90% More Chances to Win Projects With Our Estimate!

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- School & University Building

- High-Rise Building

- Shopping Complex

- Data Center Building

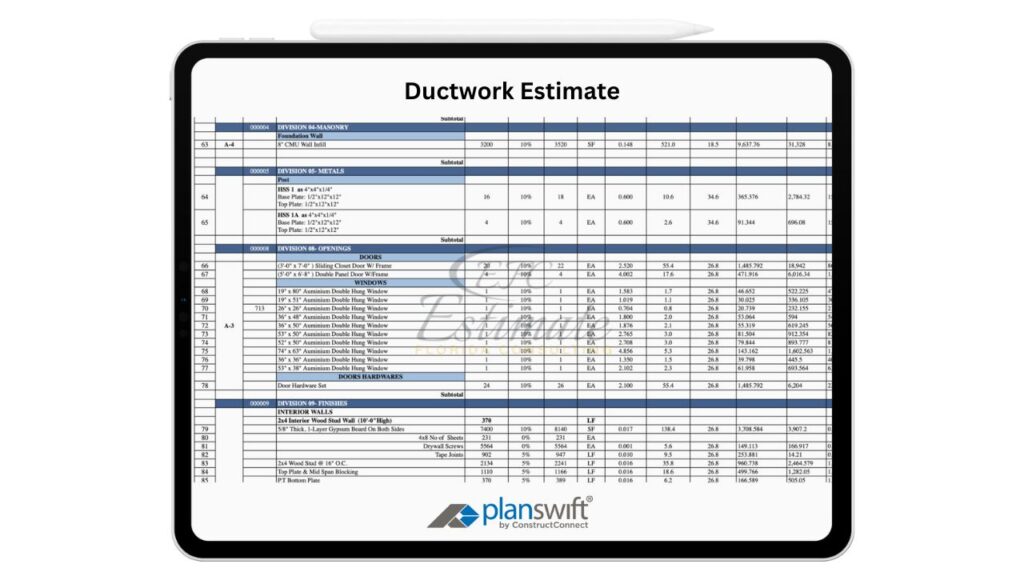

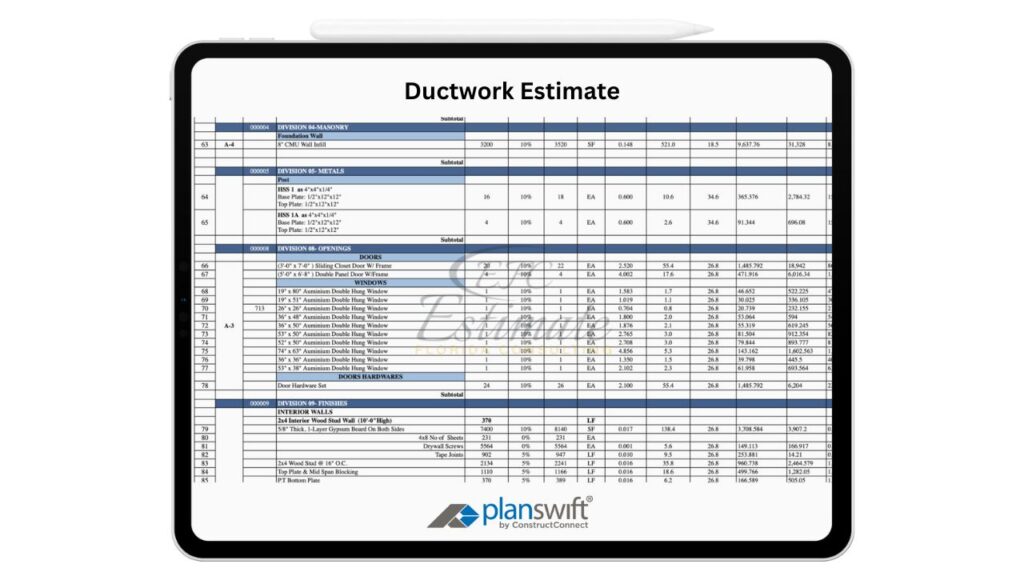

The cost per linear foot of ductwork varies by material and installation complexity. The following table summarizes the average costs:

Duct Material | Cost per Linear Foot |

Sheet Metal | $24 – $36 |

Fiberglass | $18 – $30 |

Flexible Ducts | $12 – $24 |

This breakdown is critical for homeowners and contractors to evaluate which type of ducting best fits their budget while meeting efficiency needs.

For an average-sized home, the total replacement costs can be broken down as follows:

Component | Estimated Cost |

Duct Material (600 ft) | $14,400 – $21,600 |

Labor (30 hours) | $2,700 – $5,400 |

Permits and Inspections | $120 – $600 |

Additional Costs (sealing, etc.) | $600 – $2,400 |

In addition to the direct costs of duct replacement, there are several additional factors that can add to the overall expense:

Several factors can significantly influence the costs associated with ductwork replacement. Understanding these elements can help you make informed decisions during the planning phase.

The type of material used for ductwork will greatly impact the overall cost. Common materials include:

The size and layout of the ductwork system also play a crucial role in determining costs. Larger systems require more materials and labor, while complex layouts may need additional fittings and modifications.

Labor costs can vary significantly based on location, the complexity of the installation, and the experience level of the technicians. In Florida, HVAC technicians typically charge between $90 and $180 per hour, depending on their expertise and the project’s complexity. Labor costs can account for 30% to 50% of the total replacement cost, making it a substantial portion of the budget. Furthermore, the time required for installation can vary based on the existing ductwork condition; for instance, if extensive repairs or removals are needed, this can significantly increase labor time and costs.

The accessibility of the ductwork installation area can greatly impact labor costs. If ducts are located in hard-to-reach spaces, such as crawl spaces or attics, it may require additional labor time and effort, thus increasing the overall cost. When planning a replacement, consider how accessible the ducts are and whether modifications to the existing layout may improve access for future maintenance. It may be beneficial to incorporate accessibility features, such as larger access panels, to ease any future repairs or inspections.

Adhering to local building codes and obtaining the necessary permits can add to the expense of ductwork replacement. It’s essential to check with local authorities to ensure compliance and factor these costs into your overall budget. Permits can range from $120 to $600, depending on the city and the extent of the work being done. Failure to secure the proper permits can lead to fines, forced removal of non-compliant work, and complications during the sale of a property. Always consult local regulations before starting a project to avoid fines or complications.

When estimating the costs associated with duct materials for HVAC systems, it’s essential to understand the different types available, as well as their respective price ranges per linear foot.

Duct Material | Cost per Linear Foot |

Sheet Metal | $24 – $36 |

Fiberglass | $18 – $30 |

Flexible Ducts | $12 – $24 |

Sheet metal ducts are a popular choice for many contractors due to their durability and efficiency. These ducts are typically constructed from galvanized steel or aluminum, making them a robust option that can withstand various environmental conditions. The cost of sheet metal ducts ranges from $24 to $36 per linear foot. This price reflects the material’s high strength and ability to maintain structural integrity over time, which can ultimately save money in maintenance and repairs.

Fiberglass ducts are another option frequently used in HVAC installations, particularly for their excellent insulation properties. The insulation layer helps reduce energy loss and noise, making them suitable for residential and commercial applications. The cost for fiberglass ducts generally falls between $18 and $30 per linear foot. This range reflects the material’s effectiveness in maintaining temperature control within the ductwork, contributing to overall energy efficiency in heating and cooling systems.

Flexible ducts offer versatility and ease of installation, making them a favorite among many contractors, especially in complex layouts where rigid ducts might not fit. They are usually constructed from a combination of plastic and insulation material, allowing for more straightforward routing in tight spaces. The cost of flexible ducts ranges from $12 to $24 per linear foot. This affordability, combined with their adaptability, makes flexible ducts a cost-effective solution for various HVAC projects.

Cost Type | Estimated Cost Range |

Labor Costs | $4,500 – $9,000 |

Permits and Inspections | $120 – $600 |

Insulation | $300 – $900 |

HVAC System Modifications | $600 – $2,400 |

Air Quality Improvements | $240 – $2,400 |

Labor costs are one of the most significant components of any HVAC project. Depending on the complexity of the installation and the expertise required, labor costs can range from $4,500 to $9,000. This range typically accounts for the time and skills needed to complete the installation safely and effectively. Factors influencing these costs include the size of the project, the experience level of the technicians, and the specific tasks involved, such as installing ductwork or modifying existing systems.

Obtaining the necessary permits and undergoing inspections is a crucial step in any HVAC project. These costs ensure that the work complies with local building codes and regulations. The estimated cost range for permits and inspections is between $120 and $600. This investment not only helps in maintaining safety standards but also protects homeowners and contractors from potential fines or complications in the future.

Proper insulation is essential for the efficiency of an HVAC system, as it helps to minimize energy loss and maintain consistent indoor temperatures. The costs associated with insulation typically range from $300 to $900. This investment contributes to better energy efficiency, potentially lowering utility bills in the long run while enhancing comfort in the living or working space.

In some cases, existing HVAC systems may require modifications to accommodate new equipment or improve functionality. The cost for HVAC system modifications can vary widely, falling between $600 and $2,400. This expense may cover alterations to ductwork, updating electrical systems, or integrating new technology, ensuring the system operates effectively and efficiently.

Improving indoor air quality is increasingly important for health and comfort. Enhancements such as advanced filtration systems, air purifiers, and humidifiers can range from $240 to $2,400. The investment in air quality improvements not only promotes better health and well-being but can also lead to improved system efficiency, reducing strain on HVAC equipment.

Selecting the appropriate ductwork material is essential for maximizing performance, longevity, and overall satisfaction with your HVAC system.

Flexible ducts are often the go-to choice for retrofitting existing systems or in situations where space is limited. They are lightweight, easy to install, and come in various lengths, making them a flexible option for various projects. Costs typically range from $12 to $24 per linear foot, making them an attractive option for budget-conscious homeowners. However, while their ease of installation can be appealing, it’s important to ensure they are installed properly to avoid bends or kinks that could restrict airflow, negating their benefits.

Rigid ducts, typically made of metal, are the gold standard for HVAC systems due to their durability and efficiency. These ducts maintain airflow without significant loss, making them a preferred choice for new constructions and major renovations. While they may come at a higher initial cost (around $24 to $36 per linear foot), the long-term benefits often outweigh the upfront expenses. Additionally, rigid ducts can be insulated to further enhance energy efficiency, making them suitable for both residential and commercial applications.

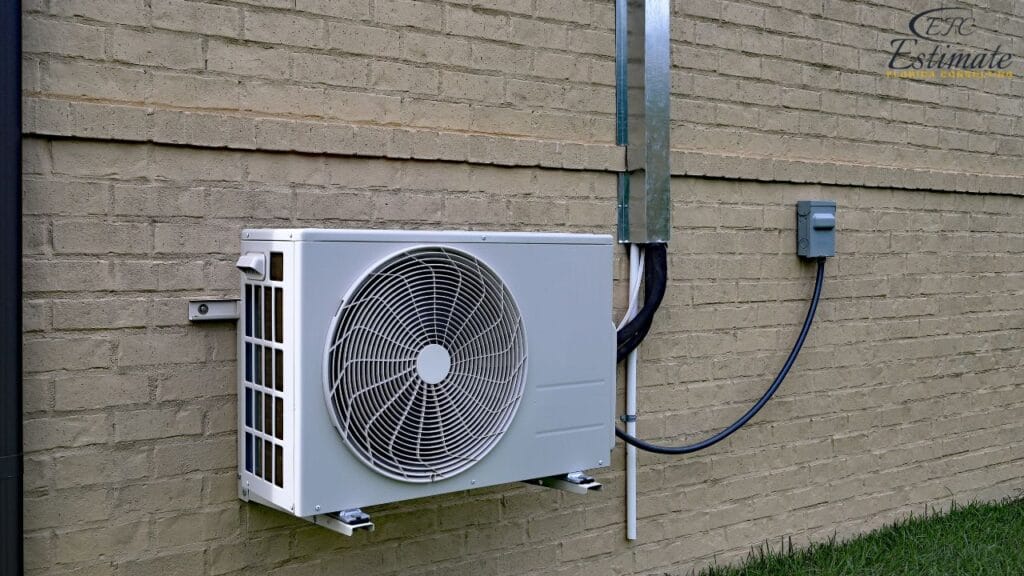

Ductless systems offer a flexible and energy-efficient alternative, particularly in homes without existing ductwork. These systems consist of an outdoor unit and one or more indoor units, allowing for customized temperature control in individual rooms. The installation cost can be higher upfront (typically around $2,000 to $6,000 for a multi-zone system), but they provide substantial savings in energy bills and improved comfort. Homeowners looking to avoid the hassle of traditional ductwork may find ductless mini-split systems to be an excellent option, especially in older homes or buildings where duct installation would be challenging.

Ductwork is a system of conduits or passages used to distribute air from heating, ventilation, and air conditioning (HVAC) systems throughout a building. These ducts serve a vital function in delivering conditioned air, maintaining indoor air quality, and ensuring thermal comfort. Ducts can be made from various materials, including sheet metal, fiberglass, and flexible plastic, each with its advantages and disadvantages. Understanding the different types of ductwork can help homeowners and builders make informed choices regarding their HVAC systems. Ducts are often located in walls, ceilings, and floors, making their design and installation critical to maximizing airflow efficiency and minimizing energy waste.

Properly designed and installed ductwork is critical for the efficient operation of HVAC systems. Ducts are responsible for moving air to and from rooms in a building, which directly affects temperature regulation and air quality. Poorly functioning ductwork can lead to several issues, including:

While some homeowners may consider DIY ductwork replacement to save on labor costs, it’s crucial to weigh the pros and cons.

Hiring licensed HVAC professionals ensures that the job is done correctly and efficiently. Professionals bring valuable experience to the table, allowing them to identify potential issues, navigate local codes, and guarantee proper installation. This can save you money in the long run, as a well-installed duct system will operate more efficiently and require fewer repairs over time. Furthermore, professionals often provide warranties or guarantees for their work, giving homeowners peace of mind regarding their investment.

Regular maintenance can prolong the life of your ductwork and enhance its efficiency, leading to lower energy costs and improved indoor air quality.

Replacing ductwork is a crucial investment that can enhance the performance of your HVAC system and improve indoor air quality. By understanding the costs involved and the factors that influence these costs, homeowners and contractors can make informed decisions that lead to better outcomes. Whether you choose to go the DIY route or hire professionals, ensuring that your ductwork is in optimal condition will yield long-term benefits in comfort, energy efficiency, and health.

The total cost to replace ductwork in an average-sized home typically ranges from $18,000 to $30,000. This estimate includes materials, labor, permits, and any additional expenses such as sealing and insulation.

The cost of ductwork varies based on the material used:

In addition to the primary duct replacement costs, consider:

The type of ductwork material influences both initial costs and long-term efficiency:

Larger homes or complex duct layouts require more materials and labor, increasing costs. An average home might need between 600 and 840 linear feet of ductwork, depending on design and HVAC efficiency.

Labor costs can range from $4,500 to $9,000, accounting for the complexity of the installation and technician experience. Labor often represents 30% to 50% of the total cost, so it's essential to choose qualified professionals.

Permits ensure that your ductwork replacement complies with local building codes, helping you avoid fines or complications during home sales. Permit costs usually range from $120 to $600.

While DIY projects can save on labor costs, hiring professionals ensures proper installation, compliance with local codes, and long-term efficiency. Mistakes made during DIY installations can lead to higher energy bills and potential safety hazards.

Consider investing in advanced filtration systems or air purifiers to enhance indoor air quality. While this can add to your costs (ranging from $240 to $2,400), it can significantly improve your living environment.

If your ductwork is located in hard-to-reach areas, such as crawl spaces or attics, this can increase labor costs. During replacement, consider modifying the layout to improve accessibility for future maintenance.

At Estimate Florida Consulting, we offer detailed cost estimates across all major trades, ensuring no part of your project is overlooked. From the foundation to the finishing touches, our trade-specific estimates provide you with a complete and accurate breakdown of costs for any type of construction project.

We take pride in delivering accurate, timely, and reliable estimates that help contractors and builders win more projects. Our clients consistently praise our attention to detail, fast turnaround times, and the positive impact our estimates have on their businesses.

Estimate Florida Consulting has helped us win more bids with their fast and accurate estimates. We trust them for every project!

Submit your project plans, blueprints, or relevant documents through our online form or via email.

We’ll review your project details and send you a quote based on your scope and requirements.

Confirm the details and finalize any adjustments to ensure the estimate meets your project needs.

Receive your detailed, trade-specific estimate within 1-2 business days, ready for your project execution.

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

All copyright © Reserved | Designed By V Marketing Media | Disclaimer