90% More Chances to Win Projects With Our Estimate!

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- School & University Building

- High-Rise Building

- Shopping Complex

- Data Center Building

Blockwork is crucial in constructing walls, foundations, and partitions, contributing to the structural integrity of buildings. The average cost of blockwork typically ranges from $16.90 to $50.70 per square foot, reflecting the type of blocks used, labor rates, and project complexity. Understanding these costs is vital for effective budgeting and planning, as they can vary based on regional differences and material availability. Knowledge of blockwork costs not only enhances project management but also improves overall quality, ensuring successful outcomes that meet or exceed expectations.

Accurate cost estimation for blockwork is essential for the success of any construction project. By thoroughly understanding these costs, contractors and developers can allocate resources effectively, minimize waste, and avoid unexpected expenses. Accurate budgeting helps maintain project timelines and quality, as financial overruns can lead to delays and reduced standards. For homeowners, understanding blockwork costs aids in making informed decisions regarding material choices and contractor selection, ultimately impacting the longevity and efficiency of their investment. Need a detailed estimate for a larger concrete block project? Use our Concrete Block Building Cost Estimator to get accurate cost projections for your entire building, including materials and labor.

Concrete blocks, often referred to as concrete masonry units (CMUs), are a staple in construction due to their durability, thermal efficiency, and versatility. These blocks come in various sizes and strengths, with costs typically ranging from $2.54 to $5.08 per block, depending on size and density.

Block Size (inches) | Estimated Cost per Block |

8 x 8 x 16 | $2.54 – $5.08 |

12 x 8 x 16 | $3.38 – $5.46 |

4 x 8 x 16 | $2.54 – $5.08 |

Concrete blocks provide excellent thermal mass, which helps in energy conservation by maintaining consistent indoor temperatures. Their strength makes them ideal for load-bearing walls, while their fire resistance contributes to overall safety. Additionally, their availability and ease of installation make them a preferred choice for various applications, from residential homes to commercial buildings.

Cinder blocks, made from concrete mixed with cinders or fly ash, are lighter than concrete blocks and are commonly used in foundation and wall construction. The average cost of cinder blocks ranges from $1.69 to $4.22 per block after adjustments.

Block Size (inches) | Estimated Cost per Block |

8 x 8 x 16 | $1.69 – $4.22 |

12 x 8 x 16 | $2.21 – $4.22 |

While cinder blocks are easier to handle due to their lighter weight, they may not provide the same level of insulation as concrete blocks. This can impact long-term energy costs, making them suitable for projects where thermal efficiency is less of a concern. Their cost-effectiveness, however, makes them a popular choice for many construction projects, particularly in non-climate-sensitive applications.

Autoclaved Aerated Concrete (AAC) blocks are innovative building materials that are lightweight, energy-efficient, and provide excellent insulation. The costs for AAC blocks typically range from $3.38 to $6.76 per block, reflecting their advanced properties and manufacturing process.

Block Size (inches) | Estimated Cost per Block |

8 x 12 x 24 | $3.38 – $6.76 |

4 x 12 x 24 | $2.54 – $5.08 |

AAC blocks significantly reduce heating and cooling costs due to their exceptional insulating properties. They are also easier to cut and shape, allowing for flexibility in design and quicker installation times. This makes them an excellent choice for energy-efficient homes, where reducing environmental impact is a priority. Their lightweight nature also makes transportation and handling easier, further contributing to cost savings on labor and equipment.

Blockwork costs are influenced by several key factors that can vary widely depending on the project’s specifics. Understanding these factors is essential for accurate cost estimation and effective project management.

The type of blocks selected for the project has a direct impact on material costs. For example, concrete blocks typically range from $3.37 to $6.40 per block, while specialized blocks, such as aerated concrete blocks, can cost between $5.50 to $10.00 per block.

Considering the overall project scale, here’s an updated cost breakdown:

Material Type | Cost per Block |

Concrete Blocks | $4.40 – $8.32 |

Aerated Concrete Blocks | $7.15 – $13.00 |

CMU Blocks | $4.36 – $8.30 |

Retaining Wall Blocks | $6.40 – $12.90 |

Concrete blocks, also known as concrete masonry units (CMUs), are commonly used in construction for their strength, durability, and fire resistance. They are suitable for various applications, including walls, foundations, and barriers. The price of concrete blocks can vary based on factors such as size, density, and local market conditions, making them a versatile and cost-effective choice for many building projects.

Aerated concrete blocks are lightweight blocks made from a mixture of cement, lime, water, and a foaming agent, which creates air pockets within the material. This results in superior thermal insulation and reduced weight, making them easier to handle. The cost is generally higher than traditional concrete blocks due to their manufacturing process and insulation properties, making them ideal for energy-efficient construction.

CMU blocks are a specific type of concrete block commonly used in load-bearing walls and various structural applications. They offer high compressive strength and fire resistance, making them suitable for both residential and commercial buildings. The pricing for CMU blocks is comparable to standard concrete blocks, with variations depending on size and local availability.

Retaining wall blocks are specially designed for constructing walls that hold back soil and prevent erosion. These blocks can be made from concrete, natural stone, or engineered materials and often feature interlocking designs for added stability. The cost varies based on the block design, material type, and weight, reflecting their specific purpose in landscaping and civil engineering projects.

Labor costs are another significant component of blockwork expenses. The average labor cost for masonry work ranges from $40.00 to $75.00 per hour, depending on the experience and skill level of the labor force.

For larger projects requiring extensive blockwork, labor costs can accumulate quickly. Here’s an updated estimate based on increased complexity and skill requirements:

Labor Type | Estimated Hourly Rate |

Skilled Masonry Labor | $52.00 – $97.50 |

General Labor | $39.00 – $65.00 |

The complexity of the blockwork project also plays a crucial role in determining costs. Factors such as intricate designs, the need for specialized installation techniques, and the inclusion of additional architectural features (like arches or decorative elements) can elevate costs significantly.

For instance, a basic block wall installation may cost approximately $20.00 to $40.00 per square foot, while a more complex wall with additional design features could range from $40.00 to $70.00 per square foot.

Site conditions can greatly affect blockwork costs, especially if extensive site preparation is necessary. Factors like soil quality, existing structures, and accessibility can all impact preparation costs, which may range from $500 to $5,000 or more.

In challenging locations requiring significant earthwork or drainage solutions, making it crucial to assess site conditions before beginning construction.

In residential projects, blockwork is typically used for foundations, exterior walls, and interior partitions. The average cost for blockwork in a residential project can range from $7,000 to $25,000, depending on the project size and complexity.

Project Element | Estimated Cost for Blockwork |

Foundation | $5,200 – $10,000 |

Exterior Walls | $6,500 – $15,000 |

Interior Partitions | $3,000 – $5,500 |

Blockwork for foundations is essential for providing a stable base for structures. This typically involves using concrete blocks or CMUs to form the foundation walls. The cost can vary based on factors such as foundation type (e.g., basement or slab), local soil conditions, depth, and height of the walls, as well as labor costs. Proper reinforcement and drainage considerations also impact the overall pricing.

Blockwork for exterior walls is a critical component in constructing durable and weather-resistant buildings. This may involve using standard concrete blocks or aerated blocks for added insulation. The cost range is influenced by factors such as the size of the building, design complexity, block type, and regional labor rates. Quality blockwork for exterior walls contributes to energy efficiency and long-term structural integrity.

Blockwork for interior partitions is used to create non-load-bearing walls that define spaces within a building. This type of construction offers advantages in terms of sound insulation and fire resistance. The cost can vary based on the size and height of the partitions, the type of blocks used, and any necessary finishing work, such as plastering or painting. Interior block partitions are a popular choice for commercial spaces and residential projects alike.

Commercial buildings often require more extensive blockwork to support larger structures. Costs can range from $25,000 to $100,000, depending on the scope and specifications of the project.

Project Element | Estimated Cost for Blockwork |

Structural Walls | $20,000 – $75,000 |

Retaining Walls | $10,000 – $30,000 |

Fire Walls | $8,000 – $20,000 |

Structural walls are integral components of a building’s framework, providing support for roofs, floors, and adjacent walls. The cost for blockwork in structural walls varies significantly based on factors such as the type of blocks used (e.g., concrete, CMU), wall height, thickness, complexity of the design, and local labor rates. High-quality blockwork in structural walls is essential for ensuring the overall stability and safety of the structure.

Retaining walls are designed to hold back soil and manage grade changes on a site. The cost of blockwork for retaining walls can fluctuate based on factors like wall height, length, block type (e.g., concrete, natural stone), and site conditions. Proper design and construction of retaining walls are crucial for preventing soil erosion and ensuring the longevity of landscaping or structural elements above them.

Fire walls are specialized walls designed to prevent the spread of fire between different sections of a building. Constructed using fire-rated blocks, the cost of fire wall blockwork varies depending on the wall’s size, height, and specific fire-resistance requirements dictated by local building codes. Effective construction of fire walls is essential for ensuring occupant safety and meeting regulatory standards in both commercial and residential buildings.

Infrastructure projects, such as bridges and tunnels, require substantial blockwork to ensure structural stability. Costs for these projects can significantly vary, often exceeding $100,000.

Project Element | Estimated Cost for Blockwork |

Bridge Support Walls | $50,000 – $200,000 |

Tunnel Linings | $100,000 – $500,000 |

Retaining Structures | $30,000 – $150,000 |

Bridge support walls play a crucial role in stabilizing and distributing the load of bridges. These walls are designed to withstand significant vertical and lateral forces, often constructed using reinforced concrete or specialized block materials. The cost can vary widely based on factors such as wall height, length, design complexity, and local soil conditions. Properly engineered bridge support walls are essential for the longevity and safety of bridge structures.

Tunnel linings provide structural support and protect tunnels from soil pressure, water infiltration, and other environmental factors. The blockwork in tunnel linings may involve advanced techniques such as shotcrete or the use of precast concrete elements, depending on the project requirements. The estimated costs can fluctuate based on tunnel size, geological conditions, and construction methods employed. High-quality tunnel linings are critical for ensuring the safety and functionality of underground infrastructure.

Retaining structures are designed to hold back soil and manage changes in elevation, preventing erosion and ensuring site stability. The blockwork for retaining structures can vary significantly based on height, length, and the materials used, including concrete or masonry blocks. The cost also depends on factors such as design requirements, site conditions, and drainage considerations. Properly constructed retaining structures are vital for protecting surrounding landscapes and ensuring the integrity of adjacent structures.

Regional variations in blockwork costs can be significant due to factors such as local demand, labor availability, and material supply chains. Understanding these variations is crucial for accurate budgeting.

In Northern Florida, blockwork costs may average around $13 to $32.50 per square foot, while in Southern Florida, costs can range from $19.50 to $39 per square foot, reflecting differences in labor rates, availability of materials, and demand for construction services.

Urban centers often experience higher costs due to increased demand for skilled labor and materials, which can lead to higher construction expenses. Conversely, rural areas may offer more competitive pricing, making them more cost-effective for certain projects.

Compliance with local building codes and regulations is essential when planning blockwork projects. Failure to adhere to these codes can result in costly delays, penalties, and necessary redesigns. Familiarity with regional codes ensures that projects are executed efficiently, minimizing disruptions and expenses. In Florida, specific codes dictate materials, installation practices, and safety measures that must be followed to ensure structural integrity and occupant safety.

Obtaining the necessary permits can also impact the overall cost of blockwork projects. In Florida, permit fees can range from $130 to $1,950, depending on the project size and complexity. Understanding these costs is vital for accurate budgeting and project planning, as they can add a significant expense to the overall project budget. Engaging with local authorities early in the planning process can streamline permitting and compliance, ultimately reducing time and costs associated with delays.

Understanding blockwork costs is essential for successful construction projects. By considering material choices, labor expenses, project complexities, and regional variations, contractors, developers, and homeowners can create accurate budgets that ensure successful project completion. With this comprehensive blockwork cost estimator guide, stakeholders can confidently navigate the complexities of blockwork projects and make informed decisions that lead to successful outcomes.

Calculating the cost of a block wall involves several factors. Start by measuring the wall’s length and height to determine the total square footage. Next, consider the cost of materials, including concrete blocks, mortar, and any reinforcement like rebar. Labor costs, which vary based on local rates and project complexity, should also be factored in. Finally, include any additional expenses, such as site preparation, permits, and disposal fees for waste. A detailed cost estimate ensures transparency and accuracy, helping you budget effectively for your construction project.

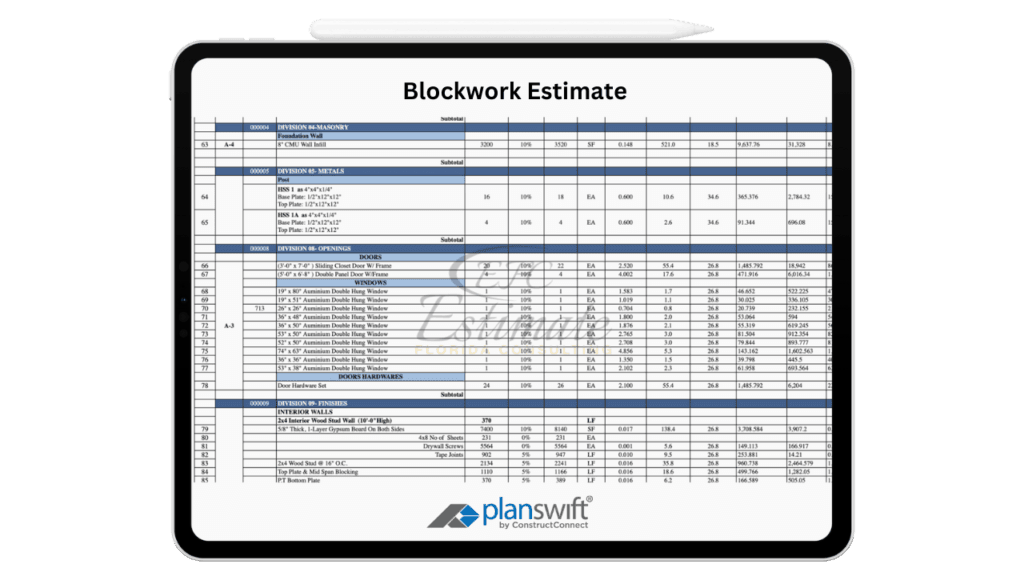

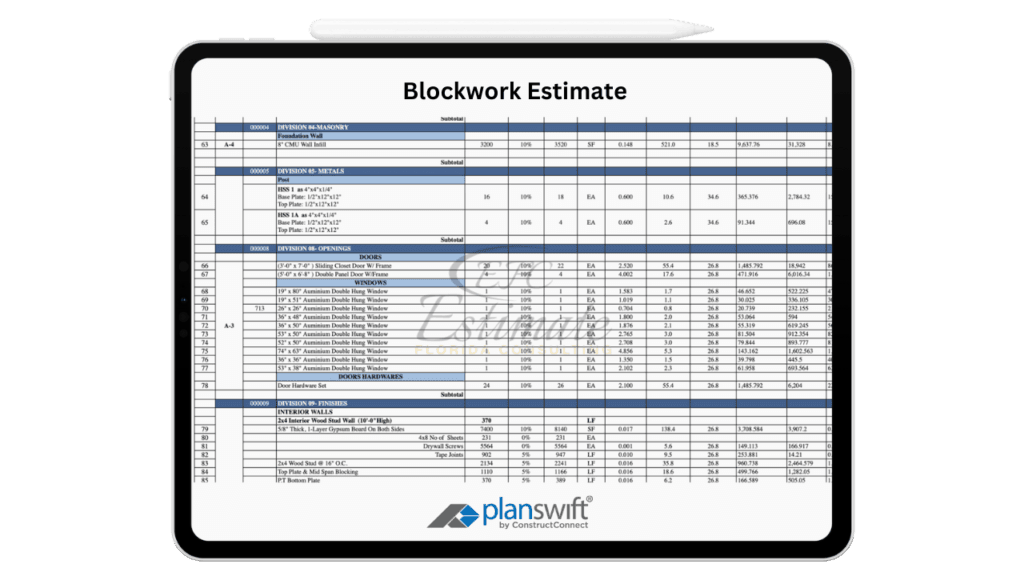

To estimate blockwork, first, measure the area where the block will be installed. Calculate the number of blocks needed by dividing the total square footage by the square footage of a single block, accounting for mortar joints. Then, estimate the cost of materials, including blocks, mortar, and any required tools or equipment. Labor costs should also be included, factoring in the complexity of the project and local labor rates. This comprehensive approach allows for a reliable estimate, ensuring all aspects of the blockwork are covered.

The cost to lay blockwork varies based on several factors, including the type of block used, the wall's height and length, and the local labor market. On average, homeowners can expect to pay between $10 and $15 per square foot for standard blockwork, including both materials and labor. Custom designs or specialized blocks may increase costs. To get an accurate estimate, it’s advisable to consult with a professional contractor who can assess your specific project needs.

Yes, a cinder block wall requires a foundation for stability and structural integrity. A proper foundation distributes the wall's weight and prevents shifting or settling over time. The type of foundation needed may vary based on the wall's height, soil conditions, and local building codes. Typically, a reinforced concrete footer is recommended to support the wall adequately. It’s essential to consult with a structural engineer or contractor to ensure compliance with local regulations and to guarantee a long-lasting installation.

Concrete block walls are known for their durability and longevity, often lasting 50 years or more with proper maintenance. Factors that influence their lifespan include environmental conditions, quality of installation, and regular maintenance practices. In areas with extreme weather or soil movement, periodic inspections and repairs may be necessary to extend the wall's life. Properly constructed and maintained, concrete block walls are a reliable choice for both residential and commercial projects.

Concrete blocks are often avoided in foundations because they may not provide the same level of strength and stability as poured concrete. While concrete blocks can be used for foundation walls, they are more susceptible to moisture infiltration and settling, which can compromise structural integrity. Poured concrete offers a monolithic structure that is generally stronger and better suited for withstanding the pressures of soil and water. For optimal performance, it’s advisable to consult with a structural engineer to determine the best foundation solution for your project.

At Estimate Florida Consulting, we offer detailed cost estimates across all major trades, ensuring no part of your project is overlooked. From the foundation to the finishing touches, our trade-specific estimates provide you with a complete and accurate breakdown of costs for any type of construction project.

We take pride in delivering accurate, timely, and reliable estimates that help contractors and builders win more projects. Our clients consistently praise our attention to detail, fast turnaround times, and the positive impact our estimates have on their businesses.

Estimate Florida Consulting has helped us win more bids with their fast and accurate estimates. We trust them for every project!

Submit your project plans, blueprints, or relevant documents through our online form or via email.

We’ll review your project details and send you a quote based on your scope and requirements.

Confirm the details and finalize any adjustments to ensure the estimate meets your project needs.

Receive your detailed, trade-specific estimate within 1-2 business days, ready for your project execution.

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

All copyright © Reserved | Designed By V Marketing Media | Disclaimer