Mechanical Cost Estimator in Fort Lauderdale, FL

Estimate Florida Consulting specializes in delivering meticulous mechanical cost estimates finely tuned to meet the unique requirements of our clients in Fort Lauderdale. Mechanical cost estimation serves as the financial roadmap for engineering and construction endeavors, ensuring projects stay within budgetary constraints. Costs can vary significantly: for smaller projects, estimates may range from $10,000 to $100,000, while mid-sized projects could entail expenses ranging from $200,000 to $1 million. Larger-scale ventures, such as those in the aerospace industry prevalent in Fort Lauderdale, might require budgets exceeding $10 million, depending on the intricacy and scale of the project.

Our team is dedicated to providing accurate estimates tailored to the specific needs of each project, facilitating informed decision-making and successful project execution.

Cost by Size of Project

Projects in Fort Lauderdale vary widely in size and complexity, with small-scale endeavors typically encompassing basic system installations or minor upgrades. Medium-scale projects involve more substantial undertakings such as facility renovations or equipment replacements. Large-scale projects encompass major developments like the construction of new launch facilities or significant infrastructure upgrades. Industrial-scale projects represent the most extensive ventures, including the construction of advanced manufacturing facilities or large-scale aerospace complexes, reflecting the complexity and magnitude of the endeavor.

Size of Project | Estimated Cost Range |

Small-scale Projects | $10,000 – $100,000+ |

Medium-scale Projects | $200,000 – $2,000,000+ |

Large-scale Projects | $5,000,000 – $50,000,000+ |

Industrial-scale Projects | $10,000,000 – $100,000,000+ |

90% More Chances to Win Projects With Our Estimate!

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- School & University Building

- High-Rise Building

- Shopping Complex

- Data Center Building

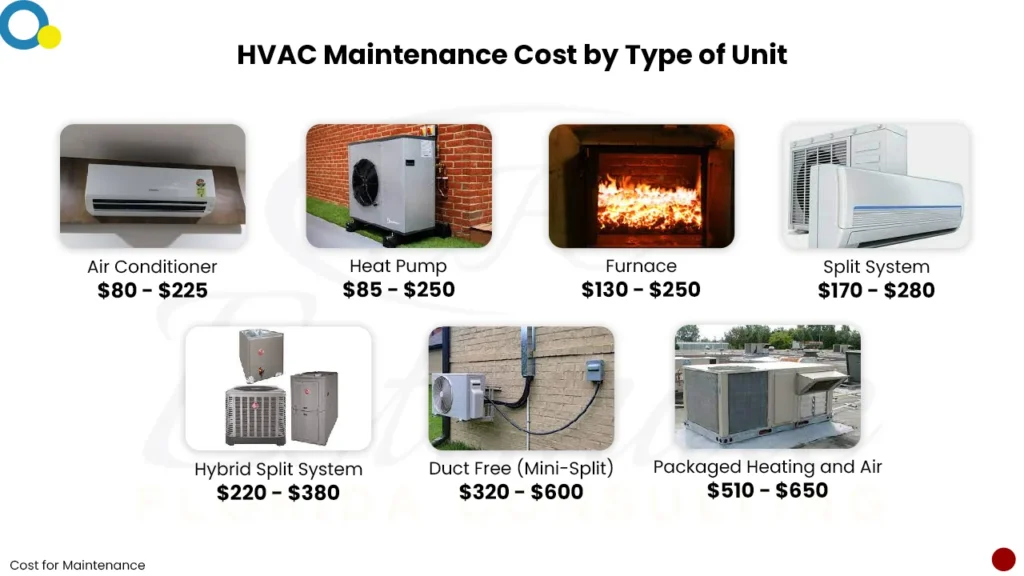

HVAC Maintenance Costs by Unit Type

Maintaining HVAC systems is vital for ensuring their efficiency and durability. Various types of units require regular maintenance to keep them functioning smoothly. Air conditioners, heat pumps, furnaces, split systems, hybrid split systems, duct-free mini-splits, and packaged heating and air conditioning units all have their specific maintenance needs. Routine servicing may include tasks such as cleaning coils, checking refrigerant levels, inspecting electrical components, and replacing filters.

Type of Unit | Cost Range |

Air Conditioner | $80 – $225 |

Heat Pump | $85 – $250 |

Furnace | $130 – $250 |

Split System | $170 – $280 |

Hybrid Split System | $220 – $380 |

Duct-Free (Mini-Split) | $320 – $600 |

Packaged Heat and Air | $510 – $650 |

Understanding the Mechanical Industry in Fort Lauderdale

Fort Lauderdale, situated on Florida’s Space Coast, is renowned for its pioneering contributions to space exploration and its vibrant mechanical industry reflects this spirit of innovation and precision. The mechanical sector in Fort Lauderdale encompasses a diverse array of activities, ranging from the design and fabrication of specialized components for spacecraft to the maintenance and operation of complex industrial machinery. This industry’s significance extends beyond the boundaries of the city, as it directly supports the operations of nearby Kennedy Space Center and numerous aerospace companies in the region, playing a critical role in advancing space exploration and technology.

Precision Machining and Fabrication

At the heart of Fort Lauderdale’s mechanical industry lies precision machining and fabrication, where skilled technicians and engineers meticulously craft components with exacting specifications. These components, ranging from intricate propulsion system parts to structural elements for launch vehicles, require unparalleled precision and reliability to withstand the extreme conditions of space travel. The expertise of Fort Lauderdale’s machinists and fabricators is evident in their ability to deliver high-quality, custom solutions that meet the rigorous standards of the aerospace industry, contributing to the success of space missions and ensuring the safety of astronauts and payloads.

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- High-Rise Building

- Shopping Complex

Robotics and Automation

Innovations in robotics and automation have revolutionized the mechanical industry in Fort Lauderdale, enhancing efficiency, safety, and reliability in various operations. Robotic systems play a crucial role in tasks such as assembly, inspection, and maintenance of spacecraft and launch infrastructure, where human intervention may be impractical or hazardous. The integration of advanced automation technologies not only streamlines processes but also enables rapid adaptability to evolving mission requirements, ensuring that Fort Lauderdale remains at the forefront of space exploration endeavors.

Environmental Control Systems

The extreme environmental conditions of space demand sophisticated environmental control systems (ECS) to regulate temperature, humidity, and air quality within spacecraft and habitats. Fort Lauderdale’s mechanical industry excels in the design, installation, and maintenance of ECS, leveraging innovative solutions to create habitable environments for astronauts during missions. These systems, which incorporate state-of-the-art filtration, monitoring, and control mechanisms, are essential for ensuring crew comfort, health, and productivity in the harsh vacuum of space.

Structural Engineering and Testing

The reliability of launch infrastructure and spacecraft hinges on rigorous structural engineering and testing processes, which simulate the intense forces and conditions encountered during launch and spaceflight. Fort Lauderdale’s mechanical industry boasts expertise in structural analysis, materials science, and testing methodologies, enabling the development of robust and resilient aerospace structures. Through extensive testing campaigns and simulations, engineers validate the integrity and performance of critical components, mitigating risks and ensuring mission success in the demanding environment of space.

Download Template For Mechanical Project Breakdown

- Materials list updated to the zip code

- Fast delivery

- Data base of general contractors and sub-contractors

- Local estimators

Fluid Dynamics and Propulsion

Fluid dynamics and propulsion systems form the backbone of space exploration, powering rockets and spacecraft through the vast expanse of the cosmos. Fort Lauderdale’s mechanical industry encompasses a wealth of expertise in propulsion technologies, ranging from traditional chemical propulsion to cutting-edge ion and plasma thrusters. Engineers and researchers in the region are at the forefront of propulsion research and development, pushing the boundaries of efficiency, reliability, and performance to enable ambitious missions to distant planets and beyond.

Materials Science and Advanced Manufacturing

The pursuit of lighter, stronger, and more durable materials drives innovation in Fort Lauderdale’s mechanical industry, where researchers and manufacturers explore novel materials and manufacturing techniques to enhance spacecraft performance. From lightweight composites and advanced alloys to additive manufacturing processes such as 3D printing, the region’s materials scientists and engineers continually push the envelope in material science and manufacturing technology. These advancements not only improve the efficiency and cost-effectiveness of spacecraft production but also enable breakthroughs in design flexibility and mission capability, propelling the exploration of space to new heights.

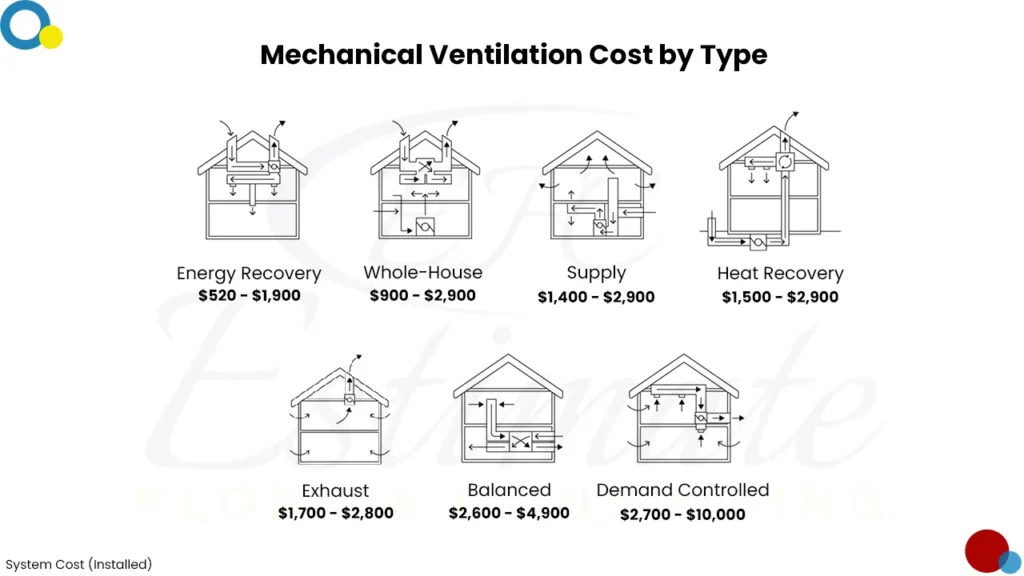

Cost of Mechanical Ventilation by Type

Mechanical air exchange systems typically cost between $520 and $10,000. These systems utilize fans installed in windows, walls, or air ducts to either remove or add air to the home. Condensation, formed when warm air meets cold surfaces, can be prevented by these fans, which either extract or introduce air to maintain balanced air quality within the room. A balanced mechanical ventilation system ensures that the air quality meets specific design specifications.

Mechanical Ventilation Type | System Cost (Installed) |

Energy Recovery | $520 – $1,900 |

Whole-House | $900 – $2,900 |

Supply | $1,400 – $2,900 |

Heat Recovery | $1,500 – $2,900 |

Exhaust | $1,700 – $2,800 |

Balanced | $2,600 – $4,900 |

Demand Controlled | $2,700 – $10,000 |

Business Finance Loan

Find out if you're pre-qualified in seconds

Get Prequalified Now

IMPORTANT: Make sure the email and phone number you enter are correct. We will email and text you a link to get started.

Factors Affecting Mechanical Cost Estimator in Fort Lauderdale

The precision and accuracy of mechanical cost estimation in Fort Lauderdale are influenced by a myriad of factors intrinsic to the unique characteristics of the aerospace and engineering landscape in the region. Understanding these factors is essential for ensuring reliable and comprehensive cost estimates that align with the requirements and constraints of each project.

Project Complexity and Scope

The complexity and scope of a mechanical project in Fort Lauderdale significantly impact cost estimation. Projects ranging from routine maintenance of launch infrastructure to the design and construction of advanced spacecraft propulsion systems vary in complexity, requiring distinct methodologies and resources for accurate estimation. Factors such as the number of components, integration requirements, and technological sophistication directly influence the time and resources needed, thereby affecting cost projections.

Technological Advancements

Rapid advancements in technology play a pivotal role in shaping the mechanical industry in Fort Lauderdale and, consequently, impact cost estimation. Emerging technologies, such as additive manufacturing, robotics, and advanced materials, offer opportunities for innovation and efficiency gains but may also entail higher initial investment costs. Integrating cutting-edge technologies into mechanical projects requires careful evaluation of their benefits and risks, as well as consideration of the long-term implications for cost estimation and project outcomes.

Regulatory Compliance and Safety Standards

The stringent regulatory environment governing aerospace and engineering activities in Fort Lauderdale imposes strict compliance requirements and safety standards that influence cost estimation. Adherence to regulations set forth by agencies such as NASA, the Federal Aviation Administration (FAA), and the Occupational Safety and Health Administration (OSHA) necessitates additional planning, documentation, and quality assurance measures, all of which contribute to project costs. Failure to account for regulatory compliance and safety considerations accurately can lead to delays, penalties, and potential liabilities, underscoring their significance in cost estimation.

Supply Chain Dynamics

The availability and cost of materials, components, and skilled labor are critical considerations in mechanical cost estimation in Fort Lauderdale. The aerospace industry’s reliance on specialized materials and technologies, coupled with fluctuating market conditions and supply chain disruptions, can introduce uncertainties and variability in cost projections. Strategic sourcing, vendor management, and supply chain resilience strategies are essential for mitigating risks and optimizing cost efficiency while ensuring project timelines and quality standards are met.

Environmental and Geographic Factors

The environmental and geographic characteristics of Fort Lauderdale, including its coastal location, subtropical climate, and proximity to sensitive ecosystems, pose unique challenges and considerations for mechanical projects. Factors such as corrosion resistance, environmental sustainability, and resilience to extreme weather events must be incorporated into cost estimation to address environmental and regulatory requirements adequately. Additionally, logistical challenges associated with transportation, site access, and infrastructure availability can impact project costs and timelines, necessitating careful planning and contingency measures.

Stakeholder Requirements and Expectations

Meeting the diverse requirements and expectations of stakeholders, including government agencies, contractors, and the public, is essential for successful mechanical projects in Fort Lauderdale. Effective communication, collaboration, and alignment of project goals and objectives are critical for managing expectations and ensuring project success. Factors such as stakeholder engagement, community impact assessments, and public relations activities may incur additional costs but are essential for maintaining project support and achieving long-term sustainability and success.

Price Table by Type of Mechanical System in Fort Lauderdale

Mechanical systems in Fort Lauderdale are integral to the region’s aerospace and engineering activities, encompassing a wide range of specialized applications tailored to support space exploration and technological innovation. From propulsion systems to environmental control units, each system serves a critical function in ensuring the success and safety of missions and projects conducted in the area.

System Type | Cost Range | Quantity |

HVAC (Heating, Ventilation, Air Conditioning) | $5,000 – $50,000 | Per System |

Plumbing | $2,500 – $25,000 | Per Project |

Fire Protection | $2,000 – $20,000 | Per System |

Industrial Machinery | $10,000 – $100,000 | Per Piece |

Renewable Energy Systems | $7,500 – $75,000 | Per System |

Refrigeration | $3,000 – $30,000 | Per Unit |

Elevator Systems | $4,000 – $40,000 | Per Elevator |

Automation Systems | $6,000 – $60,000 | Per System |

Waste Management Systems | $3,500 – $35,000 | Per System |

Water Treatment Systems | $4,500 – $45,000 | Per System |

We provide accurate pricing for the ZIP code of your project.

Turnaround time is 1-2 days.

Win More Projects With Us

Common Challenges and Solutions in Mechanical Cost Estimation:

Uncertainty in Project Scope

Challenge: The scope of mechanical projects in Fort Lauderdale can evolve or change unpredictably, leading to challenges in accurately defining project requirements and deliverables.

Solution: Implementing robust change management processes and conducting thorough feasibility studies can help identify potential scope changes early on. Additionally, maintaining open communication channels with stakeholders ensures clarity and alignment regarding project objectives and scope.

Fluctuating Market Prices

Challenge: Mechanical cost estimators must contend with volatile market conditions, including fluctuations in material costs, labor rates, and equipment prices, which can impact project budgets.

Solution: Employing dynamic pricing models that account for market trends and conducting regular market analysis enables estimators to adjust cost projections accordingly. Negotiating long-term contracts with suppliers and subcontractors can also provide stability and mitigate the impact of price fluctuations.

Regulatory Compliance

Challenge: Meeting stringent regulatory requirements imposed by government agencies and industry standards adds complexity to mechanical cost estimation, requiring adherence to safety, environmental, and quality regulations.

Solution: Establishing a comprehensive understanding of regulatory frameworks and proactively engaging regulatory authorities during project planning helps identify compliance requirements upfront. Implementing robust quality assurance and control measures ensures adherence to regulatory standards throughout project execution, minimizing the risk of costly delays or penalties.

Technological Advancements

Challenge: Rapid advancements in technology introduce new materials, equipment, and methodologies, posing challenges in accurately estimating costs for innovative solutions.

Solution: Investing in continuous professional development and staying abreast of emerging technologies enable estimators to incorporate the latest advancements into their cost models. Collaboration with engineering and research teams facilitates early involvement in technology selection and integration, ensuring accurate cost projections for cutting-edge solutions.

Resource Constraints

Challenge: Limited availability of skilled labor, specialized equipment, and logistical resources in Fort Lauderdale’s aerospace industry presents challenges in resource allocation and scheduling.

Solution: Developing strategic partnerships with subcontractors, suppliers, and training institutions helps augment resource capabilities and address skill gaps. Implementing efficient resource management practices, such as optimizing workforce utilization and investing in equipment maintenance and upgrades, maximizes productivity and minimizes project costs.

Need Template For Your Mechanical Business

We provide services for Brochure, Banner, Business Card, Envelope, Invoice, etc.

Steps in the Plumbing Cost Estimation Process in Fort Lauderdale

Project Evaluation and Scope Definition

The first step in plumbing cost estimation involves thoroughly evaluating the project requirements and defining the scope of work. This includes reviewing architectural and engineering plans, understanding plumbing system specifications, and identifying any unique considerations or constraints specific to the project site. Clear communication with project stakeholders is essential to ensure alignment on project objectives, timelines, and budgetary constraints.

Site Visit and Assessment

Conducting a site visit allows plumbing estimators to assess existing conditions, identify potential challenges, and gather essential information that may impact cost estimation. During the site assessment, factors such as access to utilities, existing plumbing infrastructure, and site layout are evaluated to inform the estimation process accurately. Additionally, site visits provide an opportunity to address any site-specific requirements or regulatory considerations that may affect plumbing system design and installation.

Material and Equipment Selection

Selecting appropriate materials and equipment is critical for ensuring the reliability and efficiency of plumbing systems while also managing costs effectively. Plumbing estimators work closely with suppliers and manufacturers to evaluate available options, compare pricing, and identify products that meet project specifications and performance requirements. Factors such as material durability, compatibility, and lifecycle costs are considered during the selection process to optimize value and minimize long-term maintenance expenses.

Material and Equipment Selection

Selecting appropriate materials and equipment is critical for ensuring the reliability and efficiency of plumbing systems while also managing costs effectively. Plumbing estimators work closely with suppliers and manufacturers to evaluate available options, compare pricing, and identify products that meet project specifications and performance requirements. Factors such as material durability, compatibility, and lifecycle costs are considered during the selection process to optimize value and minimize long-term maintenance expenses.

Labor and Resource Allocation

Estimating labor requirements involves determining the number of skilled tradespeople, such as plumbers and pipefitters, needed to complete the project within the specified timeframe. Plumbing estimators assess labor rates, productivity factors, and project complexities to develop accurate labor cost estimates. Additionally, resource allocation for equipment, tools, and subcontracted services, such as excavation or trenching, is carefully evaluated to ensure adequate resources are allocated to each aspect of the project.

Cost Calculation and Analysis

Once all project parameters have been evaluated, plumbing estimators calculate costs for materials, labor, equipment, and subcontracted services based on the information gathered during the assessment process. Detailed cost breakdowns are prepared, allowing stakeholders to understand the composition of project costs and identify areas for potential cost optimization or value engineering. Sensitivity analysis may be conducted to assess the impact of variations in key cost drivers, such as material prices or labor rates, on overall project costs.

Contingency Planning

Anticipating and mitigating potential risks is an essential aspect of plumbing cost estimation. Estimators incorporate contingency allowances into their cost projections to account for unforeseen circumstances, such as material shortages, design changes, or site conditions that may impact project timelines or budgets. Contingency planning helps minimize project disruptions and ensures that adequate resources are available to address unexpected challenges as they arise, maintaining project momentum and reducing the likelihood of cost overruns.

Are You Looking For?

Fully Insured License Hire Sub-Contractor For Mechanical Work

Hire Contractor

Make Informed Design Decisions Showcase Your Design Ideas

Get RenderingCall Us To Discuss More at 561-530-2845

Conclusion

The field of Mechanical Cost Estimation in Fort Lauderdale encompasses a wide array of projects and systems, each varying in complexity and cost. From small-scale renovations to large industrial ventures, the estimated costs can range significantly, reflecting the diverse needs and requirements of clients in this dynamic region. Precise cost estimation is essential for guiding engineering and construction endeavors, serving as the financial blueprint for projects. Additionally, mechanical systems play a critical role in maintaining comfort, safety, and efficiency across various environments, influencing daily operations and sustainability efforts across industries. With meticulous cost estimation and effective system implementation, projects in Fort Lauderdale can achieve their goals efficiently and sustainably.

Choose Your Trade & Get a Sample Project

FAQs

The cost of mechanical projects in Fort Lauderdale can be influenced by various factors, including the scale and complexity of the project, the specific requirements and specifications, the availability and cost of materials and labor, as well as any regulatory or environmental considerations unique to the area.

Estimate Florida Consulting strives to provide highly accurate cost estimates tailored to the specific needs of our clients in Fort Lauderdale. Our team utilizes industry-standard methodologies and leverages extensive experience to ensure that our estimates are as precise as possible, helping clients plan and budget effectively for their mechanical projects.

Yes, Estimate Florida Consulting offers comprehensive services beyond initial cost estimation, including ongoing budget management and cost tracking throughout the duration of a project. Our team works closely with clients in Fort Lauderdale to monitor expenses, identify potential cost-saving opportunities, and ensure that projects stay on track financially.

Estimate Florida Consulting offers cost estimation services for a wide range of mechanical systems, including HVAC (heating, ventilation, and air conditioning), plumbing, electrical systems, fire protection systems, refrigeration systems, industrial machinery, and more. Whatever the project requirements may be, our team is equipped to provide accurate cost estimates tailored to the specific needs of our clients in Fort Lauderdale.

To request a cost estimate for your mechanical project in Fort Lauderdale, simply contact Estimate Florida Consulting through our website or by phone. Our team will work closely with you to gather the necessary project details and specifications, and we’ll provide you with a comprehensive cost estimate tailored to your specific requirements on time.

Process To Get Mechanical Cost Estimate Report

Here I am going to share some steps to get your mechanical cost estimate report.

-

You need to send your plan to us.

You can send us your plan on info@estimatorflorida.com

-

You receive a quote for your project.

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

-

Get Estimate Report

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.

Google Reviews