Concrete Block Estimator

Estimate Florida Consulting, your trusted concrete block cost estimator, is committed to helping you enhance your budgeting and takeoff processes. Our goal is to empower your concrete contracting company to not only endure but also thrive in these challenging economic times, achieving newfound levels of productivity and efficiency. With our support, you can bid more effectively, leading to more successful project wins.

Labor expenses now range from $15 to $25 per square foot for concrete block wall installation.

The cost for labor, supplies, and equipment required to lay blocks is between $7.50 and $15 per block, excluding the concrete blocks themselves. The prevailing rate for block work labor has increased to $52.50 to $150 per hour.

Are You Looking For?

Make Informed Design Decisions Showcase Your Design Ideas

Get RenderingCall Us To Discuss More at 561-530-2845

How to Construct a House Using Concrete Blocks?

The expenses associated with construction using concrete blocks now range from $1.50 to $6 per block, depending on the size. For standard 8″x8″x16″ concrete blocks, expect to pay $1.88 to $3.75 each. The largest 12″x8″x16″ CMU blocks now cost $3 to $6 per block.

Stamped concrete, based on design complexity, has surged in price to $13.50 to $34.50 per square foot.

Contractors specializing in blockwork, sidewalks, driveways, and paving often face the challenge of accurately estimating costs for bidding proposals while working on-site. Our precise estimate reports for concrete block projects provide invaluable assistance.

Our team of seasoned professionals stands ready to support contractors in securing more projects through our construction estimating services.

Additionally, our concrete cost estimating service has been enhanced to offer even more accurate estimates, tailored to your specific ZIP code location. While our concrete block estimator helps you calculate material costs, our Full Concrete Block Building Cost Estimator offers a complete budget breakdown for your entire construction project.

Cinder-Block Wall Finishing Costs

The majority of cinder-block wall finishing alternatives now range from $2.25 to $15.00 per square foot. It is crucial to seal cinder-block walls due to their high water absorption. Unsealed concrete-block walls are susceptible to damage.

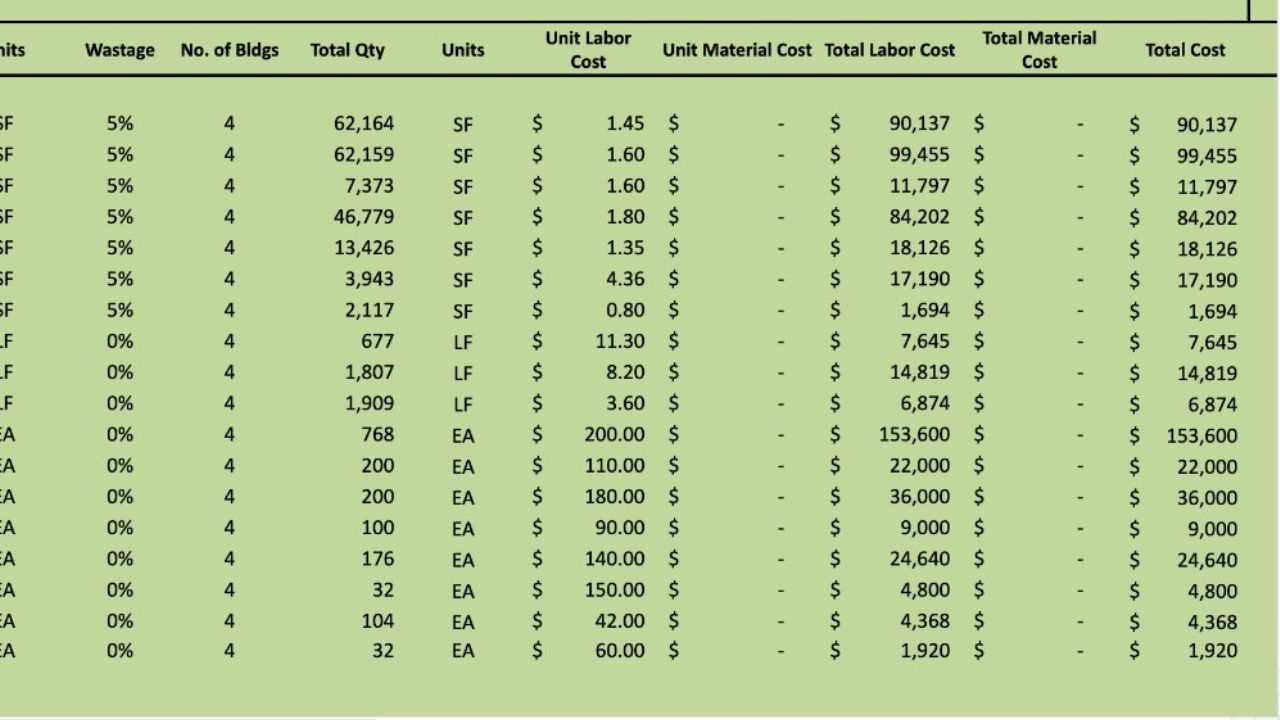

Concrete Block Wall Finishing Cost

Finishing Type | Average Cost Per Square Foot |

Painting | $0.975 – $1.20 |

Waterproofing sealant | $3.00 – $15.00 |

Plastering / Stucco | $4.50 – $6.00 |

Vinyl siding | $4.95 – $10.05 |

Concrete finish | $2.25 – $5.25 |

Stone veneer | $19.50 – $45.00 |

Comparison between Concrete Blocks and Traditional Bricks

Here’s a revised version of the table comparing concrete blocks and traditional bricks:

ASPECT | CONCRETE BLOCKS | TRADITIONAL BRICKS |

Raw Materials | Cement, aggregates, water | Clay |

Manufacturing Process | Factory-made under controlled conditions | Kiln-fired from molded clay |

Strength and Durability | Excellent compressive strength, durable | Good compressive strength, durable |

Thermal Insulation | Hollow blocks offer better insulation | Moderate insulation properties |

Fire Resistance | Inherently fire-resistant | Inherently fire-resistant |

Sound Insulation | Hollow blocks offer good sound insulation | Moderate sound insulation |

Weight | Heavier | Lighter |

Cost | Cost may vary depending on factors | Generally more expensive |

Aesthetics and Design | Modern and industrial appearance | Timeless and classic look |

This table presents a comparison between concrete blocks and traditional bricks, highlighting various aspects of both construction materials.

Enhancing Seismic Resilience with Concrete Blocks

The seismic resistance of structures holds immense significance, particularly in regions prone to earthquakes. Concrete blocks present distinct advantages in terms of seismic performance, but it’s essential to recognize that seismic resistance depends not only on the choice of material but also on the overall design, construction techniques, and compliance with seismic codes.

Concrete blocks are renowned for their robust compressive strength, a crucial factor in withstanding vertical loads.

Moreover, concrete exhibits inherent ductility, allowing it to deform without significant fracture during seismic tremors. This ductile property aids in dissipating seismic energy, thereby reducing the risk of structural failure.

Are You Looking For?

Make Informed Design Decisions Showcase Your Design Ideas

Get RenderingCall Us To Discuss More at 561-530-2845

Concrete Blocks for Sound Insulation

Concrete blocks, particularly hollow ones, are frequently employed to enhance sound insulation within construction projects. Their design, featuring air cavities, serves as a valuable tool for diminishing sound transmission between spaces, making them an ideal choice for creating quieter indoor environments. The following factors explain why concrete blocks are highly effective for sound insulation:

- Air Cavities: Hollow concrete blocks incorporate air cavities, acting as natural sound barriers. When sound waves encounter these air-filled spaces, they lose energy, reducing sound transmission.

- Density: Concrete, being a dense material, effectively absorbs and dampens sound vibrations, preventing their passage through the structure.

- Mass Effect: The mass of concrete blocks contributes to the “mass effect,” which obstructs sound waves from permeating the material. The greater the mass, the more effective the sound insulation.

- Wall Thickness: The thickness of concrete block walls also influences sound insulation. Thicker walls offer greater sound resistance, requiring sound waves to traverse more material.

- Joint Sealing: Properly sealed joints between concrete blocks further bolster sound insulation by preventing sound leakage through gaps.

- Sound Absorption: Depending on the surface finish of the concrete blocks, they can also possess sound absorption properties, reducing sound reflections within a room.

- Construction Techniques: The manner in which concrete blocks are installed can impact their sound insulation performance. Employing meticulous construction techniques, such as staggered joints and minimizing direct block-to-block contact, can significantly enhance soundproofing.

Solid Concrete Blocks

Solid concrete blocks, also known as concrete masonry units (CMUs), are widely employed in diverse construction projects. Crafted from a blend of Portland cement, aggregates (sand, gravel, or crushed stone), water, and occasionally additives, these blocks offer numerous benefits. Their impressive attributes include robustness, longevity, thermal insulation, and fire resistance, rendering them a favored choice for both load-bearing and non-load-bearing applications.

Boasting exceptional compressive strength, solid concrete blocks are well-suited for bearing substantial loads in structural roles, ensuring stability and durability in a wide range of construction endeavors.

In contrast to their counterparts, such as hollow concrete blocks, these blocks are dense and possess greater weight. This density enhances their thermal performance, leading to improved insulation.

Furthermore, the inherent non-combustible nature of concrete grants solid concrete blocks fire-resistant properties. This feature elevates safety and aids in fire containment during emergencies.

The solid composition of these blocks also bestows sound insulation capabilities, reducing sound transmission and cultivating quieter, more comfortable indoor environments.

Moreover, solid concrete blocks exhibit resistance to various weather elements, including moisture, rain, and UV rays, safeguarding the enduring strength of the structures they support.

Hollow Concrete Blocks

Hollow concrete blocks, also commonly known as concrete masonry units (CMUs), are a highly sought-after construction material employed in a multitude of projects. Distinguished from solid concrete blocks, these units feature a hollow core, offering several advantages, including reduced weight, enhanced thermal insulation, and improved ease of handling during construction.

Compared to solid concrete blocks, hollow concrete blocks are notably lighter, facilitating their transportation and handling at construction sites. Their decreased weight also contributes to an overall reduction in structural load. The hollow core within these blocks creates an air gap that augments their thermal insulation properties. Consequently, structures constructed with hollow concrete blocks often exhibit heightened energy efficiency, as they help regulate indoor temperatures and reduce the reliance on excessive heating or cooling.

The air cavities within hollow concrete blocks further enhance their sound insulation capabilities, fostering quieter indoor environments.

Despite their hollow nature, these blocks retain sufficient compressive strength to support moderate loads, rendering them suitable for a diverse array of construction applications.

Are You Looking For?

Make Informed Design Decisions Showcase Your Design Ideas

Get RenderingCall Us To Discuss More at 561-530-2845

Versatile Uses of Hollow Concrete Blocks

Hollow concrete blocks find a wide array of applications in the realm of construction:

- Load-Bearing Walls: These blocks are frequently employed to construct load-bearing walls, offering an efficient solution with their blend of strength and reduced weight.

- Non-Load-Bearing Walls: In non-structural roles, hollow concrete blocks serve as interior walls and partitions. Their lightweight nature simplifies installation and adjustments as needed.

- Infills and Insulated Panels: Hollow concrete blocks are a key choice for use as infill material in reinforced concrete frames or as integral components of insulated wall panels in contemporary construction techniques.

- Ventilation Ducts: The hollow cores within these blocks can be harnessed to establish ventilation ducts or air channels within walls, fostering natural airflow and enhancing indoor air quality.

- Cavity Walls: Hollow concrete blocks are commonly integrated into cavity wall construction, where an inner leaf and an outer leaf, with an air cavity in between, collectively deliver superior thermal performance.

Conclusion

Estimate Florida Consulting is your trusted partner in navigating the complex landscape of concrete block construction. As concrete-related costs continue to rise, our commitment to providing accurate estimates tailored to your specific location empowers your construction company to make informed decisions and enhance your budgeting and bidding processes. The detailed comparisons between concrete blocks and traditional bricks, along with the emphasis on seismic resilience and sound insulation, showcase the multifaceted advantages of concrete blocks in various construction applications. Whether you opt for solid or hollow concrete blocks, our construction estimating services ensure that you are well-prepared to meet the challenges of today’s construction industry, securing more projects and fostering success in your endeavors.

FAQs for Concrete Block Estimator Blog

Estimate Florida Consulting’s concrete block cost estimator is designed to help concrete contracting companies enhance their budgeting and takeoff processes. It empowers contractors to make more accurate estimates, leading to better project bids and increased success rates.

Labor expenses for concrete block wall installation in Florida typically range from $15 to $25 per square foot.

The cost for labor, supplies, and equipment required to lay concrete blocks typically ranges between $7.50 and $15 per block, excluding the cost of the concrete blocks themselves.

The prevailing rate for block work labor in Florida has increased to $52.50 to $150 per hour.

The expenses associated with constructing a house using concrete blocks in Florida can vary. For standard 8″x8″x16″ concrete blocks, expect to pay $1.88 to $3.75 each. Larger 12″x8″x16″ CMU blocks may cost $3 to $6 per block.

Stamped concrete, depending on design complexity, has a price range of $13.50 to $34.50 per square foot in Florida.

Estimate reports from Estimate Florida Consulting provide valuable assistance to contractors in accurately estimating costs for bidding proposals and on-site work, ultimately helping them secure more projects.

Yes, Estimate Florida Consulting’s concrete cost estimating service has been enhanced to offer more accurate estimates tailored to specific ZIP code locations in Florida.

The majority of cinder-block wall finishing alternatives in Florida range from $2.25 to $15.00 per square foot. It is crucial to seal cinder-block walls due to their high water absorption to prevent damage.

The finishing options for cinder-block walls in Florida include painting, waterproofing sealant, plastering/stucco, vinyl siding, concrete finish, and stone veneer, with average costs per square foot listed.

The blog provides a detailed comparison between concrete blocks and traditional bricks, highlighting aspects such as raw materials, manufacturing process, strength, insulation, fire resistance, sound insulation, weight, cost, and aesthetics.

The blog explains that concrete blocks offer advantages in terms of seismic performance due to their robust compressive strength and ductility, which helps dissipate seismic energy, reducing the risk of structural failure.

Concrete blocks, especially hollow ones, are effective for sound insulation due to air cavities, density, mass effect, wall thickness, joint sealing, sound absorption, and construction techniques that collectively reduce sound transmission.

Solid concrete blocks offer benefits such as compressive strength, thermal insulation, fire resistance, and sound insulation, making them suitable for various construction applications.

Hollow concrete blocks are known for their reduced weight, enhanced thermal insulation, sound insulation, and ease of handling during construction. They are versatile and used in various applications, as explained.

Hollow concrete blocks have diverse applications, including load-bearing walls, non-load-bearing walls, infills and insulated panels, ventilation ducts, and cavity walls, each described.

Process To Get Concrete Block Estimate Report

Here I am going to share some steps to get your concrete block estimate report.

-

You need to send your plan to us.

You can send us your plan on info@estimatorflorida.com

-

You receive a quote for your project.

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

-

Get Estimate Report

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.

Google Reviews