Mechanical Cost Estimator in Cape Coral, FL

Estimate Florida Consulting specializes in delivering precise mechanical cost estimates tailored to meet the unique requirements of our clients. Mechanical cost estimation plays a pivotal role in the engineering and construction sectors, serving as the financial blueprint for projects.In Cape Coral mechanical costs can broadly range as follows: For small-scale projects, costs might start from $5,500 to $55,000+. Mid-sized projects could see expenses ranging from $110,000 to $550,000+. For larger, more complex industrial or commercial endeavors, the mechanical costs can soar from $1.1 million to over $5.5 million or more, depending on the project’s scope and specifications.

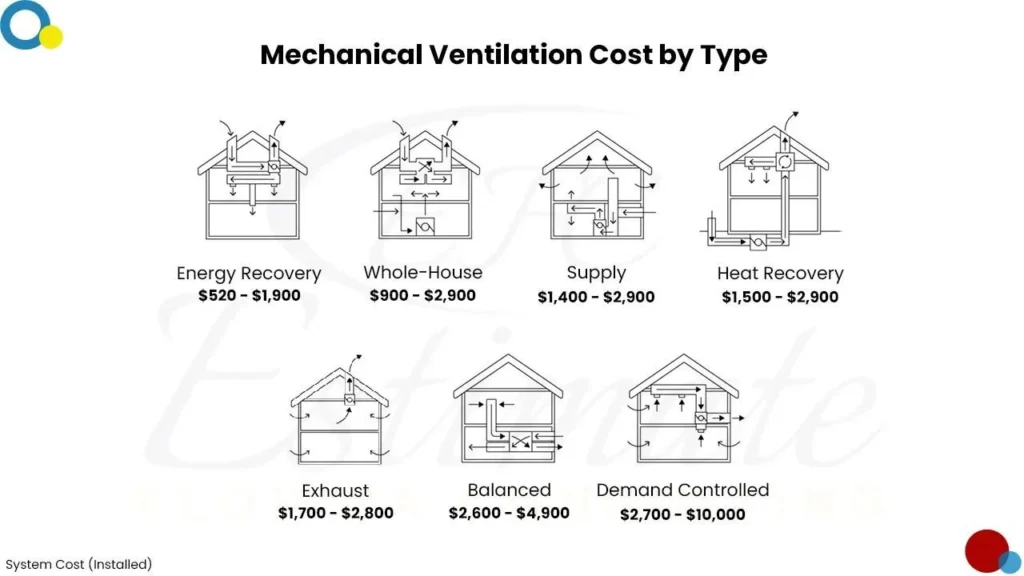

Cost of Mechanical Ventilation by Type

Mechanical air exchange systems typically cost between $520 and $10,000. These systems utilize fans installed in windows, walls, or air ducts to either remove or add air to the home. Condensation, formed when warm air meets cold surfaces, can be prevented by these fans, which either extract or introduce air to maintain balanced air quality within the room. A balanced mechanical ventilation system ensures that the air quality meets specific design specifications.

Mechanical Ventilation Type | System Cost (Installed) |

Energy Recovery | $520 – $1,900 |

Whole-House | $900 – $2,900 |

Supply | $1,400 – $2,900 |

Heat Recovery | $1,500 – $2,900 |

Exhaust | $1,700 – $2,800 |

Balanced | $2,600 – $4,900 |

Demand Controlled | $2,700 – $10,000 |

90% More Chances to Win Projects With Our Estimate!

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- School & University Building

- High-Rise Building

- Shopping Complex

- Data Center Building

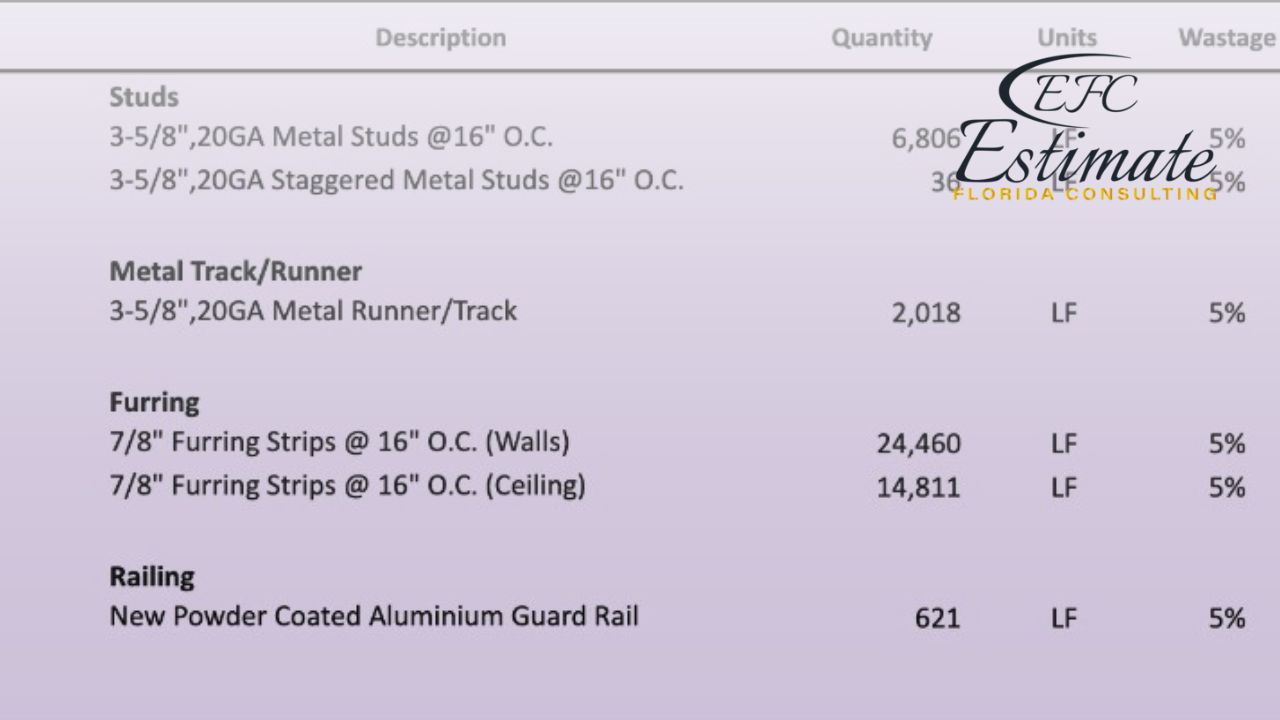

Price Table by Type of mechanical System

Mechanical systems encompass a wide array of essentials, ranging from HVAC and plumbing to specialized areas like fire protection and industrial machinery. These systems are integral for ensuring comfort, safety, and efficiency across diverse environments. Whether it’s facilitating the adoption of renewable energy or providing precise control in machinery movements, each system serves a distinct purpose tailored to specific requirements. For instance, refrigeration systems are indispensable for preserving food and supporting chemical processing. In essence, mechanical engineering’s influence is profound, shaping daily operations and driving sustainability initiatives across various industries.

System | Cost Range |

HVAC Systems | $5,500 – $110,000+ |

Plumbing Systems | $3,300 – $82,500+ |

Fire Protection Systems | $11,000 – $220,000+ |

Electrical Systems | $4,400 – $99,000+ |

Industrial Machinery | $27,500 – $1,100,000+ |

Renewable Energy Systems | $22,000 – $550,000+ |

Building Automation Systems | $16,500 – $165,000+ |

Pneumatic Systems | $5,500 – $55,000+ |

Hydraulic Systems | $11,000 – $275,000+ |

Refrigeration Systems | $30,800 – $462,000+ |

Get 5 New Leads in the Next 7 Days With Our System

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- High-Rise Building

- Shopping Complex

Factors Affecting Cost Estimates

Various factors exert substantial influence on the cost estimates of mechanical projects, necessitating a nuanced understanding for accurate budgeting and planning. In the context of Anna Maria, a blend of local conditions and broader market trends intertwine to shape these estimates.

Material Costs

Fluctuations in material prices are significant contributors to project cost variability. Factors such as global commodity prices, supply chain disruptions, and local availability all play pivotal roles. Remote locations, for instance, often incur higher material costs due to increased transportation expenses. Additionally, shifts in global markets can lead to sudden price changes, impacting project budgets. Scarcity of certain materials in specific locales can also escalate costs, underscoring the importance of strategic sourcing and procurement practices to mitigate potential fluctuations.

Labor Rates

Labor expenses constitute a substantial portion of project budgets and are subject to various influences. Factors like skill requirements, availability of qualified professionals, and regional wage standards all contribute to labor rate differentials. Competitive labor markets or high-demand skill sets typically command higher wages, particularly in urban areas compared to rural counterparts. Considerations such as unionization rates and prevailing economic conditions further compound labor cost variability, necessitating a comprehensive understanding of local labor dynamics for accurate estimation.

Project Complexity

The intricacy of mechanical projects significantly impacts their costs, often necessitating specialized expertise, customized solutions, and advanced technologies. Complex projects entail intricate design considerations, sophisticated equipment, and specialized installation processes, all of which contribute to elevated expenses. Regulatory compliance, environmental factors, and safety standards further compound project complexities, requiring additional resources and expertise. In regions with stringent regulations or unique environmental challenges, such as seismic zones or coastal areas, project complexities are heightened, leading to increased costs.

Download Template For Concrete Project Breakdown

- Materials list updated to the zip code

- Fast delivery

- Data base of general contractors and sub-contractors

- Local estimators

Location-specific Factors

The geographical location of a project exerts a profound influence on its overall costs. Accessibility issues can escalate transportation expenses and logistical hurdles, particularly in remote or isolated areas. Local regulatory frameworks, including zoning regulations and permitting requirements, can add layers of complexity and costs to project execution. Climate conditions also play a significant role, necessitating specialized design considerations and materials in response to extreme weather events or environmental hazards. Moreover, factors like land availability, infrastructure development, and proximity to suppliers further shape project costs, underscoring the importance of integrating location-specific considerations into project planning and budgeting endeavors.

Cost to Repair Ductwork by Material

There exist various types of ductwork, ranging from economical, flexible, non-metallic options to premium sheet metal variants. Each type features distinct designs and materials, with repair costs varying accordingly. Hence, the type of duct you have can significantly impact the expenses of repairs. Below outlines the primary duct types alongside their average repair costs for a standard 30 linear feet section of ductwork.

Duct Material | Repair Cost |

Flexible Non-Metallic | $220 – $850 |

Flexible Aluminum | $220 – $900 |

Fiberglass Duct Board | $280 – $980 |

Sheet Metal | $300 – $1200 |

Business Finance Loan

Find out if you're pre-qualified in seconds

Get Prequalified Now

IMPORTANT: Make sure the email and phone number you enter are correct. We will email and text you a link to get started.

Cost of Geothermal Unit

These systems harness the earth’s heat to warm indoor spaces, offering exceptional energy efficiency and substantial savings on monthly energy bills for homeowners. Geothermal units typically range in cost from $14,000 to $49,000 on average. Despite the higher upfront investment, they boast an extended lifespan, minimal environmental impact, and reduced maintenance requirements compared to conventional heating systems.

HEAT PUMP TYPE | AVERAGE COST |

Ductless mini-split | $2,800 – $19,600 |

Dual fuel or hybrid | $4,200 – $21,000 |

Gas-fired | $5,600 – $14,000 |

Air-source | $7,000 – $19,600 |

Geothermal | $14,000 – $49,000 |

Common Challenges and Solutions

Mechanical cost estimators face a myriad of challenges in a landscape rife with uncertainties and varying expectations. Here are some of the most prevalent challenges encountered, along with innovative solutions to tackle them effectively:

Data Limitations

Accurate cost estimation heavily relies on robust data; however, accessing current and comprehensive data can pose a significant hurdle. This challenge is particularly pronounced in unique or specialized projects where historical data may be scarce.

Solution: Estimators are increasingly turning to advanced software and databases that offer a broader spectrum of data points, including industry standards and costs from comparable projects. Additionally, leveraging professional networks and industry associations to share knowledge and data can help bridge data gaps effectively.

Managing Client Expectations

Clients often harbor unrealistic expectations regarding project costs and timelines, influenced by factors beyond the estimator’s control.

Solution: Clear and transparent communication from the project’s inception is paramount. Providing detailed breakdowns of cost components and elucidating the factors influencing these costs can aid in managing expectations effectively. Regular updates throughout the estimation process keep clients well-informed, making adjustments more manageable.

Estimate Your Project With Us

Rapid Market Fluctuations

Material costs and labor rates can fluctuate rapidly due to economic factors, supply chain disruptions, or geopolitical events, posing challenges in providing stable estimates.

Solution: Integrating contingencies into cost estimates and continually monitoring market trends enable estimators to adapt projections in real-time. Dynamic estimating software capable of updating estimates based on current market conditions facilitates maintaining accuracy amidst market fluctuations.

Rapid Market Fluctuations

Material costs and labor rates can fluctuate rapidly due to economic factors, supply chain disruptions, or geopolitical events, posing challenges in providing stable estimates.

Solution: Integrating contingencies into cost estimates and continually monitoring market trends enable estimators to adapt projections in real-time. Dynamic estimating software capable of updating estimates based on current market conditions facilitates maintaining accuracy amidst market fluctuations.

Technological Changes

The swift pace of technological advancement can render previous methods or materials obsolete, complicating the estimation process.

Solution: Remaining abreast of technological trends through continuous education and industry events is essential. Incorporating flexibility into estimates to accommodate potential technological solutions or alternatives ensures estimates remain relevant and up-to-date.

Scope Creep

Projects often undergo evolution, leading to changes in scope that can significantly impact costs. Managing these changes without adequate oversight can derail budgets.

Solution: Implementing stringent change management processes and maintaining clear documentation of all alterations and their cost implications are pivotal in managing scope creep effectively. Regularly reviewing the project scope with stakeholders fosters alignment and minimizes surprises along the way.

- Multi-Family Building

- School & University

- Hospital Building

- Warehouse Building

- Hotel Building

- High-Rise Building

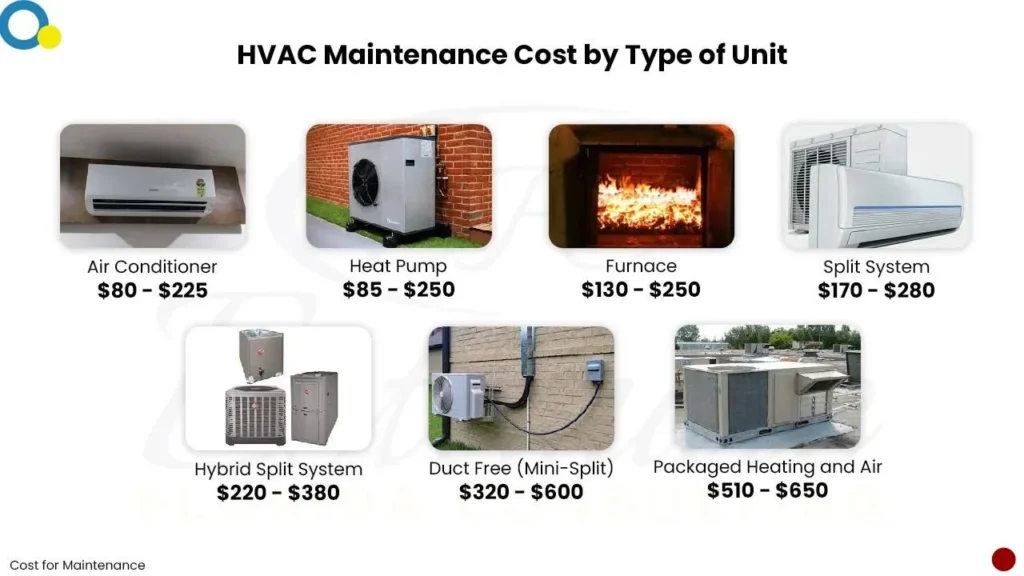

HVAC Maintenance Cost by Type of Unit

HVAC maintenance is essential for ensuring the efficiency and longevity of heating, ventilation, and air conditioning systems. Various types of units require regular maintenance to keep them running smoothly. Air conditioners, heat pumps, furnaces, split systems, hybrid split systems, duct-free mini-splits, and packaged heat and air units each have their own maintenance needs. Regular servicing can include tasks such as cleaning coils, checking refrigerant levels, inspecting electrical components, and replacing filters.

Type of Unit | Cost Range |

Air Conditioner | $80 – $250 |

Heat Pump | $25 – $250 |

Furnace | $130 – $250 |

Split System | $170 – $280 |

Hybrid Split System | $220 – $380 |

Duct Free (Mini-Split) | $320 – $600 |

Packaged Heat and Air | $510 – $650 |

Innovations in Mechanical System Technologies

The field of mechanical engineering is rapidly evolving, with new technologies enhancing efficiency, sustainability, and functionality of systems within buildings. In Cape Coral, where energy efficiency and climate resilience are particularly relevant, innovations such as variable refrigerant flow (VRF) HVAC systems, smart plumbing technologies, and energy-efficient lighting systems are revolutionizing how buildings are constructed and operated. Mechanical cost estimators need to be well-versed in these technologies, understanding their initial cost, installation requirements, and long-term savings. Keeping abreast of technological advancements allows estimators to offer competitive, forward-thinking solutions to clients, positioning projects at the forefront of efficiency and sustainability.

Need Template For Your Mechanical Business

We provide services for Brochure, Banner, Business Card, Envelope, Invoice, etc.

Impact of Climate Change on Mechanical Systems in Cape Coral

Cape Coral’s subtropical climate, characterized by hot summers and mild winters, is experiencing shifts due to climate change, including increased temperatures and more frequent extreme weather events. These changes directly impact the design and operation of mechanical systems. Estimators must account for these evolving climate conditions, ensuring that HVAC systems are capable of cooling efficiently during longer heatwaves and that plumbing and electrical systems are resilient against severe weather. This may involve investing in more robust systems upfront but can prevent costly repairs and inefficiencies in the long run.

Collaboration Between Design Teams and Cost Estimators

Successful mechanical cost estimation is rarely achieved in isolation. Collaboration between design teams, engineers, and cost estimators is crucial for aligning project visions with budgetary realities. Early involvement of cost estimators in the design process helps identify cost-saving opportunities without compromising the project’s objectives or compliance with Cape Coral’s building codes. This integrated approach fosters innovation, efficiency, and cost-effectiveness, ensuring that mechanical systems are designed to meet both current and future needs of the building and its occupants.

Regulatory Compliance and Incentive Programs

Cape Coral has stringent building codes and regulations aimed at ensuring safety, sustainability, and resilience in construction. These regulations often include specific requirements for mechanical systems, from energy efficiency ratings to environmental impact assessments. Mechanical cost estimators must navigate these regulations, incorporating compliance costs into their estimates. Additionally, they should be knowledgeable about local, state, and federal incentive programs that offer rebates or tax incentives for energy-efficient systems, as these can significantly offset initial costs and influence the choice of systems.

Are You Looking For?

Fully Insured License Hire Sub-Contractor For Mechanical Work

Hire Contractor

Make Informed Design Decisions Showcase Your Design Ideas

Get RenderingCall Us To Discuss More at 561-530-2845

Conclusion

Estimate Florida Consulting stands as a trusted partner for mechanical cost estimation in Cape Coral, FL. Our tailored estimates address the unique needs of each project, encompassing a wide range of mechanical systems from HVAC and plumbing to industrial machinery and renewable energy solutions. By considering factors such as material costs, labor rates, project complexity, and location-specific considerations, we provide accurate projections that align with our clients’ budgetary constraints and project objectives. Through innovative solutions, collaboration with design teams, and a deep understanding of regulatory compliance and incentive programs, we strive to deliver cost-effective and sustainable solutions that meet the evolving needs of Cape Coral’s construction landscape. With a commitment to transparency, professionalism, and client satisfaction, we look forward to supporting the success of mechanical projects in Cape Coral and beyond.

Choose Your Trade & Get a Sample Project

FAQs

HVAC systems in Cape Coral typically range from $5,500 to $110,000 or more, depending on the scale and complexity of the project.

Fire protection systems can vary in cost, with average estimates ranging from $11,000 to $220,000 or higher, considering factors such as the size of the building and regulatory requirements.

The cost of renewable energy systems in Cape Coral generally falls between $22,000 and $550,000, reflecting the investment required for installation and equipment tailored to harness sustainable energy sources.

Geothermal units, known for their energy efficiency and longevity, typically cost between $14,000 and $49,000 in Cape Coral, factoring in the initial investment for installation and long-term savings on energy bills.

Installing industrial machinery in Cape Coral can range from $27,500 to $1,100,000 or more, accounting for labor expenses influenced by factors such as skill requirements, project complexity, and prevailing wage standards in the region.

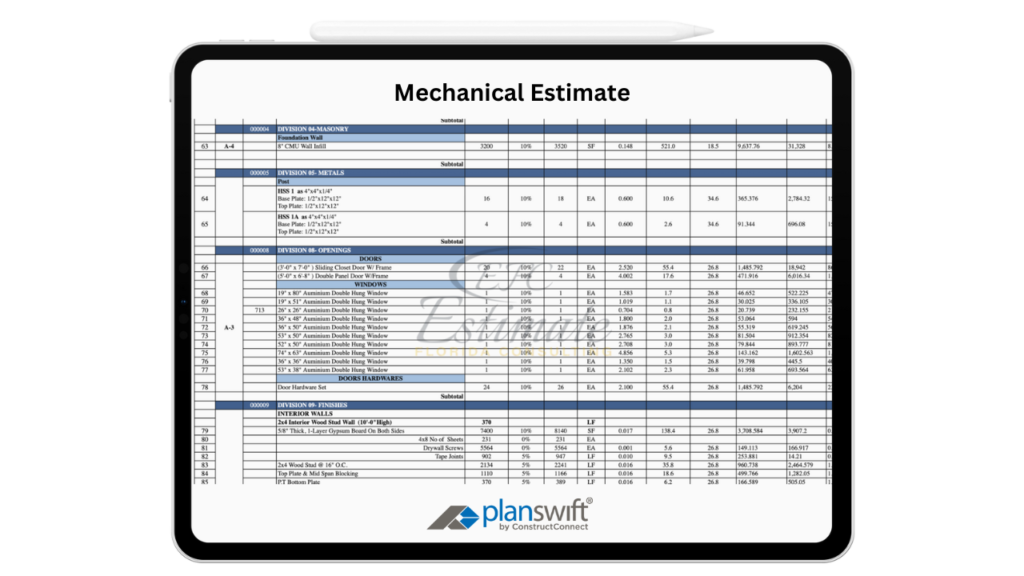

Process To Get Mechanical Cost Estimate Report

Here I am going to share some steps to get your mechanical cost estimate report.

-

You need to send your plan to us.

You can send us your plan on info@estimatorflorida.com

-

You receive a quote for your project.

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

-

Get Estimate Report

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.

Google Reviews