Mechanical Cost Estimator in Coral Springs, FL

Estimate Florida Consulting, a leading consultancy firm, specializes in delivering meticulous mechanical cost estimations tailored to the unique requirements of our clientele. Mechanical cost estimation is a cornerstone in the realms of engineering and construction, serving as the financial blueprint for projects of all scales and complexities. The costs associated with mechanical elements can vary significantly. For smaller projects, expenses may range from $5,000 to $50,000+, while mid-sized endeavors could see budgets between $100,000 and $500,000+.

For larger industrial or commercial ventures, mechanical costs can escalate substantially, ranging from $1 million to over $5 million, contingent upon the project’s intricacies and specifications. At Estimate Florida Consulting, we excel in providing accurate estimations that facilitate informed decision-making and project success.

Cost by Size of Project

Size of Project | Estimated Cost Range |

Small-scale Projects | $5,000 – $50,000+ |

Medium-scale Projects | $100,000 – $500,000+ |

Large-scale Projects | $1,000,000 – $5,000,000+ |

Industrial-scale Projects | $5,000,000 – $50,000,000+ |

Projects vary widely in size and scope, with small-scale endeavors typically encompassing basic renovations or minor installations. Medium-scale projects involve more substantial undertakings such as building construction or system upgrades. Large-scale projects encompass major developments like infrastructure improvements or commercial constructions. Industrial-scale projects represent the most extensive ventures, including large-scale manufacturing facilities or industrial complexes, reflecting the complexity and magnitude of the endeavor. These cost ranges are indicative and may vary based on project specifics and prevailing market conditions.

90% More Chances to Win Projects With Our Estimate!

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- School & University Building

- High-Rise Building

- Shopping Complex

- Data Center Building

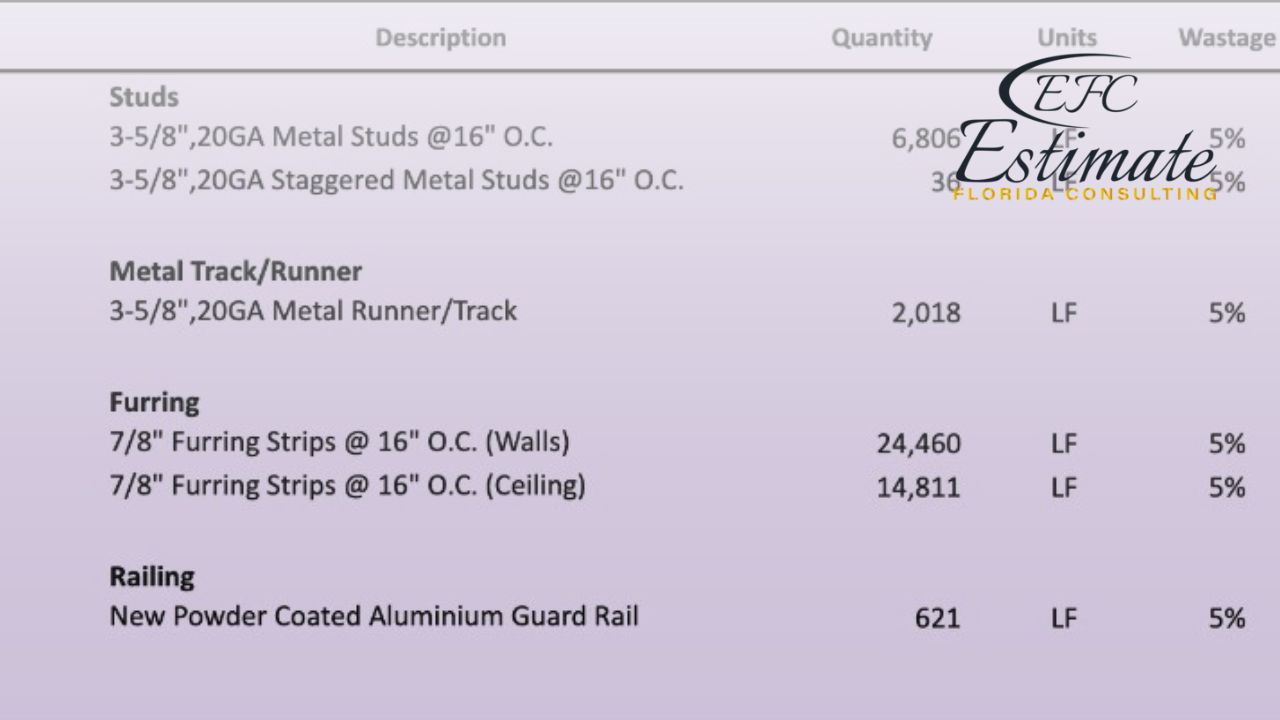

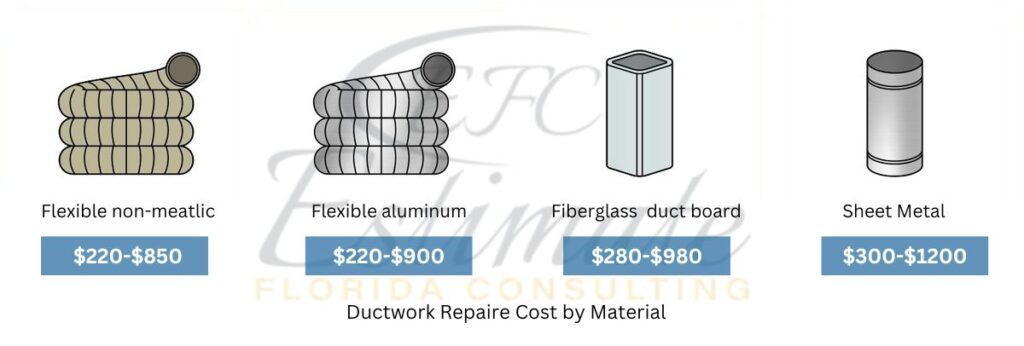

Cost to Repair Ductwork by Material

There exist various types of ductwork, ranging from economical, flexible, non-metallic options to premium sheet metal variants. Each type features distinct designs and materials, with repair costs varying accordingly. Hence, the type of duct you have can significantly impact the expenses of repairs. Below outlines the primary duct types alongside their average repair costs for a standard 30 linear feet section of ductwork.

Duct Material | Repair Cost |

Flexible Non-Metallic | $220 – $850 |

Flexible Aluminum | $220 – $900 |

Fiberglass Duct Board | $280 – $980 |

Sheet Metal | $300 – $1200 |

Understanding the Mechanical Cost Estimations in Auburndale

Coral Springs, nestled in the heart of Florida, boasts a dynamic mechanical industry that serves as the backbone for the city’s infrastructure development and maintenance.

With a blend of traditional values and innovative engineering practices, Coral Springs mechanical sector caters to diverse needs, ensuring optimal functionality and efficiency across residential, commercial, and industrial domains.

Diverse Services

The mechanical industry in Coral Springs encompasses a wide array of services, ranging from the installation and maintenance of HVAC (Heating, Ventilation, and Air Conditioning) systems in residential buildings to the design and construction of complex mechanical systems in commercial and industrial facilities. Mechanical contractors in Auburndale are adept at handling projects of varying scales, from routine repairs and upgrades to large-scale installations, leveraging their expertise to deliver cost-effective and sustainable solutions.

Plumbing and Piping

In addition to HVAC systems, plumbing and piping services form an integral part of Coral Springs mechanical industry. From residential plumbing repairs to the installation of complex piping networks in industrial settings, mechanical contractors play a vital role in ensuring the proper functioning of water supply and drainage systems. Their expertise in hydraulics, materials science, and regulatory compliance enables them to design and implement efficient and durable plumbing solutions that meet the highest standards of quality and safety.

Electrical Systems

The integration of electrical systems is another key aspect of mechanical projects in Coral Springs. Whether it’s wiring installations in residential buildings or the design of power distribution networks for commercial and industrial facilities, mechanical contractors collaborate closely with electrical engineers and technicians to ensure seamless integration and optimal performance. From lighting fixtures to control panels, every aspect of electrical systems is meticulously planned and executed to meet the specific requirements of each project while adhering to relevant codes and standards.

Get 5 New Leads in the Next 7 Days With Our System

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- High-Rise Building

- Shopping Complex

Project Management

Effective project management is essential for the success of mechanical projects in Coral Springs. Mechanical contractors oversee every aspect of the project lifecycle, from initial planning and budgeting to procurement, execution, and commissioning. By leveraging project management tools and techniques, they ensure that projects are completed on time, within budget, and to the satisfaction of clients and stakeholders. Their proactive approach to risk management and quality assurance helps mitigate potential challenges and ensures the smooth execution of mechanical projects across Auburndale.

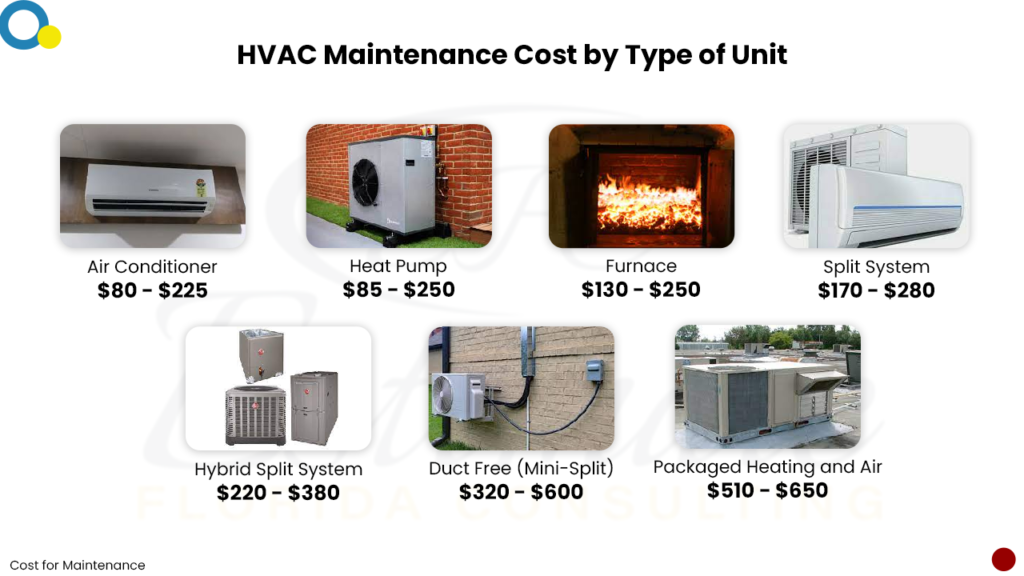

HVAC Maintenance Cost by Type of Unit

HVAC maintenance is essential for ensuring the efficiency and longevity of heating, ventilation, and air conditioning systems. Various types of units require regular maintenance to keep them running smoothly. Air conditioners, heat pumps, furnaces, split systems, hybrid split systems, duct-free mini-splits, and packaged heat and air units each have their own maintenance needs. Regular servicing can include tasks such as cleaning coils, checking refrigerant levels, inspecting electrical components, and replacing filters.

Type of Unit | Cost Range |

Air Conditioner | $80 – $250 |

Heat Pump | $25 – $250 |

Furnace | $130 – $250 |

Split System | $170 – $280 |

Hybrid Split System | $220 – $380 |

Duct Free (Mini-Split) | $320 – $600 |

Packaged Heat and Air | $510 – $650 |

Factors Affecting Mechanical Cost Estimations in Auburndale

Mechanical cost estimations in Coral Springs are influenced by a multitude of factors that span from project inception to completion. These factors play a crucial role in shaping the budgetary considerations and financial forecasts associated with mechanical projects in the region, impacting both the initial investment and long-term operational expenses.

Scope and Complexity of the Project

The scope and complexity of a mechanical project are fundamental determinants of its estimated cost. Projects with intricate requirements, such as large-scale industrial installations or complex HVAC systems in commercial buildings, typically incur higher costs due to the need for specialized equipment, materials, and labor. Conversely, smaller-scale projects involving routine maintenance or simple repairs may have more modest cost estimations. Understanding the intricacies of the project scope is essential for accurately forecasting the associated mechanical costs in Coral Springs.

Labor and Material Costs

Labor and material costs constitute significant components of mechanical cost estimations in Coral Springs. Fluctuations in labor rates and material prices can have a substantial impact on project budgets, necessitating careful monitoring and analysis throughout the estimation process. Skilled labor shortages, market demand-supply dynamics, and material availability are among the factors that contribute to cost variations in the mechanical industry. By staying abreast of market trends and leveraging strategic sourcing strategies, stakeholders can mitigate the effects of labor and material cost fluctuations on project estimations.

Regulatory Compliance and Permitting Requirements

Compliance with regulatory standards and permitting requirements is a critical consideration in mechanical cost estimations in Coarl Springs. Adherence to local building codes, environmental regulations, and safety protocols often necessitates additional expenditures in terms of documentation, inspections, and compliance assessments. Failure to account for these regulatory aspects accurately can result in delays, fines, and costly revisions during project execution. Incorporating regulatory compliance and permitting costs into the initial estimation process ensures that projects remain in compliance with applicable laws and regulations, minimizing the risk of legal liabilities and financial penalties.

Download Template For Mechanical Project Breakdown

- Materials list updated to the zip code

- Fast delivery

- Data base of general contractors and sub-contractors

- Local estimators

Site Conditions and Accessibility

Site conditions and accessibility play a significant role in determining the feasibility and cost-effectiveness of mechanical projects in Coral Springs. Factors such as terrain, soil stability, and proximity to utilities can impact construction timelines and resource allocation, thereby influencing cost estimations. Sites with challenging topography or limited access may require specialized equipment and construction techniques, leading to higher overall project costs. Conducting comprehensive site assessments and factoring in site-specific challenges during the estimation phase enables stakeholders to anticipate and mitigate potential cost escalations associated with site conditions and accessibility constraints.

Technology and Innovation

Advancements in technology and innovation have a profound impact on mechanical cost estimations in Coral Springs. Emerging technologies, such as Building Information Modeling (BIM), prefabrication, and energy-efficient systems, offer opportunities to optimize project workflows, enhance productivity, and reduce long-term operational expenses. Integrating innovative solutions into mechanical projects can result in cost savings through improved efficiency, reduced material waste, and enhanced performance. However, incorporating cutting-edge technologies may also entail upfront investments in training, software implementation, and equipment upgrades, which must be accounted for in the estimation process. By balancing the potential benefits and costs of technological innovation, stakeholders can make informed decisions that align with project objectives and budgetary constraints.

Market Conditions and Economic Trends

Market conditions and economic trends exert a significant influence on mechanical cost estimations in Coral Springs. Fluctuations in macroeconomic indicators, such as interest rates, inflation rates, and construction activity levels, can impact material prices, labor availability, and overall project costs. Additionally, regional factors, such as population growth, urbanization trends, and infrastructure development initiatives, contribute to the demand for mechanical services and subsequent pricing dynamics. Monitoring market conditions and economic trends allows stakeholders to anticipate changes in project costs and adjust their estimations accordingly, enhancing the accuracy and reliability of budget forecasts.

Business Finance Loan

Find out if you're pre-qualified in seconds

Get Prequalified Now

IMPORTANT: Make sure the email and phone number you enter are correct. We will email and text you a link to get started.

Price Table by Type of Mechanical System

System | Cost Range (per 1000 Square Feet) | Cost Range (per Square Foot) |

HVAC (Heating, Ventilation, and Air Conditioning) | $20,000 – $100,000+ | $20 – $100+ |

Plumbing | $10,000 – $50,000+ | $10 – $50+ |

Fire Protection | $5,000 – $30,000+ | $5 – $30+ |

Industrial Machinery | $50,000 – $500,000+ | $50 – $500+ |

Renewable Energy Systems | $30,000 – $150,000+ | $30 – $150+ |

Refrigeration Systems | $15,000 – $80,000+ | $15 – $80+ |

Elevator Systems | $40,000 – $200,000+ | $40 – $200+ |

Lighting and Electrical | $15,000 – $100,000+ | $15 – $100+ |

These cost ranges are approximate and may vary based on factors such as project complexity, system specifications, and regional market conditions.

Common Challenges and Solutions

Mechanical cost estimators in Coral Springs encounter various challenges in their profession, necessitating innovative solutions to ensure accurate and reliable estimations. Here are some common challenges and corresponding solutions:

Fluctuating Market Prices:

The volatile nature of material and labor costs poses a challenge for mechanical cost estimators, making it difficult to predict project expenses accurately.

Solution: Estimators can mitigate this challenge by conducting frequent market analyses and establishing strong relationships with suppliers to negotiate favorable prices. Implementing contingency plans within estimates also helps buffer against unexpected cost fluctuations.

Evolving Building Codes and Regulations:

Changes in building codes and regulations can impact project requirements and costs, requiring constant monitoring and adaptation.

Solution: Stay informed about updates to building codes and regulations through continuous education and engagement with regulatory authorities. Incorporate flexibility into estimates to accommodate potential changes during the project lifecycle.

Scope Creep and Project Changes:

Scope creep, where project requirements expand beyond initial expectations, can lead to cost overruns and schedule delays.

Solution: Implement robust change management processes to document and track project changes effectively. Clearly communicate any deviations from the original scope to stakeholders and adjust estimates accordingly to reflect the updated requirements.

Uncertain Project Timelines:

Uncertainties in project timelines, such as delays in permitting or unexpected site conditions, can disrupt cost estimations.

Solution: Conduct thorough risk assessments during the estimation process to identify potential schedule impacts and allocate appropriate contingencies. Collaborate closely with project stakeholders to establish realistic timelines and address potential bottlenecks proactively.

Estimate Your Project With Us

Limited Access to Specialized Expertise:

Access to specialized expertise, such as niche subcontractors or technical consultants, may be limited in Auburndale, complicating the estimation process for complex projects.

Solution: Build strategic partnerships with specialized firms and consultants to leverage their expertise as needed. Engage in knowledge-sharing initiatives within the industry to expand access to specialized knowledge and resources.

Inaccurate Project Documentation:

Incomplete or inaccurate project documentation can lead to discrepancies between estimated and actual costs.

Solution: Conduct thorough document reviews and site assessments to gather accurate information about project requirements and constraints. Utilize digital tools and software to streamline documentation processes and maintain a centralized repository for project data.

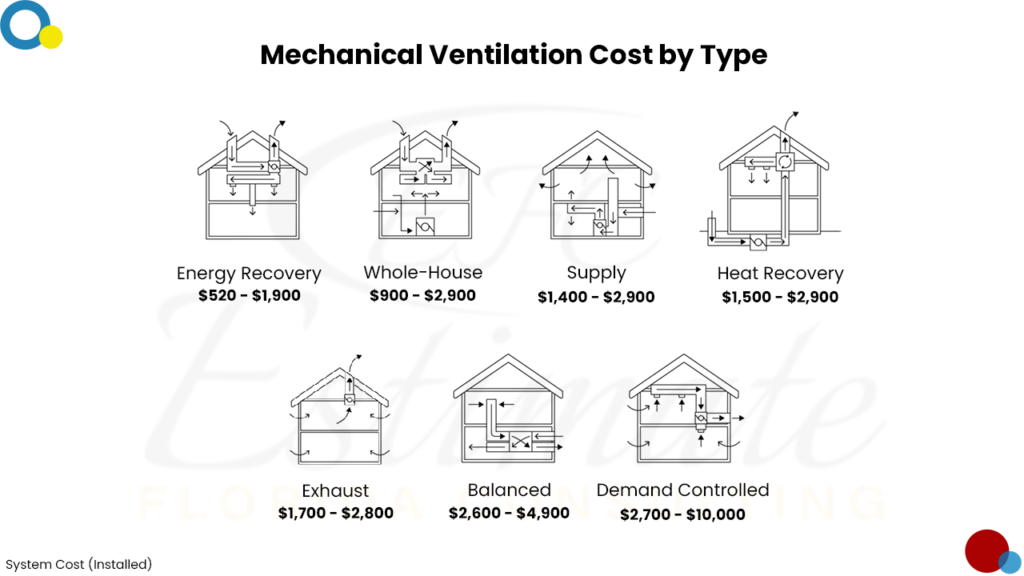

Cost of Mechanical Ventilation by Type

Mechanical air exchange systems typically cost between $520 and $10,000. These systems utilize fans installed in windows, walls, or air ducts to either remove or add air to the home. Condensation, formed when warm air meets cold surfaces, can be prevented by these fans, which either extract or introduce air to maintain balanced air quality within the room. A balanced mechanical ventilation system ensures that the air quality meets specific design specifications.

Mechanical Ventilation Type | System Cost (Installed) |

Energy Recovery | $520 – $1,900 |

Whole-House | $900 – $2,900 |

Supply | $1,400 – $2,900 |

Heat Recovery | $1,500 – $2,900 |

Exhaust | $1,700 – $2,800 |

Balanced | $2,600 – $4,900 |

Demand Controlled | $2,700 – $10,000 |

- Multi-Family Building

- School & University

- Hospital Building

- Warehouse Building

- Hotel Building

- High-Rise Building

Steps in Mechanical Cost Estimation Process in Auburndale

Project Scope Definition:

Begin by clearly defining the scope of the mechanical project in Coral Springs. This involves understanding the client’s requirements, reviewing project specifications, and identifying key deliverables and objectives.

Site Assessment:

Conduct a comprehensive assessment of the project site in Coral Springs to gather essential information, such as site conditions, access points, and existing infrastructure. This step helps identify any potential challenges or constraints that may impact cost estimation.

Data Collection:

Gather relevant data and documentation necessary for cost estimation, including architectural drawings, engineering plans, material specifications, and labor rates. Utilize historical data from similar projects and industry benchmarks to inform the estimation process.

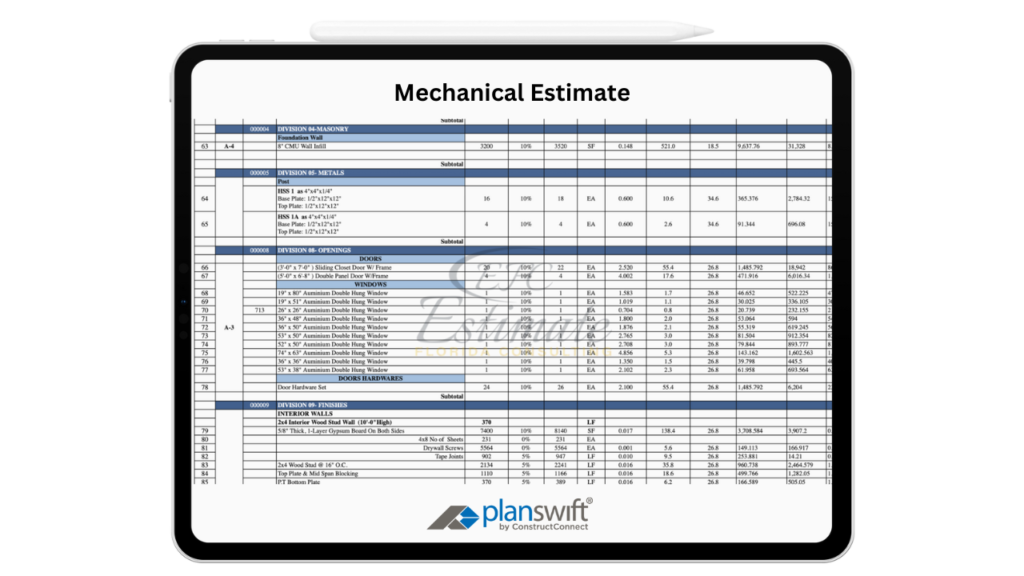

Quantity Takeoff:

Perform a detailed quantity takeoff to quantify the materials, equipment, and labor required for the mechanical project in Coral Springs. Break down the project into individual components and accurately calculate quantities based on project specifications and design criteria.

Cost Analysis:

Analyze the collected data and quantify the costs associated with materials, labor, equipment, subcontractors, overheads, and contingencies. Utilize cost estimating software and tools to facilitate accurate cost calculations and ensure consistency throughout the estimation process.

Factor in Market Conditions:

Consider market conditions, such as fluctuations in material prices and labor rates, when estimating costs for the mechanical project in Auburndale. Stay informed about current market trends and industry developments to make informed decisions regarding cost projections.

Need Template For Your Mechanical Business

We provide services for Brochure, Banner, Business Card, Envelope, Invoice, etc.

Incorporate Contingencies:

Include contingencies in the cost estimation to account for unforeseen circumstances, changes in project scope, and potential risks. Allocate contingency funds based on the level of project uncertainty and complexity to mitigate the impact of unexpected cost overruns.

Review and Validation:

Review the cost estimation thoroughly to ensure accuracy, completeness, and consistency. Verify calculations, cross-check data inputs, and validate assumptions to identify any discrepancies or errors. Seek input and feedback from relevant stakeholders to validate the estimated costs.

Documentation and Presentation:

Document the cost estimation process, including assumptions, methodologies, and key findings, in a comprehensive report or proposal. Present the estimated costs to the client or project team in Coral Springs in a clear and transparent manner, highlighting key cost drivers and potential areas for optimization.

Revision and Updates:

Be prepared to revise and update the cost estimation as the project progresses and new information becomes available. Monitor changes in project scope, schedule, and budget, and adjust the cost estimation accordingly to ensure its accuracy and relevance throughout the project lifecycle.

Are You Looking For?

Fully Insured License Hire Sub-Contractor For Mechanical Work

Hire Contractor

Make Informed Design Decisions Showcase Your Design Ideas

Get RenderingCall Us To Discuss More at 561-530-2845

Conclusion

In conclusion, construction cost estimation in Coral Springs is a critical aspect of the project lifecycle, influencing budgetary decisions, timelines, and overall project success. By meticulously analyzing project requirements, conducting thorough site assessments, and leveraging industry expertise, construction cost estimators play a pivotal role in forecasting expenses and mitigating financial risks. Throughout the estimation process, it is essential to incorporate contingency planning, risk assessment, and stakeholder collaboration to ensure the accuracy and reliability of cost estimates.

As Coral Springs continues to experience growth and development, construction cost estimators face ongoing challenges such as material price volatility, labor shortages, and regulatory complexities. However, by embracing innovative technologies, adopting best practices, and fostering open communication among project stakeholders, these challenges can be effectively addressed.

Choose Your Trade & Get a Sample Project

FAQs

Mechanical Cost Estimators in Coral Springs are responsible for accurately assessing the costs associated with mechanical projects. They analyze project requirements, gather data on materials, labor, and equipment costs, and utilize specialized software to provide detailed cost estimates.

Estimators gather information on material prices, labor rates, equipment expenses, and other project-specific factors. They conduct market research to stay updated on industry trends and utilize standardized formulas and methodologies to calculate costs accurately.

Common challenges include fluctuating material prices, labor shortages, regulatory compliance, resource availability, and weather-related disruptions. Estimators mitigate these challenges through careful planning, market analysis, and strategic partnerships with suppliers and contractors.

While estimators strive for precision, cost estimates are projections based on available data and market conditions at the time of estimation. Factors such as unforeseen changes in material prices or project scope may impact the final costs.

By hiring a Mechanical Cost Estimator, you gain access to expertise in cost analysis, budget management, and risk mitigation. Estimators help ensure projects stay within budget, adhere to timelines, and achieve successful outcomes through informed decision-making and accurate cost projections.

Process To Get Mechanical Cost Estimate Report

Here I am going to share some steps to get your mechanical cost estimate report.

-

You need to send your plan to us.

You can send us your plan on info@estimatorflorida.com

-

You receive a quote for your project.

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

-

Get Estimate Report

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.

Google Reviews