90% More Chances to Win Projects With Our Estimate!

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- School & University Building

- High-Rise Building

- Shopping Complex

- Data Center Building

Mechanical systems are vital components in any building, ensuring comfort, safety, and efficiency. These systems include HVAC, plumbing, electrical systems, and fire protection. Each system has its unique cost factors, making it essential to understand these components for accurate estimation.

Heating, ventilation, and air conditioning (HVAC) systems are essential for maintaining comfortable indoor temperatures. Below is a breakdown of common HVAC components and their costs.

HVAC Component | Material Cost | Labor Cost | Total Cost |

Central Air Conditioning | $3,000 – $7,000 | $1,000 – $2,500 | $4,000 – $9,500 |

Heating System (Furnace) | $2,000 – $5,000 | $800 – $1,500 | $2,800 – $6,500 |

Ductwork Installation | $1,500 – $4,000 | $500 – $1,200 | $2,000 – $5,200 |

Ventilation Fans | $200 – $500 | $150 – $300 | $350 – $800 |

Investing in energy-efficient HVAC systems can significantly reduce long-term operating costs. Here are some additional options with cost implications:

Energy-Efficient Option | Material Cost | Labor Cost | Total Cost |

High-Efficiency Furnace | $3,000 – $6,000 | $800 – $1,500 | $3,800 – $7,500 |

Ductless Mini-Split System | $2,000 – $5,000 | $500 – $1,200 | $2,500 – $6,200 |

Smart Thermostats | $100 – $300 | $50 – $100 | $150 – $400 |

Plumbing systems are crucial for providing water supply and waste removal. Below is a detailed cost breakdown of plumbing components.

Plumbing Component | Material Cost | Labor Cost | Total Cost |

Pipes (PVC, Copper) | $1.00 – $5.00 per foot | $1.50 – $3.00 per foot | $2.50 – $8.00 per foot |

Fixtures (Sinks, Toilets) | $100 – $500 each | $100 – $200 each | $200 – $700 each |

Water Heater | $800 – $1,500 | $200 – $500 | $1,000 – $2,000 |

Drainage Systems | $500 – $1,500 | $200 – $400 | $700 – $1,900 |

Different types of pipes can affect overall plumbing costs:

Pipe Type | Material Cost | Durability |

PVC | $1.00 – $3.00 per foot | Good for drainage |

Copper | $2.00 – $5.00 per foot | Excellent for water supply |

PEX | $0.50 – $2.00 per foot | Flexible and easy to install |

Electrical systems are vital for lighting, heating, and powering appliances. Below is a detailed cost breakdown of electrical components.

Electrical Component | Material Cost | Labor Cost | Total Cost |

Wiring (Copper, Aluminum) | $0.50 – $2.00 per foot | $1.00 – $2.00 per foot | $1.50 – $4.00 per foot |

Circuit Breaker Panel | $200 – $500 | $100 – $200 | $300 – $700 |

Light Fixtures | $50 – $200 each | $50 – $100 each | $100 – $300 each |

Outlets and Switches | $5 – $15 each | $5 – $10 each | $10 – $25 each |

Different types of wiring can significantly influence electrical system costs:

Wiring Type | Material Cost per Foot | Usage |

Copper | $0.75 – $1.50 | Most common and efficient |

Aluminum | $0.50 – $1.00 | Lightweight, but less efficient |

Proper insulation and air sealing are essential for energy efficiency and comfort. Below is a breakdown of associated costs.

Insulation Type | Material Cost per Sq. Ft. | Labor Cost per Sq. Ft. | Total Cost per Sq. Ft. |

Fiberglass Batts | $0.50 – $1.00 | $0.50 – $1.00 | $1.00 – $2.00 |

Spray Foam | $1.50 – $3.00 | $1.00 – $2.00 | $2.50 – $5.00 |

Rigid Foam Board | $1.00 – $2.00 | $0.50 – $1.00 | $1.50 – $3.00 |

Air sealing involves sealing gaps and cracks to improve energy efficiency.

Air Sealing Method | Material Cost | Labor Cost | Total Cost |

Caulking | $5 – $15 per tube | $100 – $300 total | $105 – $315 |

Weatherstripping | $0.50 – $3.00 per foot | $100 – $200 total | $100.50 – $203 |

Fire protection systems are vital for safety and compliance. Below is a detailed breakdown of costs associated with fire protection.

Fire Protection Component | Material Cost | Labor Cost | Total Cost |

Fire Alarms | $200 – $600 per system | $100 – $300 | $300 – $900 |

Sprinkler Systems | $2.00 – $6.00 per sq. ft. | $1.50 – $3.00 per sq. ft. | $3.50 – $ |

Different fire protection systems can affect costs based on the complexity and required features:

Fire Protection System Type | Material Cost | Labor Cost | Total Cost |

Standalone Fire Alarms | $200 – $400 per unit | $50 – $100 per unit | $250 – $500 per unit |

Centralized Fire Alarm Systems | $1,000 – $5,000 | $300 – $1,000 | $1,300 – $6,000 |

Sprinkler Systems (Wet Type) | $2.50 – $5.00 per sq. ft. | $2.00 – $4.00 per sq. ft. | $4.50 – $9.00 per sq. ft. |

Fire Extinguishers | $50 – $150 each | $25 – $50 each | $75 – $200 each |

Controls and automation systems enhance the efficiency and usability of mechanical systems. Below is a detailed breakdown of costs.

Control System Component | Material Cost | Labor Cost | Total Cost |

Thermostats | $50 – $150 each | $25 – $75 each | $75 – $225 each |

Smart Home Systems | $200 – $1,500 | $100 – $300 | $300 – $1,800 |

Building Automation Systems | $1,000 – $5,000 | $500 – $1,500 | $1,500 – $6,500 |

Investing in automated systems can lead to energy savings and improved comfort. Here are some options:

Automation Type | Material Cost | Labor Cost | Total Cost |

Smart Thermostat | $100 – $300 | $50 – $100 | $150 – $400 |

Automated Blinds | $200 – $600 each | $100 – $300 each | $300 – $900 each |

Labor costs can significantly affect the overall budget for mechanical systems. The following table summarizes the average labor costs associated with the installation of various mechanical systems.

System Type | Labor Cost per Hour | Estimated Hours | Total Labor Cost |

HVAC Installation | $25 – $60 | 20 – 60 | $500 – $3,600 |

Plumbing Installation | $20 – $50 | 15 – 40 | $300 – $2,000 |

Electrical Installation | $30 – $70 | 10 – 30 | $300 – $2,100 |

Fire Protection Installation | $25 – $55 | 10 – 25 | $250 – $1,375 |

When budgeting for mechanical systems in construction projects, it’s essential to understand the various factors that can influence overall costs. The mechanical systems of a building—including heating, ventilation, air conditioning (HVAC), plumbing, and electrical systems—are integral to creating a comfortable and functional environment. Here are the key factors that play a significant role in determining mechanical systems costs:

The size and complexity of a building are among the most significant determinants of mechanical systems costs. Larger buildings often require more extensive and sophisticated mechanical systems to ensure efficient operation throughout the entire space. For instance, a high-rise office building may need multiple HVAC units, advanced ductwork, and sophisticated control systems to maintain comfortable temperatures on every floor. Additionally, buildings with unique architectural designs—such as vaulted ceilings or complex layouts—may necessitate custom solutions that can drive up costs. As a result, understanding the specific requirements of a project is crucial for estimating the mechanical systems’ budget accurately.

The quality of materials used in mechanical systems directly impacts their performance, longevity, and maintenance needs. Higher-quality materials, such as high-efficiency HVAC units, durable piping, or premium insulation, often come with a higher price tag. While these materials may require a more substantial initial investment, they typically offer better performance, greater energy efficiency, and lower maintenance costs over time. For example, investing in high-quality ductwork can improve airflow and system efficiency, leading to reduced energy consumption and lower utility bills. Thus, when planning a project, it’s important to consider the long-term value of material quality in the overall budget.

Labor costs are another crucial factor affecting the total cost of mechanical systems installation. Rates for skilled labor can vary significantly based on geographic location, demand for specific trades, and regional economic conditions. In areas where there is a shortage of qualified technicians, labor rates can increase sharply, impacting the overall project budget. Furthermore, the complexity of the mechanical systems can also affect labor costs; systems requiring specialized skills or certifications may lead to higher expenses. Therefore, when planning for mechanical systems, homeowners and contractors should research local labor rates and factor them into the overall cost estimates.

Compliance with building codes and regulations is a vital aspect of any construction project, particularly regarding mechanical systems. Local building codes may require specific materials, systems, and installation practices to ensure safety and performance standards are met. For example, certain jurisdictions may mandate the use of energy-efficient HVAC systems or require specific plumbing fixtures to meet water conservation goals. These regulatory requirements can significantly impact costs, as they may necessitate the use of more expensive materials or systems that comply with the latest standards. Understanding local regulations upfront can help avoid costly changes and ensure a smoother construction process.

As energy efficiency becomes increasingly important in building design, meeting established standards can impact the initial costs of mechanical systems. Advanced systems designed to meet energy efficiency standards often incorporate cutting-edge technologies, such as variable refrigerant flow (VRF) systems, smart thermostats, and high-efficiency water heaters. While these systems may come with a higher upfront cost, they can lead to significant savings on energy bills over time and may even qualify for rebates or incentives from local utilities or government programs. Therefore, while considering mechanical systems costs, it’s crucial to evaluate both the initial investment and the potential long-term savings that energy-efficient options may provide.

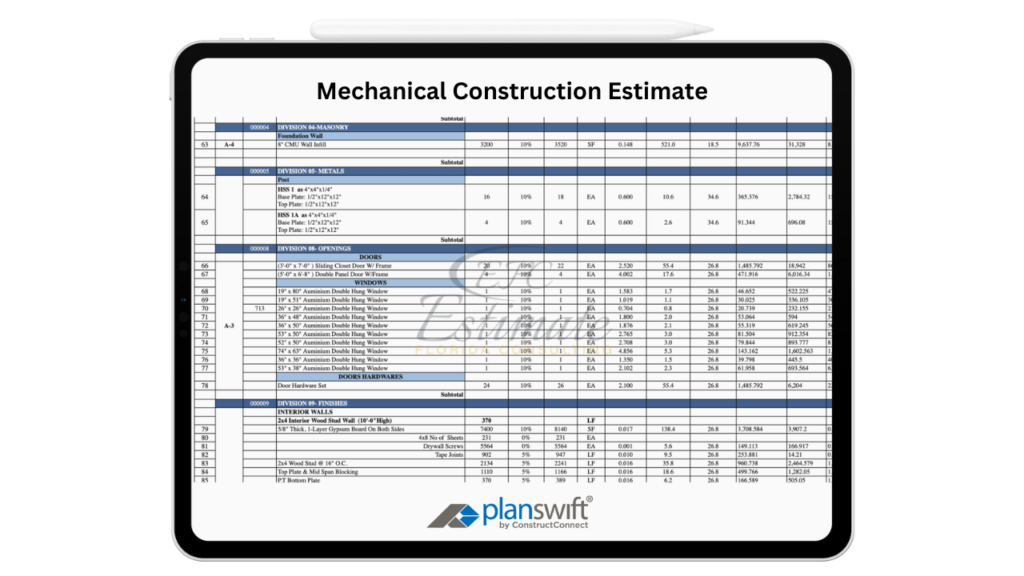

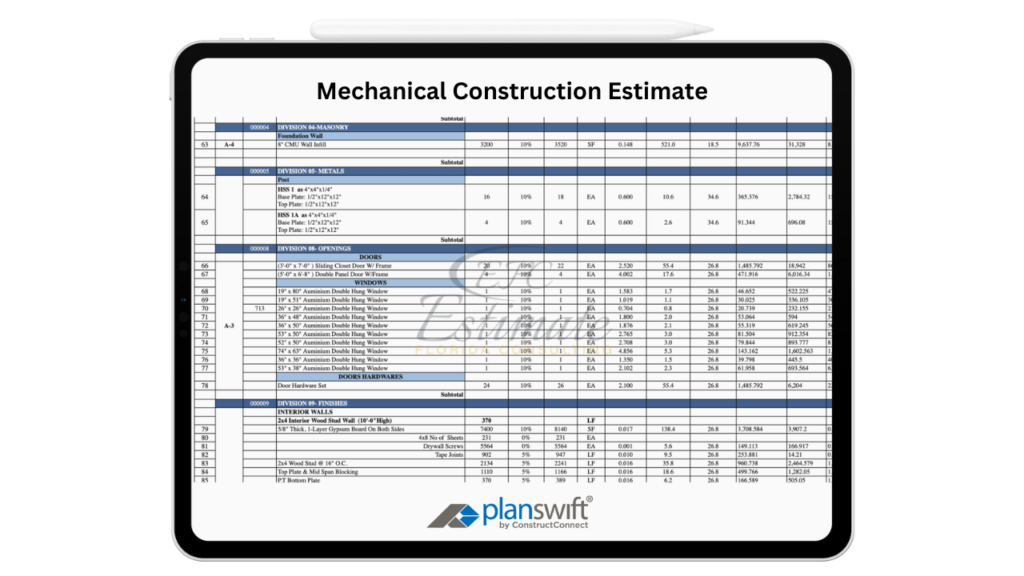

Estimating the costs of mechanical systems requires a comprehensive understanding of various components, including HVAC, plumbing, electrical systems, insulation, fire protection, and automation. By considering the material costs, labor costs, and the impact of energy efficiency and automation, general contractors, subcontractors, and developers can provide accurate estimates that reflect both initial investments and long-term savings.

Investing in high-quality materials and systems may result in higher upfront costs but can lead to significant savings in energy and maintenance over time. Accurate cost estimation is crucial for ensuring that projects stay within budget and meet quality standards.

Mechanical systems in construction refer to the essential components that ensure a building’s comfort, safety, and efficiency. These systems include heating, ventilation, and air conditioning (HVAC), plumbing, electrical systems, fire protection, and automation controls.

The cost of HVAC systems can be estimated by considering the price of essential components such as central air conditioning units, heating systems (furnaces), ductwork installation, and ventilation fans. Factors like material and labor costs should be accounted for, which can vary based on system complexity and installation requirements.

The costs of plumbing systems are influenced by various factors, including the type of pipes used (PVC, copper, or PEX), fixtures selected (sinks, toilets), water heater types, and drainage system requirements. Labor costs can also vary based on local rates and installation complexities.

Key components of electrical systems include wiring (copper or aluminum), circuit breaker panels, light fixtures, outlets, and switches. Each component has its material and labor costs, which contribute to the overall budget for electrical system installation.

Investing in energy-efficient mechanical systems, such as high-efficiency HVAC units, ductless mini-split systems, and smart thermostats, may result in higher upfront costs but can lead to significant long-term savings on energy bills. These systems often have better performance and lower maintenance needs.

Fire protection systems can vary in cost based on the type of system installed. Costs typically include fire alarms, sprinkler systems, and fire extinguishers, with materials and labor varying based on system complexity and local codes.

Larger and more complex buildings often require more extensive mechanical systems, leading to higher costs. Custom solutions may be necessary for unique architectural designs, impacting overall budgeting.

The quality of materials used in mechanical systems directly affects their performance and longevity. Higher-quality materials may require a more substantial initial investment but often lead to lower maintenance costs and improved energy efficiency over time.

At Estimate Florida Consulting, we offer detailed cost estimates across all major trades, ensuring no part of your project is overlooked. From the foundation to the finishing touches, our trade-specific estimates provide you with a complete and accurate breakdown of costs for any type of construction project.

We take pride in delivering accurate, timely, and reliable estimates that help contractors and builders win more projects. Our clients consistently praise our attention to detail, fast turnaround times, and the positive impact our estimates have on their businesses.

Estimate Florida Consulting has helped us win more bids with their fast and accurate estimates. We trust them for every project!

Submit your project plans, blueprints, or relevant documents through our online form or via email.

We’ll review your project details and send you a quote based on your scope and requirements.

Confirm the details and finalize any adjustments to ensure the estimate meets your project needs.

Receive your detailed, trade-specific estimate within 1-2 business days, ready for your project execution.

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

All copyright © Reserved | Designed By V Marketing Media | Disclaimer