How Much Does a 100x150 Steel Building Cost?

A 100×150 steel building (15,000 sq ft) typically costs between $962,500 and $2,045,000, translating to $64 to $136 per square foot. The total cost encompasses materials, labor, site preparation, insulation, and interior finishes. Lower-end costs cover basic structures with standard materials, while higher-end costs include premium materials, customized designs, and advanced insulation. Factors affecting the cost per square foot include location, design complexity, material quality, and local labor rates. Proper planning and budgeting for unforeseen expenses are crucial to keep the project within the estimated cost range.

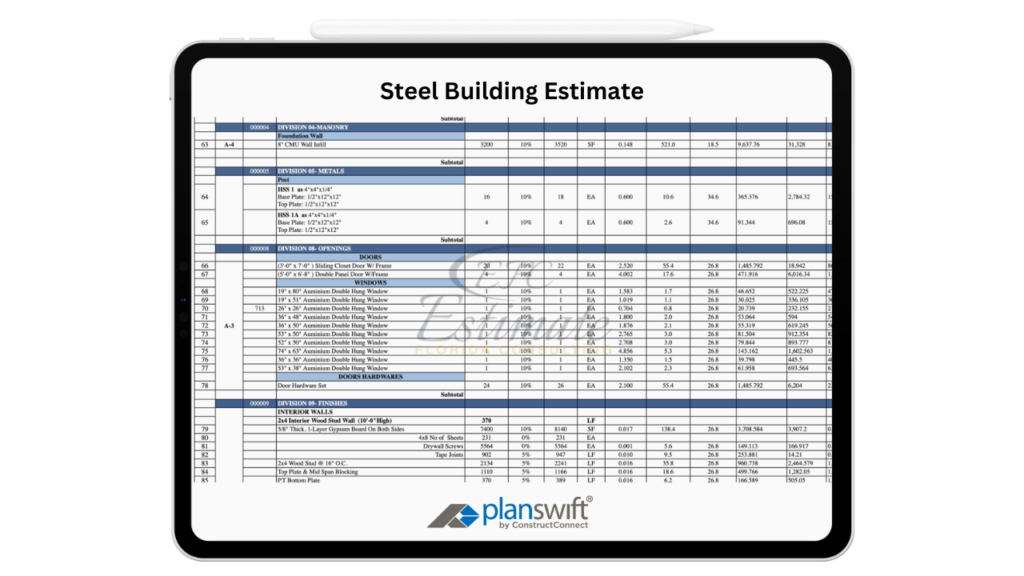

Cost Breakdown for a 100x150 Steel Building

Materials

The cost of materials for a 100×150 steel building can vary based on the quality and type of materials chosen. Here’s a breakdown of the typical costs:

Material | Estimated Cost per Sq Ft (in dollars) | Total Cost for 15,000 Sq Ft (in dollars) |

Steel Frame | $10 – $20 | $195,000 – $390,000 |

Roofing | $5 – $10 | $75,000 – $150,000 |

Siding | $5 – $10 | $75,000 – $150,000 |

Insulation | $1.50 – $3 | $22,500 – $45,000 |

Doors and Windows | $1 – $5 | $15,000 – $75,000 |

Steel Frame

The steel frame is the backbone of your building, providing structural support. The cost depends on the type and gauge of steel used, as well as the complexity of the design. A robust steel frame ensures the building’s durability and resistance to environmental factors. Additionally, high-quality steel frames allow for larger open spaces and flexible interior layouts, enhancing the building’s functionality. Choosing a reputable manufacturer for the steel frame can also guarantee better quality and reliability.

Roofing

The roofing system protects your building from weather elements and helps maintain a controlled internal environment. The choice of roofing material, such as metal panels or insulated roofing, impacts the overall cost. Quality roofing materials enhance energy efficiency, reduce maintenance costs, and ensure the roof’s longevity. Properly installed roofing systems can also prevent leaks and extend the building’s lifespan, providing a secure and stable environment for the building’s occupants and contents.

Siding

Siding covers the exterior walls of the building, providing protection and enhancing its aesthetic appeal. Options include metal panels, vinyl siding, and insulated panels, each with different cost implications. Durable and weather-resistant siding materials can improve the building’s longevity, reduce maintenance requirements, and enhance its curb appeal. High-quality siding also contributes to the building’s insulation properties, helping to maintain a comfortable interior temperature and reducing energy costs.

Insulation

Insulation is crucial for maintaining temperature control within the building, reducing energy costs, and providing a comfortable interior environment. The type and thickness of insulation can affect the cost. Proper insulation can lead to significant savings on heating and cooling expenses. Additionally, good insulation helps maintain indoor air quality and noise reduction, creating a more pleasant working environment. Investing in high-quality insulation materials can also increase the building’s energy efficiency, making it more environmentally friendly and potentially qualifying for energy efficiency rebates and incentives.

Doors and Windows

Doors and windows are essential for access, ventilation, and natural light. The cost depends on the type and quality of doors and windows installed. Energy-efficient windows and doors can improve the building’s insulation, reduce energy costs, and enhance security. High-quality options also contribute to the overall aesthetic of the building, adding to its value and comfort. Additionally, well-designed windows and doors can improve the building’s ventilation and natural lighting, creating a healthier and more productive indoor environment.

Labor Costs

Labor costs are a significant part of the overall construction budget. Here’s an estimate:

Labor Task | Estimated Cost per Sq Ft (in dollars) | Total Cost for 15,000 Sq Ft (in dollars) |

Site Preparation and Excavation | $2 – $5 | $30,000 – $75,000 |

Foundation Work | $4 – $8 | $60,000 – $120,000 |

Steel Erection | $5 – $10 | $75,000 – $150,000 |

Roofing Installation | $3 – $6 | $45,000 – $90,000 |

Siding Installation | $3 – $6 | $45,000 – $90,000 |

Doors and Windows Installation | $2 – $5 | $30,000 – $75,000 |

Electrical and Plumbing | $8 – $15 | $120,000 – $225,000 |

Insulation Installation | $2 – $4 | $30,000 – $60,000 |

Interior Finishing (if any) | $5 – $10 | $75,000 – $150,000 |

Site Preparation and Excavation

Site preparation includes clearing the land, leveling, and excavation work necessary for the foundation. Proper site prep is crucial to avoid future structural issues. It also helps manage drainage and soil stability, ensuring a solid base for your building. This step can also involve grading the land to direct water away from the building, preventing potential water damage and ensuring a stable foundation. Proper site preparation lays the groundwork for a smooth construction process and a durable finished structure.

Foundation Work

Foundation work includes pouring the concrete slab and necessary footings. A strong foundation supports the building’s weight and ensures it stays level and secure, preventing problems like settling or shifting. A well-built foundation is essential for the structural integrity of the building, providing a stable base that can withstand the test of time and various environmental conditions. Investing in a quality foundation helps prevent future maintenance issues and adds to the overall lifespan of the building.

Steel Erection

Erecting the steel frame requires skilled labor and specialized equipment. This task involves assembling the steel components and securing them in place. Proper steel erection is critical for the structural integrity of the building. Skilled labor ensures the steel frame is correctly aligned and securely fastened, providing a solid and reliable structure. Properly erected steel frames contribute to the building’s safety, stability, and overall performance, supporting long-term use.

Roofing Installation

Roofing installation includes placing roof panels, insulation, and any additional features like skylights or ventilation systems. Quality roofing protects your building from weather damage and helps maintain a controlled internal environment. A well-installed roof not only enhances the building’s appearance but also improves energy efficiency and prevents potential issues like leaks and water damage. Investing in quality roofing materials and skilled installation ensures a long-lasting and effective roof system, reducing the need for frequent repairs.

Siding Installation

Siding installation covers the exterior walls, providing protection and curb appeal. Durable siding materials improve the building’s longevity and reduce maintenance needs. Quality siding also enhances the building’s insulation properties, contributing to energy efficiency and a comfortable working environment. Additionally, choosing the right siding can significantly boost the building’s aesthetic appeal, making it more attractive to potential users. Proper siding installation ensures long-term protection against environmental elements, reducing wear and tear.

Doors and Windows Installation

Windows and doors installation is crucial for access, ventilation, and natural light. Energy-efficient options improve insulation, security, and overall comfort. High-quality windows and doors also add to the building’s aesthetic value and can enhance the living or working experience by providing better views, improved airflow, and increased natural light. Proper installation ensures that these elements function correctly and contribute to the building’s overall efficiency and security. Well-installed doors and windows can also enhance the building’s security features, providing peace of mind for occupants.

Electrical and Plumbing

Installing electrical and plumbing systems involves running the necessary wiring and pipes, setting up lighting, HVAC systems, and ensuring proper drainage and water supply. These systems are vital for the building’s functionality and safety. Properly installed electrical and plumbing systems ensure reliable and safe operation, reducing the risk of malfunctions and the need for future repairs. High-quality installation can also enhance the building’s energy efficiency and water conservation, lowering utility bills. Ensuring compliance with local codes and standards during installation is essential for safety and regulatory approval.

90% More Chances to Win Projects With Our Estimate!

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- School & University Building

- High-Rise Building

- Shopping Complex

- Data Center Building

Insulation Installation

Insulation installation is critical for maintaining temperature control within the building, reducing energy costs, and providing a comfortable interior environment. Proper insulation can lead to significant savings on heating and cooling expenses. Additionally, good insulation helps maintain indoor air quality and noise reduction, creating a more pleasant working environment. Investing in high-quality insulation materials can also increase the building’s energy efficiency, making it more environmentally friendly and potentially qualifying for energy efficiency rebates and incentives. Properly installed insulation enhances the overall performance and comfort of the building.

Interior Finishing (if any)

Interior finishing includes tasks like painting, installing flooring, and adding interior walls and fixtures. These costs can vary widely depending on the intended use of the building. High-quality interior finishes can enhance the building’s functionality, comfort, and aesthetic appeal. Proper interior finishing ensures that the building meets your specific needs and preferences. Investing in quality finishes and professional installation adds value and creates a more inviting and usable space for occupants.

Additional Costs

Additional costs can include permits, inspections, and site improvements. Here’s an estimate:

Additional Component | Estimated Cost (in dollars) |

Permits and Inspections | $10,000 – $20,000 |

Site Utilities (Water, Sewer, etc.) | $20,000 – $40,000 |

Site Improvements (Landscaping, Paving, etc.) | $30,000 – $60,000 |

Miscellaneous Expenses | $10,000 – $20,000 |

Permits and Inspections

Obtaining the necessary permits and passing inspections are crucial steps in the construction process. These ensure that your building complies with local building codes and regulations. Permit and inspection fees can vary by location, but they are essential for legal compliance and safety assurance. Proper documentation and approval processes help avoid legal issues and ensure the building meets all safety and quality standards. Permits and inspections provide a safeguard for the project’s integrity and legal standing.

Site Utilities

Installing site utilities, such as water, sewer, and electrical connections, is necessary for the building’s functionality. The cost depends on the distance to existing utility lines and the complexity of the installation. Proper utility connections are essential for daily operations and overall efficiency. High-quality utility installations ensure reliable service and reduce the risk of disruptions. Ensuring proper utility connections also contributes to the building’s compliance with health and safety standards.

Site Improvements

Site improvements include landscaping, paving, and any other enhancements to the exterior of the building. These improvements can enhance the appearance and functionality of the site. Quality landscaping can significantly improve the aesthetic appeal of your property, making it more inviting and increasing its value. Properly designed and executed site improvements can also enhance the usability of outdoor spaces, providing areas for recreation, relaxation, and efficient operations. Investing in site improvements can create a more pleasant environment for occupants and visitors.

Miscellaneous Expenses

Miscellaneous expenses can include unexpected costs that arise during the project, such as additional materials, equipment rentals, or unforeseen repairs. Having a contingency budget for these expenses helps ensure that the project stays on track and can handle any surprises without significant delays or cost overruns. Planning for contingencies provides financial flexibility and peace of mind. Including a contingency budget demonstrates thorough planning and risk management, which can instill confidence in stakeholders and financial backers.

Factors Influencing the Cost of a 100x150 Steel Building

Customization Options

The level of customization chosen for the building can significantly impact the cost. Custom features such as specialized doors, unique roof designs, and personalized interior finishes can increase the overall price. However, these features can also add significant value and functionality to the building, making it worth the investment. Customization allows you to tailor the building to your specific needs, enhancing its usability and appeal. Investing in unique design elements can also differentiate your building from standard constructions.

Building Site

The location and condition of the building site can affect costs due to varying land prices, labor rates, and local building codes. Urban areas typically have higher costs compared to rural locations. Additionally, proximity to suppliers and transportation networks can influence logistical costs and operational efficiency. Selecting an optimal location can balance cost and operational needs. The site’s geographic and environmental conditions can also affect construction methods and materials, further impacting costs.

Market Conditions

Market conditions, including the availability of materials and labor, can influence costs. Fluctuations in material prices and labor availability can cause costs to vary. Monitoring market trends and securing contracts early can help lock in prices and avoid unexpected cost escalations. Staying informed about market conditions can aid in strategic planning and budgeting. Economic factors such as inflation, supply chain disruptions, and demand fluctuations can also impact overall project costs and timelines.

Regulatory Requirements

Regulatory requirements and building codes vary by location and can affect construction costs. Compliance with local regulations, permits, and inspections is essential for legal and safety reasons. Understanding these requirements early in the planning process can help avoid delays and additional expenses. Proper documentation and approval processes ensure the building meets all safety and quality standards, providing peace of mind and preventing costly fines or delays.

Detailed Cost Comparison

Material Quality

The quality of materials used for construction can affect both the initial cost and the long-term performance of the building. Higher-quality materials tend to be more durable and reliable but come with a higher price tag.

Material Quality | Estimated Cost per Sq Ft (in dollars) | Total Cost for 15,000 Sq Ft (in dollars) |

Basic | $22.50 | $337,500 |

Mid-Range | $35.25 | $528,750 |

High-End | $48 | $720,000 |

Labor Complexity

The complexity of the construction job can influence labor costs. More complex installations, such as those involving specialized systems or extensive interior finishes, will require more time and expertise.

Labor Complexity | Estimated Cost per Sq Ft (in dollars) | Total Cost for 15,000 Sq Ft (in dollars) |

Basic | $34 | $510,000 |

Mid-Range | $51.50 | $772,500 |

High-End | $69 | $1,035,000 |

Additional Features

Adding additional features to the building, such as advanced security systems, climate control, or enhanced lighting, can increase the overall cost but provide enhanced functionality and convenience.

Feature | Estimated Cost (in dollars) |

Advanced Security Systems | $30,000 – $60,000 |

Climate Control Systems | $40,000 – $80,000 |

Enhanced Lighting | $20,000 – $40,000 |

Benefits of a 100x150 Steel Building

Durability and Strength

Steel buildings are known for their durability and strength, capable of withstanding harsh weather conditions such as heavy snow, high winds, and even earthquakes. Steel is also resistant to pests like termites and rodents, which can cause significant damage to wooden structures. This durability ensures a long lifespan with minimal maintenance, making steel buildings a cost-effective investment. Additionally, the robustness of steel allows for greater structural integrity and security, providing peace of mind to building owners.

Versatility

A 100×150 steel building is highly versatile and can be customized for various applications. Whether you need a warehouse, manufacturing facility, agricultural storage, or a large recreational center, steel buildings can be tailored to meet your specific needs. The open-span design of steel structures provides a flexible interior layout without the need for load-bearing walls, maximizing usable space. This flexibility allows for easy modifications and reconfigurations in the future, making the building adaptable to changing requirements.

Quick Construction

Steel buildings are often prefabricated, meaning the components are manufactured off-site and then assembled on-site. This significantly reduces construction time compared to traditional building methods. Faster construction means you can start using your building sooner, which is particularly beneficial for commercial projects that need to be operational quickly. The reduced construction time also minimizes labor costs and site disruption, making the process more efficient and less intrusive.

Energy Efficiency

Steel buildings can be designed with energy efficiency in mind. Insulation, energy-efficient windows, and ventilation systems can be incorporated into the design to reduce energy consumption. Properly insulated steel buildings can maintain a comfortable interior temperature year-round, reducing heating and cooling costs. This not only lowers operational expenses but also contributes to environmental sustainability by minimizing the building’s carbon footprint.

Download Template For Steel Building Project Breakdown

- Materials list updated to the zip code

- Fast delivery

- Data base of general contractors and sub-contractors

- Local estimators

Cost-Saving Tips

Plan Ahead

Planning the construction project early can help identify potential issues and reduce costs. Consider future needs and include features that can accommodate growth and changes in operations. Early planning allows for more efficient project management and resource allocation. Engaging with professionals early in the planning process can ensure all aspects are considered, leading to a more streamlined and cost-effective project.

Get Multiple Quotes

Obtain multiple quotes from contractors to compare prices and services. This can help you find the best deal and ensure that you’re getting quality work at a competitive price. Additionally, checking references and reviewing past projects can provide insights into the contractor’s reliability and workmanship. Competitive bidding can encourage better pricing and service offerings, enhancing overall project value.

Use Standard Designs

Opt for standard designs and materials instead of custom or high-end options. Standard designs are often more affordable and readily available, helping to reduce overall costs. Using pre-engineered building designs can also streamline the construction process and reduce costs. Standardized designs can simplify permitting and regulatory compliance, reducing the time and cost associated with approval processes.

Perform Some Tasks In-House

If you have the expertise and resources, consider performing some tasks in-house, such as site preparation or interior finishing. This can save on labor costs and provide more control over the project. However, it’s important to ensure that all work meets safety and quality standards. Leveraging in-house capabilities can also enhance project flexibility and responsiveness, allowing for efficient management of resources and timelines.

Plan for Contingencies

Include a contingency budget of 10-20% to cover unexpected expenses. This ensures that you are prepared for any unforeseen issues that may arise during the project. Planning for contingencies can provide peace of mind and financial flexibility, allowing you to address any surprises without derailing your budget. A well-planned contingency budget can enhance project resilience and ensure successful completion despite unforeseen challenges.

Conclusion

Building a 100×150 steel building is a significant investment that requires careful planning and budgeting. By understanding the various costs involved and the factors that influence these costs, you can make informed decisions and ensure the success of your building project. Investing in high-quality materials, working with experienced professionals, and planning for contingencies can ensure a successful and cost-effective construction process. Properly managing the project not only ensures compliance with safety standards but also maximizes the long-term benefits of the investment. Taking a proactive approach to project management and budgeting can lead to a successful outcome, providing a functional, efficient, and valuable asset that supports your specific needs and goals for years to come. By considering all aspects of the construction process and leveraging best practices in project planning and execution, you can achieve a high-quality building that meets your expectations and delivers significant return on investment. Comprehensive planning and execution will help you navigate challenges, optimize resources, and achieve a building that enhances your operational efficiency and meets all regulatory and safety requirements.

FAQs

The estimated cost of building a 100×150 steel building (15,000 sq ft) ranges from $962,500 to $2,045,000, translating to $64 to $136 per square foot.

Material costs for a 100×150 steel building include:

- Steel Frame: $195,000 – $390,000

- Roofing: $75,000 – $150,000

- Siding: $75,000 – $150,000

- Insulation: $22,500 – $45,000

- Doors and Windows: $15,000 – $75,000

Labor costs for building a 100×150 steel building vary from $510,000 to $1,035,000, covering site preparation, foundation work, steel erection, roofing installation, siding installation, doors and windows installation, electrical and plumbing, insulation installation, and interior finishing.

Additional expenses include permits, utilities, and site improvements, adding $70,000 to $140,000 to the total cost.

Customization options such as specialized doors, unique roof designs, and personalized interior finishes can significantly increase the overall cost but add value and functionality.

The location and condition of the building site affect costs due to varying land prices, labor rates, and local building codes, with urban areas typically being more expensive than rural locations.

Fluctuations in material prices and labor availability can impact costs. Securing contracts early and staying informed about market trends can help manage these fluctuations.

Site conditions, including soil quality, drainage, and accessibility, can influence costs. Extensive site preparation, such as grading or soil stabilization, can add to the expense.

To save on costs, plan ahead, get multiple quotes from contractors, use standard designs, perform some tasks in-house, and include a contingency budget for unexpected expenses.

Google Reviews

Process To Get Steel Building Cost Estimate Report

Here I am going to share some steps to get Steel Building cost estimate report.

-

You need to send your plan to us.

You can send us your plan on info@estimatorflorida.com

-

You receive a quote for your project.

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

-

Get Estimate Report

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.