Take the First Step For Estimate!

- Accurancy

- Efficiency

- Transparency

- Customization

- Time Saving

- Professionalism

- Cost Control

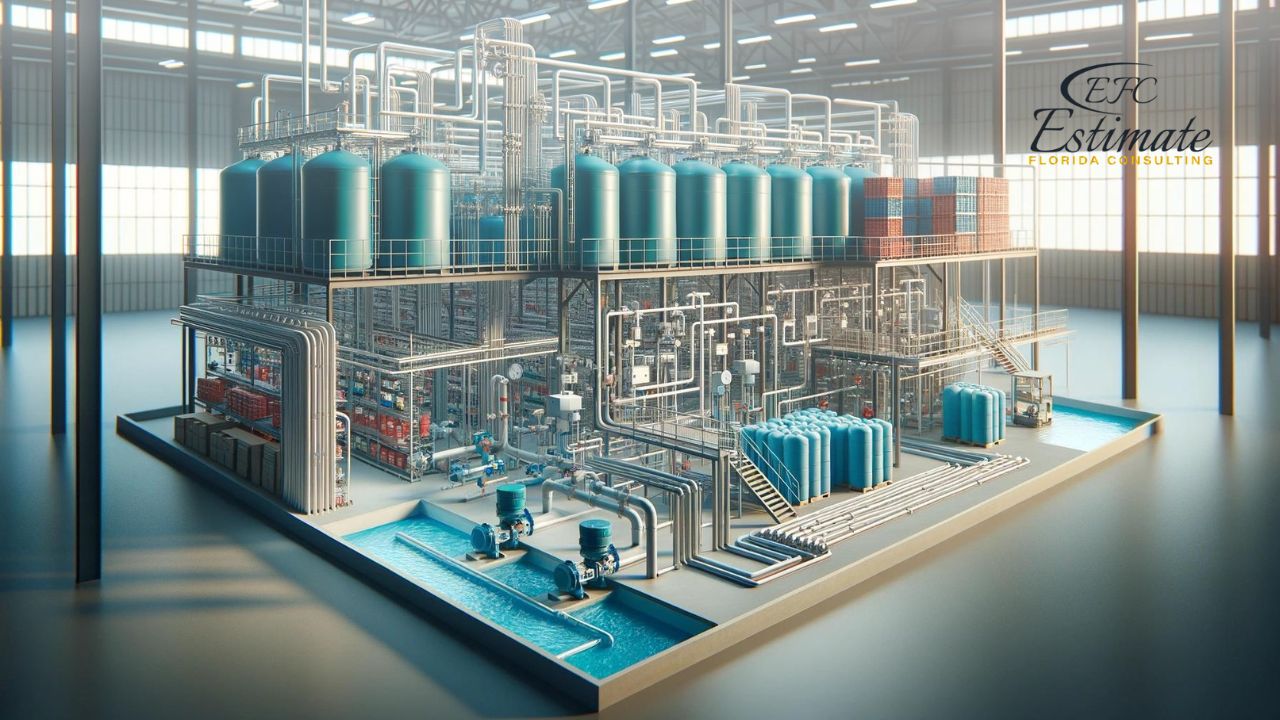

Estimate Florida Consulting is your trusted partner for precise water supply infrastructure cost estimates tailored for warehouses. Low budgets, suitable for smaller warehouses, focus on cost-effectiveness, with estimated costs ranging from $10,000 to $50,000+. Mid-budget scenarios, for medium-sized warehouses, balance costs and functionality, with costs ranging from $50,000 to $150,000+. High budgets, for large or specialized warehouses, prioritize advanced technologies and materials, with costs ranging from $150,000 to over $500,000. With our reliable estimates, contractors can navigate the bidding process effectively, meeting client needs while staying competitive in the market.

The expenses of water supply infrastructure for warehouses can vary significantly. For smaller warehouses, the costs are relatively lower, while larger warehouses entail higher investments. The investment increases with the size and complexity of the warehouse.

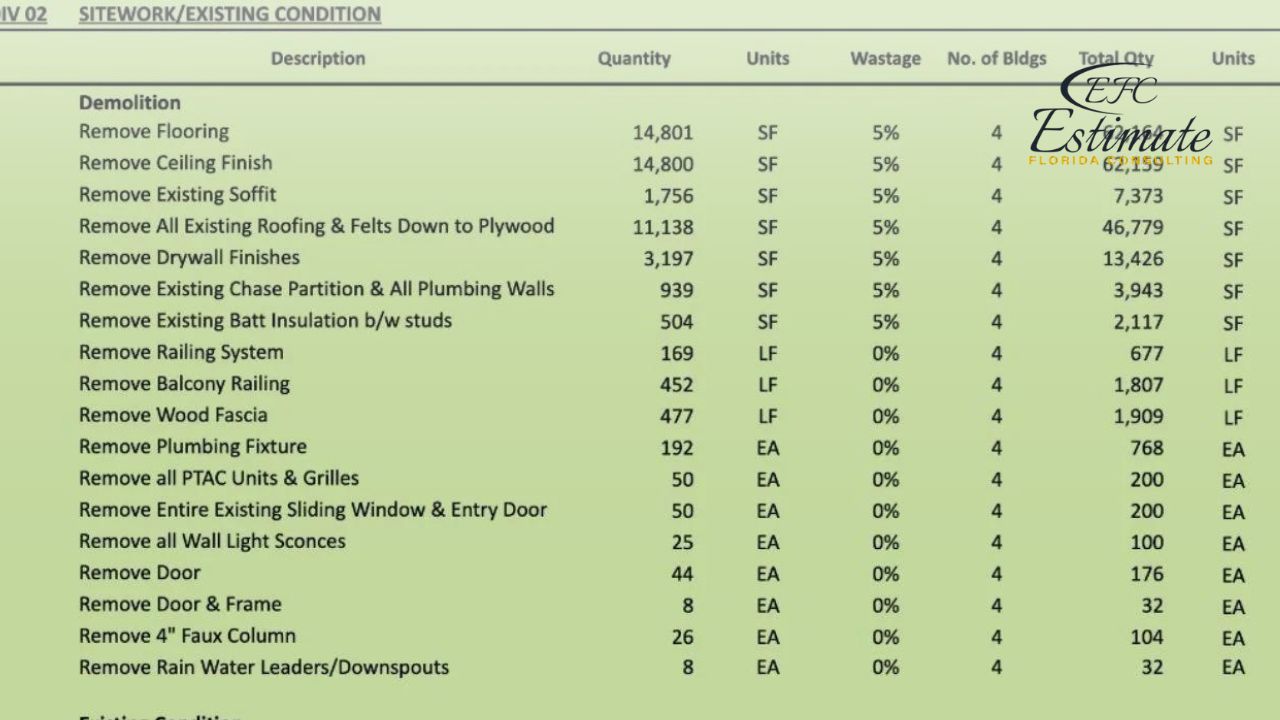

Warehouse Area (square feet) | Cost (USD) |

Less than 5,000 | $10,000 – $20,000+ |

5,000 – 10,000 | $20,000 – $30,000+ |

10,000 – 20,000 | $30,000 – $60,000+ |

20,000 – 50,000 | $60,000 – $140,000+ |

50,000 – 100,000 | $140,000 – $280,000+ |

100,000 – 200,000 | $280,000 – $560,000+ |

200,000 – 500,000 | $560,000 – $1,400,000+ |

The size of the warehouse is a pivotal factor in determining construction costs. Larger warehouses inherently require more materials, a more extensive foundation, and additional labor hours, all of which contribute to increased expenses. The dimensions of the warehouse, including its length, width, and height, play a crucial role in calculating the volume of materials needed for structural elements, roofing, and interior spaces.

Moreover, larger warehouses often entail more complex structural designs and greater structural loads, necessitating additional engineering work and potentially specialized materials. Accurately assessing the warehouse’s size and volume is paramount in cost estimation, as any underestimation can lead to budget overruns during construction.

The geographical location of the warehouse construction project significantly influences the overall cost estimation. Urban and suburban areas may have higher construction costs due to stricter building codes, zoning regulations, and safety requirements. Additionally, labor rates tend to be higher in urban environments, impacting the expenses associated with skilled workers and construction crews. Conversely, rural locations may present their own cost challenges, such as the need to extend infrastructure services over longer distances, increasing expenses related to utilities and access roads. Therefore, understanding the unique cost dynamics of the chosen location is crucial for developing an accurate budget.

ZIP Code Based Estimate

Highly Accurate

Fully Insured License

Hire Contractor for Warehouse

Make Informed Design Decisions Showcase Your Design Ideas

Get RenderingMaterial costs are crucial in construction, including warehouses, with price fluctuations significantly impacting estimations. Variables like market demand, availability, and material types affect costs. Choices between standard and premium materials also influence expenses. Planners and estimators must track market prices and anticipate fluctuations for accurate budgeting. For water supply infrastructure in warehouses, material costs might range from $55,000 to $450,000 or more, based on project specifics. Precise material cost estimation is vital for project feasibility and financial stability.

Labor costs, a substantial component of construction budgets, vary widely based on project location and complexity. Skilled labor rates, including those for construction workers, electricians, plumbers, and other trades, are influenced by local labor markets. Urban areas with higher living costs often command higher wages, while rural regions may offer more competitive rates. Hourly rates for plumbing and installation work can range from $50 to $150+ for skilled labor, depending on the region and specific skills required. The complexity of the project, such as architectural intricacies and specialized features, also impacts labor costs.

Compliance with local building codes, regulations, and permitting requirements is non-negotiable in construction projects. These regulatory requirements can vary significantly from one location to another and can dictate specific design modifications and materials that must be used. For example, areas prone to seismic activity may require additional structural reinforcements, while regions with extreme weather conditions may necessitate specialized roofing and insulation. Failing to account for regulatory requirements in the cost estimation process can lead to costly delays and revisions during construction, underscoring the importance of thorough research and adherence to local codes.

The condition of the construction site itself, including its topography, soil quality, and existing infrastructure, can exert a notable influence on cost estimation. A site with challenging terrain or poor soil conditions may require additional foundation work, retaining walls, or grading, all of which can increase construction costs. Furthermore, site conditions can impact access to the site, affecting transportation costs for materials and equipment.

Sites in remote or undeveloped areas may need extensive infrastructure development, such as utility connections and road construction, contributing to higher overall expenses. Site condition assessments are crucial for accurately factoring in site-specific challenges and contingencies in the construction budget.

The first step in estimating the cost of water supply infrastructure for warehouses is to conduct preliminary assessments. Start by performing a thorough analysis of the water needs of the warehouse. This includes evaluating the expected water demand for various purposes, such as firefighting, plumbing, sanitation, and any specialized industrial processes. Additionally, conduct a detailed site survey to assess the existing conditions of the site. Identify factors such as the availability of water sources, topography, soil quality, and any existing infrastructure that may impact the design and installation of the water supply system. These preliminary assessments provide the necessary foundation for accurate cost estimation.

After completing the preliminary assessments, move on to the design phase of the water supply infrastructure. Collaborate with experienced engineers, water supply experts, and other relevant professionals to create comprehensive design plans. During this phase, select appropriate components and layout plans that align with the warehouse’s water needs while staying within the budget constraints. Consider factors such as the size of the warehouse, the expected flow rates, water storage requirements, and the distribution network. The design phase serves as the blueprint for the entire water supply system and plays a crucial role in accurate cost estimation.

Implement cost estimation methodologies to calculate the expenses associated with the water supply infrastructure. One widely used approach is the unit cost method, which involves determining the unit cost for each component of the infrastructure, such as pipes, pumps, valves, and water storage tanks. Multiply these unit costs by the corresponding quantities required for the project to calculate the direct costs accurately. Additionally, consider indirect costs that are essential to the overall budget. Indirect costs may encompass expenses such as permits, regulatory compliance fees, insurance for the water supply system, legal fees related to approvals and contracts, and financing charges if the project requires funding through loans or bonds. Be thorough in incorporating these indirect costs to provide a comprehensive cost estimate.

New projects are waiting for you.

Connect with more construction leads!

Indirect costs play a crucial role in the overall budget and should not be underestimated. Start by factoring in permit costs, which can vary based on the project’s location and local regulations. Water supply infrastructure projects typically require permits related to water rights, environmental impact assessments, and compliance with water quality standards. These permits often come with associated fees that should be included in the cost estimation. Additionally, consider insurance costs to cover liabilities, property damage, and any potential water supply-related incidents. Legal fees for contracts, approvals, and regulatory compliance should also be accounted for. Finally, if the project relies on external financing, include financing charges and interest expenses as part of the indirect costs.

The adoption of innovative technologies in water supply infrastructure for warehouses can lead to substantial cost reductions and environmental benefits. One such innovation is the implementation of water recycling systems. These systems capture and treat wastewater generated within the warehouse, allowing it to be reused for non-potable purposes such as irrigation or cooling systems. By reducing the demand for freshwater, water recycling systems not only lower water bills but also contribute to sustainable water management.

Another valuable innovation is the integration of smart monitoring and control systems. These systems utilize sensors and data analytics to continuously monitor water usage, detect leaks, and optimize water distribution. By providing real-time insights, warehouse operators can identify inefficiencies and take proactive measures to reduce water wastage. Additionally, energy-efficient pumps and water treatment technologies can minimize energy consumption, further decreasing operational costs while promoting environmental sustainability.

Let us take your project to the next level! Send us your plans, and we’ll provide a detailed estimate with competitive pricing. Our ZIP Code-based approach means better accuracy and a 90% higher chance of winning bids. Get personalized, no-shortcut service every time.

Estimating the cost of water supply infrastructure for warehouses is a multifaceted process that involves careful consideration of various factors, from warehouse size and location to materials, labor, and regulatory requirements. By following a step-by-step guide and incorporating innovative technologies and cost-saving strategies, warehouse operators can develop accurate budgets and implement efficient and sustainable water supply solutions. These investments not only ensure reliable water access for operations but also contribute to cost savings and environmental stewardship in the long run.

The cost of water supply infrastructure can vary based on factors such as the size of the warehouse, complexity of the system required, location, regulatory requirements, type of water source, quality of materials used, and labor costs. For smaller warehouses, costs typically range from $10,000 to $50,000+, while larger or specialized warehouses may incur costs exceeding $500,000.

The cost estimate covers various components including water source installation, piping and plumbing, water treatment systems, storage tanks or reservoirs, fire protection systems, water metering and monitoring, labor and installation, permitting and compliance, maintenance and repair, and contingency funds. Costs vary depending on the size and complexity of the warehouse, ranging from $10,000 to $1,400,000+.

Determining the budget depends on factors such as the size of the warehouse, specific water usage requirements, local regulations, and client preferences. Estimate Florida Consulting provides tailored cost estimates categorized into low, mid, and high budgets, ranging from $10,000 to over $500,000, allowing clients to choose based on their needs and priorities.

To optimize cost-effectiveness, consider factors such as efficient water management practices, utilizing sustainable water sources, selecting durable yet cost-effective materials, optimizing system design for minimal waste, and conducting regular maintenance to prevent costly repairs. Estimate Florida Consulting offers guidance on cost-effective solutions while maintaining functionality, with cost ranges tailored to various budget scenarios.

By utilizing precise cost estimates from Estimate Florida Consulting, contractors can effectively navigate the bidding process by offering competitive pricing aligned with client requirements and market standards. With cost ranges specified for different warehouse sizes and budget scenarios, contractors can tailor their bids to meet client needs while remaining competitive in the market.

Here I am going to share some steps to get your water supply infrastructure cost for warehouses estimate report.

You can send us your plan on info@estimatorflorida.com

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

All copyright © Reserved | Designed By V Marketing Media | Disclaimer