Lumber Cost Estimator in Fort Lauderdale, FL

At Estimate Florida Consulting, we specialize in providing accurate and comprehensive lumber cost estimates for projects in Fort Lauderdale. In the heart of Fort Lauderdale, where construction and renovation projects bloom with the seasons, understanding the cost of lumber is fundamental for homeowners, builders, and DIY enthusiasts alike.Small projects, such as DIY crafts or minor repairs, typically range from $500 to $3000+, involving modest amounts of softwood and possibly some hardwood for aesthetic elements. Mid-sized projects, like home renovations or building a shed, can cost between $2500 and $8,500+, varying based on complexity and lumber variety.

Large-scale endeavors, including new home construction or major commercial projects, may exceed $7,500, with costs potentially reaching $75,000 or more due to extensive lumber requirements and project complexity.

Wood Siding Cost per Square Foot

Wood siding comes in various types, each with its own price range. The cost of wood siding materials varies depending on the wood species and style of boards or shingles, ranging from $1 to $30 per square foot. Additionally, installation costs typically add $1 to $5 per square foot, determined by factors such as material type, style, and complexity of installation. Overall, wood siding can range from $2 to $35 per square foot.

| Square Footage | Average Cost Range (Installed) |

|---|---|

| 500 sq.ft. | $1,000 – $17,500 |

| 1,000 sq.ft. | $2,000 – $35,000 |

| 1,500 sq.ft. | $3,000 – $52,500 |

| 2,000 sq.ft. | $4,000 – $70,000 |

| 2,500 sq.ft. | $5,000 – $87,500 |

90% More Chances to Win Projects With Our Estimate!

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- School & University Building

- High-Rise Building

- Shopping Complex

- Data Center Building

Lumber Cost by Type of Lumber

Navigating the costs associated with different types of lumber is crucial for anyone involved in construction or woodworking projects. Prices can vary widely based on the type of wood, its quality, and market availability.

Softwoods

Softwoods, characterized by their fast growth and relatively low density, encompass a variety of tree species commonly used in construction, carpentry, and woodworking. These woods, including pine, cedar, Douglas fir, and spruce, are valued for their affordability, versatility, and ease of workability. Pine, known for its accessibility and adaptability, finds widespread application in framing and furniture making. Cedar, prized for its natural resistance to decay, is a preferred choice for outdoor projects such as decking and fencing. Douglas fir, recognized for its strength and durability, is often utilized in construction for structural framing. Spruce, similar to pine in its utility but slightly stronger, serves various purposes in building and crafting.

Softwoods | Average Cost per Board Foot |

Pine | $1.50 – $7.50 |

Cedar | $3 – $9 |

Douglas Fir | $6 – $10.50 |

Spruce | $3 – $7.50 |

Hardwoods

Hardwoods represent a diverse group of trees known for their slower growth, higher density, and typically greater durability compared to softwoods. Common hardwood species such as oak, maple, cherry, and walnut are highly valued for their strength, aesthetic appeal, and suitability for a wide range of applications. Oak, available in red and white varieties, is prized for its durability and traditional charm, making it a popular choice for furniture and flooring. Maple, with its smooth texture and uniform appearance, is favored for cabinetry and fine woodworking projects. Cherry wood, cherished for its rich color and fine grain, adds warmth and sophistication to high-end furniture pieces.

Walnut, renowned for its dark hues and distinctive grain patterns, is often used in luxury woodworking projects and decorative applications.

Hardwoods | Average Cost per Board Foot |

Oak (Red) | $4.50 – $10.50 |

Oak (White) | $7.50 – $15 |

Maple (Soft) | $4.50 – $9 |

Maple (Hard) | $7.50 – $15 |

Cherry | $9 – $15 |

Walnut | $12 – $22.50 |

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- High-Rise Building

- Shopping Complex

Exotic and Specialty Woods

Exotic and specialty woods encompass a diverse array of unique timber species prized for their distinctive characteristics, exceptional durability, and striking aesthetics. These woods often originate from tropical regions and boast qualities that set them apart from more commonly used domestic species. Teak, renowned for its unparalleled resistance to moisture and decay, is a favorite choice for outdoor furniture, decking, and marine applications. Mahogany, esteemed for its rich color, fine grain, and workability, has been a cherished material for luxurious furniture and decorative accents for centuries. Ipe, celebrated for its extreme hardness and resilience, is highly sought after for demanding outdoor projects such as decking and boardwalks, where durability and longevity are paramount.

Exotic and Specialty Woods | Average Cost per Board Foot |

Teak | $30 – $45 |

Mahogany | $12 – $30 |

Ipe | $30 – $37.50 |

Download Template For Lumber Project Breakdown

- Materials list updated to the zip code

- Fast delivery

- Data base of general contractors and sub-contractors

- Local estimators

Lumber Videos

Pole Barn Construction

House Building

Building a bARNDOOR

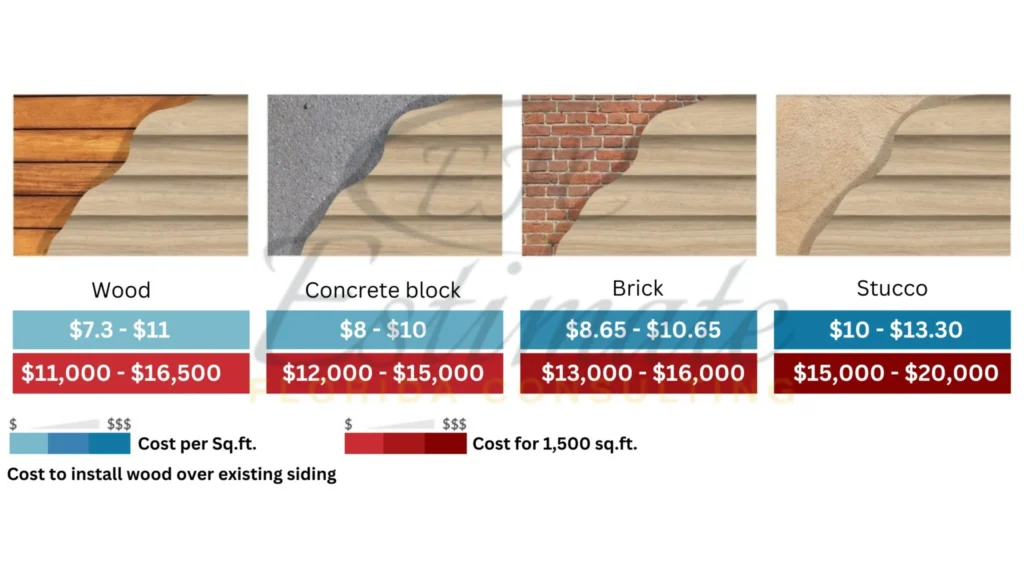

Cost to Install Wood Siding Over Existing Siding

As a Lumber Cost Estimator, it’s essential to consider the various factors involved in installing wood siding over existing siding materials rather than starting from scratch. While this approach can save time and resources, it’s crucial for contractors to assess the integrity of the current siding closely. Rotted or damaged siding pieces cannot be covered up with new ones as it may lead to structural issues. Certain materials, like vinyl siding, must be removed before new installations due to their softness and susceptibility to damage if covered over. Understanding which sidings can support wood siding installations helps ensure a smooth and structurally sound transition, ultimately impacting cost estimations for lumber-related projects.

| Existing Siding | Cost per Sq.Ft. (Installed) | Cost for 1,500 Sq.Ft. (Installed) |

|---|---|---|

| Wood | $7.30 – $11 | $11,000 – $16,500 |

| Concrete Block | $8 – $10 | $12,000 – $15,000 |

| Brick | $8.65 – $10.65 | $13,000 – $16,000 |

| Stucco | $10 – $13.30 | $15,000 – $20,000 |

Key Factors Influencing Lumber Prices

Type of Wood

The type of wood selected for a project significantly influences its overall cost and performance. Softwoods like pine and cedar are popular choices for construction due to their affordability and widespread availability. These woods are often used in framing, decking, and outdoor structures where structural strength is essential but appearance is less critical. In contrast, hardwoods such as oak and maple are prized for their durability, aesthetic appeal, and versatility. While hardwoods come at a premium price compared to softwoods, their exceptional strength, resilience, and beautiful grain patterns make them ideal for high-end furniture, cabinetry, flooring, and architectural millwork.

The choice between softwoods and hardwoods depends on factors such as budget, project requirements, and desired aesthetics, with each offering distinct advantages and considerations.

Quality and Grade

The quality and grade of lumber play a crucial role in determining its price and suitability for various applications. Lumber is graded based on its appearance and structural characteristics, with higher grades commanding higher prices due to their superior quality and minimal defects. Clear and select grades are prized for their uniform appearance, straight grain, and absence of knots or blemishes, making them ideal for projects where aesthetics are a priority. These premium grades are commonly used in fine woodworking, furniture making, and interior finishing where flawless surfaces and consistent color are desired. Lower grades, such as common or construction grade, may contain more knots, splits, and imperfections but are often more affordable and suitable for structural framing and general construction where appearance is less critical. Understanding lumber grades and selecting the appropriate grade for each project ensures optimal performance, durability, and visual appeal while balancing budgetary considerations.

Market Fluctuations

Lumber prices are subject to fluctuations influenced by various factors, including global and local market dynamics, trade policies, supply chain disruptions, and seasonal demand shifts. Economic conditions, such as changes in demand from the construction industry or fluctuations in raw material availability, can impact lumber prices significantly. Additionally, trade tariffs, transportation costs, and environmental regulations may contribute to price volatility in the lumber market. Staying informed about market trends, monitoring price fluctuations, and adjusting cost estimates accordingly are essential for accurately forecasting project expenses and mitigating financial risks. Collaborating with suppliers, tracking commodity indexes, and considering forward contracts or hedging strategies can help contractors and project managers navigate market uncertainties and secure competitive pricing for lumber materials.

Size and Dimensions

The size and dimensions of lumber also influence its cost and suitability for specific projects. Standard sizes, such as 2x4s and 2x6s, are commonly used in framing and construction due to their cost-effectiveness and structural integrity. These standard dimensions are readily available and mass-produced, resulting in lower material costs compared to custom sizes or larger dimensions required for specialized applications. However, projects with unique design requirements or architectural specifications may necessitate custom-sized lumber, which can incur higher material costs and production lead times. Additionally, larger dimensions or specialty cuts may require premium-grade lumber to ensure structural stability and uniformity. Balancing the need for specific dimensions with budgetary constraints is essential for optimizing project efficiency and cost-effectiveness. Careful planning, accurate measurements, and strategic material sourcing help minimize waste and maximize the value of lumber investments for construction and woodworking projects.

Business Finance Loan

Find out if you're pre-qualified in seconds

Get Prequalified Now

IMPORTANT: Make sure the email and phone number you enter are correct. We will email and text you a link to get started.

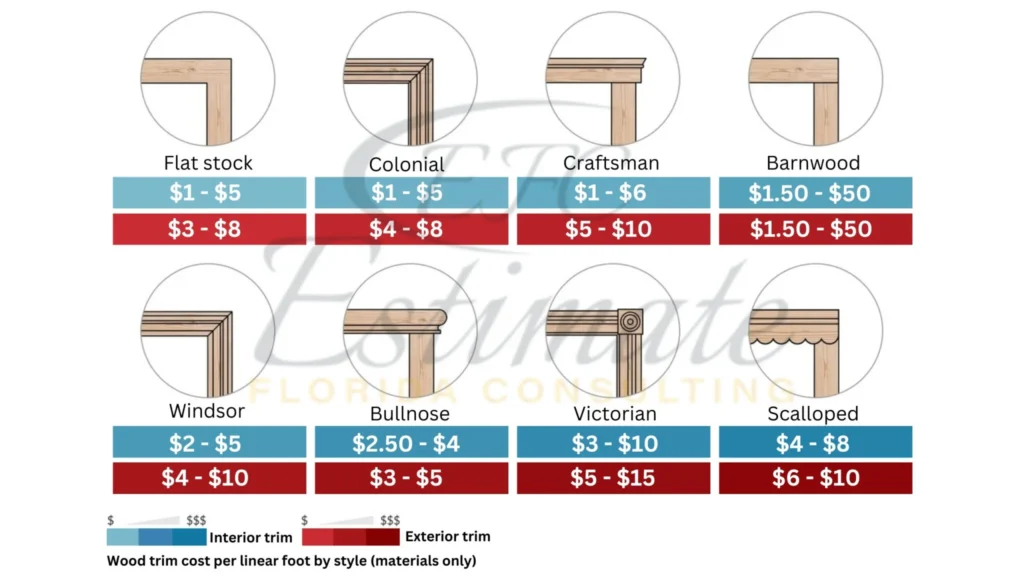

Wood Trim Cost by Style

it’s essential to recognize the diverse array of styles available in wood trim, catering to various architectural preferences and home styles. From simple and modern to historical and intricate designs, there’s a trim style to accentuate any home’s unique architecture. These styles are offered in both paint-grade and stain-grade options, available in a range of sizes and materials. Homeowners have the flexibility to choose from dark or light wood tones or opt for trim that can be painted to match the color scheme of their choice. By understanding the versatility of trim styles and materials, accurate cost estimations can be provided to meet the needs and preferences of homeowners for their lumber-related projects.

| Style | Interior Trim Cost per Linear Foot (Materials Only) | Exterior Trim Cost per Linear Foot (Materials Only) |

|---|---|---|

| Flat Stock | $1 – $5 | $3 – $8 |

| Colonial | $1 – $5 | $4 – $8 |

| Craftsman | $1 – $6 | $5 – $10 |

| Barnwood | $1.50 – $50 | $1.50 – $50 |

| Windsor | $2 – $5 | $4 – $10 |

| Bullnose | $2.50 – $4 | $3 – $5 |

| Victorian | $3 – $10 | $5 – $15 |

| Scalloped | $4 – $8 | $6 – $10 |

Estimate Your Project With Us

Budgeting Tips: Maximizing Value

Bulk Purchases

One of the most effective ways to maximize value when purchasing lumber is by buying in bulk for large-scale projects. By ordering a significant quantity of lumber at once, contractors and builders can often negotiate better rates with suppliers, benefiting from volume discounts or special pricing arrangements. Bulk purchases allow suppliers to streamline their inventory management and logistics, resulting in cost savings that can be passed on to customers. Additionally, buying in bulk reduces the frequency of ordering and delivery, minimizing administrative overhead and transportation expenses.

Off-season Shopping

Timing can play a crucial role in securing the best prices for lumber, with off-peak construction periods often offering cost-saving opportunities for savvy buyers. During times of lower demand, such as winter months or periods of economic downturn, lumber prices may decrease as suppliers seek to stimulate sales and clear excess inventory. Planning purchases during off-season periods can provide significant cost advantages, allowing contractors to capitalize on reduced prices and negotiate favorable terms with suppliers.

Additionally, scheduling projects during off-peak times may enable contractors to benefit from more flexible scheduling and faster turnaround times for deliveries and installations. However, it’s essential to balance the potential cost savings of off-season shopping with project timelines and seasonal construction constraints.

Sustainability and Cost

Incorporating sustainability considerations into lumber purchasing decisions not only aligns with environmental stewardship goals but can also offer cost-saving benefits in the long run. Opting for sustainably sourced or locally harvested lumber reduces reliance on non-renewable resources and minimizes the environmental impact of deforestation and habitat destruction. Additionally, choosing sustainable lumber options may result in reduced transportation costs and import tariffs, particularly for domestically sourced materials. By supporting sustainable forestry practices and local timber industries, contractors and builders can contribute to environmental conservation efforts while potentially lowering overall project costs. While sustainably sourced lumber may come at a slightly higher initial price compared to conventional options, the long-term benefits in terms of environmental sustainability, regulatory compliance, and reputational value outweigh the upfront costs.

Seasonal Influences on Lumber Prices

Understanding Seasonal Demand

In Fort Lauderdale, as in many other regions, seasonal changes play a significant role in influencing lumber prices due to fluctuations in construction activity. During the warmer months, typically from spring to early fall, construction projects are more feasible and abundant. This increased demand for lumber, driven by a surge in residential and commercial building activities, often leads to higher prices as suppliers adjust their rates to accommodate the heightened need. In Fort Lauderdale, where the climate allows for construction throughout much of the year, the seasonal spikes in demand may not be as pronounced as in areas with more distinct seasonal variations. However, there is still a noticeable correlation between warmer weather and increased construction activity, particularly for outdoor projects and renovations.

Need Template For Your Lumber Business

We provide services for Brochure, Banner, Business Card, Envelope, Invoice, etc.

Strategic Buying

To navigate the impact of seasonal price fluctuations on lumber costs, contractors and builders in Fort Lauderdale can adopt strategic purchasing practices aimed at maximizing value and minimizing expenses. One approach is to consider buying lumber during off-peak seasons or periods when demand is historically lower. By planning purchases strategically and timing them to coincide with times of reduced demand, contractors may be able to secure better prices and negotiate favorable terms with suppliers. This requires careful monitoring of market trends, forecasts, and historical pricing data to identify optimal buying opportunities. Additionally, aligning project schedules with periods of lower lumber prices can further mitigate the impact of seasonal fluctuations on overall project costs.

Sourcing Lumber: Local vs. Imported

Benefits of Local Sourcing

Opting to source lumber locally in Fort Lauderdale or from nearby regions can provide several significant advantages for contractors, builders, and homeowners alike. Firstly, choosing local suppliers often translates to lower transportation costs, as the distance traveled from the lumber mill to the project site is reduced. This can result in cost savings for buyers, as transportation expenses are minimized, and the overall cost of the lumber remains competitive. Additionally, supporting local lumber suppliers contributes to the vitality of the regional economy by bolstering local businesses and creating job opportunities within the community. Furthermore, local sourcing may also lead to faster delivery times, as shipments have shorter distances to travel, ensuring timely access to materials for construction projects.

Imported Lumber Considerations

While imported lumber presents opportunities for cost savings and access to specific wood types not readily available locally, it’s essential for buyers to carefully consider the potential challenges and additional costs associated with this sourcing option. One primary consideration is the imposition of tariffs or duties on imported lumber, which can significantly increase the overall cost of the materials. These additional fees must be factored into the budgeting process to accurately assess the true cost of imported lumber and determine its viability compared to domestic alternatives.

Moreover, importing lumber often entails longer lead times, as shipments may need to traverse greater distances and navigate customs clearance procedures, potentially delaying construction schedules and project timelines.

Eco-friendly Lumber Options and Their Impact on Costs

Sustainable Wood Choices

Choosing lumber from sustainably managed forests certified by organizations like the Forest Stewardship Council (FSC) presents an eco-friendly option with long-term environmental benefits. While these sustainable wood choices may initially come at a premium compared to conventional lumber, they offer significant advantages in terms of environmental conservation and responsible resource management. By opting for FSC-certified lumber, buyers can support forest ecosystems’ health, biodiversity preservation, and indigenous communities’ rights. Additionally, sustainably managed forests help mitigate climate change by sequestering carbon dioxide, promoting soil and water conservation, and minimizing habitat destruction.

Reclaimed Wood

Utilizing reclaimed or recycled wood in construction projects not only adds distinctive character and historical charm but also represents a cost-effective and eco-friendly alternative to conventional lumber. Reclaimed wood, sourced from salvaged materials such as old barns, warehouses, or buildings, offers a sustainable solution that diverts usable wood from landfills and reduces the demand for virgin timber extraction. The price of reclaimed lumber can vary widely depending on factors such as rarity, condition, and historical significance. While some reclaimed wood may command premium prices due to its unique characteristics or historical value, other sources may offer more affordable options suitable for various budgetary constraints. Beyond its environmental benefits, reclaimed wood contributes to a project’s aesthetic appeal, providing warmth, authenticity, and a sense of heritage to interior and exterior spaces.

Are You Looking For?

Fully Insured License Hire Sub-Contractor For Lumber Project

Hire Contractor

Make Informed Design Decisions Showcase Your Design Ideas

Get RenderingCall Us To Discuss More at 561-530-2845

Conclusion

In conclusion, navigating the complexities of lumber costs in Fort Lauderdale, FL, requires a comprehensive understanding of various factors influencing pricing, sourcing options, and sustainability considerations. At Estimate Florida Consulting, we specialize in providing accurate lumber cost estimates tailored to the specific needs of each project, whether small DIY endeavors or large-scale commercial constructions. By considering factors such as seasonal influences, local versus imported sourcing, and eco-friendly lumber options, stakeholders can make informed decisions to optimize project budgets and achieve their goals sustainably. With our expertise and commitment to precision, we empower clients to plan and execute projects confidently, knowing they have reliable estimates that account for the dynamic nature of the lumber market. Trust Estimate Florida Consulting for dependable guidance and cost-effective solutions in all your lumber-related endeavors in Fort Lauderdale and beyond.

We Provide Services For Other Trades in Fort Lauderdale

FAQs

For small DIY projects like crafts or minor repairs, the average cost of lumber typically ranges from $500 to $3,000 or more. This cost includes modest amounts of softwood and possibly some hardwood for aesthetic elements.

Mid-sized projects like home renovations or building a shed can cost between $2,500 and $8,500 or more in Gainesville. The cost varies based on the project’s complexity and the variety of lumber used.

Large-scale endeavors such as new home construction or major commercial projects in Gainesville may exceed $7,500, with costs potentially reaching $75,000 or more. This is due to extensive lumber requirements and project complexity.

For softwoods like pine, cedar, Douglas fir, and spruce, the average costs per board foot range from $1.50 to $10.50. For hardwoods such as oak, maple, cherry, and walnut, the average costs per board foot range from $4.50 to $22.50.

Exotic and specialty woods like teak, mahogany, and ipe can be more expensive, with average costs per board foot ranging from $12 to $45. These woods are prized for their unique characteristics, exceptional durability, and striking aesthetics.

Process To Get Lumber Cost Estimate Report

Here I am going to share some steps to get your lumber cost estimate report.

-

You need to send your plan to us.

You can send us your plan on info@estimatorflorida.com

-

You receive a quote for your project.

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

-

Get Estimate Report

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.

Google Reviews

Reach Out To Us

Places to visit if you new in Fort Lauderdale

Sink your toes into the soft sands of Fort Lauderdale Beach. Stretching along the Atlantic Ocean, this picturesque beach offers crystal-clear waters, vibrant sunsets, and a bustling promenade lined with shops, restaurants, and entertainment venues.

Discover the vibrant energy of Las Olas Boulevard. This iconic thoroughfare is known for its eclectic mix of boutiques, art galleries, cafes, and nightlife spots, making it a must-visit destination for shopping, dining, and people-watching.

Stroll along the scenic Riverwalk Fort Lauderdale. This lush waterfront promenade winds along the New River, offering picturesque views of passing boats, historic landmarks, and lush greenery, as well as access to museums, parks, and cultural attractions.

Fort Lauderdale Swap Shop & Thunderbird Drive-In Theater

Experience a blast from the past at the Fort Lauderdale Swap Shop & Thunderbird Drive-In Theater. Browse through a vast array of vendors selling everything from clothing to electronics, then catch a movie under the stars at one of the last remaining drive-in theaters in Florida.