90% More Chances to Win More Projects With Our Estimate!

- Accurancy

- Efficiency

- Transparency

- Customization

- Time Saving

- Professionalism

- Cost Control

Estimate Florida Consulting, specializing in precise metal cost estimations tailored to the unique requirements of our clients in Cape Canaveral. Metal cost estimation serves as a crucial financial roadmap for engineering and construction projects in the region. Metal costs can vary significantly, depending on the scale and complexity of the project. For smaller-scale endeavors, expenses may range from $10,000 to $100,000+, while mid-sized projects could see costs between $200,000 to $1 million+. Larger industrial or commercial projects in Cape Canaveral might incur metal costs ranging from $2 million to over $10 million, contingent upon the project’s intricacies and specifications.

Projects in Cape Canaveral vary widely in size and scope, with small-scale endeavors typically encompassing basic metal installations or minor renovations. Medium-scale projects involve more substantial undertakings such as constructing metal structures or upgrading existing metal systems. Large-scale projects encompass major developments like building entire metal facilities or large-scale metal infrastructure improvements. Industrial-scale projects represent the most extensive ventures, including constructing massive metal manufacturing facilities or industrial complexes, reflecting the complexity and magnitude of the metal construction endeavor.

Size of Project | Estimated Cost Range |

Small-scale Projects | $10,000 – $100,000+ |

Medium-scale Projects | $200,000 – $1,000,000+ |

Large-scale Projects | $2,000,000 – $10,000,000+ |

Industrial-scale Projects | $5,000,000 – $50,000,000+ |

Cape Canaveral, renowned for its space exploration history and stunning coastal landscapes, hosts a dynamic plumbing industry that is fundamental to the city’s infrastructure and community well-being. From residential homes to commercial establishments, plumbing services in Cape Canaveral play a pivotal role in ensuring efficient water distribution, sanitation, and environmental sustainability across the region. The plumbing industry encompasses a diverse array of services and projects, ranging from routine maintenance and repairs to large-scale installations and innovative water conservation initiatives.

The reliable and efficient distribution of water is a cornerstone of daily life in Cape Canaveral. Plumbing professionals are instrumental in designing, installing, and maintaining water distribution systems that meet the needs of both residential and commercial properties. From underground piping networks to water mains and connections, these systems must adhere to strict safety and quality standards to ensure the consistent supply of clean water to households, businesses, and public facilities throughout the city.

Fully Insured License Hire Sub-Contractor For Metal Construction

Hire Contractor

Make Informed Design Decisions Showcase Your Design Ideas

Get RenderingWith a growing emphasis on sustainability and environmental responsibility, the plumbing industry in Cape Canaveral is increasingly focused on implementing eco-friendly practices and technologies. From the installation of water-saving fixtures and appliances to the adoption of rainwater harvesting systems and greywater recycling initiatives, plumbing professionals are at the forefront of promoting water conservation and reducing resource consumption in both residential and commercial settings. These sustainable plumbing practices not only help minimize water waste but also contribute to lower utility bills and a healthier environment for future generations.

In emergencies such as burst pipes, leaks, or sewer backups, prompt and reliable plumbing services are essential to minimize damage and restore functionality swiftly. Plumbing contractors in Cape Canaveral offer emergency services around the clock, ensuring that residents and businesses receive timely assistance when faced with unexpected plumbing issues. Equipped with advanced tools and expertise, these professionals swiftly diagnose and address plumbing emergencies, providing peace of mind to the community and safeguarding property from water damage.

Maintaining high water quality is paramount to the health and well-being of Cape Canaveral residents. Plumbing professionals play a crucial role in monitoring and improving water quality through regular testing, filtration, and treatment measures. Whether it’s ensuring compliance with regulatory standards or addressing specific contaminants and pollutants, plumbing experts employ specialized techniques and equipment to safeguard the purity and safety of the city’s drinking water supply.

As Cape Canaveral continues to grow and evolve, the plumbing industry plays a vital role in supporting infrastructure development and renovation projects across the city. From new construction projects to the renovation of existing buildings and facilities, plumbing contractors collaborate closely with architects, engineers, and developers to design and implement plumbing systems that meet the unique requirements of each project. Whether it’s upgrading aging infrastructure, expanding utility networks, or incorporating innovative technologies, these professionals contribute to the sustainable development and resilience of Cape Canaveral’s plumbing infrastructure for the future.

The metal cost estimation process in Cape Canaveral is influenced by various factors that reflect the unique characteristics of the aerospace and construction industries in the region. Understanding these factors is essential for accurate project budgeting and financial planning, ensuring that stakeholders have a clear understanding of the potential cost implications associated with metal-related endeavors in Cape Canaveral.

The fluctuating demand for metals, driven by factors such as economic conditions, industry trends, and project requirements, significantly impacts metal prices in Cape Canaveral. High demand for specific metals, particularly those used in aerospace manufacturing and construction projects, can lead to price spikes and supply shortages, affecting cost estimates for metal-related endeavors. Conversely, periods of low demand or excess supply may result in more favorable pricing conditions, influencing project budgets accordingly.

New projects are waiting for you.

Connect with more construction leads!

The choice of metals and their respective specifications play a crucial role in determining project costs in Cape Canaveral. Metals with specialized properties or higher quality standards, such as aerospace-grade alloys or corrosion-resistant materials, often command premium prices due to their unique characteristics and performance requirements. Metal cost estimators must carefully consider the specified materials and their associated costs when preparing project budgets, ensuring compliance with industry standards and performance expectations.

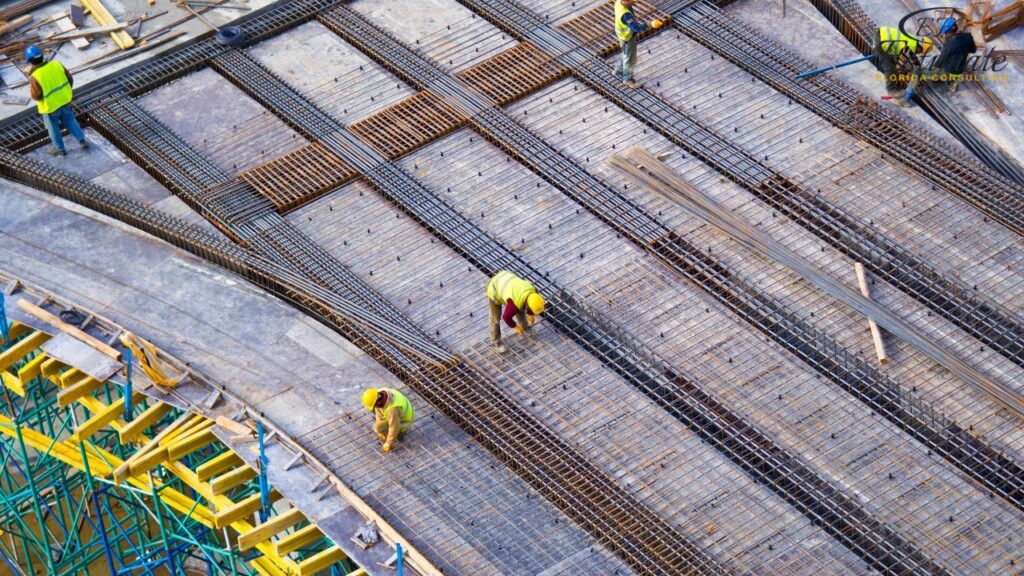

The availability of skilled labor and the complexity of metal installation processes significantly impact project costs in Cape Canaveral. Skilled metalworkers, welders, and technicians proficient in aerospace-grade materials and construction techniques are essential for executing metal-related projects effectively. Labor costs, including wages, benefits, and overhead expenses, contribute significantly to overall project budgets. Additionally, factors such as project location, access constraints, and safety requirements can influence installation costs, requiring careful consideration during the estimation process.

Adherence to regulatory standards, environmental regulations, and permitting requirements is critical for metal-related projects in Cape Canaveral. Compliance with federal, state, and local regulations governing metal fabrication, handling, and disposal ensures project legality and minimizes the risk of costly fines or delays. Metal cost estimators must account for regulatory compliance costs, including permit fees, inspections, and environmental assessments, when preparing project budgets, ensuring full compliance with applicable laws and regulations.

The inherent volatility of metal markets and broader economic conditions can introduce uncertainty into cost estimations for projects in Cape Canaveral. Fluctuations in commodity prices, currency exchange rates, and geopolitical factors can impact the cost of raw materials and transportation, influencing overall project budgets. Economic indicators such as inflation rates, interest rates, and labor market conditions also play a role in shaping metal cost estimations, requiring careful monitoring and risk management strategies to mitigate potential financial impacts.

Metal applications in construction and aerospace projects in Cape Canaveral vary widely in scope and complexity, encompassing a diverse range of materials and fabrication methods. These applications serve crucial functions, from structural support and enclosure to specialized components essential for aerospace engineering. Each metal application contributes to the integrity, durability, and performance of the final product, reflecting the rigorous standards and demands of the industries involved. Whether it’s aluminum for lightweight structures or stainless steel for corrosion resistance, choosing the right metal application is vital for project success.

Metal Application | Total ( 1,000 square feet ) | Cost per Square Foot |

Structural Steel | $5,000 – $50,000 | $5 – $50 |

Aluminum Components | $2,000 – $20,000 | $2 – $20 |

Stainless Steel Fabrication | $3,000 – $30,000 | $3 – $30 |

Titanium Components | $10,000 – $100,000 | $10 – $100 |

Sheet Metal Fabrication | $1,000 – $10,000 | $1 – $10 |

Welding Services | $500 – $5,000 | $0.50 – $5 |

Metal Machining | $1,500 – $15,000 | $1.50 – $15 |

Metal Finishing | $700 – $7,000 | $0.70 – $7 |

Aerospace Components | $20,000 – $200,000 | $20 – $200 |

These cost ranges are indicative and may vary based on project specifications, material requirements, labor costs, and market dynamics at the time of estimation.

Why delay? Share your project plans with us and give us a call today. We’re eager to help you make your project a resounding success!

The fluctuating prices of metals can pose challenges for accurate cost estimation, as market conditions can change rapidly, impacting project budgets.

Solution: Employing hedging strategies, such as forward contracts or options, can help mitigate the risks associated with price volatility by securing favorable pricing for metal procurement. Additionally, maintaining close relationships with suppliers and monitoring market trends allows estimators to adjust cost projections accordingly.

Metal-related projects in Cape Canaveral often involve intricate specifications and specialized requirements, making it challenging to accurately estimate costs without a thorough understanding of project scope.

Solution: Collaborating closely with engineers, architects, and project stakeholders from the outset allows estimators to gain insights into project intricacies and develop comprehensive cost estimates tailored to specific project requirements. Clear communication and regular updates ensure that cost projections align with evolving project needs.

Securing skilled labor proficient in metal fabrication and installation can be a challenge, particularly for projects requiring specialized expertise or working in remote locations.

Solution: Partnering with reputable subcontractors or metal fabrication firms with proven track records and a skilled workforce can help ensure access to qualified labor. Offering competitive wages, training programs, and incentives can also attract and retain skilled professionals, ensuring project success.

Navigating regulatory requirements and obtaining permits for metal-related projects in Cape Canaveral can be time-consuming and complex, leading to potential delays and cost overruns.

Solution: Engaging legal experts or regulatory consultants familiar with local regulations and permitting processes can streamline compliance efforts and expedite approvals. Incorporating compliance costs and timelines into project schedules allows for better planning and resource allocation, minimizing the impact on project budgets.

The rapid pace of technological advancements in metal fabrication and construction techniques presents both opportunities and challenges for cost estimators, who must stay abreast of new technologies to remain competitive.

Solution: Investing in training and professional development programs to familiarize estimators with emerging technologies and software tools can enhance efficiency and accuracy in cost estimation processes. Collaborating with technology vendors and industry experts allows estimators to leverage innovative solutions, such as Building Information Modeling (BIM) and digital fabrication techniques, to optimize project costs and delivery timelines.

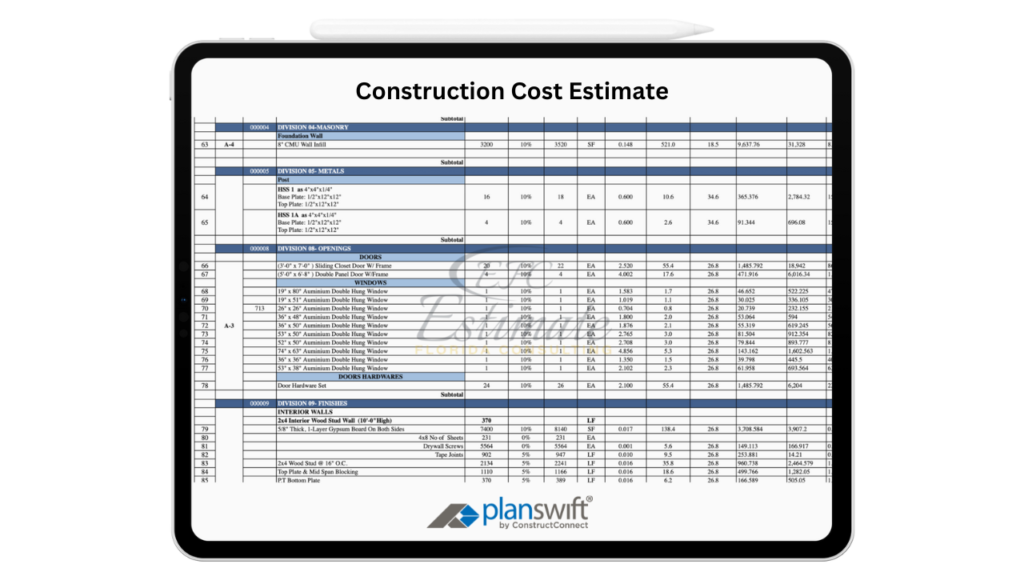

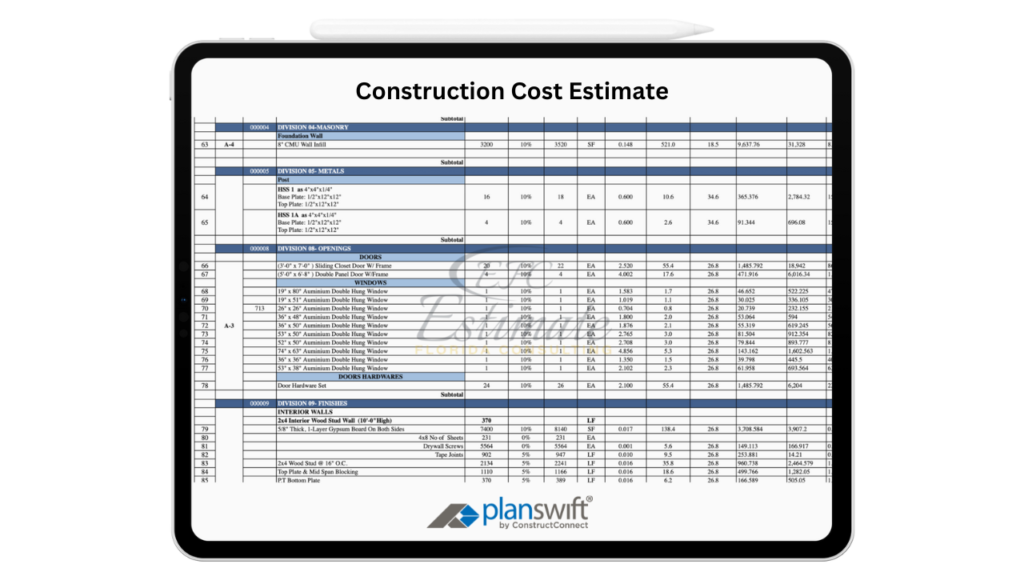

The process begins with a comprehensive definition of the project scope, including the specific requirements, objectives, and deliverables. This step involves gathering detailed information about the project, such as architectural plans, engineering drawings, and material specifications, to establish a clear understanding of the work to be estimated.

Once the project scope is defined, the next step is to identify and select the appropriate materials for the metal components involved in the project. This includes considering factors such as material type, grade, size, and quantity. Specifications are established based on project requirements, industry standards, and regulatory guidelines to ensure compliance and quality.

Estimators identify the resources required for the project, including labor, equipment, and subcontractors. This step involves assessing the skills and expertise needed for metal fabrication, welding, machining, and installation, as well as determining the availability and cost of specialized equipment and services.

Estimators conduct a detailed breakdown of costs associated with materials, labor, equipment, and overhead expenses. This involves researching current market prices, obtaining quotes from suppliers and subcontractors, and analyzing historical data from similar projects. Cost factors such as transportation, taxes, and tariffs are also taken into account to ensure accuracy.

Quantity takeoff is performed to determine the quantities of metal materials required for the project. This involves measuring and quantifying the dimensions of structural components, fittings, fasteners, and other metal elements based on engineering drawings and specifications. Accurate quantity takeoff is essential for precise cost estimation and procurement planning.

Using the information gathered during the previous steps, estimators calculate the total project cost based on the cost breakdown and quantity takeoff. This involves applying unit prices to individual components and multiplying them by the respective quantities to obtain cost estimates. Contingencies and allowances for potential risks, fluctuations in material prices, and unforeseen circumstances are also factored into the final cost estimation.

The final step involves reviewing and validating the cost estimation to ensure accuracy and reliability. This may include peer reviews, consultations with subject matter experts, and comparison with benchmark data from similar projects. Any discrepancies or inconsistencies are addressed, and adjustments are made as necessary to produce a comprehensive and trustworthy estimate.

By following these steps, metal cost estimators in Cape Canaveral can develop accurate and reliable cost estimates that support informed decision-making and successful project execution in the aerospace and construction industries.

Metal cost estimation in Cape Canaveral is a multifaceted process that requires careful planning, analysis, and expertise to ensure project success. From defining the project scope to conducting detailed cost breakdowns and quantity takeoffs, each step in the estimation process plays a crucial role in producing accurate and reliable cost estimates. Challenges such as material price volatility, complex project requirements, and regulatory compliance necessitate innovative solutions and meticulous attention to detail. By leveraging advanced software tools, collaborating with industry partners, and staying abreast of technological advancements, metal cost estimators can overcome these challenges and deliver cost estimates that align with project objectives and stakeholder expectations. Ultimately, accurate cost estimation is essential for effective budgeting, resource allocation, and decision-making, enabling successful project execution and the realization of aerospace and construction initiatives in Cape Canaveral.

Metal cost estimators in Cape Canaveral often employ hedging strategies, such as forward contracts or options, to mitigate the risks associated with price volatility. Additionally, they stay updated on market trends, maintain close relationships with suppliers, and incorporate contingencies into their cost estimates to address potential price fluctuations.

Labor costs for metal-related projects in Cape Canaveral can vary based on factors such as the skill level and availability of workers, project complexity, location, and union requirements. Estimators account for these factors by conducting thorough labor market analyses, considering prevailing wage rates, and assessing the specific labor requirements of each project.

Metal cost estimators in Cape Canaveral work closely with legal experts, regulatory consultants, and local authorities to navigate regulatory requirements and obtain necessary permits for metal-related projects. They stay informed about relevant laws and regulations, incorporate compliance costs into their estimates, and allocate resources accordingly to ensure adherence to regulatory standards.

Subcontractors often provide specialized services, such as metal fabrication, welding, and installation, that are essential for metal-related projects in Cape Canaveral. Metal cost estimators collaborate with subcontractors to obtain quotes, assess capabilities, and incorporate subcontracting costs into their estimates. Building strong relationships with reputable subcontractors ensures quality workmanship and timely project delivery.

Metal cost estimators in Cape Canaveral anticipate potential risks and changes by incorporating contingencies into their cost estimates. They also maintain open communication channels with project stakeholders, monitor project progress closely, and adjust estimates as necessary to accommodate changes in scope, schedule, or budget. Effective risk management strategies and proactive problem-solving help mitigate the impact of unforeseen circumstances on project outcomes.

Here I am going to share some steps to get your metal cost estimate report.

You can send us your plan on info@estimatorflorida.com

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

All copyright © Reserved | Designed By V Marketing Media | Disclaimer