How Much Does It Cost to Frame a 1,200 Sq Ft House?

Framing is one of the most critical steps in constructing a house, forming the structural skeleton that supports the walls, roof, and floors. Without proper framing, the stability and durability of the house can be compromised. The framing process involves using lumber, fasteners, and other materials to create the basic structure, including walls, floors, and roof supports. The cost to frame a house can vary widely based on factors such as materials, labor, design complexity, and location. Understanding these costs is essential for effective budgeting and planning.

This guide will provide a detailed cost breakdown, discuss the factors influencing framing costs, and offer tips for managing your framing project efficiently. With a comprehensive understanding of these elements, you can ensure your project is both successful and financially viable, resulting in a well-constructed home that stands the test of time.

Average Cost Breakdown

The cost to frame a 1,200 sq ft house typically ranges from $42.28 to $75.46 per square foot. This translates to a total cost range of $50,736 to $90,552. Here’s a more detailed cost breakdown:

Cost Breakdown by Component

Component | Cost per Square Foot (in dollars) | Total Cost (in dollars) |

Lumber and Materials | $19.60 – $29.40 | $23,520 – $35,280 |

Labor | $17.64 – $33.32 | $21,168 – $39,984 |

Additional Costs | $5.04 – $12.74 | $6,048 – $15,288 |

Detailed Cost Breakdown

Lumber and Materials

The cost of lumber and materials forms a significant portion of the framing budget. The type of lumber (e.g., softwood vs. hardwood), the quality, and the amount needed all affect the total cost. Additional materials may include nails, screws, brackets, and other hardware. Choosing the right materials is crucial for the durability and safety of the house. High-quality materials ensure that the frame is strong enough to support the structure and withstand various stresses over time, such as wind, snow, and earthquakes. Investing in quality materials can also prevent issues like warping or termite damage, which can lead to costly repairs down the line.

Breakdown of Lumber and Materials Costs

Component | Cost per Square Foot (in dollars) | Total Cost (in dollars) |

Softwood Lumber | $14.28 – $19.60 | $17,136 – $23,520 |

Hardwood Lumber | $19.60 – $29.40 | $23,520 – $35,280 |

Hardware and Fasteners | $5.04 – $7.14 | $6,048 – $8,568 |

Softwood lumber is generally less expensive and commonly used for most residential framing projects. Hardwood lumber, while more costly, is chosen for its durability and strength, often used in specific structural components. The choice between these materials can impact not only the initial cost but also the long-term maintenance and resilience of the structure. Ensuring high-quality materials are used can prevent future issues and contribute to the longevity of the house, reducing the need for costly repairs or reinforcements in the future. Additionally, using engineered wood products like laminated veneer lumber (LVL) can provide added strength and stability, although they may come at a higher initial cost.

Labor

Labor costs can vary significantly based on the complexity of the design, the experience of the framers, and local labor rates. Experienced framers may charge more, but their efficiency and quality of work can be worth the investment. Proper framing is crucial for the structural integrity of the house, so it’s essential to hire skilled labor. Skilled framers ensure that the structure is built accurately and according to design specifications, reducing the risk of structural failures or the need for rework. High-quality workmanship can also speed up the construction process, minimizing delays and ensuring that the project stays on schedule.

Breakdown of Labor Costs

Labor Task | Cost per Square Foot (in dollars) | Total Cost (in dollars) |

Basic Framing | $14.28 – $21.56 | $17,136 – $25,872 |

Complex Framing | $21.56 – $33.32 | $25,872 – $39,984 |

Basic framing involves straightforward designs with minimal complexities, while complex framing includes intricate architectural details, multiple angles, and additional structural elements. Complex designs require more time and expertise, leading to higher labor costs. However, the investment in skilled labor ensures the house is built to high standards, minimizing future issues. Skilled labor also contributes to faster project completion, which can save money in the long run by reducing overall project duration and associated costs. It’s important to consider that while hiring cheaper, less experienced labor might save money initially, it could lead to higher costs in the future due to potential errors and the need for corrections.

Additional Costs

Additional costs can include permits, waste disposal, and transportation of materials. These costs can add up and should be factored into the overall budget. Proper planning for these expenses ensures a smooth construction process and compliance with local regulations. Each of these costs plays a vital role in ensuring that the construction process is legal, efficient, and environmentally responsible. For example, permits and inspections are necessary to ensure that the construction adheres to local building codes, which can prevent future legal issues and ensure the safety of the structure.

Breakdown of Additional Costs

Additional Costs | Cost per Square Foot (in dollars) | Total Cost (in dollars) |

Permits and Inspections | $2.52 – $5.04 | $3,024 – $6,048 |

Waste Disposal | $1.26 – $2.52 | $1,512 – $3,024 |

Transportation | $1.26 – $5.04 | $1,512 – $6,048 |

Permits and inspections ensure compliance with local building codes, while waste disposal covers the cost of removing construction debris. Transportation costs include delivering materials to the construction site. These additional costs are essential for the project’s overall success and compliance with local regulations. Permits and inspections are crucial for ensuring that the construction meets safety standards, while proper waste disposal is important for maintaining a clean and safe work environment. Transportation costs can vary based on the distance and accessibility of the construction site, impacting the overall project timeline and budget. It’s important to account for these costs early in the planning process to avoid surprises and ensure the project stays within budget.

Additional Cost Details

Structural Components

In addition to basic lumber and fasteners, framing requires specific structural components like beams and headers. These components provide critical support and add to the overall stability of the house. Beams and headers are used to support loads above doorways, windows, and other openings, ensuring that the structure can bear weight without compromising stability.

Breakdown of Structural Component Costs

Component | Cost per Square Foot (in dollars) | Total Cost (in dollars) |

Beams and Headers | $3.50 – $5.60 | $4,200 – $6,720 |

Joists | $2.80 – $4.20 | $3,360 – $5,040 |

Sheathing | $2.10 – $3.50 | $2,520 – $4,200 |

Using high-quality structural components is crucial for the overall safety and longevity of the house. Beams and headers, for example, must be capable of supporting significant loads, and using substandard materials can lead to structural failures. Joists are used to support floors and ceilings, while sheathing provides a solid surface to which exterior materials can be attached. Investing in quality structural components ensures that the house remains sturdy and safe over the long term.

90% More Chances to Win Projects With Our Estimate!

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- School & University Building

- High-Rise Building

- Shopping Complex

- Data Center Building

Tools and Equipment

Framing also requires specific tools and equipment, which can add to the cost if not already owned by the contractor or included in their service fees. The right tools are essential for ensuring precision and efficiency in the framing process, reducing the likelihood of errors and rework.

Breakdown of Tools and Equipment Costs

Equipment | Estimated Cost (in dollars) |

Nail Guns and Compressors | $2,100 – $4,200 |

Saws and Cutting Tools | $1,400 – $2,800 |

Safety Gear | $700 – $1,400 |

Investing in proper tools and equipment is essential for a successful framing project. Nail guns and compressors, for example, can significantly speed up the framing process and ensure that nails are driven in securely and accurately. Saws and cutting tools are necessary for cutting lumber to the correct sizes and shapes, while safety gear helps protect workers from injuries. While these costs may seem high, they are necessary for ensuring that the framing process is efficient, safe, and precise.

Factors Influencing Framing Costs

Material Choice

The type of lumber used significantly impacts the cost. Softwood is generally less expensive than hardwood. However, hardwood may be chosen for its durability and aesthetic appeal, despite the higher cost. Engineered wood products, such as LVL (laminated veneer lumber) or glulam beams, can also affect costs. These materials offer increased strength and stability but come at a higher price. The choice of materials affects not only the initial cost but also the long-term maintenance and durability of the structure. High-quality materials can reduce the need for future repairs and provide better resistance against environmental factors.

Design Complexity

The complexity of the house design affects labor costs. Simple rectangular houses are easier and faster to frame, while houses with multiple corners, angles, and intricate architectural details require more time and skill, increasing labor costs. Complex designs may also require additional materials, such as custom-cut lumber or specialized fasteners. The complexity of the design can significantly impact both the timeline and cost of the project. Detailed and unique architectural features can enhance the aesthetic appeal and functionality of the house but also add to the construction challenges and expenses.

Location

Location influences both material and labor costs. Urban areas with higher living costs typically have higher labor rates. Additionally, the availability of materials can affect costs; regions far from lumber mills may incur higher transportation fees. Local building codes and regulations can also impact costs, as more stringent requirements may necessitate additional materials or labor. The location of the project can also affect the ease of access for workers and materials, influencing overall costs. Proximity to suppliers and local labor markets can also affect the availability and cost of materials and skilled labor.

Labor Availability and Skill

The availability and skill level of local labor can impact framing costs. Highly skilled framers may charge more per hour but can complete the job more quickly and to a higher standard. In contrast, areas with a labor shortage may see increased costs due to higher demand. Ensuring that the chosen framers have experience with similar projects can help avoid costly mistakes and delays. The quality of labor directly affects the structural integrity and safety of the house. Hiring skilled and experienced framers ensures that the construction process is efficient and meets high standards of quality and safety.

Permits and Regulations

Local building codes and regulations can affect framing costs. Obtaining the necessary permits and ensuring compliance with local codes may add to the overall cost. Inspections are also required at various stages to ensure the framing is up to code. Non-compliance can result in fines or required modifications, further increasing costs. Adhering to local regulations ensures the project progresses smoothly and legally. Compliance with building codes and regulations is essential for the safety and legality of the construction project, preventing future legal and financial issues.

Tips for Managing Framing Costs

Plan and Budget Carefully

Developing a detailed plan and budget before starting the framing process is essential. Consider all potential costs, including materials, labor, permits, and additional expenses. A comprehensive budget can help avoid unexpected expenses and keep the project on track. Including a contingency fund for unforeseen issues can provide financial flexibility. A well-thought-out budget ensures that all aspects of the project are considered and accounted for. Detailed planning helps prevent overspending and ensures that resources are allocated efficiently throughout the project.

Choose the Right Contractor

Selecting a reputable and experienced framing contractor can make a significant difference in managing costs. Obtain multiple quotes, check references, and ensure the contractor has experience with similar projects. A reliable contractor can help identify cost-saving opportunities and manage the project efficiently. Contracts should clearly outline the scope of work, timelines, and payment schedules to avoid misunderstandings. Choosing the right contractor ensures high-quality work and efficient project management. A skilled contractor can also provide valuable insights and recommendations for optimizing the framing process and controlling costs.

Opt for Standard Designs

Using standard designs and materials can help reduce costs. Custom designs and high-end materials can quickly increase the budget. Working with an architect or designer to develop a cost-effective yet functional design can help manage expenses. Simplifying the design can reduce the need for custom materials and specialized labor, making the project more budget-friendly. Standard designs often benefit from streamlined construction processes and readily available materials. Opting for standard designs can also expedite the construction process, reducing labor costs and minimizing potential delays.

Monitor the Project Closely

Regularly monitoring the framing project can help identify and address any issues promptly. Staying involved in the project ensures that it stays on schedule and within budget. Regular site visits and progress meetings with the contractor can help keep the project on track. Clear communication between all parties involved can prevent delays and ensure that any changes are managed efficiently. Close monitoring allows for proactive problem-solving and ensures the project meets the expected quality standards. Effective oversight helps ensure that the construction adheres to the planned schedule and budget, preventing costly overruns.

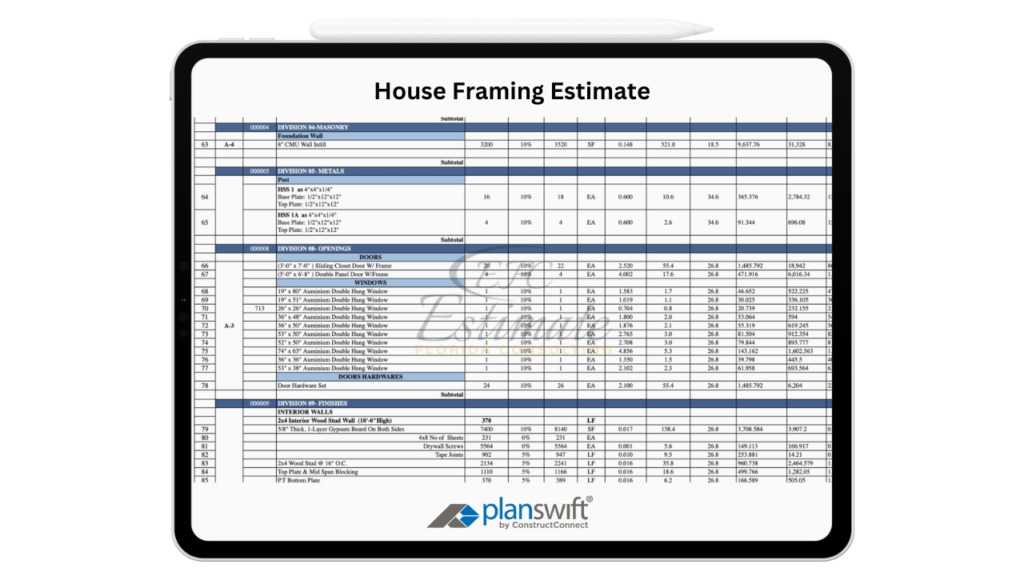

Download Template For House Framing Project Breakdown

- Materials list updated to the zip code

- Fast delivery

- Data base of general contractors and sub-contractors

- Local estimators

Plan for Contingencies

Including a contingency budget of 10-20% of the total framing cost can help cover unexpected expenses. This ensures that you are prepared for any unforeseen issues that may arise during the framing process, such as discovering existing structural issues that need to be addressed. Having a contingency plan can prevent project delays and financial strain. A contingency budget provides a financial cushion to handle surprises without derailing the project. Being prepared for contingencies ensures that the project can continue smoothly even when unexpected challenges occur.

Conclusion

Framing a 1,200 sq ft house is a significant investment that requires careful planning and budgeting. By understanding the various costs involved and the factors that influence these costs, you can make informed decisions and ensure the success of your framing project. Investing in high-quality materials, working with experienced professionals, and planning for contingencies can ensure a successful and cost-effective framing process. Whether you’re building your dream home or expanding your real estate portfolio, careful planning and management are key to framing a house that meets your needs and budget. With proper oversight and strategic planning, you can achieve a well-framed structure that forms the foundation for a beautiful and durable home. Effective management of the framing process ensures the house is safe, sturdy, and built to last, providing a solid foundation for your future living space.

FAQs

The cost typically ranges from $42.28 to $75.46 per square foot, translating to a total of $50,736 to $90,552. These costs can vary depending on materials used, labor rates, and design complexity.

The major components include lumber and materials, labor, and additional costs such as permits, waste disposal, and transportation. Each component plays a crucial role in the overall framing process and impacts the total cost.

Lumber and materials cost between $19.60 and $29.40 per square foot, totaling $23,520 to $35,280. The type and quality of lumber (e.g., softwood vs. hardwood) and additional hardware like nails and brackets influence these costs.

Factors include the type of lumber (softwood is cheaper, hardwood is more durable and aesthetically appealing), quality of materials, and additional hardware requirements. The availability of materials and proximity to suppliers also affect costs.

Labor costs range from $17.64 to $33.32 per square foot, resulting in a total of $21,168 to $39,984. These costs depend on the complexity of the house design, the experience of the framers, and local labor rates.

Labor costs are influenced by the complexity of the design, the experience and skill level of the framers, and the local labor market rates. Experienced framers may charge more but often provide higher quality work and greater efficiency.

Additional costs include permits and inspections, waste disposal, and transportation of materials. These costs range from $5.04 to $12.74 per square foot, totaling $6,048 to $15,288.

Permits and inspections ensure compliance with local building codes and add $2.52 to $5.04 per square foot, or $3,024 to $6,048 in total. These costs cover application fees and inspection costs at various stages of construction.

Proper waste disposal of construction debris is essential and costs $1.26 to $2.52 per square foot, or $1,512 to $3,024 in total. This includes removing scrap materials and the safe disposal of any hazardous waste.

Transportation of materials to the construction site costs $1.26 to $5.04 per square foot, totaling $1,512 to $6,048. These costs depend on the distance from suppliers to the site and the ease of access.

Specific structural components like beams and headers, joists, and sheathing are required, adding to the overall cost. These components provide critical support and add to the overall stability of the house.

Google Reviews

Process To Get House Framing Cost Estimate Report

Here I am going to share some steps to get hous framing cost estimate report.

-

You need to send your plan to us.

You can send us your plan on info@estimatorflorida.com

-

You receive a quote for your project.

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

-

Get Estimate Report

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.