How Much Does It Cost to Build a 30,000 Sq Ft Warehouse?

Building a warehouse is a significant investment that requires careful planning and budgeting. Warehouses serve as essential facilities for storage, distribution, and manufacturing, making them critical components of many businesses. Whether you’re expanding your business operations or starting a new venture, understanding the costs involved in constructing a 30,000-square-foot warehouse is crucial. This guide will provide a detailed cost breakdown, discuss the factors that influence these costs, and offer tips for managing your warehouse construction project effectively. By having a comprehensive understanding of these elements, you can ensure your project is both successful and financially viable.

Average Cost Breakdown

The cost to build a 30,000 sq ft warehouse can vary widely depending on several factors, including location, design, materials, and labor. On average, you can expect to pay between $50.70 and $130 per square foot. This translates to a total cost range of $1,521,000 to $3,900,000. Here’s a more detailed cost breakdown:

Construction Costs

Component | Cost per Square Foot (in dollars) | Total Cost (in dollars) |

Basic Shell Construction | $50.70 – $84.50 | $1,521,000 – $2,535,000 |

Interior Build-Out | $26 – $65 | $780,000 – $1,950,000 |

HVAC Installation | $6.50 – $13 | $195,000 – $390,000 |

Electrical and Plumbing | $6.50 – $19.50 | $195,000 – $585,000 |

Site Preparation and Grading | $2.60 – $6.50 | $78,000 – $195,000 |

Permits and Inspections | $1.30 – $3.90 | $39,000 – $117,000 |

Detailed Cost Breakdown

Basic Shell Construction

The basic shell construction includes the foundation, walls, roof, and structural framework of the warehouse. This is often the most significant portion of the budget and includes materials such as steel or concrete and the labor required for assembly. The choice between steel and concrete can affect not only the initial costs but also long-term maintenance and durability. Steel structures, for instance, offer flexibility and quicker construction times, while concrete structures provide excellent insulation and fire resistance.

Component | Cost per Square Foot (in dollars) | Total Cost (in dollars) |

Foundation | $10.14 – $16.90 | $304,200 – $507,000 |

Steel Frame | $16.90 – $33.80 | $507,000 – $1,014,000 |

Roofing | $8.45 – $16.90 | $253,500 – $507,000 |

Exterior Walls | $8.45 – $16.90 | $253,500 – $507,000 |

Interior Build-Out

The interior build-out includes finishes, office spaces, restrooms, and any other interior features necessary for the warehouse’s operation. The complexity and quality of the interior build-out can significantly influence the cost. Higher-end finishes and more complex layouts will drive up costs, whereas basic finishes and simpler layouts will be more cost-effective.

Component | Cost per Square Foot (in dollars) | Total Cost (in dollars) |

Office Spaces | $13 – $26 | $390,000 – $780,000 |

Restrooms | $2.60 – $6.50 | $78,000 – $195,000 |

Flooring | $6.50 – $13 | $195,000 – $390,000 |

Lighting | $3.90 – $6.50 | $117,000 – $195,000 |

HVAC Installation

Heating, ventilation, and air conditioning (HVAC) systems are crucial for maintaining a suitable working environment. The cost can vary based on the size of the system and the specific requirements of the warehouse. For instance, warehouses requiring temperature control for sensitive goods will need more sophisticated and thus more expensive HVAC systems. Proper HVAC systems not only ensure a comfortable working environment but also protect stored goods from extreme temperatures and humidity.

Component | Cost per Square Foot (in dollars) | Total Cost (in dollars) |

HVAC System | $6.50 – $13 | $195,000 – $390,000 |

Electrical and Plumbing

Electrical and plumbing systems are essential for the functionality of the warehouse. Costs can vary depending on the complexity of the systems and the specific needs of the warehouse. For example, a warehouse with extensive automation systems or specialized machinery will have higher electrical costs. Similarly, warehouses that require extensive plumbing for restrooms or specialized processes will incur higher costs.

Component | Cost per Square Foot (in dollars) | Total Cost (in dollars) |

Electrical Systems | $3.90 – $10.40 | $117,000 – $312,000 |

Plumbing Systems | $2.60 – $9.10 | $78,000 – $273,000 |

Site Preparation and Grading

Preparing the site for construction includes clearing the land, grading, and ensuring proper drainage. These initial steps are crucial for a stable foundation and can vary based on the condition of the land. Difficult terrain or previously developed land may require more extensive preparation, increasing costs. Proper site preparation is essential to prevent future structural issues and to ensure a smooth construction process.

Component | Cost per Square Foot (in dollars) | Total Cost (in dollars) |

Site Preparation | $2.60 – $6.50 | $78,000 – $195,000 |

Permits and Inspections

Permits and inspections are required to ensure that the construction meets local building codes and regulations. These costs can vary depending on the location and the complexity of the project. The permitting process may involve multiple stages and various inspections to ensure compliance with all relevant regulations. Timely and thorough inspections help avoid future compliance issues and ensure the safety and functionality of the warehouse.

Component | Cost per Square Foot (in dollars) | Total Cost (in dollars) |

Permits | $0.65 – $1.95 | $19,500 – $58,500 |

Inspections | $0.65 – $1.95 | $19,500 – $58,500 |

90% More Chances to Win Projects With Our Estimate!

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- School & University Building

- High-Rise Building

- Shopping Complex

- Data Center Building

Factors Influencing Warehouse Construction Costs

Location

The location of the warehouse can significantly impact construction costs. Urban areas with higher land prices and stricter building codes can increase costs, while rural areas may offer lower land costs but higher transportation expenses. Additionally, local labor rates and availability can affect the overall budget. Proximity to suppliers, transportation hubs, and target markets can also influence operational costs and efficiency, making location a critical consideration.

Design and Materials

The design and materials used for the warehouse play a crucial role in determining the cost. Custom designs and high-quality materials, such as reinforced steel or specialized roofing, can drive up costs. Conversely, opting for a more standardized design and cost-effective materials can help manage the budget. The choice of materials also impacts the durability, maintenance needs, and energy efficiency of the building, affecting long-term costs.

Size and Layout

The size and layout of the warehouse can also influence costs. Larger warehouses with complex layouts, multiple levels, or specialized areas (such as temperature-controlled sections) will require more materials and labor, increasing the overall cost. Efficient space utilization can optimize operational workflows and storage capacity, affecting the warehouse’s functionality and profitability.

Labor Costs

Labor costs vary depending on the location and the availability of skilled workers. Areas with a high demand for construction services may see increased labor costs. Additionally, the complexity of the project and the required expertise can impact labor expenses. Skilled labor ensures high-quality construction, reducing the risk of future repairs and maintenance issues.

Additional Features

Additional features, such as advanced security systems, automated racking systems, or specialized loading docks, can add to the overall cost. These features can enhance the functionality and efficiency of the warehouse but should be considered in the initial budget planning.

Investing in advanced features can improve operational efficiency, reduce labor costs, and enhance the safety and security of the facility.

Tips for Managing Warehouse Construction Costs

Plan and Budget Carefully

Developing a detailed plan and budget before starting construction is essential. Consider all potential costs, including site preparation, materials, labor, and additional features. Having a comprehensive budget can help avoid unexpected expenses and ensure the project stays on track. Involving key stakeholders in the planning process can provide valuable insights and ensure all requirements are considered.

Choose the Right Contractor

Selecting a reputable and experienced contractor can make a significant difference in managing costs. Obtain multiple quotes, check references, and ensure the contractor has experience with warehouse construction. A reliable contractor can help identify cost-saving opportunities and manage the project efficiently. Collaborating with a knowledgeable contractor can ensure high-quality construction and adherence to the project timeline and budget.

Opt for Standard Designs

Using standard designs and materials can help reduce costs. Custom designs and high-end materials can quickly increase the budget. Working with an architect or designer to develop a cost-effective yet functional design can help manage expenses. Standard designs often benefit from streamlined construction processes and readily available materials, reducing delays and costs.

Monitor the Project Closely

Regularly monitoring the construction project can help identify and address any issues promptly. Staying involved in the project ensures that it stays on schedule and within budget. Regular site visits and progress meetings with the contractor can help keep the project on track. Effective communication with the construction team can prevent misunderstandings and ensure that any adjustments are made swiftly.

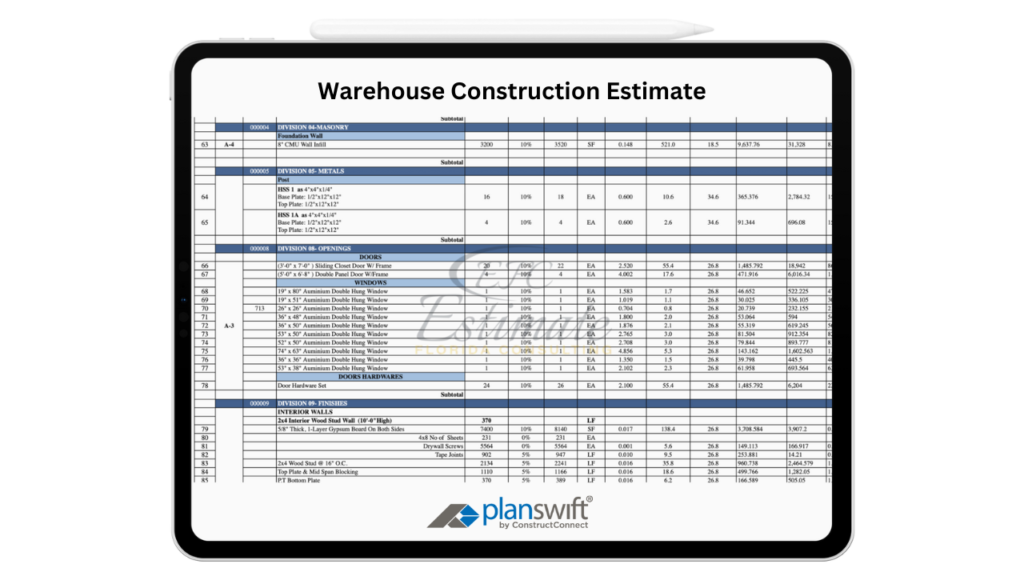

Download Template For Warehouse Construction Project Breakdown

- Materials list updated to the zip code

- Fast delivery

- Data base of general contractors and sub-contractors

- Local estimators

Plan for Future Expansion

If you anticipate future growth, consider designing the warehouse with expansion in mind. Planning for future expansion during the initial construction can save money compared to retrofitting or expanding the warehouse later. Designing with flexibility allows for easier modifications and can accommodate changes in business needs, enhancing the warehouse’s long-term value.

Conclusion

Building a 30,000 sq ft warehouse is a significant investment that requires careful planning and budgeting. By understanding the various costs involved and the factors that influence these costs, you can make informed decisions and ensure the success of your construction project. Investing in high-quality materials, working with experienced professionals, and planning for contingencies can ensure a successful and cost-effective warehouse construction. Whether you’re expanding your business operations or starting a new venture, careful planning and management are key to building a warehouse that meets your needs and budget. With the right approach, your warehouse can become a valuable asset that supports your business growth and operational efficiency for years to come. Effective management of the construction process ensures that the warehouse is built on time, within budget, and to the required standards, providing a solid foundation for your business’s success.

FAQs

The average cost to build a 30,000 sq ft warehouse ranges from $1,521,000 to $3,900,000, which translates to about $50.70 to $130 per square foot.

Factors include location, design, materials, labor costs, site conditions, and additional features like HVAC, electrical, and plumbing systems.

Basic shell construction costs between $50.70 and $84.50 per square foot. This includes the foundation, steel frame, roofing, and exterior walls.

Interior build-out costs range from $26 to $65 per square foot, covering office spaces, restrooms, flooring, and lighting.

HVAC installation costs between $6.50 and $13 per square foot, depending on the system size and specific requirements.

Electrical systems cost between $3.90 and $10.40 per square foot, while plumbing systems cost between $2.60 and $9.10 per square foot.

Site preparation and grading costs range from $2.60 to $6.50 per square foot, covering land clearing, grading, and ensuring proper drainage.

Google Reviews

Process To Get Warehouse Construction Cost Estimate Report

Here I am going to share some steps to get warehouse construction cost estimate report.

-

You need to send your plan to us.

You can send us your plan on info@estimatorflorida.com

-

You receive a quote for your project.

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

-

Get Estimate Report

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.