How To Price Concrete Jobs?

Pricing concrete jobs accurately is a multi-faceted process that goes beyond simple arithmetic; it involves a deep understanding of various factors that can influence costs and profitability. Whether you are a contractor aiming to submit a competitive bid or a property owner looking to budget for an upcoming project, gaining a clear insight into the elements that affect concrete cost is crucial. This guide will walk you through each step of the pricing process, providing a thorough and detailed approach that ensures you cover all necessary bases and are well-prepared to set your project up for success. By understanding how each aspect contributes to the overall cost, you can develop a pricing strategy that is both fair and profitable, while also maintaining a competitive edge in the market.

Understand the Scope of the Project

The first and most critical step in pricing a concrete job is to fully comprehend the scope of the project. This involves more than just identifying the area that needs to be covered with concrete; it requires a detailed evaluation of the specific requirements, constraints, and potential challenges that the project might present. Understanding the full scope of the project allows you to anticipate the resources needed and the complexity of the work involved, both of which are crucial for accurate pricing. For instance, the size of the area, the required thickness of the concrete, and the inclusion of any specialized features or finishes must all be considered. Each of these factors plays a significant role in determining the overall material and labor requirements, which, in turn, impacts the total cost.

Key Details to Consider

Area Size

Accurately measuring the total square footage or cubic footage that needs to be covered is the foundation of pricing any concrete job. This measurement should be precise, as even small errors can lead to significant cost miscalculations. Understanding the exact dimensions of the area to be concreted is crucial for ordering the correct amount of material and ensuring that you don’t over- or under-order, both of which can result in wasted resources or project delays.

Concrete Thickness

The required thickness of the concrete slab is another critical factor, as different projects may necessitate varying slab thicknesses. For example, a residential driveway might require a 4-inch slab, while a commercial parking lot might need a thicker, more durable slab to withstand heavier loads. Thicker slabs increase the amount of concrete needed, which directly raises material costs. Accurately determining the required thickness ensures that the concrete will meet the structural demands of the project, preventing potential failures or the need for costly repairs down the line.

Reinforcement

Many concrete jobs require reinforcement to add strength and durability to the structure. This could involve the use of rebar, wire mesh, or other reinforcement materials. Including reinforcement in your project adds both material and labor costs, as it requires additional preparation and installation time. The type and amount of reinforcement needed will depend on the specific requirements of the project, such as the load it needs to bear or the environmental conditions it must withstand.

Finishing

Consider any specific finishing techniques that may be required, such as stamping, staining, or polishing the concrete. These finishes can significantly impact the overall cost, not only because of the additional materials required but also due to the increased labor time needed to achieve the desired finish. Decorative finishes can add aesthetic value and durability to the concrete, making them a popular choice for both residential and commercial projects. However, they also add complexity to the job, which should be reflected in your pricing.

Concrete Videos

Concrete Pour

Concrete Driveway

Concrete Garage

Calculate the Material Costs

Material costs represent a substantial portion of the overall pricing for concrete jobs, and getting these calculations right is essential for maintaining profitability. Accurately calculating material costs requires a detailed understanding of the amount of concrete and other materials necessary for the project. This process involves more than just basic arithmetic; it also requires careful consideration of factors such as waste, environmental conditions, and the specific requirements of the job. Ensuring that you account for all these factors will help you avoid unexpected costs and keep the project within budget.

Steps to Calculate Material Costs

Concrete Volume

Begin by calculating the volume of concrete needed using the formula:

Volume=Area Size×Thickness

For instance, if you’re pouring a 4-inch thick slab over a 1,000 square foot area, the volume of concrete required is:

1,000 sq ft×124 ft=333.33 cubic feet

This volume should then be converted to cubic yards (since concrete is typically sold by the cubic yard):

27 cubic feet per cubic yard333.33 cubic feet=12.35 cubic yards

Accurately calculating the concrete volume is critical for ordering the right amount of material. Ordering too much can lead to waste and increased costs, while ordering too little can cause delays and additional expenses due to reordering.

Concrete Cost

Multiply the volume of concrete by the cost per cubic yard. If concrete costs $150 per cubic yard, the material cost would be:

12.35 cubic yards×$150=$1,852.50

It’s important to remember that concrete prices can vary based on factors such as location, supplier, and market conditions. Always check for the most current prices before finalizing your estimate. Additionally, consider any potential price fluctuations that might occur between the time you estimate the job and when you actually order the concrete.

Additional Materials

Don’t forget to add costs for any reinforcement materials (e.g., rebar, wire mesh), formwork materials, and finishing products (e.g., stains, sealers). These additional materials can significantly increase the overall cost and should be carefully factored into your pricing. Reinforcement materials are particularly important in projects where the concrete will bear heavy loads or be exposed to harsh environmental conditions. Formwork, which is necessary for shaping the concrete, can also add substantial costs, especially in complex or large-scale projects.

90% More Chances to Win Projects With Our Estimate!

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- School & University Building

- High-Rise Building

- Shopping Complex

- Data Center Building

Estimate Labor Costs

Labor costs are another major component of pricing concrete jobs, and they can vary widely depending on the complexity of the project and the experience of your crew. Estimating labor costs accurately is essential for ensuring that you can cover your expenses while providing fair wages to your workers. Labor costs are not just about the number of hours worked; they also encompass the skill level required, the potential for overtime, and the specific tasks involved in the project. By carefully estimating labor costs, you can avoid underbidding, which can lead to financial losses, or overbidding, which can make your quote less competitive.

Factors Affecting Labor Costs

Crew Size

Determine the number of workers needed for the project and their respective hourly rates. Larger or more complex projects may require a bigger crew or more specialized labor, which can drive up costs. It’s important to consider the skill levels of your workers; more experienced or specialized labor typically commands higher wages but can also improve efficiency and quality, potentially saving money in the long run.

Job Duration

Estimate the total time required to complete the project, including site preparation, pouring, finishing, and curing. Time management is critical in construction projects; underestimating the duration can lead to rushed work, increased overtime, or project delays, all of which can drive up costs. Accurate time estimates ensure that your pricing reflects the true labor effort required.

Complexity

Consider whether the job involves complex tasks such as forming curves, working on sloped surfaces, or adding decorative finishes. These tasks often require more skill and time, which should be reflected in your labor cost estimate. Complex projects may also involve additional coordination or the need for specialized tools and equipment, which can further increase labor costs.

To estimate labor costs, multiply the number of hours required by the total hourly wage of the crew. For example, if a project requires a crew of 4 workers at $30 per hour for 3 days (24 hours), the labor cost would be:

4 workers×24 hours×$30=$2,8804 \text{ workers} \times 24 \text{ hours} \times \$30 = \$2,8804 workers×24 hours×$30=$2,880

Accurately estimating labor costs ensures that your pricing covers all expenses and allows for a reasonable profit margin, helping you maintain the financial health of your business.

Include Overhead and Profit Margins

Overhead costs include various indirect expenses such as equipment rental, fuel, insurance, and permits. These costs are often overlooked, but they can add up quickly and significantly impact your overall profitability. In addition to covering overhead, you’ll also need to include a profit margin to ensure that the job contributes to your business’s financial health. Properly accounting for overhead and profit in your pricing not only ensures that you cover your costs but also allows your business to grow and invest in future projects.

Considerations for Overhead

Equipment Rental

If you need to rent equipment such as concrete mixers, trowels, or pumps, be sure to include these costs in your pricing. Equipment rental can be a significant expense, especially for larger projects, so it’s important to account for it accurately. Additionally, consider the cost of maintaining and transporting equipment, as these can also affect your overhead.

Transportation

Include costs for transporting materials and workers to and from the job site. Fuel prices, distance, and the number of trips required can all affect transportation costs. Efficiently managing transportation logistics can help reduce costs and ensure that your project stays on schedule.

Permits and Insurance

Account for any necessary permits and insurance coverage. These costs are essential for ensuring that the project complies with local regulations and that you’re protected against potential liabilities. Failing to account for permits and insurance can lead to unexpected costs and delays, so it’s important to include them in your initial pricing.

Profit margins are typically added on top of material, labor, and overhead costs. A standard profit margin for concrete jobs ranges from 10% to 20%, depending on the market and the complexity of the job. Setting the right profit margin is crucial for maintaining a healthy cash flow and ensuring that your business can grow. A well-calculated profit margin also provides a buffer for any unexpected costs that may arise during the project, helping to protect your bottom line.

Prepare a Detailed Quote

Once you’ve calculated all the costs, it’s time to prepare a detailed quote that outlines the scope of work, materials, labor, overhead, and profit margin. A well-prepared quote not only provides transparency to your client but also establishes trust and sets clear expectations for both parties. Providing a clear and transparent quote helps build trust with your clients and ensures that there are no misunderstandings about what is included in the job. A detailed quote also serves as a reference point throughout the project, helping to prevent scope creep and disputes over costs.

Elements of a Detailed Quote

Project Description

Clearly describe the work to be done, including dimensions, materials, and finishes. The more specific you are, the less room there is for misunderstandings or disputes later on. A detailed project description also helps the client understand the value they are receiving for their investment, which can justify the costs.

Itemized Costs

Break down the costs for materials, labor, equipment, and overhead. Itemizing costs helps the client understand where their money is going and provides transparency in your pricing. It also allows for easier adjustments if the scope of the project changes or if the client requests modifications.

Timeline

Provide an estimated timeline for the project, including start and completion dates. Clients appreciate knowing when the work will be completed, and a clear timeline can help manage expectations. Including a timeline also helps you coordinate with other trades and suppliers, ensuring that the project runs smoothly.

Terms and Conditions

Include payment terms, warranty information, and any other relevant conditions. Clear terms and conditions protect both you and the client by outlining the responsibilities of each party. This section should also address potential contingencies, such as weather delays or unforeseen site conditions, to prevent disputes and ensure a smooth project execution.

Adjust for Market Conditions and Competition

Finally, consider the local market conditions and competition when pricing your concrete job. Market conditions can vary greatly depending on location, economic factors, and the level of competition in your area. Adjusting your pricing to reflect these conditions can help you stay competitive while ensuring that your business remains profitable. Understanding the competitive landscape allows you to position your services effectively and make strategic pricing decisions that align with your business goals.

Market Considerations

Competition

Research what other contractors are charging for similar jobs in your area. Understanding the competition helps you position your pricing effectively, whether you aim to offer premium services or compete on price. If your competitors are offering lower prices, consider what additional value you can provide, such as superior workmanship, faster completion times, or better customer service.

Demand

If there is high demand for concrete work in your area, you may be able to charge higher rates. Conversely, if demand is low, you might need to adjust your pricing to attract more clients. Monitoring market demand allows you to adjust your pricing strategy in real-time, ensuring that you remain competitive without sacrificing profitability.

Specialization

If you offer unique services or specialize in high-end finishes, you may be able to charge a premium. Your pricing should reflect the added value you bring to the project, whether through specialized skills, quality of work, or reputation. Specialization can differentiate your business from competitors and justify higher prices, especially if you are known for delivering exceptional results.

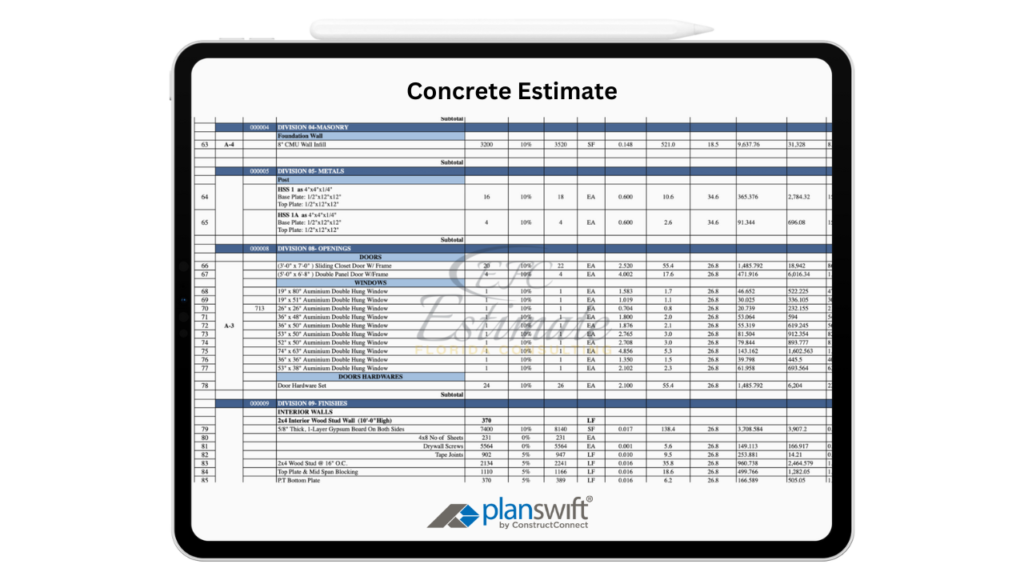

Download Template For Concrete Project Breakdown

- Materials list updated to the zip code

- Fast delivery

- Data base of general contractors and sub-contractors

- Local estimators

Conclusion

Pricing concrete jobs requires a thorough understanding of materials, labor, overhead, and market conditions. By following these steps and preparing a detailed quote, you can ensure that your pricing is accurate, competitive, and profitable. Estimate Florida Consulting can assist you in creating precise estimates for your concrete projects, ensuring that all aspects are covered and that you achieve the desired results within budget. Taking the time to accurately price your concrete jobs not only helps you win more contracts but also ensures that your business remains profitable and sustainable in the long run. A well-structured pricing strategy allows you to deliver high-quality work, maintain client satisfaction, and grow your business in a competitive market.

FAQs

Several factors affect the cost of a concrete job, including the size and complexity of the project, the thickness of the concrete slab, the type of reinforcement used, the finishing techniques,

To calculate the amount of concrete needed, multiply the area size by the required thickness of the slab. This will give you the volume in cubic feet, which can then be converted to cubic yards (since concrete is typically sold by the cubic yard).

The cost per cubic yard of concrete typically ranges from $100 to $150, depending on the supplier, location, and market conditions. Additional materials such as rebar or finishing products can also affect this price.

Labor costs depend on the size of the crew, their hourly wages, the duration of the job, and the complexity of the project. Multiply the total hours by the hourly wage of the workers to estimate labor expenses.

Overhead costs are indirect expenses like equipment rental, fuel, permits, and insurance. These should be calculated based on the specific needs of the project and added to your pricing to cover all operational costs.

Profit margins typically range from 10% to 20% for concrete jobs. This margin ensures your business remains profitable and allows you to reinvest in future projects.

Adjust your pricing based on local demand and competition. If there’s high demand for concrete work in your area, you may be able to charge higher rates. Conversely, in a competitive market, you might need to offer additional value or adjust prices to stay competitive.

A detailed quote should include a project description, itemized costs for materials and labor, a timeline for completion, and clear terms and conditions. This ensures transparency and sets clear expectations for both you and your client.

Yes, you should include the costs of any necessary permits and insurance coverage in your pricing. These are essential for legal compliance and protecting your business from potential liabilities.

Avoid underpricing by accurately calculating all material, labor, and overhead costs, and factoring in a reasonable profit margin. Avoid overpricing by staying competitive and adjusting your rates based on local market conditions and what similar contractors are charging.

Google Reviews

Process To Get The Concrete Estimate Report

Here I am going to share some steps to get the concrete estimate report.

-

You need to send your plan to us.

You can send us your plan on info@estimatorflorida.com

-

You receive a quote for your project.

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

-

Get Estimate Report

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.