Tap into Success – Zip Code Estimates for Fire Safety Excellence!

- Accurancy

- Efficiency

- Transparency

- Customization

- Time Saving

- Professionalism

- Cost Control

Fire safety is a paramount concern for industrial facilities, and the installation of a reliable fire hydrant system is a critical component of any comprehensive fire protection strategy.

This article delves into the various factors influencing the cost of implementing a fire hydrant system in industrial settings, providing facility managers and stakeholders with insights into the key considerations for budgeting and planning.

A properly equipped fire hydrant system is invaluable for safeguarding lives and protecting assets within industrial facilities. In the event of a fire emergency, the system provides a critical water supply, enabling rapid response by firefighting personnel. This swift intervention is vital for minimizing the impact of the fire, preventing loss of life, and preserving valuable equipment and infrastructure.

Fully Insured Licensed Hire a Contractor For Fire Safety

Get Contractor

Make Informed Design Decisions Showcase Your Design Ideas

Get RenderingIndustrial facilities with a well-maintained and compliant fire hydrant system often benefit from reduced insurance costs. Insurance providers recognize the importance of robust fire protection measures, and facilities demonstrating proactive safety measures may qualify for lower premiums. Additionally, a properly functioning system helps mitigate potential liabilities, as adherence to safety standards and regulations is crucial for minimizing legal consequences in the event of a fire.

The value of a properly equipped fire hydrant system extends beyond immediate firefighting capabilities. It contributes to business continuity and operational resilience by minimizing the potential for extensive fire damage. Timely response facilitated by the hydrant system aids in controlling and extinguishing fires before they escalate, allowing the facility to resume normal operations more swiftly after an incident. This operational continuity is essential for maintaining productivity and sustaining the overall stability of the industrial facility.

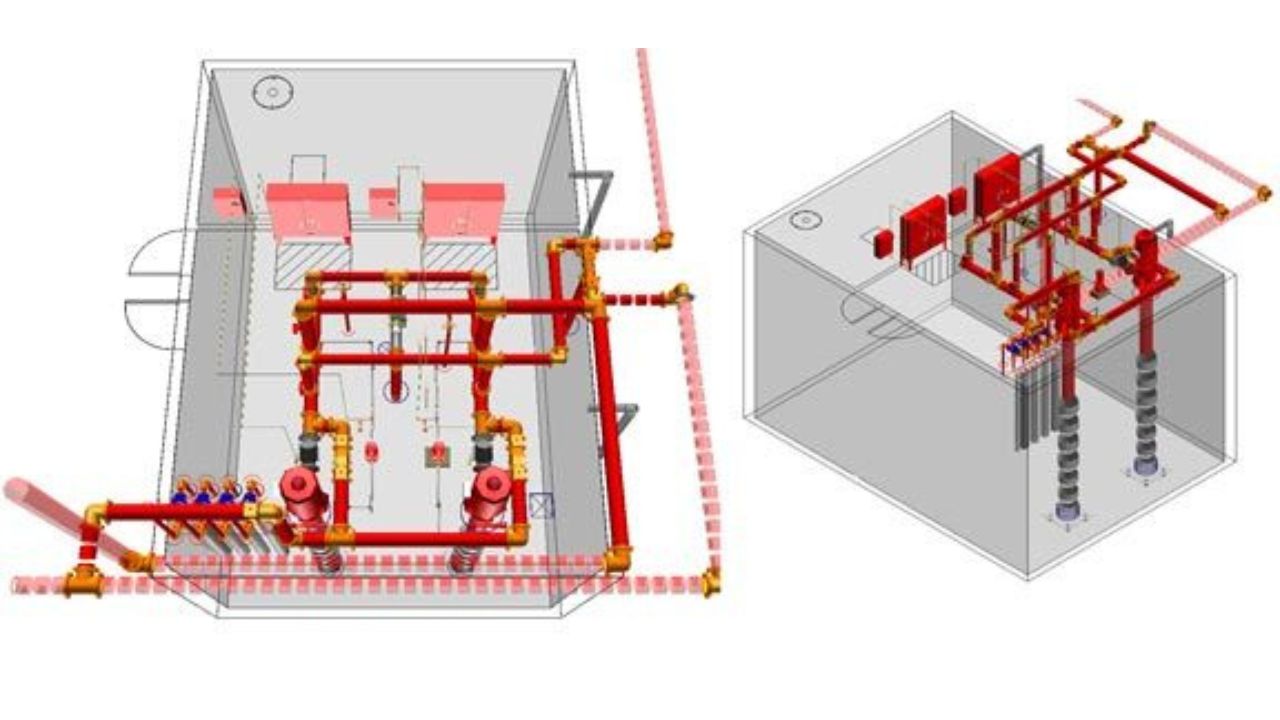

The size and layout of an industrial facility play a pivotal role in determining the scope and complexity of a fire hydrant system. Larger facilities or those with intricate layouts may require an extensive network of hydrants, underground pipes, and valves to ensure adequate coverage. The more extensive the system, the higher the material and labor costs associated with installation.

Industrial facilities are subject to strict fire safety regulations and standards. Compliance with these regulations is non-negotiable and involves additional costs such as specialized materials, testing, and certification. Meeting these standards is crucial not only for safety but also to avoid penalties and legal consequences.

The availability and adequacy of water supply directly impact the design and cost of a fire hydrant system.

Facilities located in areas with limited water resources may need to invest in additional water storage solutions or pumps to meet fire protection requirements.

Ensuring sufficient water pressure throughout the system is essential for effective firefighting.

The type and quantity of hydrants required depend on the specific needs of the industrial facility. Factors such as the type of materials handled, fire risk, and the layout of the facility influence the selection and placement of hydrants. The number of hydrants directly affects the overall system cost, including the purchase of hydrants, installation, and associated infrastructure.

The extent of underground piping required and the complexity of installation significantly impact costs. Facilities with challenging terrain or existing infrastructure may incur higher expenses for excavation, trenching, and pipe laying. Installation in areas with obstacles or congested layouts may also require additional labor and specialized equipment.

The ease of access to hydrants for maintenance purposes is a practical consideration. Hydrants should be strategically located for easy inspection, testing, and maintenance. Facilities with hydrants in hard-to-reach areas may face higher ongoing maintenance costs due to increased labor and time requirements.

Considering the multifaceted factors influencing fire hydrant system costs in industrial facilities, the financial outlay can exhibit significant variability.

As a broad estimation, anticipate an expenditure starting at $24,000 or more for a fundamental system in a small facility, with costs potentially exceeding $120,000 or more for intricate systems in large, high-risk industrial facilities.

Engaging with fire safety professionals for a comprehensive assessment and system design is crucial. Professionals can analyze the facility’s specific needs, ensuring an efficient and compliant fire hydrant system. Their expertise can identify cost-saving measures and avoid unnecessary expenses.

Implementing a proactive and routine maintenance schedule is a cost-effective strategy. Regular inspections, testing, and preventive maintenance help identify issues early, reducing the risk of system failures and minimizing long-term costs. Neglecting maintenance can lead to costly repairs and compromise the effectiveness of the fire hydrant system.

Implementing water conservation measures, such as utilizing water storage tanks or incorporating water-efficient hydrant technologies, can contribute to cost savings over time. These measures not only align with sustainability goals but also optimize water usage for firefighting purposes.

Anticipating future expansion or changes in facility layout is essential during the initial design phase. Planning for scalability can help avoid significant retrofitting costs in the future. Installing additional hydrants or designing the system with expansion in mind allows for a more cost-efficient and adaptable solution.

Obtaining quotes from multiple reputable contractors through a comparative bidding process is a strategic approach. This allows facility managers to assess not only the pricing but also the expertise and reputation of the contractors. Comparative bidding ensures a balance between cost-effectiveness and the quality of workmanship.

In conclusion, the cost of implementing a fire hydrant system in industrial facilities is influenced by various factors such as facility size, regulatory compliance, water supply, and maintenance considerations. The value of a properly equipped system goes beyond firefighting capabilities, encompassing life and asset protection, reduced insurance costs, and ensuring business continuity. The cost range, ranging from $24,000 for basic systems in small facilities to over $120,000 for complex systems in large facilities, reflects the diverse elements impacting the investment. To optimize costs, engaging with fire safety professionals, prioritizing maintenance, considering water conservation, evaluating future expansion needs, and implementing a comparative bidding process are recommended strategies for facility managers and stakeholders. These measures ensure a cost-effective and efficient fire hydrant system that enhances overall safety and protects critical industrial assets.

A fire hydrant system is crucial for safeguarding lives and assets during fire emergencies. It provides a vital water supply for swift firefighting responses, minimizing the impact of fires and preserving valuable equipment and infrastructure.

Industrial facilities with compliant and well-maintained fire hydrant systems may experience reduced insurance costs. Proactive safety measures often qualify for lower premiums, and a functioning system helps mitigate potential liabilities, minimizing legal consequences.

The size and layout of the facility, regulatory compliance, water supply, pressure requirements, type and number of hydrants, underground piping complexity, and accessibility for maintenance are key factors influencing the cost.

Engaging fire safety professionals for system design, prioritizing regular maintenance, considering water conservation measures, evaluating future expansion needs during the initial design, and implementing a comparative bidding process are strategies to optimize costs.

The cost can vary significantly, but a broad estimation suggests an expenditure starting at $24,000 or more for a basic system in a small facility, with costs potentially exceeding $120,000 or more for complex systems in large, high-risk industrial facilities.

Beyond firefighting capabilities, a well-equipped system aids in minimizing extensive fire damage, facilitating a timely response to control and extinguish fires. This, in turn, contributes to business continuity by allowing the facility to resume normal operations swiftly after an incident.

Here I am going to share some steps to get your Fire Hydrant System Cost estimate report.

You can send us your plan on info@estimatorflorida.com

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

All copyright © Reserved | Designed By V Marketing Media | Disclaimer