How To Estimate Construction Costs Accurately?

Construction estimating involves calculating all the costs needed for a construction project, including direct costs (like materials and worker wages) and indirect costs (such as equipment depreciation and office worker salaries). Professional construction estimators handle this crucial preconstruction step to help ensure that both owners and contractors can complete a project profitably.

Accurately estimating project costs requires a detailed understanding of construction materials, specifications, techniques, codes, and pricing trends.

We’ll guide you through the steps that professional estimators use to determine project costs—from reviewing a bid package to accounting for contingency and profit.

The Importance of Accurate Estimating

Accurate estimating is crucial for the success of any construction project. Both owners and contractors rely on precise cost estimates to transition a project from preconstruction to completion smoothly.

For owners, understanding the project’s costs upfront is vital to determine if the project is feasible within the budget. If initial estimates show that costs exceed the budget, design or scope modifications may be necessary to bring the project in line with financial constraints.

Contractors, on the other hand, need accurate estimates to prepare bids that are both competitive and profitable. Underestimating project costs can force a contractor to dip into their profit margin to cover expenses. Conversely, overestimating costs can result in a bid that’s too high to win the project. Even in negotiated bidding scenarios, accurate estimates are essential to balance the owner’s budget with the contractor’s profit margin.

8 Steps in Construction Estimating

Construction estimators, whether they work for a general contractor, specialty contractor, or owner, follow a similar process to arrive at an accurate project price, either for competitive or negotiated bidding.

The estimating process generally starts with a thorough review of bid documents, construction specifications, and contract documents. Estimators then proceed through a series of steps to account for all known costs, including materials, labor, insurance, and overhead. The final construction estimate will include all required costs, plus a markup for profit and contingency, ensuring a comprehensive and competitive bid.

1. Review Bid Package

The bid package includes all the essential documents for bidding, such as owner-contractor agreements, bond forms, general conditions, supplementary general conditions, and construction specifications. Contractors are required to complete the work outlined in the bid package, so professional estimators spend significant time familiarizing themselves with every project detail. This meticulous review ensures that nothing is overlooked, which is crucial for both the accuracy of the estimate and the project’s overall success.

Subdividing Drawings

- Purpose Categories: Drawings are categorized by purpose, including site, architectural, structural, mechanical, electrical, and more. This categorization helps in identifying specific needs and potential challenges in each area of the project.

- General vs. Specialty Contractors: General contractors review all documents to understand the full scope of the project, while specialty contractors focus on documents relevant to their specific tasks. This division of labor ensures that each contractor is fully aware of their responsibilities and can prepare accurate bids.

Standard Process for Reviewing the Bid Package

- Ensure Completeness: Verify all drawings and specifications are present. Documents may be sequentially numbered or subdivided based on the design firm’s preference. Missing documents can lead to inaccurate estimates and project delays, so thoroughness at this stage is critical.

- Project Overview: Quickly scan through the specs to get an initial idea of the project’s scope, material needs, and finish quality. This step provides a high-level understanding that guides further detailed review.

- Structural Requirements: Evaluate structural drawings to understand material and equipment needs. This includes assessing the foundation, framework, and any load-bearing elements that are critical to the project’s integrity.

- MEP Requirements: Consider mechanical, electrical, and plumbing (MEP) needs and how they impact the construction process, including potential underground work. MEP systems are integral to building functionality, and their complexity often requires careful planning and coordination.

- Identify Nonstandard Items: Pay attention to unusual floor plans, features, or finishes that could affect costs. Unique design elements can introduce unexpected challenges and costs, so identifying them early is important for accurate budgeting.

Throughout the estimating process, estimators continually refer back to the bid documents to ensure their estimate includes all specified aspects and requirements. Regular cross-referencing helps maintain accuracy and consistency, reducing the likelihood of errors.

Subdividing the Project into Work Packages:

- General Contractors: Estimators for general contractors divide the project into work packages, which may be assigned to specialty contractors. This helps ensure all work is accounted for and no tasks are duplicated. Work packages provide clarity and organization, making it easier to manage and track the project’s progress.

- Construction Specifications: By reviewing technical specifications (or specs), the estimator clearly understands the scope of work across various divisions of the Construction Specification Institute (CSI)’s MasterFormat: concrete, masonry, metals, finishes, plumbing, and more. This detailed review helps in identifying specific materials and labor requirements for each aspect of the project.

Example Work Packages

- Rough-in Plumbing: Includes materials and labor for initial plumbing installations. This package covers everything from pipe installation to fixture placement, ensuring that all plumbing needs are addressed early in the construction process.

- Windows and Installation: Covers the cost and labor for window installation. This package ensures that all windows are correctly installed, sealed, and insulated to meet energy efficiency standards.

- Attention to Detail: The estimator must ensure all aspects of the project are included in a work package and avoid overlapping tasks to keep the bid competitive. Overlapping tasks can lead to increased costs and inefficiencies, so precise planning is essential.

Soliciting Bids

Once work packages are defined, general contractors can solicit bids from specialty contractors for some or all of the required construction work. This division ensures clarity and completeness, ultimately leading to a more accurate and competitive project estimate. By clearly defining the scope of each work package, contractors can provide more precise bids, reducing the risk of cost overruns and project delays.

90% More Chances to Win Projects With Our Estimate!

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- School & University Building

- High-Rise Building

- Shopping Complex

- Data Center Building

2. Conduct a Site Visit

While a site visit isn’t always mandatory before submitting a bid, it is highly recommended. A thorough site visit allows estimators to gain a better understanding of the site conditions compared to relying solely on elevation drawings or photographs. This hands-on approach enables the estimator to identify potential challenges and nuances that may not be evident in the documentation, ultimately leading to a more accurate and realistic cost estimate.

For certain projects, specialty contractors might skip the site visit, relying instead on documentation provided by the project’s owner and general contractor. However, this can be risky. The documentation might not capture all the site-specific variables that can impact costs. For example, there could be hidden underground utilities, unexpected topographical changes, or unanticipated access restrictions that could affect the project’s timeline and budget.

Purpose of a Site Visit

The main goal of a site visit is to gain a clear understanding of the site conditions and how they might affect project costs. Here are a few key considerations:

- Drainage and Soil Conditions: Poor drainage or difficult subsurface soil can add complexity and increase costs. For instance, if the soil is too rocky or sandy, it may require additional excavation or stabilization efforts, which can be both time-consuming and expensive.

- Site Accessibility: Limited access can make it challenging to maneuver equipment and materials, leading to higher costs. Tight urban environments or sites with narrow access roads may necessitate the use of specialized equipment or creative logistical solutions, both of which can increase costs.

- Utility Locations: Poorly located utilities might require additional underground work, raising overall expenses. If utilities like water, electricity, or gas are far from the construction site, additional trenching and conduit installation may be necessary, adding to the project’s complexity and cost.

During the site visit, estimators will take notes, photographs, and collaborate with contractors to assess how the site conditions might influence project delivery. They will also look for any potential hazards or obstacles that could affect the construction process, such as overhead power lines, nearby structures, or environmental concerns.

Understanding the Surrounding Area

Besides the site itself, the estimator should also consider the surrounding area, focusing on:

- Local Codes and Regulations: Understanding local requirements, such as permits, noise regulations, and working hours, is crucial. Non-compliance with local laws can result in fines, work stoppages, and other legal issues that can delay the project and increase costs.

- Availability of Resources: Check the availability of specialty contractors and construction equipment rentals in the area.

If the necessary resources are not readily available locally, the project may face delays and increased costs due to transportation and accommodation for out-of-town workers.

- Nearby Roadways: Ensure that nearby roads can accommodate heavy equipment and delivery vehicles. If the roads are too narrow or not designed for heavy traffic, alternative routes or road modifications might be necessary, impacting the project’s logistics and budget.

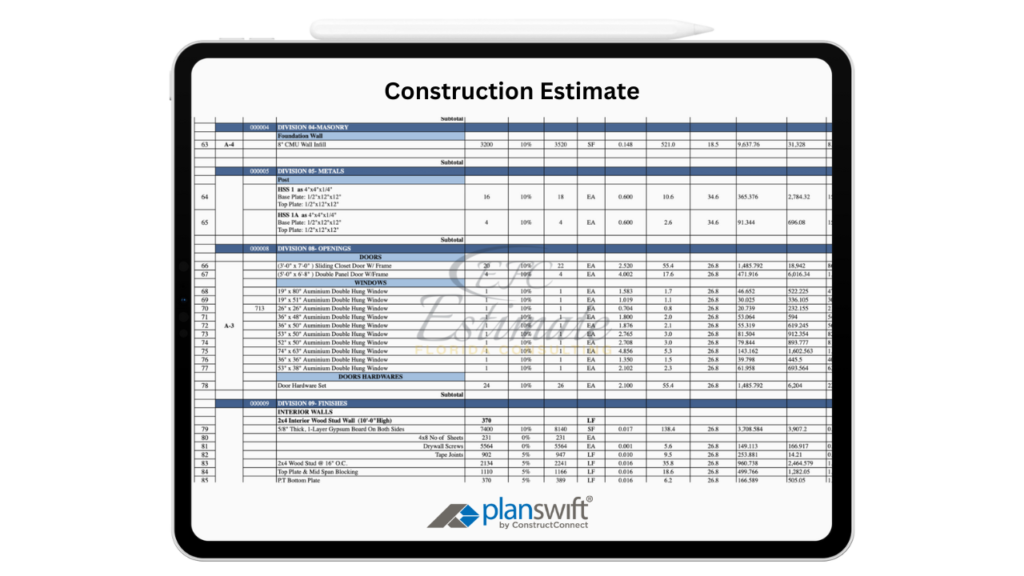

3. Perform a Material Takeoff

Performing a material takeoff, also known as a quantity takeoff, involves a meticulous review of construction documents to identify and quantify every item required for the project. This step is crucial for creating an accurate estimate and ensuring that all necessary materials are accounted for, avoiding potential delays and cost overruns. Materials are typically categorized based on how they are measured. For example:

- Quantity: This includes items that can be counted, such as doors, windows, and fixtures. Ensuring an accurate count prevents shortages or surpluses during the construction process.

- Area: Measured in square units, like drywall, flooring, and roofing materials. Accurate area measurements help in estimating the exact amount of material needed to cover the specified spaces.

- Volume: Measured in cubic units, such as concrete, asphalt, and soil. Precise volume calculations are essential for materials used in foundations, pavements, and landscaping.

- Length: Measured in linear units, like wires, pipes, and lumber. Accurate length measurements ensure that sufficient materials are available for installations and connections.

Role of General and Specialty Contractors

- General Contractors: Typically perform a takeoff to create accurate work packages. These packages can either be completed by the general contractor or assigned to specialty contractors. Accurate work packages help streamline the construction process, ensuring that each task is clearly defined and resourced.

- Specialty Contractors: Review specifications and perform their own material takeoff to ensure they have an accurate count of materials before contacting suppliers and vendors. This step is crucial for specialty contractors to provide precise bids and avoid under or overestimating their material needs.

Importance of a Bill of Quantities (BOQ)

On large construction projects, the owner or engineer may provide a Bill of Quantities (BOQ) to streamline the bid comparison process. The BOQ breaks down the scope of work into an itemized list of activities and materials. Even when a BOQ is available, most contractors still perform their own takeoff to verify quantities and identify any discrepancies. This additional verification helps to catch errors or omissions in the BOQ, ensuring a more accurate estimate.

Manual vs. Digital Takeoff

- Manual Takeoff: Involves using paper drawings, rulers, highlighters, digital measuring tools, and pencils to count and measure materials based on the specifications. While this method can be time-consuming, it allows for a hands-on approach to understanding the project’s needs. Estimators can gain a deeper insight into the project’s complexities by manually interacting with the drawings.

- Digital Takeoff: Most estimators now use construction estimating software, which greatly speeds up the process. Digital tools can automatically calculate quantities from digital plans, reducing human error and increasing efficiency. However, many estimators still double-check the digital takeoff to ensure accuracy. This cross-verification helps to confirm that the software’s calculations align with the project’s requirements.

Finalizing the Takeoff: After completing a takeoff, estimators have a detailed list of every material required to complete the project. This list also helps determine the necessary equipment for each work package. The detailed material list ensures that all aspects of the project are considered, from foundational elements to finishing touches.

With this detailed information, contractors can work with material and equipment suppliers to get pricing information for their bid. Accurate pricing helps in creating a competitive and realistic bid. By understanding the exact quantities and costs of materials, contractors can better manage their budgets and timelines, ultimately contributing to the project’s success.

Download Template For Construction Project Breakdown

- Materials list updated to the zip code

- Fast delivery

- Data base of general contractors and sub-contractors

- Local estimators

4. Solicit Pricing from Suppliers and Vendors

Once specialty contractors have a comprehensive list of materials and equipment, they begin working with suppliers and vendors to obtain pricing information. This step is crucial for creating an accurate and competitive bid. Contractors must establish good relationships with reliable suppliers to ensure timely delivery and fair pricing, which can significantly impact the project’s overall cost and timeline.

Key Considerations for Pricing Materials

- Material Waste: Contractors need to account for inevitable material waste. While efforts should be made to minimize waste, some is unavoidable due to factors like material sizing. By reviewing past projects, contractors can estimate the expected amount of waste and order accordingly. For instance, cutting large pieces of material to fit specific dimensions often results in leftover scraps that can’t be used. Understanding typical waste percentages for different materials helps in ordering the right quantities without excessive overage.

- Bulk Pricing: Bulk pricing structures can influence order sizes. For example, a contractor may need 37,000 cubic yards of a material but find it more cost-effective to purchase 40,000 cubic yards due to supplier pricing tiers. This strategy can lead to cost savings despite ordering more than initially required. Additionally, bulk purchasing can reduce the number of deliveries needed, potentially lowering transportation costs and minimizing project delays caused by waiting for materials.

- Quote Validity: Quotes from suppliers have limited lifespans. Contractors must ensure that the quotes they receive are valid long enough to secure their bid and place orders. This timing is critical to avoid price fluctuations that could impact the project’s budget. Contractors often need to negotiate with suppliers to lock in prices for a specific period, ensuring that material costs remain stable until the project starts.

Equipment Considerations

Contractors who do not already own essential equipment will also need to reach out to equipment vendors for leasing or rental pricing. This includes determining the costs for using the equipment throughout the project’s duration. Selecting the right equipment vendor is essential for maintaining efficiency and managing costs effectively.

- Ownership vs. Leasing/Renting: Contractors must decide whether to use owned equipment, purchase new equipment, or lease/rent equipment for the project. Each option has associated costs such as depreciation, maintenance, and operational expenses that need to be factored into the estimate. Owned equipment may have lower operational costs but higher upfront and maintenance expenses, while leasing or renting might offer lower initial costs with higher operational expenses.

- Cost Impact: The decision on how to procure equipment affects the overall project cost. Owned equipment might have lower operational costs but higher maintenance and depreciation expenses, while leased or rented equipment might offer more flexibility with different cost implications. Contractors need to consider the project duration and equipment utilization rates when deciding the most cost-effective option.

Finalizing Material and Equipment Costs

At this stage, contractors will have the first definitive dollar figures to include in the project costs. These figures provide a foundation for building a comprehensive estimate that incorporates all direct, indirect, and overhead costs. Accurate pricing from suppliers and vendors ensures that the bid reflects the true cost of materials and equipment, reducing the risk of unexpected expenses during the project.

By soliciting accurate pricing and considering factors like material waste, bulk pricing, and equipment costs, contractors can develop a more precise understanding of the project’s financial requirements.

This thorough approach helps ensure that the final bid is competitive and reflective of all necessary expenditures, contributing to the project’s overall success. Additionally, contractors should maintain open communication with suppliers and vendors to stay updated on any changes in pricing or availability, allowing them to adjust their estimates and bids accordingly.

5. Evaluate Labor Requirements

Once the material takeoff is complete, estimators can determine the labor needed for the project. This involves several key steps:

- Identify Required Roles: Estimators must specify which roles are necessary for the project. This includes identifying all the different types of workers required, such as tradespeople (electricians, plumbers, carpenters), laborers, and assistants. Additionally, for more complex projects, roles might also include specialized professionals like project managers, site supervisors, safety officers, and quality control inspectors. Each role needs to be clearly defined to ensure all aspects of the project are covered.

- Calculate Labor Hours: Estimators need to estimate the total number of labor hours required to complete the project. This involves breaking down the project into tasks and assigning an estimated duration to each task. The sum of these durations gives an overall estimate of the labor hours needed. This calculation should consider factors such as the complexity of tasks, the efficiency of the workforce, and potential delays. Estimators often use historical data from similar projects to inform these estimates, ensuring they are as accurate as possible.

- Assess Crew Productivity: Estimators evaluate how productive the crew will be based on past project data and the specific conditions of the current project. Productivity can be influenced by numerous factors, including worker experience, weather conditions, site accessibility, and the availability of tools and materials. For example, working in a congested urban area might slow down productivity due to limited space and logistical challenges, whereas a clear, open site might allow for faster progress.

For specialty contractors, the crew mix usually includes tradespeople, laborers, and assistants. For general contractors, it may also involve project-specific managers or other professionals whose roles are direct costs tied to the specific project. These roles ensure that every aspect of the project is managed and executed efficiently. Project-specific managers are crucial for coordinating between different trades, ensuring that the workflow is smooth and that any issues are addressed promptly.

Calculating the Loaded Labor Rate

Estimators must calculate the loaded labor rate, which includes more than just the hourly wage. The loaded labor rate comprises:

- Wages: The base pay for each worker, which varies depending on their role, experience, and the region’s labor market conditions.

- Taxes: Federal, state, and local taxes that the employer must pay, including Social Security and Medicare taxes.

- Insurance: Health, dental, vision, life insurance, unemployment, and worker’s compensation insurance. These benefits are essential for attracting and retaining skilled workers.

- Retirement Contributions: Employer contributions to retirement plans, which can be a significant part of the total compensation package.

- Union Dues: If applicable, the costs associated with union membership, which can include pension funds and training programs.

- Leave: Costs for sick leave and vacation time, which need to be accounted for to ensure workers are compensated fairly throughout the project.

Including all these factors ensures that the estimate accurately reflects the true cost of labor. By considering the full range of expenses associated with employing workers, estimators can provide a more precise and reliable estimate, helping to avoid budget shortfalls and ensuring the financial viability of the project.

Get Acquainted with Construction

Additional Considerations

- Overtime and Shift Differentials: If the project requires overtime or work during non-standard hours, these additional costs need to be included in the labor estimate.

- Training and Certification: Some projects may require specific training or certifications for workers, which can add to the labor costs.

- Local Labor Market Conditions: Availability of skilled labor in the local market can affect labor costs. In areas with labor shortages, higher wages might be necessary to attract qualified workers.

By thoroughly evaluating all aspects of labor requirements, estimators can develop a comprehensive and accurate estimate that covers all potential costs. This detailed approach helps ensure that the project stays within budget and progresses smoothly, ultimately leading to successful completion.

6. Determine Insurance and Bonding Costs

Insurance and bonding are essential for mitigating risks for both owners and contractors, but these protections come with costs that need to be included in project estimates. Properly managing these costs ensures that the project is financially sound and compliant with all regulatory and contractual obligations.

Insurance Requirements

Nearly all construction companies require general liability insurance to cover potential accidents and damages. This insurance protects against third-party claims of bodily injury, property damage, and personal injury. However, depending on the company’s size, scope, and role, additional insurance policies may also be necessary:

- Builder’s Risk Insurance: This policy covers property and materials during construction. It is crucial for protecting the project from losses due to events like fires, vandalism, or natural disasters. Without this insurance, contractors might face significant financial setbacks if the site is damaged.

- Errors and Omissions or Professional Liability Insurance: This insurance protects against claims of negligence or mistakes in professional services. For example, if an architect or engineer makes a design error that results in costly rework, this insurance can cover the associated costs.

- Inland Marine Insurance: Covers tools and equipment in transit. Construction often involves moving valuable equipment from one site to another, and this insurance ensures that these assets are protected against theft, damage, or loss during transportation.

- Commercial Auto Insurance: Covers vehicles used for business purposes. This is essential for companies with fleets of trucks or vans used to transport materials, tools, and personnel to and from job sites.

Bonding Requirements

In addition to insurance, contractors working on public projects (and some commercial projects) may require various construction bonds. These bonds provide financial security and assurance that the contractor will fulfill their obligations:

- Payment Bonds: Ensure subcontractors and suppliers get paid. This bond protects the owner from claims and liens by guaranteeing that all parties involved in the project are compensated for their work and materials.

- Performance Bonds: Guarantee that the contractor will complete the project according to the contract terms. This bond protects the owner if the contractor fails to meet the project specifications or deadlines, ensuring that the project will be completed as promised.

- Bid Bonds: Provide assurance that the contractor will honor their bid and provide the required performance and payment bonds if awarded the contract. This bond discourages frivolous bids and ensures that only serious contractors participate in the bidding process.

Cost Implications

Both bonds and insurance come with costs that contractors must cover through the projects they undertake. Generally, bond and insurance coverage have annual costs, which contractors then allocate across multiple projects throughout the year. However, specific projects may require additional bonding capacity or increased insurance coverage, incurring extra costs. For instance, a particularly large or complex project might necessitate higher limits on insurance policies or additional bonds, leading to increased premiums.

Incorporating Costs into Estimates

Estimators must include the costs of bonding and insurance in the project estimate to ensure the financial viability and risk management of the project. This involves calculating the annual cost of the necessary policies and bonds, then distributing these costs proportionally across all projects. Additionally, any project-specific increases in coverage must be factored into the estimate. By accounting for these expenses, contractors can protect themselves and their clients from potential financial losses while ensuring the project runs smoothly and complies with legal and contractual requirements.

Additional Considerations

- Market Fluctuations: Insurance premiums and bond costs can fluctuate based on market conditions, regulatory changes, and the contractor’s past performance. Estimators need to stay updated on these factors to provide accurate cost predictions.

- Negotiating Rates: Contractors can often negotiate better rates by maintaining a good safety record, implementing robust risk management practices, and building strong relationships with insurers and bonding companies.

- Documentation: Proper documentation and record-keeping are essential for managing insurance and bonding requirements. Estimators should ensure that all relevant policies and bonds are in place and that their terms are clearly understood and adhered to.

By thoroughly considering and including insurance and bonding costs in their estimates, contractors can ensure that they are fully prepared to manage the financial risks associated with construction projects. This comprehensive approach helps in delivering projects that are not only on time and within budget but also secure and compliant with all necessary regulations.

7. Calculate Overhead and Indirect Costs

Beyond direct project costs, estimators must account for the indirect field costs and overhead expenses necessary for running a construction business. These costs, while not always explicitly outlined in the bid package, are essential for project completion and business operations.

Indirect Field Costs: Indirect field costs are expenses that, while not directly tied to specific construction activities, are crucial for project execution. These can include:

- Permits: Fees for obtaining necessary construction permits from local authorities.

- Trailers or Temporary Offices: Costs for setting up and maintaining on-site offices.

- Site Cleaning: Expenses for keeping the construction site clean and safe.

- Professional Services: Fees for services such as surveying, legal advice, and consulting.

- Equipment Costs: This encompasses depreciation, insurance, maintenance, taxes, and fuel for construction equipment.

- Software: Costs for construction management and estimation software.

Estimators need to assess the rate for each of these items and the duration they’ll be needed. For example, the cost of a temporary site office must be calculated based on the project’s expected timeline.

Overhead Costs: In addition to indirect field costs, there are general overhead costs, also known as general and administrative (G&A) expenses. These are the costs of keeping the business operational, regardless of whether there are active projects. They include:

- Rent for Office Space: Costs associated with leasing office premises.

- Administrative Salaries: Wages for non-project-specific staff, such as administrative assistants and office managers.

- Software Subscriptions: Fees for various business software used in day-to-day operations.

- Utilities: Expenses for electricity, water, and other utilities in the office.

- Taxes: Business taxes that need to be paid.

- Depreciation: Reduction in value of business assets over time.

- Insurance: Costs for general business insurance policies.

Allocating Overhead Costs: To ensure the business remains profitable and operational, contractors must distribute overhead costs across all projects. Estimators typically consider the company’s total expected annual revenue and the total expected annual overhead cost. With these figures, they can allocate a specific percentage of the overhead cost to each project, ensuring that every job contributes its fair share to covering these essential expenses.

By accurately calculating and including both indirect field costs and overhead expenses, estimators provide a comprehensive view of the project’s total cost. This ensures that all necessary expenditures are covered, leading to more accurate bids and healthier profit margins for the construction business.

8. Account for Profit and Contingency

After calculating all the costs for a construction project, the estimator adjusts the total to include both profit margin and contingency. The profit represents the contractor’s earnings from the contract, which can be reinvested to grow the business. Contingency funds, on the other hand, are set aside to cover unexpected overruns and waste, which are common in construction projects.

Determining Profit Margin: Each construction business sets its own minimum attractive profit margin based on factors like growth goals, market conditions, and competitive landscape. This profit margin ensures that the company not only covers its costs but also generates enough revenue to sustain and expand its operations.

Setting Contingency Funds: Contingency amounts can vary widely across the industry depending on the type of construction, company size, and project risk. Typically, construction businesses add between 5-10% of the contract price to cover contingency. This buffer helps manage unforeseen issues without jeopardizing the project’s financial health.

Finalizing the Estimate: At the end of this process, the estimator arrives at the sales price that encompasses all project costs—materials, labor, equipment, indirect field costs, overhead, and contingency—while also ensuring a healthy profit. This final number equips contractors to submit a competitive bid or engage in negotiations with project owners or general contractors, confidently knowing they have accounted for all necessary expenses and potential risks.

Turning an Estimate into a Bid Proposal

Aligning with Construction Specifications: To ensure the bid reviewers understand that everything is included, it’s crucial to use the same terminology found in the construction specifications and drawings. This consistency helps avoid misunderstandings and ensures that the bid aligns perfectly with the project requirements.

Using the CSI Format: Utilizing the Construction Specifications Institute (CSI) format in the estimating process simplifies the comparison between each section of the bid price and the corresponding section of the specifications. Even for lump sum contracts, adhering to a standard format makes it easier to create a schedule of values. Additionally, it enhances the integration between estimating software and accounting systems, streamlining the entire process.

By meticulously aligning the bid proposal with the project specifications and using a standardized format, bid managers can present a comprehensive and professional proposal that stands up to scrutiny and increases the chances of winning the contract.

Get 5 New Leads Next 7Days With Our System

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- High-Rise Building

- Shopping Complex

Types of Estimates

Estimators prepare various types of estimates, each serving different purposes throughout the project lifecycle. These estimates are tailored to meet specific needs at different stages of a project.

Early Estimates: Early estimates provide developers with a rough cost for a proposed project. This preliminary figure helps determine whether the project is financially viable and if securing financing is feasible. These estimates are often less detailed but crucial for initial decision-making.

Design Phase Estimates: During the design phase, estimates help ensure that the project stays within budget. For example, if costs start to exceed expectations, an estimate can guide decisions on modifying finishes or materials to align with the budget. These estimates are more detailed than early estimates and provide a clearer picture of potential costs.

Detailed Estimates: As the project progresses, more detailed estimates are required. The American Society of Professional Estimators (ASPE) outlines five levels of detail in estimating, each increasing in precision and detail. These range from broad, conceptual estimates to detailed, line-item estimates used for bidding and final budgeting.

Level | Name | Description |

1 | Order of Magnitude | Based on data from similar past projects, this type of estimate provides a very rough idea of potential costs. |

2 | Schematic Design | Typically involves cost per square foot calculations for existing buildings with similar scope and finishes. |

3 | Design Development | Using a tentative design and lists of expected materials and quantities, estimators provide a rough estimate for the project. |

4 | Construction Documents | Using a nearly finished design, estimators establish a realistic budget for a project. |

5 | Bid Estimate | Contractors use the bid documents to prepare a bid estimate, which is the cost at which they can complete the project. |

Construction Estimating Software

Construction estimating software significantly streamlines the process of creating estimates by automating various aspects. However, the expertise of a skilled estimator remains crucial. While software aids in calculation and tabulation, a knowledgeable estimator understands the intricacies of construction projects, costs, processes, and productivity rates, which are essential for accurate data entry.

Despite the necessity of human expertise, construction estimating software has greatly reduced the workload for estimators. It allows for quick adjustments and eliminates the need to manually recalculate entire projects, enhancing efficiency and accuracy.

How Estimating Software Supports the Construction Process

- Automated Takeoffs: Using machine learning, the software can scan project drawings and documents to automatically determine the quantity of materials needed, saving time and increasing accuracy.

- Error Reduction: Computerized calculations minimize human errors and allow estimators to make minor cost adjustments that update the entire estimate instantly, ensuring precision.

- Increased Productivity: Estimators can focus more on critical aspects of estimating, such as selecting the necessary equipment and sourcing better pricing information, rather than getting bogged down by manual calculations.

Benefits of Construction Estimating Software

- Efficiency: By automating repetitive tasks, software allows estimators to complete their work faster.

- Accuracy: Automated calculations and data entry reduce the risk of mistakes.

- Flexibility: Easy adjustments to estimates save time and effort.

- Competitiveness: Enhanced productivity leads to more competitive bids and the potential for winning more projects.

Data-Driven Estimating for Long-Term Growth

Construction estimating is vital for the success of any construction business. To thrive and grow, a company must understand its costs and ensure profitability, which starts with an accurate and efficient estimating process.

Financially sound construction businesses rely on data-driven estimating. By leveraging job costing data from past projects and thoroughly understanding indirect and overhead costs, companies can create precise estimates. This approach enables them to submit bids that are both competitive and profitable, paving the way for sustainable growth and long-term success.

Conclusion

Accurate construction cost estimation is critical for the successful completion of any project, ensuring profitability and feasibility for both owners and contractors. This involves a detailed understanding of materials, labor, specifications, and pricing trends. Professional estimators follow a thorough process, from reviewing bid packages and conducting site visits to performing material takeoffs and soliciting supplier pricing. By meticulously calculating direct and indirect costs, overhead, insurance, and contingency, estimators provide precise bids that help manage financial risks and ensure project success. This data-driven approach supports long-term growth and competitiveness in the construction industry.

FAQs

Construction estimating involves calculating all costs needed for a construction project, including direct costs (materials, labor) and indirect costs (equipment depreciation, office salaries). Professional estimators handle this step to ensure both owners and contractors can complete a project profitably.

Accurate estimating is crucial for the success of any construction project. It helps owners determine project feasibility and budget constraints. Contractors rely on precise estimates to prepare competitive and profitable bids, avoiding underestimation or overestimation that could impact project success.

Review Bid Package: Ensure all documents are complete, understand the project scope, and identify specific needs.

Conduct a Site Visit: Assess site conditions, drainage, accessibility, and local codes to understand potential challenges and costs.

Perform a Material Takeoff: Identify and quantify all materials needed, using manual or digital tools.

Solicit Pricing from Suppliers and Vendors: Obtain accurate pricing for materials and equipment, considering factors like bulk pricing and material waste.

Evaluate Labor Requirements: Determine labor needs, calculate labor hours, and assess productivity, including calculating the loaded labor rate.

Determine Insurance and Bonding Costs: Include costs for required insurance policies and construction bonds.

Calculate Overhead and Indirect Costs: Account for indirect field costs and general overhead expenses to ensure all necessary expenditures are covered.

Account for Profit and Contingency: Adjust the total estimate to include profit margin and contingency funds for unexpected overruns.

The bid package includes essential documents like owner-contractor agreements and construction specifications. Estimators ensure all documents are present, understand the project scope, evaluate structural and MEP requirements, and identify nonstandard items to avoid overlooking any details.

A site visit helps estimators gain a clear understanding of site conditions, including drainage, soil, accessibility, and utility locations. It also involves assessing the surrounding area for local codes, resource availability, and nearby roadways to ensure accurate cost estimation.

Google Reviews

Process To Get Construction Estimate Report

Here I am going to share some steps to get construction estimate report.

-

You need to send your plan to us.

You can send us your plan on info@estimatorflorida.com

-

You receive a quote for your project.

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

-

Get Estimate Report

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.