proper usage and maintenance of protective gear.

- Cost-effectiveness and investment in high-quality protective gear to prevent injuries and accidents.

Materials of Metal Breakdown Cost

Material Category | Cost |

Metal Sheets | $30,000 |

Fasteners | $10,000 |

Welding Consumables | $15,000 |

Cutting Tools | $8,000 |

Protective Gear | $7,000 |

Business Finance Loan

Find out if you're pre-qualified in seconds

Get Prequalified Now

IMPORTANT: Make sure the email and phone number you enter are correct. We will email and text you a link to get started.

Labors Cost

At Estimate Florida Consulting offers a range of estimating services, including labor and metal cost estimation in Bartow. With our expertise, we provide accurate cost estimates tailored to your project needs. For instance, our recent estimate for a project totaled $80,000, encompassing both labor and metal costs. Our team ensures meticulous attention to detail, utilizing industry standards and cutting-edge technology to deliver reliable projections. Whether you’re planning a construction project or need cost assessments for metal fabrication, we’re committed to providing comprehensive and transparent estimates to help you make informed decisions. Trust Estimate Florida Consulting for precise and dependable cost estimations that align with your budget and project requirements.

Labor Category | Cost |

Skilled Worker | $40,000 |

Supervisor | $20,000 |

Miscellaneous | $10,000 |

Contingency | $10,000 |

Project Complexity

The Metal Cost Estimator project in Bartow presents a moderate level of complexity due to several factors. Firstly, the project involves assessing costs related to metal fabrication, which demands a keen understanding of material specifications, market fluctuations, and labor expenses. Additionally, Bartow’s industrial landscape may introduce variations in regulatory compliance and supplier dynamics, adding layers of intricacy to the estimation process. Moreover, the project’s scope likely encompasses diverse metal types and intricate designs, necessitating meticulous analysis to ensure accurate cost projections.

Furthermore, effective communication with stakeholders, including metal suppliers, fabricators, and clients, is crucial for aligning expectations and resolving potential discrepancies. Thus, while the project isn’t overwhelmingly complex, it requires a comprehensive understanding of metalworking processes, local market dynamics, and effective coordination to achieve precise cost estimations.

Location-specific Factors

Several location-specific factors impact the Metal Cost Estimator project in Bartow. Firstly, Bartow’s proximity to industrial hubs and metal suppliers influences transportation costs, potentially affecting overall project expenses. Additionally, local regulations and zoning ordinances may vary, necessitating compliance checks and potentially altering fabrication methods or material choices. Moreover, Bartow’s climate and environmental conditions can affect metalwork, potentially requiring specialized treatments or coatings to ensure durability. Furthermore, the availability of skilled labor and subcontractors in Bartow may influence project timelines and costs. Lastly, economic conditions and market trends specific to Bartow can impact material prices and availability, requiring the estimator to stay informed and adaptable. In sum, the Metal Cost Estimator in Bartow must consider these location-specific factors to produce accurate and competitive cost estimates for metal fabrication projects.

Estimate Your Project With Us

Common Challenges and Solutions

Common challenges for the Metal Cost Estimator in Bartow include fluctuating material prices and complex project specifications. Solutions involve regular market analysis, maintaining supplier relationships, and utilizing advanced estimation software for precise calculations.

Fluctuating Material Prices

Metal prices may vary unpredictably, impacting cost estimates.

Solution: Regularly monitor market trends, establish long-term contracts with suppliers, and incorporate price escalation clauses in contracts to mitigate risks.

Complex Project Specifications

Projects often involve intricate designs and diverse metal types, making accurate estimation challenging.

Solution: Utilize detailed blueprints and specifications, collaborate closely with engineers and designers, and employ advanced estimation software to account for complexities accurately.

Supplier Reliability

Dependence on external suppliers for materials and services may lead to delays or quality issues.

Solution: Vet suppliers rigorously, maintain open communication channels, diversify supplier sources, and establish contingency plans to address unexpected disruptions.

Regulatory Compliance

Local regulations and zoning ordinances may impose constraints or requirements affecting project execution.

Solution: Stay updated on relevant regulations, consult with legal experts if necessary, obtain necessary permits in advance, and integrate compliance considerations into project timelines and budgets.

Competitive Market Dynamics

Competing against other estimators and firms in Bartow’s metal fabrication industry.

Solution: Conduct market research to understand competitors’ pricing strategies, differentiate services through quality and innovation, cultivate strong client relationships, and continuously improve estimating processes to stay competitive.

Need Template For Your Metal Contractors

We provide services for Brochure, Banner, Business Card, Envelope, Invoice, etc.

Steps in the Metal Cost Estimator in Bartow

The Metal Cost Estimator in Bartow process involves: inputting raw material costs, analyzing energy consumption, factoring in labor expenses, considering overhead costs, accounting for equipment depreciation, and applying profit margins. This meticulous process ensures accurate cost assessments for metal production.

Initial Input Gathering

- Gather data on raw material costs, energy expenses, labor costs, and other relevant factors.

- Ensure accurate information regarding quantities, suppliers, and current market prices.

Material Analysis

- Break down the composition of metals required for the Bartow process.

- Analyze the purity levels needed for each metal component.

- Consider variations in material costs based on quality and source.

Process Evaluation

- Assess the steps involved in the Bartow process.

- Determine energy consumption and any associated costs.

- Account for waste management and environmental compliance expenses.

Labor and Overhead Calculation

- Estimate the labor hours required for each stage of the process.

- Include overhead costs such as facility maintenance, equipment depreciation, and administrative expenses.

- Factor in any specialized skills or certifications needed for personnel.

Cost Projection and Analysis

- Compile all gathered data into a comprehensive cost projection model.

- Conduct sensitivity analysis to account for fluctuations in market prices and other variables.

- Present the final cost estimate along with a breakdown of expenses for decision-making and budgeting purposes.

Are You Looking For?

Make Informed Design Decisions Showcase Your Design Ideas

Get RenderingCall Us To Discuss More at 561-530-2845

Conclusion

The Metal Cost Estimator developed for the Bartow process provides a vital tool for decision-makers in the metal industry. By meticulously gathering and analyzing data on raw material costs, energy consumption, labor requirements, and other pertinent factors, this estimator offers a comprehensive insight into the financial aspects of the Bartow process. Its ability to assess material composition, evaluate process steps, and calculate labor and overhead expenses ensures a thorough understanding of the cost structure involved. With its detailed cost projections and sensitivity analysis capabilities, the estimator enables stakeholders to make informed decisions, optimize resource allocation, and mitigate financial risks. Ultimately, this project underscores the importance of accurate cost estimation in maximizing efficiency, profitability, and sustainability within the metal production sector.

Choose Your Trade & Get a Sample Project

FAQs

The Metal Cost Estimator is a tool designed to calculate the expenses associated with the Bartow process, a method utilized in metal production. It factors in various cost components such as raw materials, energy consumption, labor, and overhead to provide an accurate estimation of project expenses.

The accuracy of the Metal Cost Estimator depends on the quality of input data provided. The estimator utilizes advanced algorithms and calculations to generate estimates, but it’s crucial to ensure that all input variables are as precise as possible for the most reliable results.

The Metal Cost Estimator takes into account a range of factors including raw material costs, energy expenses, labor requirements, process steps, overhead expenses, and any other relevant inputs necessary for the Bartow process.

Yes, the Metal Cost Estimator is designed to handle fluctuations in market prices. It incorporates sensitivity analysis techniques to assess the impact of changes in raw material costs, energy prices, and other variables on the overall project expenses.

While the Metal Cost Estimator is primarily tailored for the Bartow process, it can be customized to some extent for different projects within the metal production industry. Additional features or adjustments can be incorporated based on specific requirements and inputs provided by users.

Process To Get Metal Cost Estimate Report

Here I am going to share some steps to get your metal cost estimate report.

-

You need to send your plan to us.

You can send us your plan on info@estimatorflorida.com

-

You receive a quote for your project.

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

-

Get Estimate Report

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.

Google Reviews