Mechanical Cost Estimator in Apopka

At Estimate Florida Consulting provides comprehensive mechanical cost estimation services in Apopka. Our expertise ensures accurate projections for your projects, with cost estimates typically ranging from $140,000 to $220,000. Additionally, we estimate costs at a rate of $6 to $8 per square foot, ensuring transparency and reliability in budget planning. Whether you’re embarking on a new construction project or renovating existing structures, our mechanical cost estimators are committed to delivering precise assessments tailored to your specific needs. Trust Estimate Florida Consulting for professional guidance and meticulous attention to detail in cost estimation, enabling you to proceed with confidence in your financial planning.

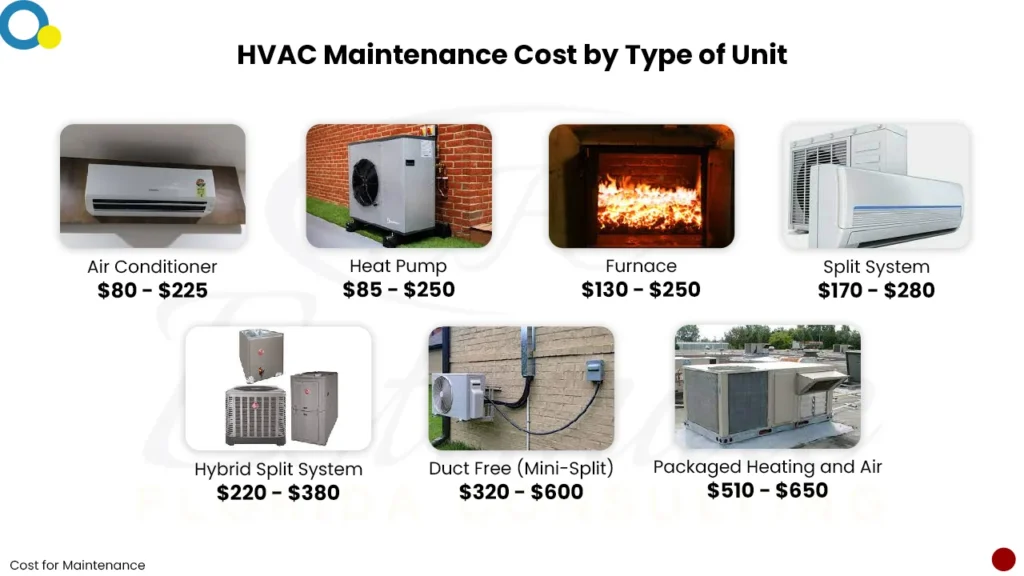

Types of HVAC Units and Their Maintenance Costs

Keeping HVAC systems well-maintained is essential to preserve their efficiency and lifespan. Various types of units require regular upkeep to ensure smooth operation. Air conditioners, heat pumps, furnaces, split systems, hybrid split systems, duct-free mini-splits, and packaged heating and air conditioning units all come with their own set of maintenance needs. Typical servicing may include activities like coil cleaning, refrigerant level checks, electrical component inspections, and filter replacements.

Type of Unit | Cost Range |

Air Conditioner | $80 – $225 |

Heat Pump | $85 – $250 |

Furnace | $130 – $250 |

Split System | $170 – $280 |

Hybrid Split System | $220 – $380 |

Duct-Free (Mini-Split) | $320 – $600 |

Packaged Heat and Air | $510 – $650 |

90% More Chances to Win Projects With Our Estimate!

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- School & University Building

- High-Rise Building

- Shopping Complex

- Data Center Building

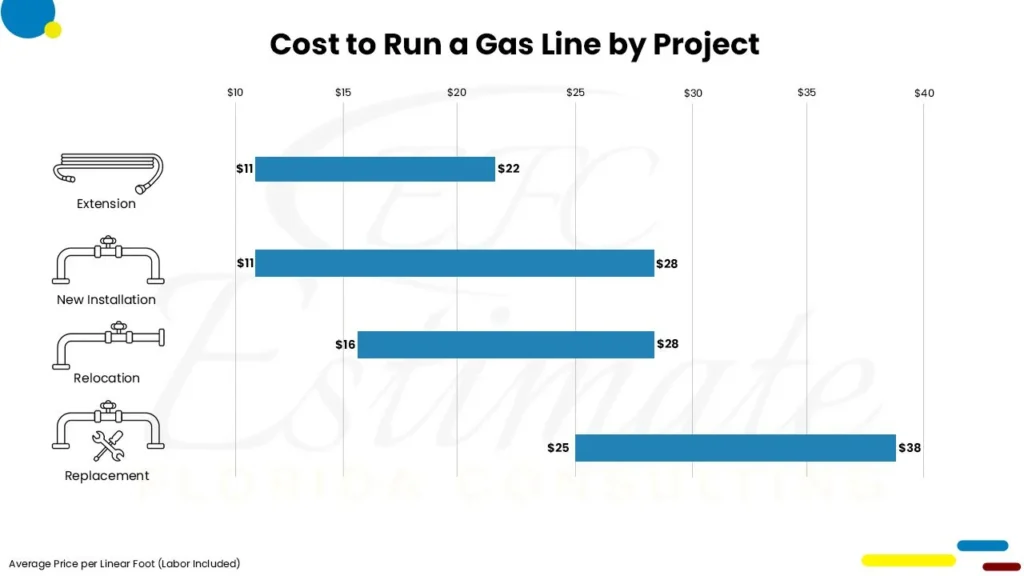

Cost of Installing a Gas Line for Your Project

There are numerous elements that contribute to the expenses associated with plumbing your home for gas installation. These costs vary based on factors such as your location, the specific appliances you’re installing, the length of the gas line required, and the intricacies of the installation process itself.

The installation of a gas line involves coordination between plumbers, who handle connections from the meter to appliances within the home, and utility companies, responsible for laying the line from the street to your property. These professionals operate under separate pricing structures but must collaborate to ensure an efficient gas pipe installation. Additionally, within the confines of your home, various installation methodologies can further impact the project’s complexity and cost.

There are numerous elements that contribute to the expenses associated with plumbing your home for gas installation. These costs vary based on factors such as your location, the specific appliances you’re installing, the length of the gas line required, and the intricacies of the installation process itself.

The installation of a gas line involves coordination between plumbers, who handle connections from the meter to appliances within the home, and utility companies, responsible for laying the line from the street to your property. These professionals operate under separate pricing structures but must collaborate to ensure an efficient gas pipe installation. Additionally, within the confines of your home, various installation methodologies can further impact the project’s complexity and cost.

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- High-Rise Building

- Shopping Complex

Mechanical Breakdown Cost

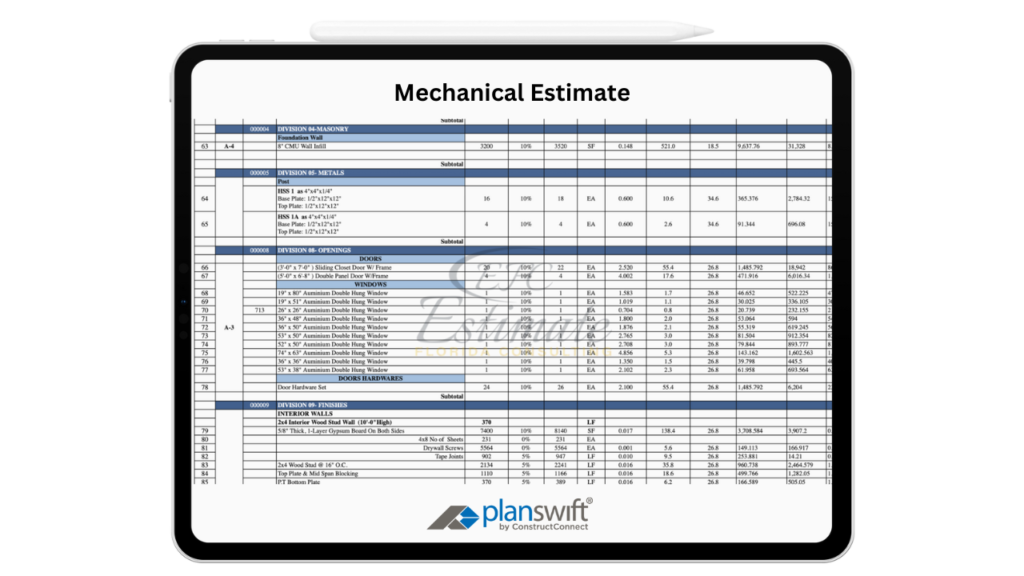

The breakdown cost for the Mechanical Cost Estimator project in Apopka includes labor, materials, equipment, and overhead expenses. Labor costs encompass skilled technicians and engineers, while material expenses cover components like piping, valves, and HVAC systems. Equipment expenses account for specialized machinery required for installations and repairs, while overhead includes administrative and operational costs essential for project management and execution.

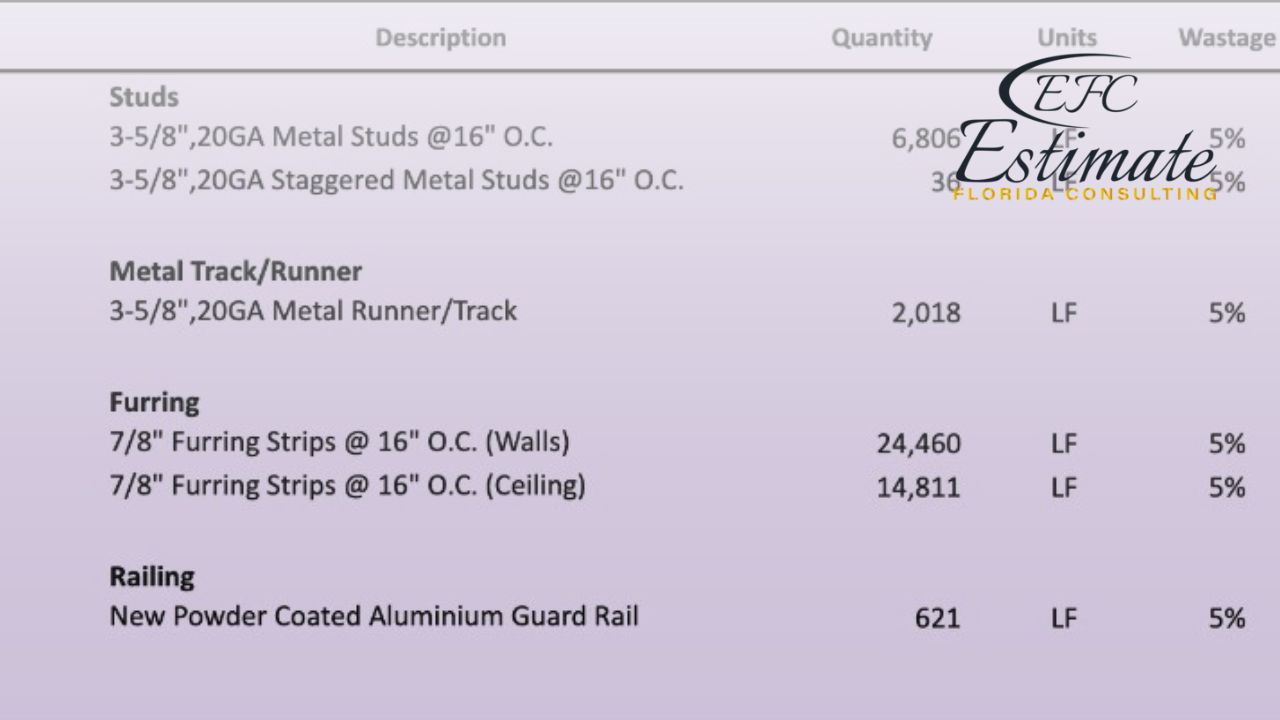

Item | Cost |

Labor | $110,000 |

Materials | $60,000 |

Equipment | $30,000 |

Overhead | $20,000 |

Cost by Size of Project

Costs for the Mechanical Cost Estimator project in Apopka vary by project size. Smaller projects entail fewer labor hours and material quantities, thus resulting in lower overall costs. Conversely, larger projects necessitate more extensive resources, leading to higher expenditure for labor, materials, and equipment.

Size of Project | Estimated Cost Range |

Small-scale Projects | $140,000 – $170,000 |

Medium-scale Projects | $170,000 – $190,000 |

Large-scale Projects | $190,000 – $220,000 |

Download Template For Mechanical Project Breakdown

- Materials list updated to the zip code

- Fast delivery

- Data base of general contractors and sub-contractors

- Local estimators

Diverse Mechanical Projects

HVAC System Installation: Installing state-of-the-art heating, ventilation, and air conditioning systems tailored to meet the specific needs of residential, commercial, or industrial spaces. This includes designing ductwork, selecting energy-efficient equipment, and ensuring optimal airflow and temperature control.

Plumbing System Renovation: Revamping existing plumbing infrastructure to enhance efficiency, durability, and safety. This involves replacing old pipes, upgrading fixtures, installing water-saving devices, and implementing modern technologies for better water distribution and waste management.

Industrial Boiler Installation: Implementing robust boiler systems in industrial facilities to meet high-demand heating requirements. This encompasses selecting suitable boiler types, integrating safety features, optimizing fuel efficiency, and adhering to stringent industry standards for reliable operation.

Renewable Energy System Integration: Integrating renewable energy sources such as solar, wind, or geothermal power into mechanical systems to reduce reliance on traditional energy sources. This involves designing and installing equipment for harnessing renewable energy and integrating it seamlessly into existing mechanical infrastructure.

Fire Protection System Upgrade: Upgrading fire suppression and detection systems to enhance safety and compliance with regulations. This includes installing advanced fire alarm systems, automatic sprinklers, fire extinguishers, and emergency lighting to mitigate fire risks and protect lives and property.

Ventilation System Retrofit: Upgrading ventilation systems in buildings to improve indoor air quality and occupant comfort. This involves installing energy-efficient ventilation fans, ductwork modifications, air purification systems, and humidity control devices to optimize airflow and reduce contaminants.

Mechanical System Automation: Implementing automation solutions to streamline mechanical system operations and enhance efficiency. This includes integrating sensors, actuators, and control systems for remote monitoring, predictive maintenance, and energy optimization across various mechanical components.

Refrigeration System Expansion: Expanding refrigeration systems in commercial or industrial settings to accommodate growing demand or specialized requirements. This involves adding refrigeration units, cold storage facilities, and temperature control systems while ensuring energy efficiency and compliance with food safety standards.

Hydraulic System Overhaul: Overhauling hydraulic systems in machinery or equipment to improve performance, reliability, and longevity. This includes replacing worn components, upgrading hydraulic pumps and valves, optimizing fluid flow, and conducting thorough testing and calibration to ensure optimal operation.

Piping Network Optimization: Optimizing piping networks in industrial plants or building complexes to improve fluid transport efficiency and reduce energy consumption. This involves redesigning layouts, replacing outdated pipes with modern materials, minimizing pressure losses, and implementing smart control systems for monitoring and optimization.

Business Finance Loan

Find out if you're pre-qualified in seconds

Get Prequalified Now

IMPORTANT: Make sure the email and phone number you enter are correct. We will email and text you a link to get started.

Different Types of Mechanical and Breakdown Cost

Item | Cost per square foot |

HVAC System Installation | $20 – $40 per square foot |

Plumbing System Renovation | $15 – $35 per square foot |

Industrial Boiler Installation | $30 – $60 per square foot |

Renewable Energy System Integration | $40 – $80 per square foot |

Fire Protection System Upgrade | $10 – $30 per square foot |

Ventilation System Retrofit | $15 – $35 per square foot |

Mechanical System Automation | $20 – $50 per square foot |

Refrigeration System Expansion | $25 – $50 per square foot |

Hydraulic System Overhaul | $30 – $60 per square foot |

Piping Network Optimization | $20 – $40 per square foot |

Factors Influencing Mechanical

Several factors influence the mechanical cost estimator project in Apopka, Florida. Firstly, labor costs are impacted by the availability of skilled technicians and engineers in the local market, as well as prevailing wage rates. Material costs are subject to fluctuations in prices influenced by factors like supply chain disruptions, material shortages, and market demand. Additionally, project scope and complexity play a crucial role, as larger or more intricate projects typically require higher labor and material expenditures. Geographic location also affects costs due to varying regulations, permitting requirements, and environmental considerations. Furthermore, technological advancements and innovations in mechanical systems can influence costs, with more advanced equipment often commanding higher prices. Lastly, economic conditions, such as inflation rates and interest rates, can impact overall project costs, requiring careful consideration and analysis during the estimation process.

Project Objective

The objective of the Mechanical Cost Estimator project in Apopka is to accurately assess and forecast the financial requirements of mechanical projects within the region. By meticulously analyzing labor, material, equipment, and overhead costs, the aim is to provide clients with reliable estimates essential for budgeting and decision-making processes. The project seeks to streamline cost estimation procedures, leveraging industry expertise and technological tools to enhance efficiency and accuracy. Additionally, the objective involves staying abreast of market trends, regulatory changes, and technological advancements to ensure estimations align with current industry standards.

Ultimately, the goal is to deliver cost estimates that enable clients to plan and execute mechanical projects effectively, fostering successful outcomes and maximizing value for all stakeholders involved.

Key Components and Methodology

The Mechanical Cost Estimator project in Apopka integrates several key components and methodologies to produce accurate cost estimates. Firstly, it encompasses detailed analysis of labor, materials, equipment, and overhead expenses, ensuring comprehensive coverage of all project-related costs. Methodologically, the project relies on historical data, industry benchmarks, and local market trends to inform estimations. Advanced cost estimation software and tools are employed to facilitate calculations and enhance accuracy. Additionally, the project incorporates risk assessment and contingency planning to account for unforeseen variables that may impact costs. Collaboration with industry experts and stakeholders further enriches the estimation process, providing valuable insights and validation. By integrating these components and methodologies, the Mechanical Cost Estimator project aims to deliver reliable and transparent cost estimates essential for informed decision-making and successful project execution in Apopka.

Factors Affecting Cost Estimates

Factors affecting cost estimates for the Mechanical Cost Estimator project in Apopka include labor availability, material prices, project scope, technological advancements, regulatory requirements, and economic conditions. Thorough analysis and consideration of these variables ensure accurate estimations for successful project planning.

Estimate Your Project With Us

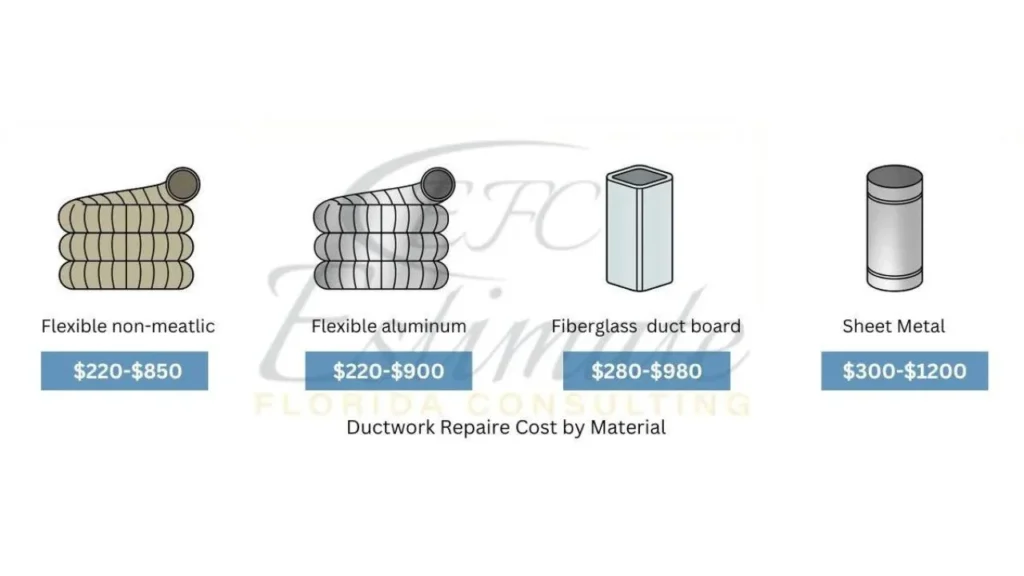

Cost to Repair Ductwork by Material

There exist various types of ductwork, ranging from economical, flexible, non-metallic options to premium sheet metal variants. Each type features distinct designs and materials, with repair costs varying accordingly. Hence, the type of duct you have can significantly impact the expenses of repairs. Below outlines the primary duct types alongside their average repair costs for a standard 30 linear feet section of ductwork.

Duct Material | Repair Cost |

Flexible Non-Metallic | $220 – $850 |

Flexible Aluminum | $220 – $900 |

Fiberglass Duct Board | $280 – $980 |

Sheet Metal | $300 – $1200 |

We provide accurate pricing for the ZIP code of your project.

Turnaround time is 1-2 days.

Win More Projects With Us

Labors Cost

Estimate Florida Consulting provides comprehensive services for estimating the labor costs of Mechanical Cost Estimator projects in Apopka, Florida. Our meticulous approach involves analyzing local labor markets, prevailing wage rates, and project specifications to generate accurate estimates. For the Apopka project, our cost estimation indicates labor expenses totaling $110,000. This figure is derived from detailed assessments of the required manpower, skill levels, and project duration. By partnering with Estimate Florida Consulting, clients benefit from our expertise in cost estimation, ensuring that budgets are carefully calculated and transparently communicated. Our commitment to precision and reliability empowers clients to make informed decisions and effectively manage project finances for successful outcomes.

Labors Breakdown Cost

Labor Category | Cost |

Skilled Worker | $70,000 |

Supervisor | $30,000 |

Miscellaneous | $5,000 |

Contingency | $5,000 |

Materials Cost

At Estimate Florida Consulting offers comprehensive estimation services for the materials cost of Mechanical Cost Estimator projects in Apopka, Florida. Leveraging our expertise and industry knowledge, we meticulously assess material requirements, sourcing options, and market prices to generate precise estimates. For the Apopka project, our estimation indicates material expenses totaling $60,000. This figure reflects our thorough analysis of project specifications, quality standards, and quantity assessments. By collaborating with Estimate Florida Consulting, clients gain access to accurate and transparent cost estimations, enabling them to plan effectively and allocate resources efficiently.

Our commitment to excellence ensures that clients receive reliable estimates tailored to their project needs, facilitating successful project execution and cost management.

Diverse Materials for Mechanical Projects

Steel: Is a versatile and widely used material in mechanical projects due to its strength, durability, and affordability. It is commonly employed in structural components, machinery parts, pipelines, and various industrial applications. Different grades of steel offer varying properties such as hardness, corrosion resistance, and weldability, making it suitable for a wide range of mechanical engineering purposes.

Copper: Is valued in mechanical projects for its excellent conductivity, corrosion resistance, and malleability. It finds extensive use in electrical wiring, plumbing systems, heat exchangers, and various mechanical components where efficient heat transfer and electrical conductivity are essential. Copper alloys, such as brass and bronze, further expand its applications in mechanical engineering.

Aluminum: Is lightweight yet robust, making it an ideal material for mechanical projects requiring strength with reduced weight. It is widely used in aerospace, automotive, and construction industries for components like aircraft parts, vehicle frames, and structural elements. Aluminum’s corrosion resistance and recyclability also contribute to its popularity in mechanical engineering.

PVC (Polyvinyl Chloride): Is a synthetic polymer widely used in mechanical projects for its durability, chemical resistance, and low cost. It is commonly employed in piping systems for water supply, drainage, and ventilation, as well as in cable insulation, window frames, and other building materials. PVC’s ease of installation and maintenance make it a preferred choice in various mechanical and construction applications.

- Multi-Family Building

- School & University

- Hospital Building

- Warehouse Building

- Hotel Building

- High-Rise Building

Brass: An alloy of copper and zinc, offers excellent machinability, corrosion resistance, and aesthetics in mechanical projects. It finds applications in valves, fittings, decorative elements, and musical instruments due to its unique combination of properties. Brass’s ability to be easily shaped and polished makes it suitable for both functional and decorative purposes in mechanical engineering.

Stainless Steel: Is prized for its exceptional corrosion resistance, high strength-to-weight ratio, and hygienic properties, making it indispensable in mechanical projects requiring durability and cleanliness. It is extensively used in food processing equipment, medical devices, architectural structures, and marine applications where resistance to rust and staining is crucial.

Cast Iron: Is known for its excellent castability, damping capacity, and wear resistance, making it a preferred material for mechanical components subjected to heavy loads and abrasive conditions. It is commonly used in engine blocks, machine tool frames, brake drums, and cookware due to its strength and heat retention properties.

Titanium: Is renowned for its high strength-to-weight ratio, corrosion resistance, and biocompatibility, making it a premium material choice in demanding mechanical applications. It is utilized in aerospace components, medical implants, chemical processing equipment, and sports equipment where superior performance and durability are paramount.

Polyethylene: A thermoplastic polymer, offers excellent chemical resistance, flexibility, and low friction properties, making it suitable for various mechanical and industrial applications. It is commonly used in pipelines, storage tanks, packaging materials, and automotive components due to its versatility, durability, and cost-effectiveness.

Fiberglass: Composed of glass fibers embedded in a resin matrix, provides high strength, stiffness, and corrosion resistance in mechanical projects. It is utilized in boat hulls, wind turbine blades, automotive body panels, and construction materials where lightweight, durable, and non-conductive properties are desired. Fiberglass’s versatility and ease of molding make it a preferred choice in diverse mechanical engineering applications.

Materials of Mechanical Breakdown Cost

Item | Cost per square foot |

Steel | $5 – $10 per square foot |

Copper | $10 – $20 per square foot |

Aluminum | $8 – $15 per square foot |

PVC (Polyvinyl Chloride) | $3 – $5 per square foot |

Brass | $10 – $25 per square foot |

Stainless Steel | $5 – $30 per square foot |

Cast Iron | $3 – $12 per square foot |

Titanium | $20 – $50 per square foot |

Polyethylene | $2 – $6 per square foot |

Fiberglass | $3 – $15 per square foot |

Let us take your project to the next level! Send us your plans, and we’ll provide a detailed estimate with competitive pricing. Our ZIP Code-based approach means better accuracy and a 90% higher chance of winning bids. Get personalized, no-shortcut service every time.

Project Complexity

The project complexity of the Mechanical Cost Estimator in Apopka varies based on numerous factors. Factors such as the size of the project, the intricacy of mechanical systems involved, and the technological requirements significantly impact its complexity. Large-scale projects with diverse mechanical components, intricate designs, or specialized installations tend to be more complex. Additionally, projects that involve adherence to stringent regulatory standards, challenging environmental conditions, or tight deadlines add further layers of complexity. Furthermore, integrating modern technologies, such as automation or renewable energy systems, can increase complexity but may also offer opportunities for innovation and efficiency. Successfully estimating costs for projects of varying complexities in Apopka demands a nuanced understanding of mechanical systems, meticulous planning, and the ability to adapt to evolving project requirements.

Location-specific Factors

Location-specific factors significantly influence the Mechanical Cost Estimator project in Apopka, Florida. Apopka’s geographical location introduces unique considerations such as local building codes, environmental regulations, and climate conditions that directly impact project costs. For instance, Florida’s humid subtropical climate may necessitate specialized HVAC systems or corrosion-resistant materials, affecting both material selection and installation requirements. Moreover, Apopka’s proximity to urban centers and industrial zones can influence labor availability and material sourcing, potentially affecting cost estimations. Additionally, understanding Apopka’s market dynamics, including supply chain logistics and prevailing wage rates, is crucial for accurate cost estimations. By incorporating these location-specific factors, the Mechanical Cost Estimator project can provide clients with tailored and precise estimates that account for Apopka’s unique context, ensuring successful project planning and execution.

Common Challenges and Solutions

Common challenges for the Mechanical Cost Estimator project in Apopka include fluctuating material prices, labor shortages, and evolving regulations. Solutions involve regular market analysis, fostering supplier relationships, and staying updated on industry standards for accurate estimations.

Project Scope Definition

Defining the exact scope of a mechanical cost estimator project in Apopka can be challenging due to the diverse nature of mechanical systems and their associated costs.

Solution: Conduct a thorough initial assessment to identify all components and factors that contribute to the project’s scope. Utilize standardized templates or software to streamline the process and ensure comprehensive coverage of all relevant aspects.

Data Accuracy and Availability

Accessing accurate and up-to-date data related to material costs, labor rates, and market trends specific to Apopka can pose a significant challenge.

Solution: Establish partnerships with local suppliers and contractors to access reliable data on material costs and labor rates. Implement regular updates and verification processes to ensure data accuracy and relevance to the Apopka area.

Cost Variability and Uncertainty

Dealing with cost variability and uncertainty due to fluctuations in material prices, labor availability, and unforeseen project changes is a constant concern.

Solution: Incorporate contingency measures into cost estimates to account for unforeseen circumstances and mitigate risks. Regularly monitor market trends and adjust estimates accordingly to minimize the impact of cost variability.

Integration of Technology

Integrating technology into the mechanical cost estimation process, such as Building Information Modeling (BIM) or specialized software, can be complex and require additional expertise.

Solution: Invest in training and development to ensure team members are proficient in utilizing technology tools effectively. Collaborate with experts in software development or BIM implementation to tailor solutions specific to the needs of the mechanical cost estimator project in Apopka.

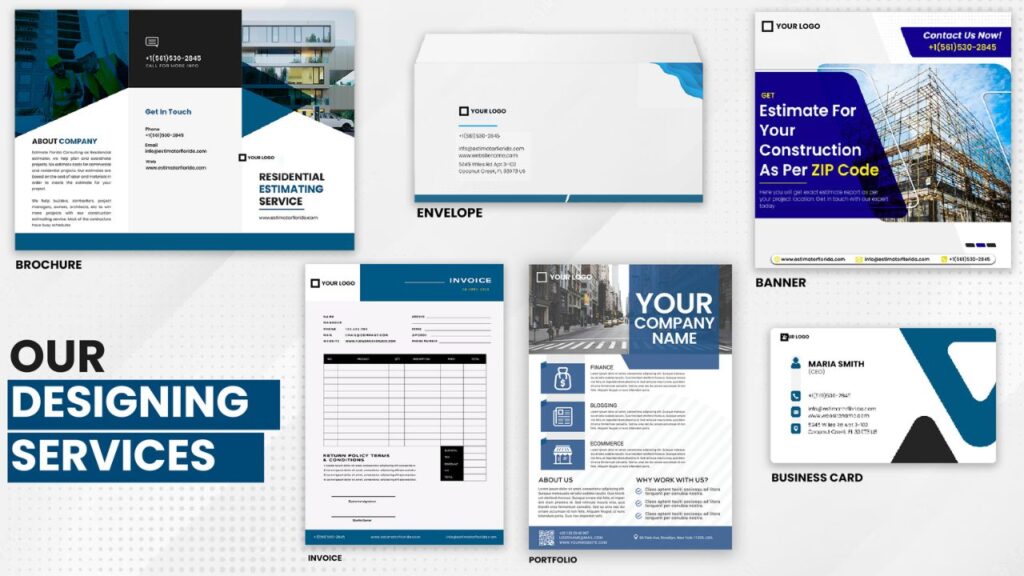

Need Template For Your Mechanical Business

We provide services for Brochure, Banner, Business Card, Envelope, Invoice, etc.

Stakeholder Communication and Expectation Management

Managing stakeholder expectations and ensuring clear communication throughout the project lifecycle can be challenging, especially when dealing with complex cost estimation processes.

Solution: Establish transparent communication channels with stakeholders and provide regular updates on project progress, challenges, and potential impacts on cost estimates. Clearly define roles and responsibilities to avoid misunderstandings and foster collaborative decision-making. Utilize visual aids, such as charts or graphs, to enhance communication and facilitate understanding of cost estimation processes.

Steps in the Mechanical Cost Estimator in Apopka

The Mechanical Cost Estimator in Apopka meticulously analyzes material costs, labor rates, and market trends to produce accurate estimates. Leveraging local data and technology integration, they navigate challenges, ensuring precise projections and transparent communication with stakeholders throughout the process.

Initial Assessment and Scope Definition

Conduct a comprehensive evaluation of project requirements, identifying all mechanical components and associated costs specific to the Apopka area. Define project scope to ensure accurate estimation.

Data Collection and Analysis

Gather data on material prices, labor rates, and market trends from local suppliers and industry databases. Analyze historical data and current market conditions to inform cost estimates accurately.

Utilization of Technology Tools

Implement advanced software and tools, such as Building Information Modeling (BIM) or specialized cost estimation software, to streamline the estimation process. Leverage technology for precise calculations and efficient data management.

Risk Assessment and Contingency Planning

Identify potential risks and uncertainties that may impact project costs, such as material price fluctuations or unforeseen delays. Develop contingency plans to mitigate risks and ensure budgetary resilience.

Stakeholder Communication and Reporting

Maintain transparent communication with project stakeholders, providing regular updates on cost estimates, factors influencing pricing, and potential adjustments. Utilize clear and concise reporting mechanisms to facilitate informed decision-making throughout the project lifecycle.

Are You Looking For?

Fully Insured License Hire Sub-Contractor For Mechanical Work

Hire Contractor

Make Informed Design Decisions Showcase Your Design Ideas

Get RenderingCall Us To Discuss More at 561-530-2845

Conclusion

The Mechanical Cost Estimator project in Apopka represents a critical endeavor in ensuring the efficient and accurate estimation of mechanical project costs within the local context. Through meticulous initial assessments, comprehensive data collection, and the integration of advanced technology tools, the project aims to deliver precise estimates tailored to the unique requirements of the Apopka area. By proactively identifying and addressing potential risks through contingency planning, the project seeks to enhance budgetary resilience and mitigate the impact of unforeseen challenges. Furthermore, transparent communication and reporting practices foster collaborative decision-making and stakeholder engagement, promoting a shared understanding of cost estimation processes. Overall, the Mechanical Cost Estimator project in Apopka underscores a commitment to excellence in cost management, contributing to the successful execution of mechanical projects and the overall development of the community.

Choose Your Trade & Get a Sample Project

FAQs

A Mechanical Cost Estimator is a professional responsible for assessing and estimating the costs associated with mechanical systems in construction projects. In Apopka, where every project demands accurate budgeting to ensure feasibility and success, the role of a Mechanical Cost Estimator becomes indispensable.

We ensure accuracy by conducting thorough initial assessments, utilizing local data on material prices and labor rates, analyzing market trends, and integrating advanced technology tools like Building Information Modeling (BIM). This approach enables us to produce precise estimates tailored to the specific requirements of projects in Apopka.

We address fluctuations through proactive risk assessment and contingency planning. By regularly monitoring market trends and maintaining strong relationships with local suppliers and contractors, we can adjust estimates accordingly and mitigate the impact of price variability on project budgets.

We maintain transparent communication channels with stakeholders through regular updates, progress reports, and detailed explanations of cost estimation methodologies. Our goal is to ensure that stakeholders are well-informed throughout the project lifecycle, facilitating collaboration and informed decision-making.

Hiring a Mechanical Cost Estimator ensures that your project is budgeted accurately, minimizing the risk of cost overruns and delays. By leveraging their expertise and industry knowledge, you can achieve greater cost efficiency, mitigate risks, and enhance the overall success of your project in Apopka.

Process To Get Mechanical Cost Estimate Report

Here I am going to share some steps to get your mechanical cost estimate report.

-

You need to send your plan to us.

You can send us your plan on info@estimatorflorida.com

-

You receive a quote for your project.

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

-

Get Estimate Report

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.

Google Reviews

Reach Out To Us

Places to visit if you new in Apopka

Attwater Prairie Chicken National Wildlife Refuge

The Attwater Prairie Chicken National Wildlife Refuge is a special place designated by the federal government to protect a large piece of coastal prairie in southeast Texas. It’s an important home for the Attwater’s prairie chickens, a type of bird that’s in danger of disappearing, and it’s one of the few places left where they live in the wild.

Animal enthusiasts will appreciate a visit to this ranch, where they can observe exotic wildlife such as antelopes, zebras, and giraffes roaming in spacious habitats. Guided tours offer educational experiences and the chance to learn about wildlife conservation efforts.

Eagle Lake is a city in southeastern Colorado County, Texas, United States. The population was 3,442 at the 2020 census. It is home to a golf course, the largest private lake in Texas, and the Eagle Lake Regional Airport, which serves light aircraft.

The lake itself is the focal point of the area, offering opportunities for fishing, boating, and other water-based activities. Whether you’re an avid angler or just looking to relax by the water, Eagle Lake provides a picturesque setting for outdoor recreation.