Bid Confidently, Win Consistently – Zip Code Estimates Made Easy!

- Accurancy

- Efficiency

- Transparency

- Customization

- Time Saving

- Professionalism

- Cost Control

For business owners in Florida, managing energy expenses, particularly for large commercial warehouses, is a critical aspect of financial planning. With vast spaces, high ceilings, and specialized equipment, warehouses often have distinct electrical requirements. Accurately estimating electric costs is vital for effective budgeting, strategic planning, and implementing energy-efficient measures. Here, we explore the key factors influencing electric costs in Florida’s warehouses and provide insights into estimation tools and cost-reduction strategies.

The size and type of a warehouse are pivotal factors influencing its electrical costs. Larger warehouses inherently demand more energy, driven by expansive square footage and heightened operational needs. Furthermore, the nature of the facility, whether refrigerated or climate-controlled, introduces distinctive equipment and lighting requirements, adding complexity to energy consumption patterns. The interplay between warehouse dimensions and its designated purpose profoundly impacts the intricacies of estimating and managing electric costs.

ZIP Code Based Estimate Highly Accurate

Get Estimate

Fully Insured Licensed Hire a Contractor For Commercial Electrical

Hire Contractor

Make Informed Design Decisions Showcase Your Design Ideas

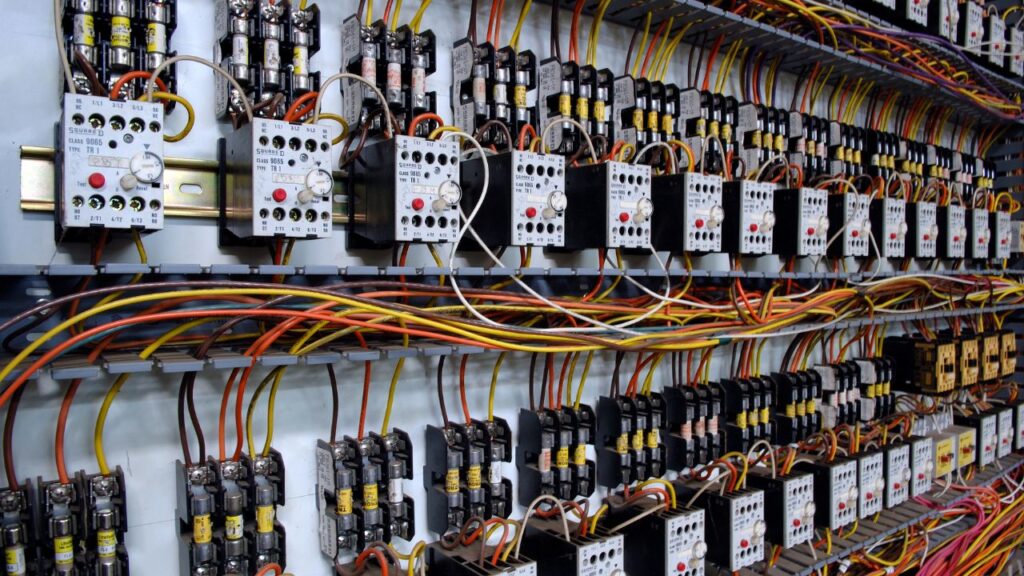

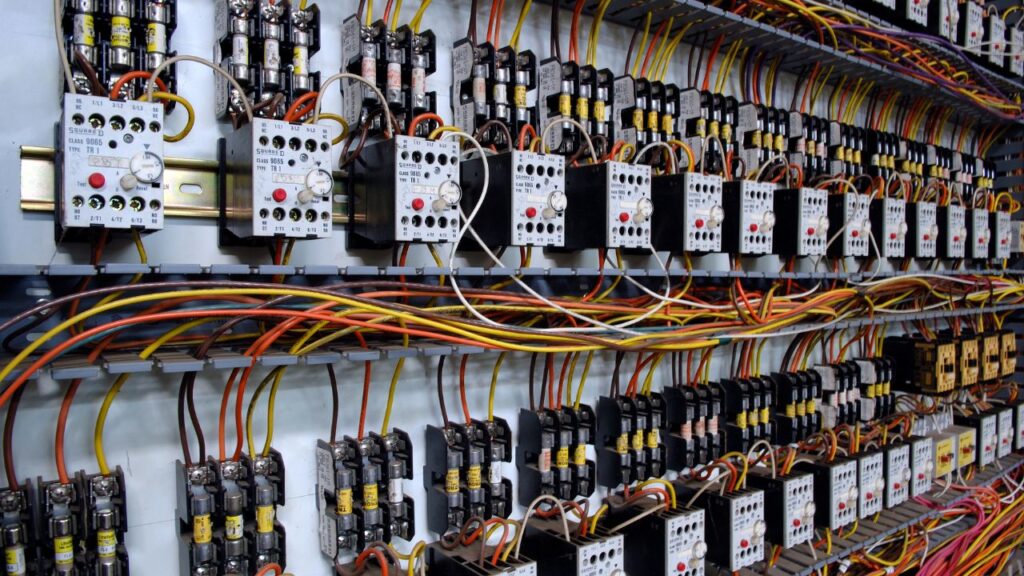

Get RenderingThe electricity consumption of a warehouse is significantly shaped by the type and quantity of machinery employed within its operational framework. Heavy-duty machinery, refrigeration units, and conveyor systems stand out as primary contributors to energy consumption, exerting a direct influence on overall operational costs. Understanding the energy demands of specific equipment categories is imperative for effective planning and implementing strategies to optimize electricity usage.

Conventional lighting sources, such as incandescent or fluorescent bulbs, represent a noteworthy aspect of energy expenses in warehouses. The choice of lighting significantly affects electricity costs. Transitioning from traditional options to energy-efficient LED lighting stands out as a proactive measure, offering not only immediate cost savings but also long-term reductions in electricity expenditures. This shift aligns with sustainability goals while enhancing the overall energy efficiency of the warehouse.

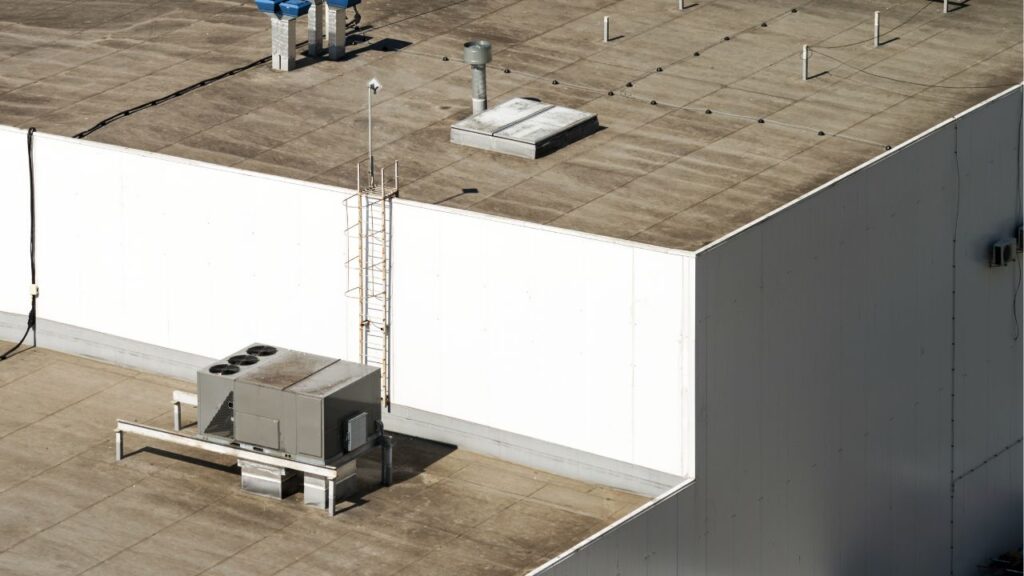

Effective climate control in a warehouse, particularly in Florida’s hot and humid climate, necessitates substantial energy input. The demand for maintaining optimal temperatures requires well-designed and efficient HVAC systems. Additionally, proper insulation becomes a crucial component in minimizing energy consumption. Recognizing the pivotal role of climate control in energy usage underscores the importance of strategic investments and operational considerations to enhance efficiency and reduce long-term electricity costs.

The operational dynamics of a warehouse, including the number of hours it functions and the level of occupancy, directly influence its electricity usage. Extended operating hours and high levels of occupancy naturally lead to increased energy consumption. Optimizing these factors involves careful planning and management, such as implementing energy-efficient practices during peak hours and adjusting operations based on demand. A nuanced understanding of the relationship between operational parameters and electricity usage is fundamental for accurate cost estimations.

The financial landscape of a warehouse’s electric costs is intricately tied to utility rates and tariffs. Understanding the specific rate structures set by local utility providers is essential for precise cost estimation. Variations in rates based on location and utility providers necessitate a thorough awareness of these factors. A comprehensive grasp of utility rates and tariffs empowers warehouse operators to make informed decisions, strategically manage energy consumption, and effectively plan for associated costs.

Florida Power & Light (FPL) recognizes the distinctive energy demands that commercial warehouses face. In a bid to equip business owners with accurate cost estimates, FPL provides an exclusive business energy calculator accessible through their website. This interactive tool delves into specific warehouse details, taking into account critical elements such as:

With just a few clicks, FPL’s business energy calculator serves as a valuable starting point for budgeting and planning your warehouse’s electric costs.

The U.S. Department of Energy (DOE), a proponent of energy efficiency, extends support to businesses through a robust tool available on their website. The commercial building energy use benchmark tool facilitates the evaluation of your warehouse’s performance against comparable structures. By inputting your warehouse’s characteristics, you gain access to insightful features such as:

The DOE’s benchmark tool empowers you to move beyond basic cost estimates, fostering a data-driven approach to optimize your warehouse’s electrical consumption.

For nuanced cost estimates related to electrical upgrades or installations in your warehouse, specialized commercial electrical estimating software proves invaluable. These programs conduct a comprehensive analysis of your project, considering factors such as:

Commercial electrical estimating software empowers confident budgeting for electrical projects, minimizing surprises and ensuring projects align with financial constraints.

By leveraging these diverse resources, you gain a nuanced understanding of warehouse electric costs, benchmark performance, and plan for future upgrades with precision and confidence. Optimizing energy efficiency becomes an investment not only in sustainability but also in profitability.

Say farewell to the dim glow and hefty bills of traditional incandescent and fluorescent lighting—embrace the future of illumination with LED lighting! This revolutionary technology offers a multitude of benefits for your warehouse, making it a no-brainer upgrade:

When it comes to warehouse equipment, every watt counts. Choosing energy-efficient models can significantly reduce your overall energy consumption and contribute to a more sustainable operation:

Your warehouse’s HVAC system plays a crucial role in maintaining a comfortable work environment while also impacting energy consumption. By optimizing your system, you can achieve both:

Lighting accounts for a significant portion of a warehouse’s energy consumption. By implementing occupancy sensors and timers, you can ensure that lights are only on when and where they’re needed:

Managing electric costs for commercial warehouses in Florida requires a comprehensive strategy. Factors such as warehouse size, equipment, lighting, climate control, operating hours, and utility rates influence costs significantly. Utilizing tools like Florida Power & Light’s business energy calculator and the U.S. Department of Energy’s benchmark tool aids in precise estimations. Commercial electrical estimating software ensures detailed analysis for upgrades. To reduce costs, consider LED lighting upgrades, energy-efficient equipment, HVAC optimization, and implementing occupancy sensors. Overall, a proactive approach to understanding, estimating, and optimizing electric costs is crucial for sustainability and profitability, offering a strategic investment for a greener and more cost-effective future.

To gauge your warehouse’s electrical needs, consider factors like square footage, operational requirements, and whether it is refrigerated or climate-controlled.

The type and quantity of machinery, such as heavy-duty equipment and refrigeration units, significantly impact energy usage and overall operational costs.

LED lighting offers substantial energy efficiency, reducing consumption by over 75%. The technology also provides long-lasting performance and minimal heat emission, contributing to lower electricity bills.

Effective climate control, especially in Florida’s climate, demands substantial energy. Well-designed HVAC systems and proper insulation are vital for minimizing energy consumption and associated costs.

Extended operating hours and higher occupancy lead to increased energy consumption. Strategic planning, energy-efficient practices, and adjusting operations based on demand can optimize these factors.

Understanding specific rate structures set by local utility providers is essential. Awareness of variations in rates based on location empowers informed decision-making and strategic energy consumption management.

Florida Power & Light offers a business energy calculator, and the U.S. Department of Energy provides a benchmark tool for evaluating warehouse performance. Commercial electrical estimating software offers detailed analysis for upgrades.

Consider upgrading to LED lighting, investing in energy-efficient equipment, optimizing HVAC systems, and implementing occupancy sensors. Regular maintenance and smart technology integration further contribute to sustainable cost reductions.

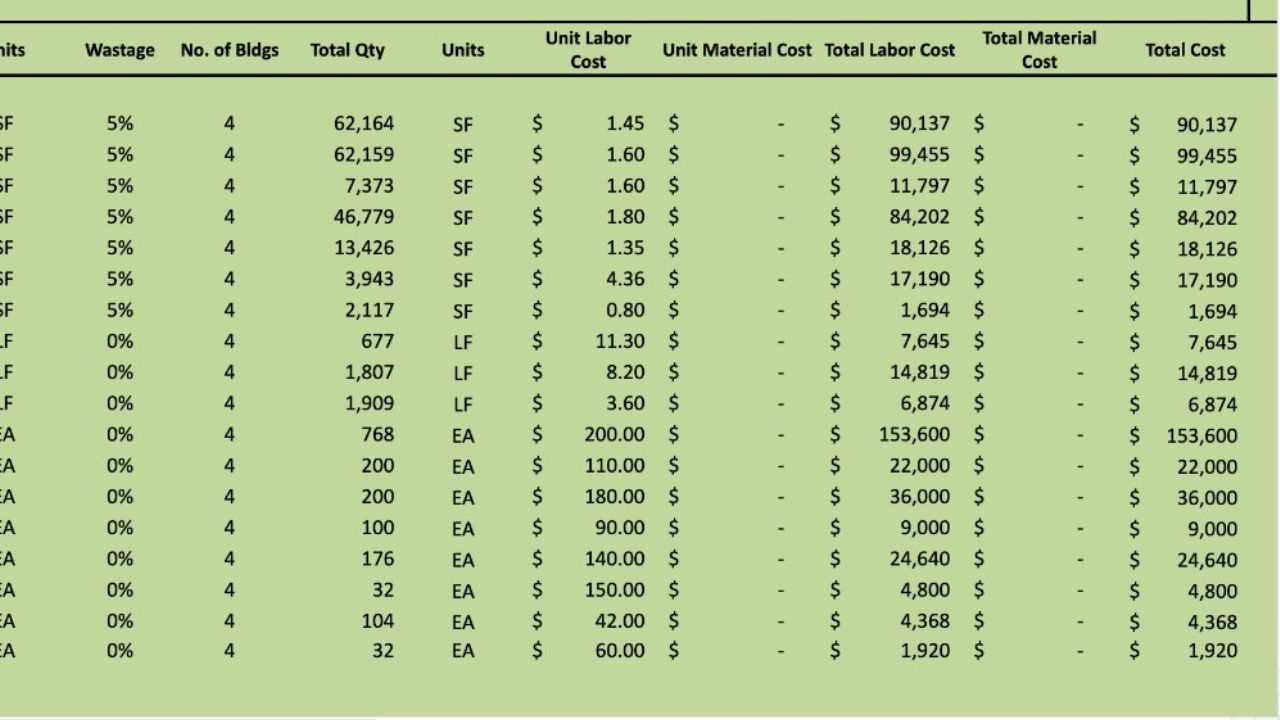

Here I am going to share some steps to get your commercial warehouse electric cost estimate report.

You can send us your plan on info@estimatorflorida.com

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

All copyright © Reserved | Designed By V Marketing Media | Disclaimer