Take the First Step For Estimate!

- Accurancy

- Efficiency

- Transparency

- Customization

- Time Saving

- Professionalism

- Cost Control

Sloped roofs are increasingly becoming the choice for warehouse buildings due to their numerous benefits, including enhanced drainage, aesthetic appeal, and potential for energy efficiency. This article aims to provide a comprehensive overview of the costs and considerations. So the estimated total cost for the sloped roof installation project for the warehouse building is approximately $138,000.involved in installing a sloped roof on a warehouse, helping owners make informed decisions.

Item | Cost |

Materials Cost | $75,000 |

Labor Cost | $45,000 |

Additional Features | $18,000 |

Total Cost | $138,000 |

Metal roofs are a popular choice for warehouses due to their exceptional durability and longevity. These roofs are typically made from materials such as steel or aluminum, which can withstand harsh weather conditions, including heavy rain, snow, and high winds. This makes them a reliable option for protecting the contents of a warehouse.

One of the key advantages of metal roofs is their low maintenance requirements. They are resistant to rot, pests, and fire, which can help reduce ongoing repair and replacement costs. Additionally, metal roofs are known for their energy efficiency, as they reflect sunlight and heat, helping to keep the warehouse interior cooler during hot weather. This can lead to energy savings on cooling costs over time.

Asphalt shingles are a cost-effective and versatile roofing option for warehouses. They are made from layers of fiberglass or organic materials coated with asphalt, which provides excellent waterproofing and protection against the elements. Asphalt shingles come in a variety of colors and styles, allowing warehouse owners to choose a design that suits their aesthetic preferences.

One of the primary advantages of asphalt shingles is their affordability. They are budget-friendly and relatively easy to install, which can help warehouse owners save on construction costs.

Moreover, asphalt shingles are readily available and can be replaced individually if damaged, making maintenance more straightforward. While they may not offer the same level of longevity as metal or tile roofs, they provide a cost-effective roofing solution for warehouses on a budget.

Tile roofs offer a unique aesthetic and excellent durability, making them a distinctive choice for warehouses. These roofs are typically made from materials such as clay, concrete, or terracotta, and they come in various shapes, sizes, and colors. Tile roofs add a touch of elegance and character to warehouses, making them stand out in terms of curb appeal.

One of the key advantages of tile roofs is their long lifespan. When properly maintained, tile roofs can last for several decades, providing warehouse owners with peace of mind and reducing the need for frequent replacements. Additionally, tile roofs are resistant to fire, rot, and pests, ensuring the warehouse’s contents remain protected.

Solar tiles are an innovative roofing option that combines the benefits of a traditional roof with solar energy generation. These tiles are designed to seamlessly integrate into the roof, providing an eco-friendly and energy-efficient solution for warehouses. Solar tiles capture sunlight and convert it into electricity, which can be used to power the warehouse’s operations, resulting in long-term energy savings.

The primary advantage of solar tiles is their ability to reduce energy costs and promote sustainability. Over time, the electricity generated by solar tiles can offset a significant portion of the warehouse’s energy consumption, making it an environmentally responsible choice. Additionally, some governments offer incentives and tax credits for installing solar panels or tiles, further enhancing the economic benefits of this roofing option.

ZIP Code Based Estimate

Highly Accurate

Fully Insured Licensed Hire Sub-Contractor for Warehouse Sloped Roof Installation

Hire Contractor

Make Informed Design Decisions Showcase Your Design Ideas

Get RenderingSloped roofs are designed with a pitch or angle that allows rainwater, snow, and other precipitation to run off easily. This natural drainage system minimizes the risk of water accumulation on the roof’s surface, reducing the likelihood of leaks and water damage to the building’s interior. Proper drainage is essential for maintaining the structural integrity of the roof and preventing moisture-related issues such as mold growth and rot. By efficiently directing water away from the roof, sloped roofs contribute to the overall longevity and reliability of the building.

Sloped roofs are often constructed with durable materials like metal, asphalt shingles, or tiles, which can significantly extend their lifespan. Metal roofs, for example, are known for their exceptional durability and resistance to harsh weather conditions, including heavy rainfall, hail, and strong winds. Properly maintained sloped roofs can last for several decades, providing long-term protection and structural integrity to the building. This longevity not only saves on replacement and maintenance costs but also ensures the continued functionality of the roof throughout its lifespan.

Sloped roofs can enhance the overall appearance of a building, contributing to its aesthetic appeal. The varied pitch angles and roofing materials available offer architectural versatility, allowing for unique and eye-catching designs. For instance, tile roofs can provide a distinct Mediterranean or Spanish-style look, while metal roofs can convey a modern and industrial aesthetic. A well-designed sloped roof can complement the building’s architectural style and increase its curb appeal, making it more visually appealing to both occupants and passersby.

Certain roofing materials and designs can enhance the energy efficiency of a building with a sloped roof. For example, reflective roofing materials like metal or white asphalt shingles can help reduce heat absorption, keeping the building cooler during hot weather. Additionally, sloped roofs can accommodate attic spaces with proper insulation, which can further improve energy efficiency by reducing heat loss during the winter and heat gain during the summer. The energy-efficient characteristics of sloped roofs can translate into lower heating and cooling costs for the building, providing economic and environmental benefits.

The size of the warehouse is a primary factor influencing the cost of sloped roof installation. Larger roofs require more roofing materials, a greater amount of labor, and additional structural support, which all contribute to higher costs. Roofing contractors typically calculate the cost per square foot, so a larger warehouse with a greater roof area will naturally result in a higher total installation cost. Furthermore, larger roofs may require more time to complete the installation, leading to increased labor expenses.

The selection of roofing material plays a significant role in determining the overall cost of the installation. Different roofing materials come with varying price points, maintenance requirements, and lifespans. For instance, metal roofing tends to be more expensive upfront but offers excellent durability and a longer lifespan, potentially reducing long-term maintenance costs. On the other hand, asphalt shingles are often more budget-friendly but may have a shorter lifespan and higher maintenance needs. Tile roofs can be costly due to their aesthetic appeal and longevity. The choice of roofing material should align with the warehouse owner’s budget and preferences.

The complexity of the roof design also impacts the cost of installation. A simple, straightforward sloped roof design will generally be less expensive to install compared to a roof with intricate architectural features, multiple slopes, valleys, dormers, or skylights. Complex designs require more labor and specialized skills to ensure proper installation and waterproofing. Roofing contractors may charge higher rates for intricate designs, so warehouse owners should consider design complexity when budgeting for their sloped roof installation.

The geographic location of the warehouse can influence the cost of sloped roof installation due to factors such as local climate conditions and market rates. In regions with extreme weather, additional materials and labor may be necessary to ensure the roof’s durability and resistance to weather-related damage. Furthermore, market rates for roofing materials and labor can vary by location, impacting the overall project cost. Warehouse owners should consider local factors and consult with roofing professionals familiar with the area to obtain accurate cost estimates.

Selecting the right material involves balancing cost, durability, maintenance needs, and climate considerations. For instance, metal roofs are excellent for longevity and energy efficiency but come at a higher initial cost.

The first step in installing a sloped roof on a warehouse is conducting an initial assessment. This assessment involves determining the best roof type and design for the specific needs of the warehouse. Factors such as the size of the warehouse, its location, climate conditions, and the building’s intended use all play a role in selecting the most suitable roofing solution. This phase also involves consulting with roofing professionals or architects to develop a comprehensive plan that addresses the warehouse’s unique requirements and budget constraints.

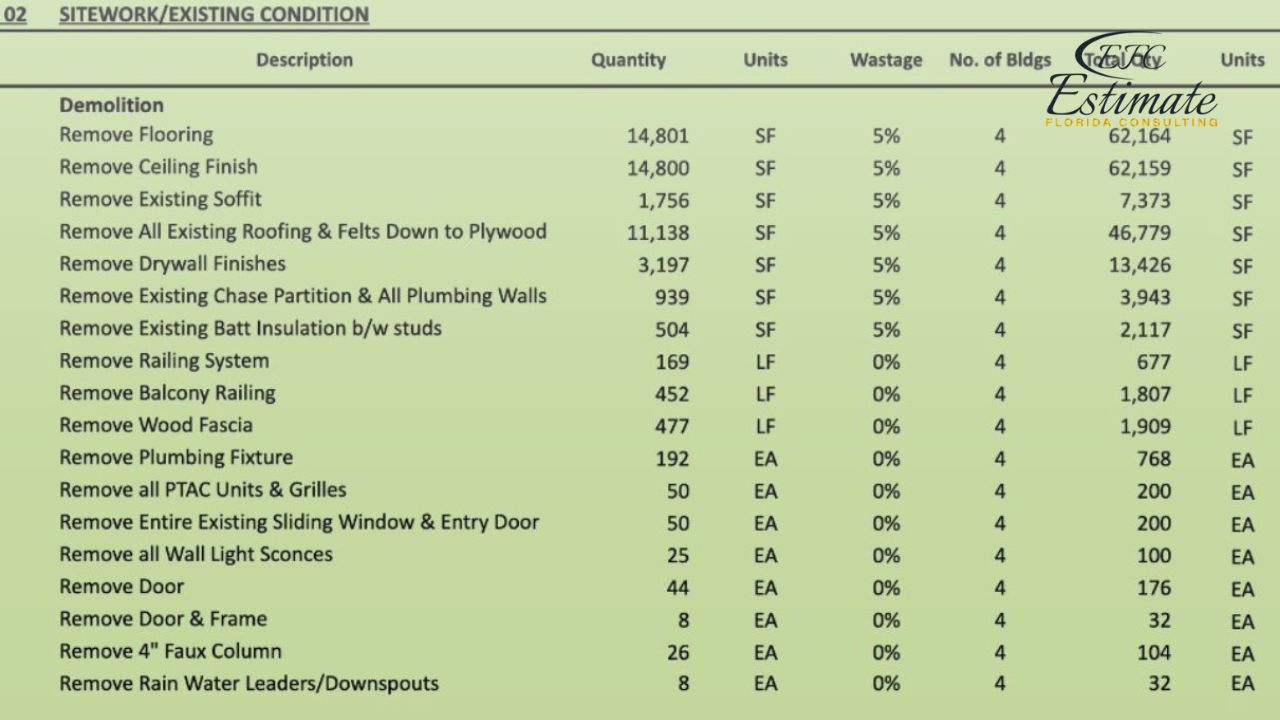

In cases where there is an existing roof on the warehouse that needs replacement or renovation, the removal of the old roof is the next step. This process can add to the overall cost and timeline of the roof installation project. Roofing contractors will carefully remove the old roofing material, ensuring that any underlying structural damage is identified and repaired as needed. The removal of the existing roof is a critical step to ensure that the new sloped roof is installed on a sound and stable foundation.

Once the initial assessment is completed, and any necessary removal of the existing roof is done, the installation phase begins. This phase involves following the chosen roof design and material specifications outlined in the project plan. Roofing professionals will start by installing the necessary structural support, including trusses and rafters, to create the desired slope for the roof. Depending on the chosen roofing material, layers of underlayment, insulation, and waterproofing membranes are applied to ensure the roof’s integrity and protection against the elements.

The actual roofing material, whether it’s metal panels, asphalt shingles, tile, or another option, is then installed according to the manufacturer’s guidelines and industry best practices. Proper sealing, flashing, and ventilation are critical aspects of the installation process to ensure a watertight and durable roof. The installation is typically performed by experienced roofing crews who have the necessary skills and equipment to complete the project efficiently and with attention to detail.

Once the sloped roof is fully installed, the final step involves conducting thorough inspections to ensure quality and adherence to local building codes and industry standards. Inspectors will assess the roof’s structural integrity, waterproofing, flashing, and overall workmanship to ensure that it meets safety and performance criteria. Any deficiencies or issues discovered during the inspection phase are addressed and corrected by the roofing contractor to ensure the roof’s long-term reliability and functionality.

Selecting the right material involves balancing cost, durability, maintenance needs, and climate considerations. For instance, metal roofs are excellent for longevity and energy efficiency but come at a higher initial cost.

Sloped roof installation can be a significant financial investment. To help mitigate the upfront costs, consider exploring various financing options:

By exploring these financing options, you can find a solution that aligns with your budget and helps make sloped roof installation more affordable.

Proper maintenance and care are essential for ensuring the longevity and performance of sloped roofs. Here are some key aspects of roof maintenance:

By implementing a proactive maintenance plan, you can extend the life of your sloped roof, protect your investment, and avoid costly repairs or replacements in the future. Regular care also helps ensure that the roof continues to provide reliable protection for your property.

Estimate Florida Consulting can provide estimates for your entire projects based on your local pricing. So the estimated cost will be accurate

Sloped roofs offer numerous advantages for warehouse buildings, including improved drainage, durability, aesthetic appeal, and potential energy efficiency. Estimating the cost of sloped roof installation involves factors such as roofing materials, size, labor, complexity, and geographic location. Warehouse owners should carefully consider their choices, select a qualified roofing contractor, explore financing options, and implement regular maintenance to ensure the longevity and performance of their sloped roofs. Making informed decisions in these areas can lead to a successful sloped roof installation that enhances the warehouse’s functionality and appearance.

Sloped roofs offer improved drainage, reducing the risk of water accumulation and potential leaks. They also provide longevity and durability, especially when made from materials like metal or tiles. Additionally, sloped roofs can enhance the aesthetic appeal of a warehouse and potentially improve energy efficiency through better insulation and ventilation.

The cost varies significantly based on several factors, including the size of the warehouse, the roofing material chosen, and the complexity of the roof design. Prices can range from $5 to $25 per square foot, with the total project cost potentially falling between $5,000 for small warehouses to $300,000+ for large facilities.

The “best” material depends on your specific needs, including budget, climate, and aesthetic preferences. Metal roofs are durable and low-maintenance, asphalt shingles are cost-effective and versatile, tile roofs offer a unique look and excellent durability, and solar tiles provide energy savings.

Key factors include the warehouse’s size, the type of roofing material, labor costs, which vary by region, the complexity of the roof’s design, and any additional features or considerations, such as insulation and ventilation systems.

Financing options include traditional bank loans, roofing company financing programs, leasing options, and potentially government grants or incentives for energy-efficient roofing systems. Evaluating these options can help you find a financial solution that fits your budget and project goals.

Regular maintenance includes bi-annual inspections to check for potential issues, timely repairs of any damage, keeping gutters and downspouts clear, trimming overhanging tree branches, and possibly hiring a professional for periodic maintenance checks to ensure the roof remains in good condition.

Here I am going to share some steps to get your sloped roof installation for warehouse buildings estimate report.

You can send us your plan on info@estimatorflorida.com

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

All copyright © Reserved | Designed By V Marketing Media | Disclaimer