90% More Chances to Win Projects With Our Estimate!

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- School & University Building

- High-Rise Building

- Shopping Complex

- Data Center Building

Masonry takeoff is a critical aspect of construction, especially for projects involving bricks, concrete blocks, and stonework. For general contractors, subcontractors, material suppliers, developers, and homeowners, a detailed masonry takeoff provides an accurate estimate of the materials and labor needed. Understanding this process ensures that projects are completed on time and within budget while minimizing material waste.

At Estimate Florida Consulting, we specialize in delivering precise masonry takeoff services that help you optimize costs and resources. Whether you’re working on a residential property, commercial development, or industrial project, our team of professional estimators ensures every material is accounted for, avoiding unnecessary expenses.

A masonry takeoff is the process of estimating the quantity of masonry materials—such as bricks, blocks, mortar, and reinforcing steel—that are required for a construction project. By conducting a thorough masonry takeoff, contractors can determine the exact materials needed, avoiding both shortages and surplus.

Masonry takeoffs also account for labor costs, waste percentages, and specific project requirements, helping you create a precise budget. Whether you’re working on a residential build or a large-scale commercial structure, a masonry takeoff ensures you have the resources and the cost data to execute the project successfully.

Masonry takeoff is an essential component of any construction project, as it helps avoid costly delays and miscalculations. By knowing how much material is needed ahead of time, you can streamline the procurement process and ensure that your project stays on track. Here’s why masonry takeoffs are so important:

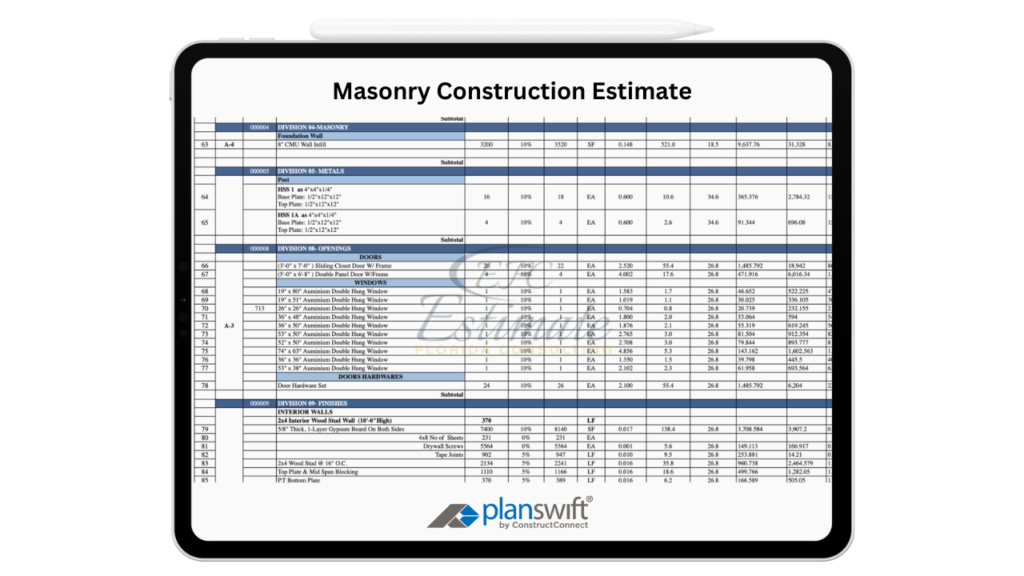

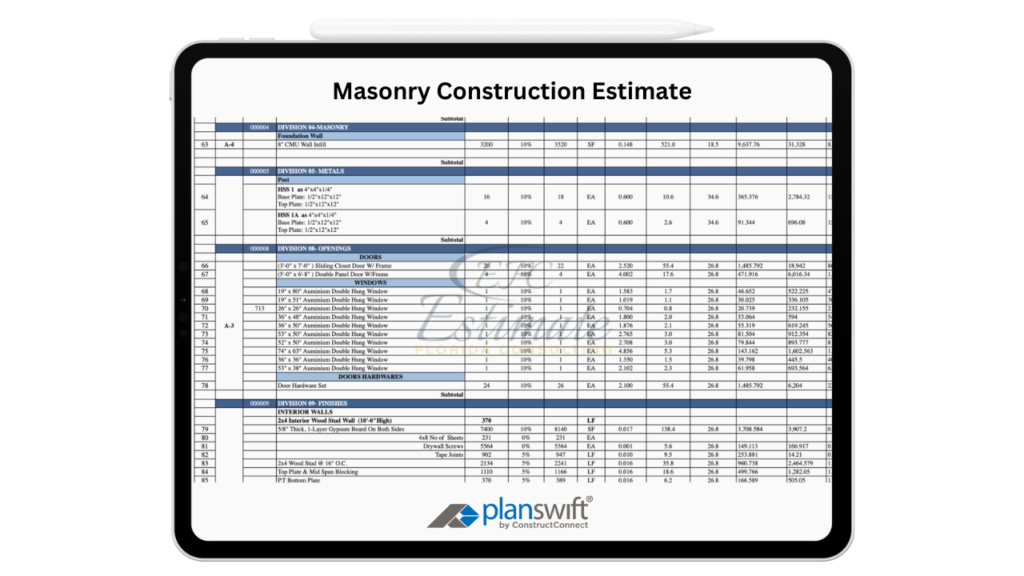

A successful masonry takeoff involves multiple steps, each contributing to an accurate and detailed estimate. The following steps outline the masonry takeoff process:

Before starting a masonry takeoff, it is important to thoroughly review the project plans and specifications. This step ensures you understand the type of masonry materials required and the scope of the project. Depending on the project, you may need to estimate for different materials like bricks, concrete blocks, natural stone, or even specialty masonry units.

Once you have a full understanding of the project, the next step is to quantify the materials. This involves calculating the square footage of walls, the number of bricks or blocks needed, and other specific materials like mortar and reinforcing steel. A typical masonry takeoff includes the following:

Labor costs are a crucial part of the masonry takeoff process. Depending on the complexity and scale of the project, labor costs may vary. Estimating the number of man-hours required for the installation of masonry materials ensures that you have a comprehensive budget. Masonry labor costs typically range from $50 to $100 per hour, depending on location and skill level.

Construction projects often have waste due to material breakage, cutting, or over-ordering. To compensate, it’s essential to include a waste factor in your takeoff. Typically, the waste percentage for masonry materials is 5% to 10%, depending on the project complexity and materials used.

Once you’ve gathered all the material quantities and labor estimates, the final step is to compile these numbers into a comprehensive cost estimate. This includes breaking down material costs, labor costs, and any additional fees like transportation or permits. Having a detailed estimate allows for greater cost transparency and helps in keeping the project within budget.

Several factors influence the cost of masonry takeoff, from the type of materials used to the complexity of the design. Understanding these factors can help you make more accurate estimates and manage project costs effectively.

The type of masonry material—whether bricks, blocks, stone, or specialty units—plays a significant role in determining the cost of the project. For example, bricks tend to be more affordable than natural stone, but they may require more labor due to their smaller size. Below is a cost comparison for common masonry materials:

Material Type | Average Cost per Unit | Labor Cost per Square Foot |

Brick | $0.50 – $1.50 | $5 – $12 |

Concrete Block | $1.00 – $3.00 | $6 – $15 |

Natural Stone | $10.00 – $20.00 | $20 – $50 |

Specialty Masonry | $5.00 – $15.00 | $10 – $30 |

The size and complexity of the project also affect the total cost of the masonry takeoff. Larger projects will naturally require more materials and labor, leading to higher costs. Similarly, intricate designs or architectural features, such as arches or detailed stonework, may require more time and specialized labor, increasing the overall price.

Labor rates can vary depending on your location. Urban areas or regions with high demand for construction workers typically have higher labor costs, while rural areas may offer more affordable rates. It’s important to account for these regional differences when estimating masonry costs.

For structural projects, reinforced masonry may be required to ensure stability and compliance with building codes. The inclusion of steel reinforcement bars, concrete grout, or other structural elements will add to both material and labor costs. Reinforced masonry typically costs between $15 and $30 per square foot.

The accessibility of the construction site also impacts the overall cost. If the site is difficult to access, such as in urban areas with limited space for staging materials, additional labor and equipment may be required, increasing costs. Proper planning and site management can help mitigate these expenses.

Here’s a general breakdown of the costs involved in a masonry takeoff:

Cost Component | Average Cost |

Bricks/Blocks | $0.50 – $3.00 per unit |

Mortar | $5 – $12 per bag |

Reinforcing Steel | $0.50 – $2.00 per linear foot |

Labor | $50 – $100 per hour |

Waste Factor (5-10%) | Included in material costs |

Total Project Cost (per sqft) | $10 – $50 per square foot |

The cost of bricks or blocks typically ranges from $0.50 to $3.00 per unit, depending on the type and quality of the materials used. For example, basic clay bricks might fall on the lower end of this spectrum, while decorative or specialized blocks, such as concrete or stone, can push the price higher. The number of bricks or blocks required will depend on the size of the structure, but selecting the right material is crucial for ensuring both aesthetic appeal and long-term durability.

Mortar, used to bind the bricks or blocks together, costs between $5 and $12 per bag. The quality of the mortar mix and the type of masonry being built will influence this price. Higher-quality mortars are designed to withstand environmental factors like moisture and temperature changes, making them a worthwhile investment for long-lasting construction. It’s important to factor in the number of mortar bags required based on the size of the project and the material used, as well as considering any specific durability requirements for your project.

Reinforcing steel is often used in masonry to increase structural integrity, particularly in larger or more complex builds. The cost of reinforcing steel ranges from $0.50 to $2.00 per linear foot. This component is critical for adding strength to the masonry, especially in areas prone to earthquakes or high winds. While the price per foot might seem minimal, the total cost can add up significantly depending on the size of the structure and the amount of reinforcement needed for the design.

Labor costs in masonry projects are generally one of the larger expenses, with hourly rates ranging from $50 to $100 per hour. This rate can vary depending on the experience of the workers, the complexity of the job, and regional labor costs. Skilled masons are crucial to ensuring that the project is completed with precision, as masonry work often requires detailed craftsmanship. Opting for experienced masons may increase the hourly cost, but it also ensures that the job is done right the first time, minimizing potential issues down the line.

A waste factor of 5-10% is typically included in the material costs to account for any breakage or miscalculations during the project. Masonry projects often experience some level of material loss due to the cutting or shaping of bricks and blocks to fit the design, as well as handling during the installation process. Including this waste factor in the overall cost ensures that you have enough materials to complete the project without any unexpected shortages.

For contractors and developers working on large or complex projects, professional masonry takeoff services can be a game-changer. Professional estimators use their experience and expertise to create precise takeoffs that minimize material waste and reduce overall project costs. Here are some of the key benefits of using professional masonry takeoff services:

At Estimate Florida Consulting, we pride ourselves on delivering highly accurate, detailed, and reliable masonry takeoff services. Here’s why choosing us makes a difference:

Masonry takeoff is a critical part of any construction project, providing you with the detailed estimates needed to plan and budget effectively. Whether you’re a contractor, developer, or homeowner, understanding the masonry takeoff process ensures that your project runs smoothly and stays within budget. By using the right tools, taking into account all cost factors, and possibly relying on professional services, you can streamline the estimation process and improve the accuracy of your bids.

In construction, a takeoff refers to the process of measuring and listing all materials, labor, and equipment needed for a project. It’s essential for estimating costs and creating an accurate budget before construction begins.

To do a masonry estimate, follow these steps:

After gathering this data, compile the costs for materials, labor, and equipment to create an accurate masonry estimate.

To calculate masonry work, follow these steps:

By combining material, labor, and additional costs, you can accurately calculate the total cost of masonry work.

On average, a skilled mason can complete between 400 to 600 bricks per day under standard working conditions. The actual number varies depending on several factors:

This is a general estimate, and specific project conditions can influence the daily output.

The main difference between a bricklayer and a stonemason lies in the materials they work with and their skills:

Both professions involve masonry work, but stonemasons often require more specialized skills due to the variability and complexity of working with stone.

At Estimate Florida Consulting, we offer detailed cost estimates across all major trades, ensuring no part of your project is overlooked. From the foundation to the finishing touches, our trade-specific estimates provide you with a complete and accurate breakdown of costs for any type of construction project.

We take pride in delivering accurate, timely, and reliable estimates that help contractors and builders win more projects. Our clients consistently praise our attention to detail, fast turnaround times, and the positive impact our estimates have on their businesses.

Estimate Florida Consulting has helped us win more bids with their fast and accurate estimates. We trust them for every project!

Submit your project plans, blueprints, or relevant documents through our online form or via email.

We’ll review your project details and send you a quote based on your scope and requirements.

Confirm the details and finalize any adjustments to ensure the estimate meets your project needs.

Receive your detailed, trade-specific estimate within 1-2 business days, ready for your project execution.

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

561-530-2845

info@estimatorflorida.com

Address

5245 Wiles Rd Apt 3-102 St. Pete Beach, FL 33073 United States

All copyright © Reserved | Designed By V Marketing Media | Disclaimer