- Homepage

- How Much Does Steel I-Beam Installation Cost?

How Much Does Steel I-Beam Installation Cost?

Leading provider of metal construction services.

Installing a steel beam in residential construction typically costs between $130 and $520 per foot, amounting to an average of $1,560 to $5,460. Replacing a load-bearing wall with a support beam generally ranges from $5,200 to $13,000, depending on the complexity of the project. For materials alone, steel I-beams are priced at approximately $7.80 to $23.40 per foot. These costs reflect the strength and durability steel beams provide, making them a popular choice for structural support.

Support Beam Cost Installed | Per Foot Installed | Total Cost Installed |

LVL Beam | $65 – $260 | $1,040 – $3,250 |

Steel I-Beam | $130 – $520 | $1,560 – $5,460 |

Steel I-Beam (Complex) | $650+ | $7,800 – $13,000 |

Steel I-Beam Prices | Weight Per Foot (pounds) | Material Cost Per Foot |

S3 x 5.7 | 5.7 | $7.80 – $10.40 |

S4 x 7.7 | 7.7 | $9.10 – $15.60 |

S6 x 12.5 | 12.5 | $15.60 – $23.40 |

Steel beams offer numerous advantages over traditional wood structural beams, making them a superior choice for many construction projects.

- They provide significantly higher weight-bearing capacity and are resistant to both fire and rot, enhancing the durability and safety of your home.

- Incorporating steel beams will strengthen your home’s structure and give you greater design flexibility, allowing you to open up walls or support heavier building materials with ease.

- Steel beams also enable the use of extended rooflines or longer balconies without the need for support columns below—no other material can match the engineering possibilities that steel offers.

Cost to Install a Steel Beam

The average cost to install a steel beam now ranges from $1,560 to $5,460, or $130 to $520 per foot. This estimate includes a structural engineer’s inspection, permits, the beam itself, delivery, and installation.

For highly complex installations involving underpinnings or long spans, the cost can rise to $650 or more per foot, totaling between $7,800 and $13,000.

Cost to Install a Steel Beam | Cost |

National Average Cost | $3,770 |

Minimum Cost | $1,040 |

Maximum Cost | $13,000 |

Average Range | $1,560 to $5,460 |

To install a steel support beam, the process begins with having a contractor custom-order the specific type of steel beam recommended by a structural engineer.

90% More Chances to Metal Construction Bids with Our Estimate

Steel Beam Installation Cost Breakdown

Item | Average Cost |

Steel I-Beam | $78 – $234 |

Delivery | $104 – $520+ |

Installation | $650 – $2,600 |

Structural Engineer | $390 – $1,300 |

Permits | $98 – $650 |

Total Cost | $1,320 – $5,304 |

The total cost and process for installing a new beam can include several factors, each adding to the overall expense:

- Permit fees from your city council

- Inspections by a structural engineer to determine the appropriate type of beam

- Labor and disposal fees for removing any existing beam

- Costs for removing a load-bearing wall if replacing it with a beam

- Labor costs for additional support, such as underpinnings and columns

- The cost of the beam itself, including delivery fees for custom steel or LVL beams

- Crane rental fees to lift a new steel beam into place

- Labor and materials needed to refinish your ceiling, floors, and walls after the beam installation is complete.

Steel Beam Cost Calculator

A structural engineer’s inspection, costing between $325 and $1,300, is essential to determine the weight your beam must support and the space available for installation. Steel beam prices are influenced by several factors, including:

- The length, flange width, and thickness of the beam

- The type of beam—whether it’s an I-beam, H-beam, U-beam, or another shape

- The weight, grade, and quality of the steel

- The current market value of steel or the supplier’s current stock

- Whether you need a painted beam or one that’s galvanized with a zinc coating

- Shipping or local delivery costs, depending on the beam’s weight

Steel Beam Cost Per Foot

Steel I-beams typically range from $7.80 to $23.40 per foot, while the stronger H-beams cost between $14.30 and $104 per foot. I-beams are generally more affordable than H-beams due to differences in shape, weight, span, and load-bearing capacity.

Steel Beam Cost Per Foot

Type | Size | Weight Per Foot (pounds) | Cost Per Linear Foot |

I-Beam | S3 x 5.7′ | 5.7 | $7.80 – $10.40 |

I-Beam | S4 x 7.7′ | 7.7 | $9.10 – $15.60 |

I-Beam | S6 x 12.5′ | 12.5 | $15.60 – $23.40 |

H-Beam | W4 x 13′ | 13 | $14.30 – $20.80 |

H-Beam | W6 x 12′ | 12 | $15.60 – $18.20 |

H-Beam | W12 x 65′ | 65 | $31.20 – $104.00 |

For Metal Building and Other Projects

Turnaround time is 1-2 days.

Win More Projects With Us

Steel Support Beam Prices by Length

The cost of steel support beams varies based on length and type. For example, a 10′ steel I-beam typically costs between $78 and $234, while a 30′ steel I-beam ranges from $234 to $702. H-beams, which are stronger and can support longer spans, can cost nearly double that of I-beams. Steel beam prices fluctuate due to market conditions.

Steel I-Beam Prices by Length

Length | I-Beam Cost | H-Beam Cost |

8′ | $58.50 – $195 | $104 – $169 |

10′ | $78 – $234 | $143 – $208 |

16′ | $123.50 – $377 | $227.50 – $331.50 |

20′ | $156 – $468 | $286 – $416 |

24′ | $188.50 – $559 | $344.50 – $500.50 |

30′ | $234 – $702 | $429 – $624 |

40′ | $312 – $936 | $572 – $832 |

Structural Steel Prices

The cost of raw structural steel for common-size I-beams typically ranges from $1.17 to $2.08 per pound, or $2.60 to $4.42 per kilogram when purchased by the beam. In bulk, structural steel costs around $117 per ton. Buying steel based on weight is generally reserved for bulk orders, and prices fluctuate regularly due to market conditions.

Structural Steel Prices

Unit | Average Cost |

Per Lb. | $1.17 – $2.08 |

Per Kg. | $2.60 – $4.42 |

Per Ton | $2,340 – $4,030 |

Steel Beam vs. Wood vs. LVL Cost

Softwood and LVL beams are typically the most affordable options for construction, while concrete beams fall into a mid-range price category. Heavy timber and steel are the most expensive but also the strongest choices available.

The most significant cost difference comes from installation and delivery rather than the beams themselves. Steel beams, for example, incur higher shipping fees and often require cranes to lift them into place. Additionally, attaching a home’s components to steel is more complex than with wood, as steel requires pre-formed holes for bolts, necessitating architectural planning ahead of time.

Steel Beam vs. Wood vs. LVL Cost

Material | Average Cost Per Linear Foot |

Steel | $7.80 – $23.40 |

LVL (Engineered) | $3.90 – $15.60 |

Glulam (Engineered) | $7.80 – $44.20 |

Wood – Softwood | $6.50 – $39.00 |

Wood – Hardwood | $11.70 – $27.30 |

Concrete | $9.10 – $20.80 |

Load-Bearing Support Beam Cost

A load-bearing support beam typically costs between $6.50 to $26 per foot for the beam alone, or $65 to $260 per foot when including installation. Besides steel, support beam materials include engineered beams like LVL or Glulam, wood, and concrete. LVL beams cost $3.90 to $15.60 per foot, while wood beams range from $6.50 to $26.

Builders may use multiple materials to create a custom beam that meets building code requirements. Steel beams are particularly popular due to their durability and fire resistance.

Engineered Beam Cost

An engineered beam costs between $3.90 and $44.20 per foot, depending on the size and type of composite structural lumber. Composite wood beams, made from multiple layers of wood bonded with strong adhesives, include Glulam and LVL beams, which are among the most popular types of engineered beams.

Engineered Beam Cost

Type | Cost Per Linear Foot |

LVL | $3.90 – $15.60 |

Glulam | $7.80 – $44.20 |

Engineered beams are stronger than standard lumber and often preferred over steel because they can be trimmed on-site to fit into irregularly shaped areas. In contrast, steel pieces must fit exactly, and resizing requires sending them back to the factory.

LVL Beams Cost

LVL beams typically cost between $3.90 and $15.60 per linear foot. These beams are more affordable and stronger than traditional wood beams, offering benefits such as fire resistance, shrink-proofing, and ease of installation in longer lengths.

“LVL” stands for laminated veneer lumber, a thick plank made from layers of thin plywood bonded together. Also known as “Microlam” or micro-laminated beams, LVL beams are a popular choice for various construction projects.

LVL Beams Cost

Size (Inches) | Cost Per Linear Foot |

1.75 x 7.25-11.25 | $3.90 – $6.50 |

1.75 x 14-24 | $7.80 – $14.30 |

3.5+ | $13.00 – $15.60 |

Glulam Beam Cost

Glulam beams typically cost between $7.80 and $44.20 per linear foot. “Glulam” stands for “glued laminated timber,” which consists of multiple thin layers of wood bonded together with strong adhesives. These engineered beams are extremely strong and highly customizable, even available in curved shapes for applications like vaulted ceilings.

Get Acquainted with House Construction

House Construction

House Construction

COMPLETE House Construction

90% More Chances to Win Projects With Our Estimate!

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- School & University Building

- High-Rise Building

- Shopping Complex

- Data Center Building

Glulam Beam Cost Estimator

Size (Inches) | Cost Per Linear Foot |

3 x 6-12 | $7.80 – $18.20 |

5 x 12-18 | $22.10 – $44.20 |

6.75 x 12 | $29.90 – $49.40 |

Wood Support Beams Cost

Wood support beams typically range from $6.50 to $39 per linear foot, with some exotic wood species costing between $39 and $117 per foot. The prices of wood I-beams primarily depend on the type of wood and the size of the beam. Lightweight softwoods are generally more affordable due to their greater availability, which significantly impacts cost.

Wood Support Beams Cost

Wood Type | Size (Inches) | Cost Per Linear Foot |

Softwood | 6 x 6 | $6.50 – $39 |

Softwood | 6 x 12 | $13 – $78 |

Softwood | 12 x 12 | $26 – $117 |

Hardwood | 4 x 2-19 | $11.70 – $23.40 |

Hardwood | 6 x 6 | $11.70 – $27.30 |

Hardwood | 6 x 12 | $24.70 – $42.90+ |

Softwoods – Light structural lumber, such as Spruce, Hemlock, Pine, Douglas Fir, and Cedar, is typically cheaper but has the lowest weight-bearing capacity of all beams. Builders may combine multiple softwood beams to create a custom beam, but this should only be done with approval from a structural engineer.

Hardwoods – Hardwoods, or heavy timber beams, are generally stronger, denser, and more fire-resistant than softwoods. Common hardwood species include Hickory, Oak, Maple, Mahogany, Walnut, and Teak.

Cost of Reclaimed Wood Beams

Reclaimed wood beams typically cost between $7.80 and $19.50 per linear foot for 6″ x 6″ beams, while 10″ x 10″ upcycled beams range from $58.50 to $78 per linear foot. The most common reclaimed wood beams are made from Hickory, Oak, and Maple, which can support greater loads and offer better fire resistance.

Concrete Beam Prices

Precast or prestressed concrete beams typically cost between $9.10 and $20.80 per linear foot. These beams are reinforced with rebar for added structural strength. For enhanced soundproofing, you can opt for “ICF” beams (Insulated Concrete Forms), which feature insulation foam surrounding the steel rebar frame and concrete.

Concrete Beam Prices

Size (Inches) | Cost Per Linear Foot |

12 x 6 | $9.10 – $10.40 |

12 x 12 | $18.20 – $20.80 |

Builders often create custom concrete beams by pouring concrete into handmade forms and then mounting the beams after the concrete has cured. Additionally, masons may construct concrete-block columns to support these beams, as they are stronger than wood posts and can be customized to any required size.

Steel Support Beams for Residential House Construction

In residential construction, steel support beams are commonly used in sizes ranging from 4″ to 6″ tall, up to 8″ wide, with lengths between 10′ and 20′. However, each home’s load-bearing structure is unique, and a larger support beam may be necessary to handle additional weight, especially in basements or multi-story homes.

Replacing Load-Bearing Wall with Steel Beam

The cost to remove a load-bearing wall and replace it with a steel beam typically ranges from $5,200 to $13,000. The final price depends on factors such as beam size, wall size, house structure, permits, inspections, beam transportation, preparation, labor, and finishing costs.

Installing a steel beam may require support columns, depending on the span, and could involve rerouting plumbing and electrical utilities after removing the wall. Hiring a structural engineer, which is essential for inspecting, designing, and sizing the new beam, costs between $390 and $1,300.

Cost to Install a Recessed Load-Bearing Beam

Installing a recessed steel beam generally costs between $221 and $585 per linear foot, or $2,600 to $10,400 on average. Hiding the beam costs more due to the ceiling modifications required. Prices vary based on the number of underpinnings and piers needed to support the beam’s weight.

LVL beams are typically more affordable than steel beams; however, steel beams take up less space and are easier to install within a ceiling. A more budget-friendly option could be painting the beam to blend with the ceiling or creating a decorative trim around it.

Extra Costs to Hide a Beam Include

- Modifying ceiling joists to accommodate the new beam

- Using temporary ceiling supports during installation

- Altering the attic or crawl space to fit the construction

- Adding new footings under the foundation

Replacing the Main Beam in a House Cost

The cost to replace the main beam in a house typically ranges from $9,100 to $32,500, depending on the beam’s length, the material used, and the job’s complexity. Replacing the main beam is a challenging and costly project since it bears a significant amount of weight and requires additional temporary supports.

The main beam supports the internal weight of the house, running across the foundation, usually near the top of the wall. This beam is held up by one or several support posts known as jack posts or lally columns.

Replacing Support Beams in Basement Cost

Replacing support beams in a basement costs between $8,450 and $13,000 for a straightforward installation, and can reach $19,500 to $32,500 for more complex jobs involving numerous load-bearing walls or long spans. Basement beam replacement requires an inspection and detailed design plans by a structural engineer.

Basement Beam Replacement Process

- Reinforcing foundation footings if needed to handle the extra weight when switching to a steel beam.

- Installing stronger temporary support walls.

- Removing and disposing of the old beam.

- Relocating HVAC ductwork.

- Installing the new beam.

- Refinishing the walls or ceiling.

Replacing Support Beam in Crawl Space Cost

The cost to replace a support beam in a crawl space typically ranges from $1,950 to $5,200, depending on factors like accessibility, beam size and type, and the condition of the foundation. Crawl spaces are often only 1′ to 3′ deep, which increases the complexity and labor required for the job.

Cost to Expose Ceiling Beams

Exposing ceiling beams generally costs between $260 and $585 to remove and dispose of drywall from an average 350-square-foot ceiling. Additional costs may apply for refinishing the exposed rafters or rerouting any electrical lines. This is different from creating an exposed vaulted ceiling, which can range from $19,500 to $32,500.

If exposing your ceiling beams isn’t feasible, another option is to install hollow faux wooden beams under your ceiling, costing between $182 and $364 each.

Types of Steel Support Beams

Steel beams come in two primary designs: the I-beam and the H-beam. I-beams are the most common choice for residential construction, available in lengths up to 100 feet. H-beams are heavier and stronger, capable of supporting spans up to 300 feet, but they are more expensive per foot.

Understanding Steel Beam Names

- The first letter indicates the shape of the beam.

- The first number represents the beam’s height in inches.

- The second number denotes the beam’s weight per linear foot.

I-Beams / S-Beams

I-beams, also known as S-beams, cost between $7.80 and $23.40 per linear foot and weigh 6 to 12 pounds per foot. These beams are commonly used in residential construction due to their lightweight design and ability to support spans up to 96 feet. I-beams are often used to reinforce a house’s foundation and are also referred to as Junior beams.

I-beams typically have tapered edges and a longer beam height compared to their flange width (the width of the flat side or base). Unlike H-beams, I-beams are not suitable for use as columns because they only support weight in one direction.

Subtypes of I-Beams

- S-beams: The “S” stands for the rounded inside corners of certain types of I-beams, which resemble a C channel. Some suppliers refer to I-beams as “American Standard Steel Beams.”

- RSJ-beams: RSJ stands for “rolled steel joist,” meaning they are often made by rolling a single piece of steel into the final shape. RSJ beams are priced similarly to I-beams.

H-Beams / W-Beams

H-beams, also known as W-beams, cost between $14.30 and $20.80 per linear foot and are stronger than I-beams, though they weigh more at 13 to 15 pounds per foot. Due to their superior weight-bearing capacity, H-beams are ideal for columns and longer beam spans, supporting lengths of up to 300 feet.

The most common H-beams have extra-wide flanges or bases and are more square-shaped, with nearly equal height and width dimensions. These beams are typically used in large houses, deep foundations, or for framing commercial buildings where significant strength and stability are required.

Steel I-Beam Installation Cost Factors

Installing a steel I-beam is a significant project that involves various cost factors, each of which can influence the overall budget considerably. Understanding these factors is essential to planning and managing the project effectively, ensuring that all necessary elements are accounted for in your financial planning.

Size

Steel I-beams are a popular choice for structural support due to their ability to carry substantial weight while maintaining a relatively slim profile, making them ideal for many residential and commercial projects. The cost of installing steel I-beams generally ranges from $130 to $520 per square foot, including both labor and materials. However, if you have the necessary skills, time, and the project falls within the legal parameters for DIY work, purchasing just the materials can help reduce overall costs. For instance, a 10-foot steel I-beam typically costs between $78 and $234, while a 40-foot beam can range from $312 to $936. The exact cost will depend on the beam’s size, weight, and the specific requirements of your project, such as additional supports or customizations.

Steel I-Beam Size | Average Cost |

10 feet | $78 – $234 |

40 feet | $312 – $936 |

Structural Engineer Assessment

Given the complexity and importance of correctly installing a steel I-beam, ensuring the safety and stability of the structure is critical. In addition to the costs associated with the beam and its installation, hiring a structural engineer for an assessment is an essential step. This service typically costs between $520 and $780. A structural engineer will evaluate your home’s existing structure and provide precise calculations and recommendations for the type and size of beam required to safely bear the load. Bob Tschudi, a respected member of the Angi Expert Review Board and a general contractor in Raleigh, NC, advises against making structural changes without a licensed structural engineer’s review. He notes that such professionals not only ensure that the new framing is secure but can also offer valuable insights and alternative solutions that other contractors might not consider.

Permits

Obtaining the necessary permits is a crucial part of any construction project, especially when it involves significant structural changes like replacing a wall with a supporting beam. Permit costs can vary widely, ranging from $195 to $2,600, depending on your location and the specific requirements of your local building codes. It’s important to contact your local construction and inspections office to determine the exact permits you’ll need for your project. Additionally, if your project involves relocating plumbing or electrical systems, you may need additional permits, which can add to the overall cost. The fees for an architect or structural engineer often include ensuring that your structure has the appropriate strength to support the added weight. Skipping this step could result in structural failure or collapse, posing serious risks to your home and its occupants.

Labor

Labor is a significant portion of the cost when installing a steel I-beam, and hiring a local structural engineer is a crucial part of the process. Structural engineers typically charge between 1% and 20% of your overall project cost, with the national average being around $3,900. The cost of labor will depend on various factors, including the complexity of the project, the beam’s location, and the accessibility of the work areas. For example, installing a beam in an open, easily accessible space will generally be less expensive than in a cramped or hard-to-reach area. Additionally, labor costs can increase if the project requires specialized equipment or additional steps, such as reinforcing existing structures or rerouting utilities.

Delivery Costs

Delivery fees are another important cost factor to consider when installing a steel I-beam. While these fees are often included in the contractor’s flat estimate, they typically range from $104 to $520. Delivery costs can vary based on factors such as the distance from the supplier, the weight of the beam, and the accessibility of your property. If you live in a remote area or in a location with limited access, such as a mountainous region or a dense urban environment, these fees may be higher. Additionally, if there is a low local supply of steel beams, delivery costs may increase due to the need for long-distance shipping or special arrangements to transport the beam to your site. These factors should be considered when planning your budget, as they can significantly impact the overall cost of your project.

Cost of Common Steel I-Beam Installation Add-Ons

Installing a steel I-beam typically involves additional work to ensure your home’s structure is properly supported, which can significantly increase the overall installation cost. Various fixtures and structural elements may need to be addressed before or during the I-beam installation to ensure everything is done safely and up to code.

Remove a Wall

Before installing a steel I-beam, you may need to remove an existing wall, especially if it’s being replaced by the beam for support. It’s crucial to determine whether the wall is load-bearing before removal, as removing a weight-bearing wall can cost anywhere from $1,300 to $13,000. This cost includes safely dismantling the wall, reinforcing the structure, and preparing the space for the new beam.

Relocating Gas Lines

If your project involves constructing a new wall or performing pier-and-beam foundation repairs, you might encounter gas lines that need to be relocated. This is a delicate task that only a specialized contractor should handle. The cost to hire a professional to move gas lines typically ranges from $325 to $975, depending on the length of the pipe and the complexity of the relocation.

Relocating Plumbing

If you’re redesigning a kitchen, bathroom, or basement, moving plumbing lines might be necessary. The cost to relocate plumbing pipes usually ranges between $468 and $2,600, depending on the type and complexity of the plumbing involved. For instance, moving a washer and dryer hookup can cost up to $2,600 on average, particularly if the relocation requires extensive piping work or modifications to existing plumbing systems.

Removing Asbestos

In older homes, asbestos may be present in walls, insulation, or other building materials, posing a significant health risk. If asbestos is detected, it must be removed before any structural work can proceed. The cost of asbestos removal typically ranges from $1,560 to $4,160, depending on the extent of the contamination and the area that needs to be cleared. It’s essential to have the area professionally inspected for asbestos before disturbing old insulation or other materials.

Installing a New Ceiling

Making structural changes, such as removing walls or installing a steel I-beam, can also impact the adjacent ceiling. Ceiling repairs can range from $58.50 to $117 per square foot, while replacing drywall typically costs between $58.50 and $71.50 per square foot. Additionally, you may need to install new ceiling beams or roof joists to accommodate the new steel I-beam, adding to the overall project cost.

Adding Foundational Piers

If your home’s foundation requires additional support, or if you’re constructing a pier-and-beam foundation, installing I-beam foundation piers may be necessary. The cost of adding foundation piers typically ranges from $2,600 to $5,200 per pier, including labor. This expense ensures that the foundation is stable and capable of supporting the weight and structure of the new steel I-beam.

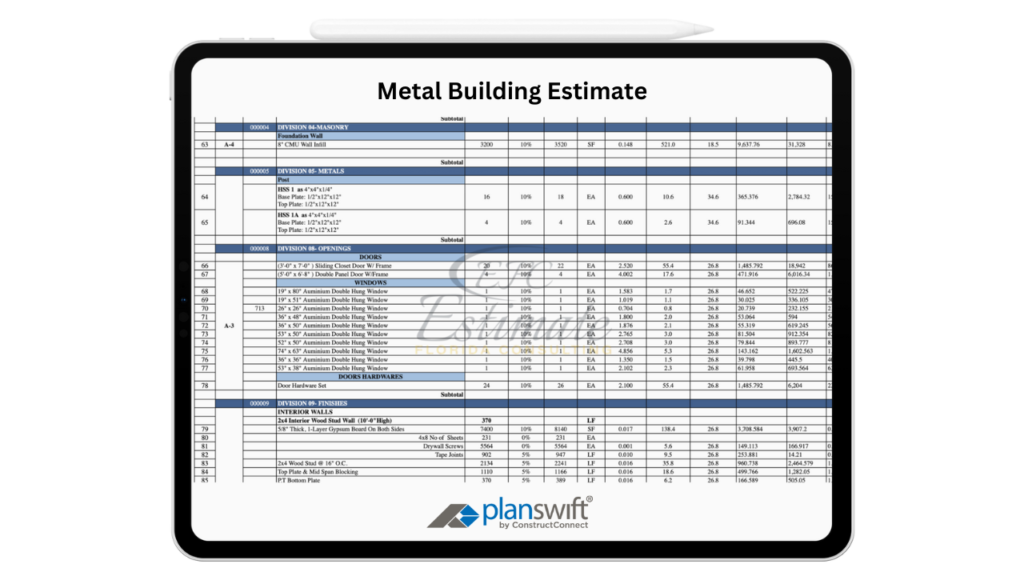

Download Template For Metal Building Project Breakdown

- Materials list updated to the zip code

- Fast delivery

- Data base of general contractors and sub-contractors

- Local estimators

Hiring a Structural Engineer & General Contractor

When installing a new beam, it’s crucial to hire a qualified general contractor—this is not a DIY project. Improper installation can lead to severe structural damage to your home. Professionals assess your home’s structure, determine the appropriate beam type, manage permits, and ensure the job is done correctly.

Start by having a structural engineer or architect inspect your property to recommend the right beam type and size. Afterward, a general contractor can provide an accurate quote. Contractors must adhere to the engineer or architect’s guidelines to comply with building codes.

Tips for Hiring a Contractor

- Obtain at least three estimates for comparison.

- Read reviews and check out previous work on HomeGuide, Google, and other platforms.

- Choose licensed, bonded, and insured companies with at least 5 years of experience.

- Always get estimates in person, and be wary of unusually low bids.

- Schedule payments in advance, and never pay the full amount upfront.

- Get a written copy of your contract and warranty before work begins.

Questions to Ask

- Are you bonded, licensed, and insured?

- How many years have you been in business?

- Can you provide references from recent customers with contact information?

- Is prep work and cleanup included in your bid?

- Do you offer a warranty? If so, what does it cover?

- How much of a down payment is required?

- Will you be using subcontractors?

- When can you start and finish the project?

Conclusion

Installing a steel I-beam is a significant investment, with costs typically ranging from $130 to $520 per foot, translating to an average total of $1,560 to $5,460. Factors influencing the cost include the complexity of the project, beam size, and additional structural work, such as removing load-bearing walls, which can cost between $5,200 and $13,000. Steel I-beams offer superior strength and durability, making them a preferred choice for residential construction. However, the installation process requires careful planning, including hiring a structural engineer and securing permits, to ensure the stability and safety of your home.

Frequently Asked Question

The cost to install a steel I-beam typically ranges from $130 to $520 per foot, with total project costs averaging between $1,560 and $5,460. For more complex installations, costs can rise to $650 per foot, or $7,800 to $13,000.

Key factors influencing the cost include the size and weight of the beam, complexity of the project, need for additional supports, labor costs, and permit fees. Delivery and installation conditions, such as accessibility and location, also impact the final price.

Replacing a load-bearing wall with a steel beam typically costs between $5,200 and $13,000. The final price depends on the beam size, structural requirements, and any additional work like rerouting utilities or adding support columns.

Steel I-beams generally cost between $7.80 and $23.40 per foot, depending on the size and weight. H-beams, which offer greater strength, range from $14.30 to $104 per foot.

Yes, hiring a structural engineer is essential for safe installation. The cost for an assessment typically ranges from $390 to $1,300. The engineer evaluates your home’s structure and recommends the appropriate beam size and type.

Additional costs can include permit fees ($195 to $2,600), labor costs, delivery fees ($104 to $520+), and potential expenses for removing existing walls, relocating utilities, or asbestos removal.

Replacing support beams in a basement can cost between $8,450 and $13,000 for straightforward installations, with more complex jobs costing up to $32,500.

Steel beams generally cost more than wood or LVL beams, with prices ranging from $7.80 to $23.40 per foot for steel, compared to $3.90 to $15.60 per foot for LVL beams. However, steel offers superior strength and durability.

Yes, steel beams can be customized based on the specific needs of your project, including size, weight, and additional features like galvanized coatings or custom lengths. Customization may increase the overall cost.

To hire the right contractor, obtain at least three estimates, check reviews and references, ensure the contractor is licensed and insured, and clarify all project details, including warranties and payment schedules, before work begins.

Comprehensive Trade-Specific Estimates

At Estimate Florida Consulting, we offer detailed cost estimates across all major trades, ensuring no part of your project is overlooked. From the foundation to the finishing touches, our trade-specific estimates provide you with a complete and accurate breakdown of costs for any type of construction project.

Testimonials

What Our Clients Say

We take pride in delivering accurate, timely, and reliable estimates that help contractors and builders win more projects. Our clients consistently praise our attention to detail, fast turnaround times, and the positive impact our estimates have on their businesses.

Estimate Florida Consulting has helped us win more bids with their fast and accurate estimates. We trust them for every project!

Steps to Follow

Our Simple Process to Get Your Estimate

01

Upload Plans

Submit your project plans, blueprints, or relevant documents through our online form or via email.

02

Receive Quotation

We’ll review your project details and send you a quote based on your scope and requirements.

03

Confirmation

Confirm the details and finalize any adjustments to ensure the estimate meets your project needs.

04

Get Estimate

Receive your detailed, trade-specific estimate within 1-2 business days, ready for your project execution.