A Wining Cost Estimate

That Helps You To Win More Flooring Construction Projects

Epoxy coating for garage floors can have different prices, depending on various factors. Such as the type of epoxy used, size of the garage, and degree of repairs required. Below are factors that affect the price of epoxy coating:

Factors | Description |

Type of Epoxy | Different types offer varying resistance and durability. |

Size of Garage | Larger areas need more materials, increasing cost. |

Degree of Repairs Required | This determines the amount of preparation needed before epoxy is applied. High degrees require more labor input and a higher price. |

Additional Factors | |

Polyurethane Coating | May be added to protect against UV rays or abrasions. |

Maintenance Service | Cleaning and reapplication services cost extra. |

The expected lifespan of the epoxy coating also influences its price. A longer lifespan will result in a higher cost, as it offers more protection and longevity.

Pro Tip: Consider professional installation. They have access to specialized tools and can help lower costs by avoiding wrong installations or wastage.

If you want epoxy coating for your garage, remember it’ll cost more than just your time. But, it’s worth it for a shiny, durable floor.

To estimate the price of epoxy coating for your garage floors, understanding the cost of materials is essential. You can start by assessing the type of epoxy coating needed and the quantity required for the job. These sub-sections will help you make informed decisions and estimate the cost of materials accurately, enabling you to plan and budget your project effectively.

Do you want to understand the “epoxy coating variation” more? Read on!

These are the three main types of epoxy coatings: solvent-borne, waterborne, and 100% solids. Each type has certain characteristics that make it suitable for different uses.

For example, solvent-borne is great for heavy-duty industrial flooring and metal surfaces. Waterborne epoxy is commonly used in construction projects. And 100% solids is perfect for harsh environments like marine applications and industrial plants.

Before picking an epoxy coating, consider factors like temperature, chemical exposure, UV exposure, surface prep, end use-requirements, and cost.

Also, work with experienced professionals who can guide you from budgeting to installation. Lastly, follow manufacturer’s guidelines.

To figure out the exact amount of epoxy coating needed for a project, several factors must be taken into account. These include surface area, thickness, and application method. Calculating the right amount helps with planning, budgeting, and making sure the project is done correctly.

The table below reveals the quantity of epoxy coating needed for different surfaces:

Surface Area | Thickness Required (inches) | Quantity of Epoxy Coating (gallons) |

|---|---|---|

100-200 sq.ft | 1/8 inch | 2 |

201-400 sq.ft | 1/8 inch | 4 |

401-600 sq.ft | 1/8 inch | 6 |

Over 601 sq.ft | Refer to manufacturer data* |

*For surfaces over 601 sq.ft., consult manufacturer data or technical specs to calculate the quantity needed.

It’s important to remember that this calculation applies to one coat only. If additional coats are needed, more material must be taken into account.

The application method used has an effect on the amount of epoxy coating required. Rolling or brushing may need more material than spraying, due to differences in thickness and coverage.

For accurate quantification of epoxy coating, it’s best to consult experienced professionals or use online calculators and measurement tools. This offers an estimate that considers different types of coatings and applications.

By factoring in surface area, thickness requirements, and application methods, contractors can accurately determine the amount of epoxy coating needed. Accurately estimating the needed materials keeps budgets in check while keeping quality standards in place.

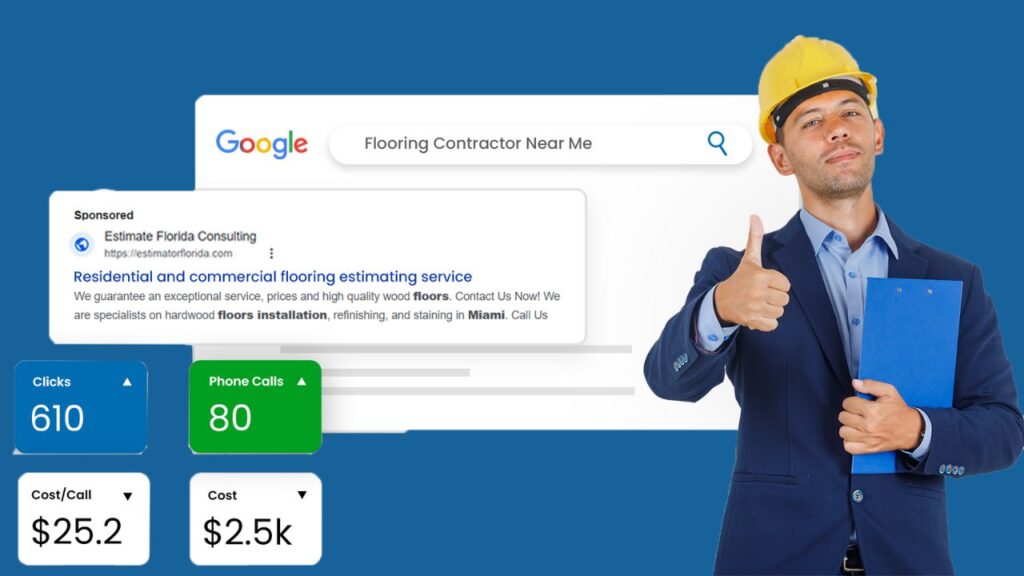

We help contractors find new customers with high-converting websites and locally targeted niche-specific lead-generation programs. You’ll never need to worry about running out of work again! We focus on quality over quantity with our leads for contractors.

To estimate the cost of labor, you need to consider a few things. With “Labor costs” in “How to Estimate the Price of Epoxy Coating for Garage Floors” and two sub-sections, “Preparation of the garage floor” and “Application of epoxy coating”, you’ll learn how each step impacts labor costs.

Prepping the garage floor is important. This includes prepping the concrete surface so it’s durable for future tasks. Here are five steps to take:

Low-cost labor may look cheap at first, but can cost more in the long run due to lower-quality results. It’s important to use best practices when working with tools and materials during preparation.

In summary, properly preparing the garage floor is key for avoiding damage. Ancient homes didn’t have access to such construction nuances, as they mostly used clay and stone blocks, held together with straw fibers instead of concrete.

Putting on an epoxy coating can be expensive, but it won’t eat into your profits!

Applying an epoxy coating is a process that requires precision and care. Here’s how:

Epoxy coatings are popular for garage floors, warehouses, and other industrial settings. They’re also used in homes due to their ability to resist moisture and heavy wear and tear.

Fun Fact: Epoxy coatings were first used commercially in the 1950s. They were a result of research done on aircraft components during World War II.

To factor in additional costs, we introduce the section ‘Additional costs’ when estimating the price of epoxy coating for garage floors. The sub-sections – ‘Repair of cracks or damages in the garage floor’ and ‘Removal of old coating or flooring’ – will be explored as solutions to ensure the longevity and effectiveness of the epoxy coating.

Homeowners must make sure their garage floors are in top shape for both safety and looks. It can be a big job fixing cracks and damage – but here’s a 3-step guide to help!

Remember, repairs can take longer and cost more than expected. Measurements must be precise – too much repair agent can create bubbles and make things harder to fix.

My friend had an expensive repair job due to water getting into cracks and creating mold. Don’t ignore what may seem like superficial cracks – they could be signs of bigger issues. And taking out old flooring? Just like breaking up with a clingy ex – it’s messy, takes time and costs more than anticipated.

When it comes to revamping a space, removal of the pre-existing flooring can be pricey. This includes taking out the old surface material for new flooring. Here’s a 3-step guide on how to do it.

Note: Removing old coatings, like epoxy or paint containing lead, needs extra care to avoid contamination. Safety and disposal techniques should be prioritized when dealing with hazardous materials. Disposing of flooring materials properly is key to obeying environmental laws.

A business owner upgraded their office space by removing outdated tiles from the lobby and hallway. It took longer than expected due to multiple layers of tiles, but they were pleased with the end result.

If you’re considering epoxy coating for your garage floor, be prepared to break the bank, but hey, at least your floor will look super shiny!

To estimate the total cost of epoxy coating for your garage floor, calculating the cost of materials and labor, including additional costs, and considering the size of the floor are important. This section on ‘Estimating the total cost of epoxy coating for garage floors’ with sub-sections ‘Calculating the cost of materials and labor, Including additional costs, and Considering the size of the garage floor’ will be your ultimate guide towards estimating the total cost of epoxy coating for your garage.

To figure out expenses for epoxy-coating garage floors, a comprehensive cost calculating approach can be used. By assessing the total budget plan, the cost of materials and labor required can be estimated.

Let’s take a look at the table:

Materials | Cost ($) |

|---|---|

100% Solid Epoxy Coat (Gallon) | $150-200 |

Primer Coat (Gallon) | $30-50 |

Acid Etching Solution (Pint) | $15 |

Tools and Supplies | $50-100 per kit |

Note: Labor costs may vary depending on location, size of garage floor, and complexity level of job.

The table helps with making sound financial decisions by analyzing market trends and researching prices. Disposal costs for hazardous waste materials, like solvents or paints that have not dried properly, must also be factored in.

I wanted my garage floor to be different from my neighbors’, so I chose high-quality epoxy painting. However, I didn’t consider labor costs fully beforehand. That showed me how much it could affect my budget. Always plan properly before starting any project.

Extra expenses are like finding more cobwebs in your garage – never a pleasant surprise.

Maximize your roofing construction business’s potential with our competitive financing options

To cost up epoxy coating for a garage, extra prices must be taken into account. These will affect the budget muchly, so it’s essential to grasp them before beginning the task.

Unexpected issues during installation may lead to extra costs.

Pro Tip: Ask your contractor for a detailed quote, including all expenses. This way, you can check if there are cheaper materials available, avoiding being overcharged. Calculate carefully; epoxy coating for a garage floor can be as expensive as a small country!

Considering the size of your garage floor is essential when calculating the cost of an epoxy coating. Here are 6 points to bear in mind:

Remember, every garage floor is unique and two garages with the same size may not have equal costs. Every detail counts!

Pro Tip: Accurately measure and research different coating options to get an accurate estimate for your garage floor project. Why settle for one quote when you can find the right coating for your garage floor?

To compare quotes from different epoxy coating contractors with the goal of finding the best price for your budget, requesting quotes from multiple contractors is a good start. But it’s important to not just stop there. In order to make an informed decision, reviewing the quotes for accuracy and completeness is also key. This sub-section will discuss these steps in detail.

Requesting quotes from various epoxy coating contractors is crucial for getting the best deal. Consider the following when comparing quotes:

Reports show customers who got quotes from 3+ contractors saved an average of $1,000. Zoom in on these quotes for the best results!

To guarantee accuracy and completeness of epoxy coating contractors’ quotes, examine them carefully. Compare the details from each and see which has the best value. In the table above, notice itemized cost breakdown, warranty length, and labor-only quotes. Ask for references and evidence of proper licensing insurance coverage. Check the experience level of contractors too. By doing this, you’ll likely find a reliable one with excellent value. For the best value on garage floor coatings? Don’t be shy – haggle! Just don’t bring up your ex’s negotiating skills.

When working out the cost of epoxy coating for garage floors, keep these tips in mind:

Remember: cost is important, but don’t compromise on quality.

Fun fact: epoxy coating was first used by the US Navy in WWII, on ships in corrosive sea environments. Now it’s used on industrial, commercial and residential floors.

Estimating the price of epoxy coating for garage floors depends on a number of factors such as the size of the garage, condition of the existing floor, and the complexity of the project. A typical epoxy coating cost for a garage floor can range from $3 to $12 per square foot.

While it is possible to apply epoxy coating to garage floors by yourself, it is strongly recommended that you hire a professional contractor to ensure that the application is properly done. Proper preparation of the surface is crucial for the longevity of the coating, and professionals have the necessary expertise and equipment to achieve a high-quality application.

The cost of epoxy coating for garage floors is influenced by different factors such as the size of the garage, the condition of the existing floor, the complexity of the project, and the type of epoxy coating selected.

The duration of applying epoxy coating to a garage floor varies depending on the size of the area, the condition of the existing floor, and the complexity of the project. While some garage floor epoxy applications can be done within a day, others may take up to three days to complete.

Epoxy coating for garage floors provides a highly durable and attractive option to enhance the look and performance of your garage floor. It is resistant to stains, spills, and damage from chemicals, making it an ideal option for high-traffic areas such as garage floors.

The lifespan of epoxy coating for garage floors depends on a number of factors such as the quality of the coating, the level of use, and the degree of maintenance. With proper installation and maintenance, epoxy coating for garage floors can last for up to 7-10 years.

Here I am going to share some steps to get your flooring construction cost estimate report.

You can send us your plan on info@estimatorflorida.com

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

We do flooring construction cost estimating and prepare a detailed report for your project. At last, you finalize the report and finish the project.

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

All copyright © Reserved | Designed By V Marketing Media | Disclaimer

IMPORTANT: Make sure the email and cell phone number you enter are correct. We will email and text you a link to get started.

By clicking “I Agree” above you give Estimate Florida Consultin express written consent to deliver or cause to be delivered calls and messages to you by email, telephone, pre-recorded message, autodialer, and text. Message and data rates may apply. You are able to opt-out at any time. You can text STOP to cancel future text messages.