90% More Chances to Win Projects With Our Estimate!

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- School & University Building

- High-Rise Building

- Shopping Complex

- Data Center Building

Fabrication refers to the process of constructing products or structures from raw materials. This process is essential in various industries, including construction, manufacturing, and engineering. Fabrication encompasses a range of activities, including cutting, bending, assembling, and finishing materials to create custom products. In construction, fabrication is crucial as it allows for the creation of components that meet specific design requirements and project specifications, ensuring that buildings are both functional and aesthetically pleasing.

Fabrication refers to the systematic process of constructing products or structures from raw materials through various techniques, including cutting, bending, assembling, and finishing. This process is integral to numerous industries, particularly construction, where tailored components are essential to meet specific project requirements. Fabrication can include a wide range of activities, from creating steel beams and frames for buildings to crafting intricate woodwork for interiors. Understanding fabrication is crucial, as it directly affects the quality and performance of the end product. Properly executed fabrication not only ensures the structural integrity of a project but also plays a significant role in achieving the desired aesthetic outcome, making it a cornerstone of effective construction.

When estimating fabrication costs, it’s essential to break down the expenses into specific categories. Below is a detailed look at the key components of fabrication costs.

Material costs are the expenses incurred for the raw materials needed for fabrication. These costs can vary significantly based on market fluctuations, material types, and quality.

Material Type | Estimated Cost per Unit |

Steel | $0.90 – $1.80 per lb |

Aluminum | $1.80 – $3.60 per lb |

Wood | $2.40 – $6.00 per sq ft |

Plastic | $1.20 – $2.40 per lb |

Labor costs encompass the wages paid to workers involved in the fabrication process. The complexity of the work and the expertise required will influence these costs.

Labor Type | Estimated Cost per Hour |

Skilled Labor | $30 – $60 per hour |

Unskilled Labor | $18 – $30 per hour |

Fabrication Technician | $24 – $42 per hour |

Overhead costs include indirect expenses related to the fabrication process, such as equipment maintenance, facility costs, and administrative expenses.

Overhead Category | Estimated Cost |

Equipment Maintenance | $600 – $1,800 per month |

Utilities | $240 – $600 per month |

Administrative Expenses | $360 – $840 per month |

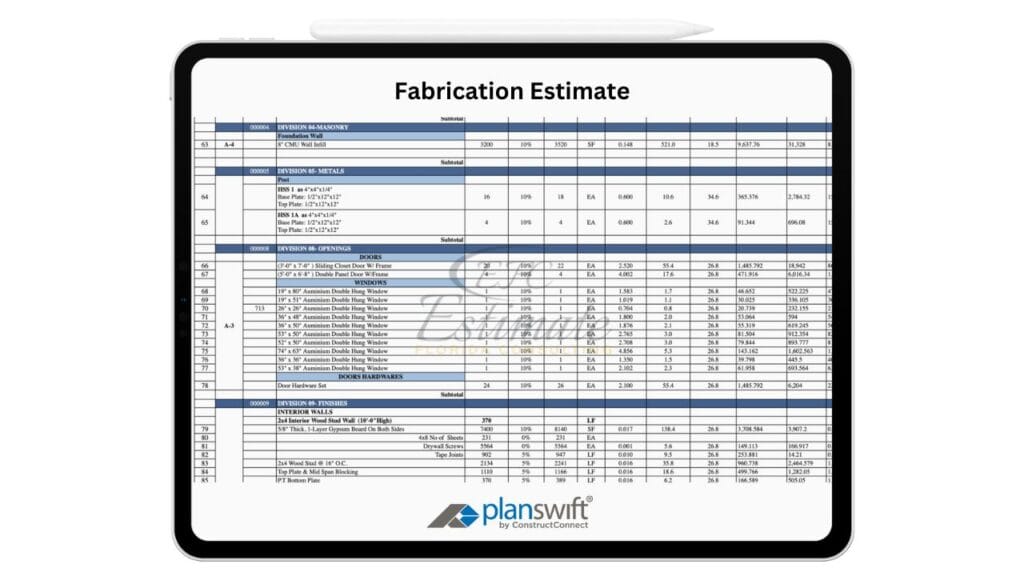

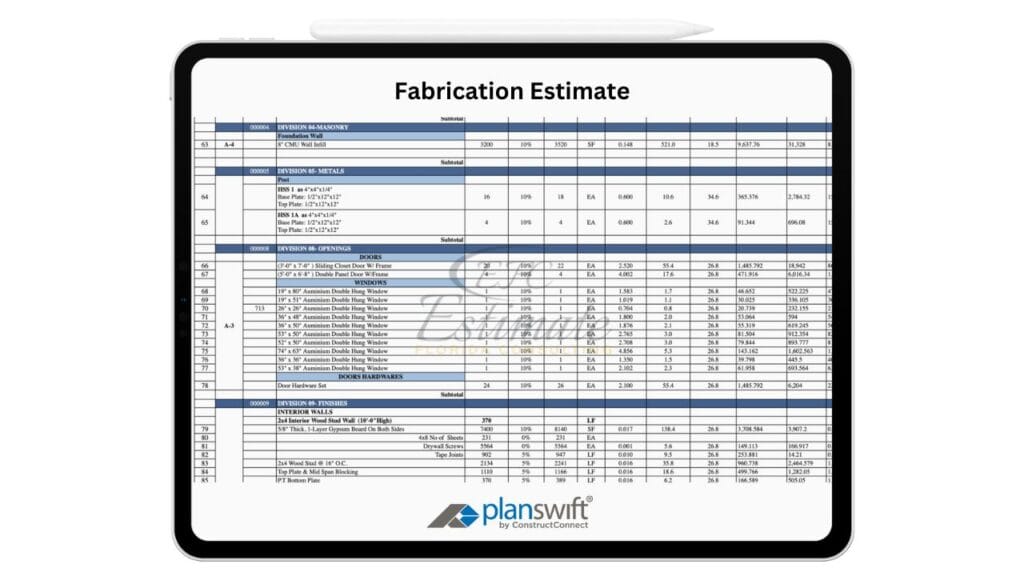

Here’s a sample fabrication cost estimation table to give you an overview of potential project costs. This table is based on a hypothetical project involving metal fabrication.

Item | Quantity | Unit Cost | Total Cost |

Steel Beams | 10 | $1.50/lb | $1,500 |

Labor (Skilled) | 40 hrs | $42/hr | $1,680 |

Equipment Overhead | 1 month | $1,200 | $1,200 |

Fabrication services vary widely, depending on the materials used and the specific requirements of the project. Here are some of the most common types of fabrication services offered in the industry:

Metal fabrication involves working with various metals, including steel, aluminum, and stainless steel, to create structural components. This type of fabrication is commonly used in commercial and industrial construction projects, where strength and durability are paramount. Metal fabrication can include processes such as welding, machining, and finishing, and is essential for producing items such as beams, frames, and supports that meet stringent structural standards.

Wood fabrication focuses on crafting wooden structures and components, which are particularly important for residential projects. This service includes the design and production of framing, cabinetry, and custom furniture. Skilled wood fabricators can create intricate designs that enhance the aesthetic appeal of a space, making it essential for both new constructions and renovations. The versatility of wood allows for a wide range of applications, from structural elements to decorative finishes.

Plastic fabrication involves creating products from plastic materials, and it is gaining popularity in various industries. This type of fabrication is often used for signage, displays, and components for industrial applications. Plastic fabrication allows for lightweight and durable products, making it suitable for projects where weight savings are critical. Additionally, advancements in plastic fabrication techniques have expanded the possibilities for customization and design flexibility.

Choosing the right fabrication contractor is crucial for the success of your project and involves several key considerations:

Accurate fabrication estimates bring a host of benefits that can enhance project outcomes:

Despite the importance of accurate cost estimation, several challenges can arise during the process:

While fabrication costs can be substantial, there are several strategies you can employ to minimize expenses:

At Estimate Florida Consulting, we specialize in providing accurate fabrication cost estimates tailored to your project needs. Our team of experts understands the intricacies of fabrication and can help you navigate the complexities of cost estimation. We utilize advanced tools and methodologies to ensure that our estimates are both precise and comprehensive, allowing you to make informed decisions for your construction projects. Whether you’re embarking on a new build or a renovation, our tailored services provide the insights necessary to achieve your goals within budget.

Accurate fabrication cost estimation is essential for the successful execution of construction projects. By understanding the factors influencing fabrication costs, choosing the right contractor, and implementing strategies to reduce expenses, you can achieve significant savings while ensuring high-quality results. At Estimate Florida Consulting, we are dedicated to providing you with the insights and tools needed to streamline your fabrication processes, ultimately leading to a more efficient and cost-effective construction experience. With our expertise in the Florida market, we are well-positioned to assist you in realizing your construction goals.

Fabrication refers to the process of constructing products or structures from raw materials. In construction, it involves various activities such as cutting, bending, assembling, and finishing materials to create custom components tailored to specific design requirements. This is crucial for ensuring that buildings are not only functional but also aesthetically pleasing.

Fabrication costs can be broken down into three main categories:

To estimate fabrication costs, create a detailed breakdown of materials, labor, and overhead. For instance, you can use a sample table format to outline costs for specific items and services. This will help you get a clearer picture of your overall budget and expenses.

There are several types of fabrication services, including:

Choosing the right contractor involves several key factors:

Accurate estimates provide several advantages, such as:

Some common challenges include:

Here are a few tips to minimize expenses:

At Estimate Florida Consulting, we offer detailed cost estimates across all major trades, ensuring no part of your project is overlooked. From the foundation to the finishing touches, our trade-specific estimates provide you with a complete and accurate breakdown of costs for any type of construction project.

We take pride in delivering accurate, timely, and reliable estimates that help contractors and builders win more projects. Our clients consistently praise our attention to detail, fast turnaround times, and the positive impact our estimates have on their businesses.

Estimate Florida Consulting has helped us win more bids with their fast and accurate estimates. We trust them for every project!

Submit your project plans, blueprints, or relevant documents through our online form or via email.

We’ll review your project details and send you a quote based on your scope and requirements.

Confirm the details and finalize any adjustments to ensure the estimate meets your project needs.

Receive your detailed, trade-specific estimate within 1-2 business days, ready for your project execution.

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

All copyright © Reserved | Designed By V Marketing Media | Disclaimer