How Much Does It Cost to Build a Modular Multifamily Building?

Building a modular multifamily building offers several advantages, including faster construction times, reduced waste, and often lower costs compared to traditional construction methods. Understanding the cost implications of modular construction is crucial for developers, investors, and stakeholders to ensure the project is completed within budget and meets quality standards. This guide breaks down the key components that contribute to the total cost of building a modular multifamily building, including a detailed cost estimator to help you plan your project effectively. By considering all these factors, you can make informed decisions, avoid unexpected expenses, and achieve a successful project outcome.

Accurate cost estimation is not only essential for financial planning but also for scheduling and resource management, ensuring that every phase of the project progresses smoothly and efficiently.

Factors Influencing the Cost of Building a Modular Multifamily Building

Several factors influence the cost of building a modular multifamily building. These include the type of building, materials used, size and complexity of the project, labor costs, location, and additional features such as amenities and landscaping. Understanding these factors helps in estimating the total cost accurately and planning the project efficiently. Each factor plays a crucial role in determining the overall budget, and careful consideration of these aspects can lead to more effective resource allocation and project management.

Type of Building

The type of building significantly impacts the overall cost. Modular multifamily buildings can range from low-rise structures with a few stories to mid-rise buildings with multiple floors, each having different requirements for materials, labor, and design complexity.

The choice of building type significantly impacts construction costs.

Building Type | Cost per Square Foot | Total Cost (for 100 units) |

Low-Rise | $273 – $455 | $54,600,000 – $91,000,000 |

Mid-Rise | $364 – $637 | $72,800,000 – $127,400,000 |

- Low-Rise Buildings: $273 – $455 per square foot. Low-rise buildings are typically three to four stories tall and are less complex to construct compared to mid-rise buildings. These structures often use standard construction materials and techniques, making them more cost-effective. Low-rise buildings are usually easier to manage and require less sophisticated construction equipment, reducing labor and machinery costs.

- Mid-Rise Buildings: $364 – $637 per square foot. Mid-rise buildings range from five to ten stories and require more complex designs and structural elements. These buildings often include elevators, additional safety features, and higher-quality materials. The construction of mid-rise buildings involves more stringent building codes and often requires advanced engineering solutions to ensure stability and safety. The increased complexity of mid-rise buildings can also introduce more design elements, such as balconies and shared spaces, which add to the overall cost.

Materials Used

The choice of materials greatly influences building costs. High-quality, durable materials may have a higher initial cost but can reduce maintenance expenses and increase the lifespan of the building.

The choice of materials significantly impacts construction costs.

Material Type | Cost per Square Foot | Total Cost (for 100 units) |

Standard Materials | $273 – $455 | $54,600,000 – $91,000,000 |

Premium Materials | $364 – $637 | $72,800,000 – $127,400,000 |

Eco-friendly Materials | $455 – $819 | $91,000,000 – $163,800,000 |

- Standard Materials: $273 – $455 per square foot. Standard materials include basic construction materials such as wood, concrete, and brick. These materials are commonly used in modular construction and provide a balance of cost and durability. While they may require more maintenance over time, they are generally sufficient for most residential projects, providing reliable performance at a lower cost.

- Premium Materials: $364 – $637 per square foot. Premium materials such as high-grade steel, marble, and specialty glass offer enhanced durability and aesthetic appeal, often used in luxury modular buildings. These materials provide a high-end finish and are designed to withstand wear and tear, reducing long-term maintenance costs. The use of premium materials can also attract higher rental rates and improve the marketability of the apartments.

- Eco-friendly Materials: $455 – $819 per square foot. Eco-friendly materials, including sustainable wood, recycled metal, and green roofing, contribute to energy efficiency and environmental sustainability but can increase initial costs. These materials often require specialized installation techniques and may come with higher upfront costs, but they offer significant long-term benefits in terms of energy savings and environmental impact. Using eco-friendly materials can also qualify the project for green building certifications, enhancing its appeal to environmentally conscious tenants and investors.

Size and Complexity of the Project

The size and complexity of the project are crucial factors in determining the overall cost. Larger projects require more materials and labor, and complex designs or structural requirements increase costs due to additional engineering and specialized installation techniques. Complexity can also introduce additional risks and uncertainties, which need to be managed carefully to avoid cost overruns.

The size and complexity of the project are critical factors in determining the overall cost.

Project Size | Cost Range |

Small Projects | $5,460,000 – $10,920,000 |

Medium Projects | $10,920,000 – $54,600,000 |

Large Projects | $54,600,000 – $273,000,000+ |

- Small Projects (up to 20 units): $5,460,000 – $10,920,000. Small modular multifamily buildings typically include fewer units and less complex designs, making them more cost-effective. These projects often involve standard construction practices and materials, making them more predictable in terms of cost and schedule. The simplicity of small projects can also lead to faster completion times and lower overall project management costs.

- Medium Projects (20 to 100 units): $10,920,000 – $54,600,000. Medium-sized projects often involve more complex designs and additional structural requirements, requiring more detailed planning and coordination. These projects might include multiple modular units connected together to create larger living spaces. The increased complexity can introduce challenges such as integrating new structures with existing ones, requiring more expertise and time.

- Large Projects (100 to 500 units): $54,600,000 – $273,000,000+. Large projects such as a 500-unit modular multifamily building involve significant planning efforts and coordination among multiple stakeholders. These projects often require extensive regulatory approvals, detailed engineering designs, and meticulous project management. The scale and complexity of large projects can lead to higher costs due to the need for specialized labor and materials, as well as the potential for delays and unforeseen challenges. Large projects benefit from economies of scale but require robust management and coordination to ensure success.

90% More Chances to Win Projects With Our Estimate!

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- School & University Building

- High-Rise Building

- Shopping Complex

- Data Center Building

Labor Costs

Labor costs vary based on the complexity of the project and the location. Skilled labor is essential for ensuring quality construction, and wages can differ significantly from one region to another. Investing in skilled labor can prevent costly mistakes and rework, ensuring the project is completed to the highest standards. Additionally, labor costs can be influenced by the availability of skilled workers, local wage rates, and the level of unionization in the area.

Labor costs vary based on the complexity of the installation and the location.

Labor Type | Cost per Hour | Total Cost (for 2,000 hours) |

Unskilled Labor | $63.70 – $101.92 | $127,400 – $203,840 |

Skilled Labor | $127.40 – $191.10 | $254,800 – $382,200 |

Specialized Labor | $191.10 – $254.80 | $382,200 – $509,600 |

Total | $63.70 – $254.80 | $764,400 – $1,095,640 |

- Unskilled Labor: $63.70 – $101.92 per hour. Unskilled labor is used for basic tasks such as carrying materials and assisting skilled workers. While these tasks do not require specialized skills, they are essential for supporting the overall installation process. Proper management of unskilled labor can help keep the project on schedule and within budget. Efficient use of unskilled labor can optimize overall labor costs by freeing up skilled workers for more complex tasks.

- Skilled Labor: $127.40 – $191.10 per hour. Skilled labor is necessary for tasks that require specific expertise, such as framing, plumbing, electrical work, and finishing. Skilled workers ensure that the installation is performed correctly, preventing issues such as structural weaknesses or safety hazards. Their expertise can significantly impact the quality and durability of the construction. Investing in skilled labor can reduce long-term maintenance costs and enhance the overall quality of the building.

- Specialized Labor: $191.10 – $254.80 per hour. Specialized labor includes professionals such as electricians, plumbers, and HVAC technicians who have advanced skills in specific areas of the project. These workers are critical for achieving high-quality finishes and ensuring the structural integrity of the building. Hiring specialized labor can be more expensive but is often necessary for complex or high-stakes projects. Specialized labor ensures that technical systems are installed correctly and meet all regulatory standards, reducing the risk of future issues.

Location

The location of the property affects costs due to variations in labor rates and local regulations. Urban areas typically have higher costs compared to suburban or rural locations. The availability of resources and proximity to suppliers also play a role in determining location-based costs. Understanding the impact of location on costs helps in planning and budgeting more effectively.

- Urban Areas: Higher labor costs and more stringent regulations. Urban construction projects benefit from easy access to amenities and services but come with higher overall expenses. The increased demand for skilled labor and premium materials in urban areas drives up costs. Additionally, urban projects may face more stringent building codes and zoning laws, adding to the complexity and cost. The logistics of working in densely populated areas can also contribute to higher costs, including restrictions on work hours and higher transportation costs for materials.

- Suburban Areas: Moderate costs, balanced access to materials and labor. Suburban areas offer a compromise between cost and convenience, making them a popular choice for many projects. These areas typically have lower regulatory hurdles and labor costs compared to urban centers, making them more cost-effective while still offering good access to suppliers and services. Suburban projects often benefit from a more predictable regulatory environment and easier logistics, reducing the risk of delays and unexpected costs.

- Rural Areas: Lower costs, but potentially higher transportation expenses for materials. Rural projects can be more cost-effective, but logistical challenges may increase certain expenses. The distance from suppliers and the availability of skilled labor can affect overall project costs, and rural locations may also face unique environmental challenges that need to be addressed. However, the lower cost of land and labor in rural areas can offset some of these additional expenses. Rural projects may also benefit from less stringent regulatory requirements, reducing overall compliance costs.

Download Template For Multi-family Project Breakdown

- Materials list updated to the zip code

- Fast delivery

- Data base of general contractors and sub-contractors

- Local estimators

Additional Features

Additional features can significantly impact the overall cost of building construction.

Feature | Cost per Unit | Total Cost (for 100 units) |

Amenities | $7,840 – $19,600 | $784,000 – $1,960,000 |

Landscaping | $9,800 – $39,200 | $980,000 – $3,920,000 |

Custom Finishes | $3,920 – $15,680 | $392,000 – $1,568,000 |

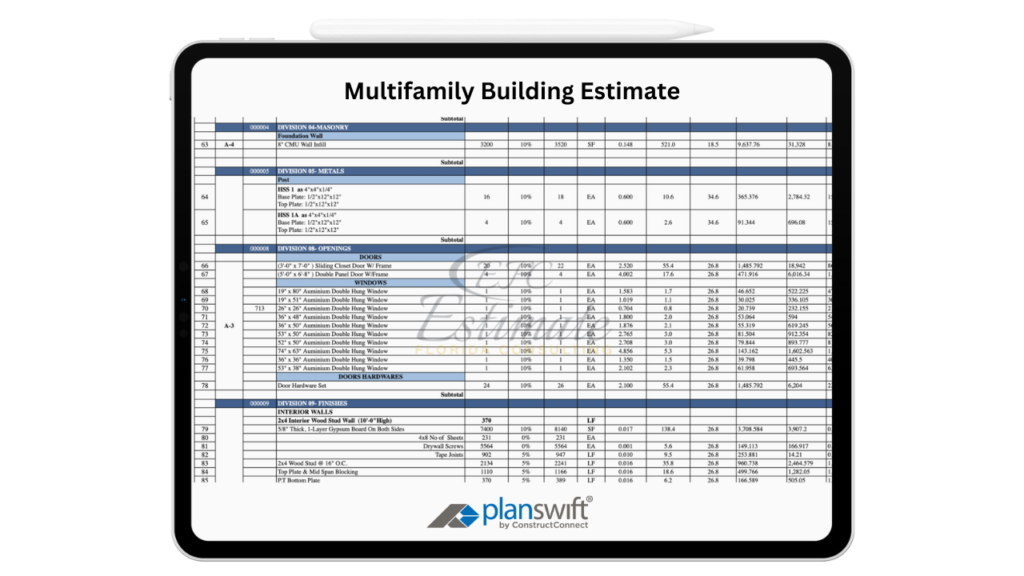

Detailed Cost Breakdown

To provide a clear picture of the construction costs for a modular multifamily building, we have broken down the expenses into various categories. This detailed breakdown helps in understanding where the money is spent and in planning the budget more effectively. By examining each category, stakeholders can identify potential areas for savings and ensure that funds are allocated efficiently.

Environmental Impact and Sustainability

Sustainable Materials and Practices

Using sustainable materials and construction practices can significantly impact the overall cost of building a modular multifamily building. Although these choices may come at a higher initial cost, they offer long-term savings through durability and reduced maintenance. Eco-friendly materials such as bamboo flooring, recycled steel, and low-VOC (volatile organic compounds) paints contribute to a healthier living environment and lower energy costs.

- Cost of Sustainable Materials: $455 – $819 per square foot. These materials often require specialized installation techniques and may come with higher upfront costs, but they offer significant long-term benefits in terms of energy savings and environmental impact. Using eco-friendly materials can also qualify the project for green building certifications, enhancing its appeal to environmentally conscious tenants and investors.

- Long-term Benefits: Reduced energy costs, lower maintenance expenses, and increased property value. Sustainable practices also improve indoor air quality and reduce the building’s overall carbon footprint, contributing to environmental conservation.

Energy Efficiency

Incorporating energy-efficient systems and technologies can increase the initial construction cost but result in substantial long-term savings. These systems include high-efficiency HVAC units, solar panels, and energy-efficient windows and insulation.

- Initial Cost of Energy-Efficient Systems: $28,000 – $70,000 per unit. This includes the cost of installing solar panels, energy-efficient HVAC systems, and high-performance windows and insulation.

- Long-term Savings: Reduced utility bills, lower maintenance costs, and potential tax incentives. Energy-efficient systems can also enhance the property’s marketability, attracting tenants who prioritize sustainability.

Project Management and Planning

Importance of Effective Project Management

Effective project management is essential for controlling costs and ensuring timely completion. This includes detailed planning, regular monitoring, and coordination between different teams. Hiring a competent project manager can save money by avoiding delays, reducing waste, and ensuring that all aspects of the project meet the required standards.

- Cost of Project Management: $280,000 – $700,000 for a large project. This includes the salary of a project manager and the cost of project management software and tools.

- Benefits: Avoiding delays, reducing waste, and ensuring high-quality construction. A project manager also ensures that communication among all stakeholders is clear and efficient, helping to resolve issues quickly and maintain project momentum.

Get 5 New Leads Next 7Days With Our System

- Multi-Family Building

- Hotel Building

- Hospital Building

- Warehouse Building

- High-Rise Building

- Shopping Complex

Risk Management and Contingency Planning

Unexpected issues can arise during building construction, making it essential to include a contingency fund in the budget. This fund covers unforeseen expenses such as delays, design changes, or additional materials. Allocating around 10-15% of the total budget for contingencies can help manage these surprises and keep the project on track.

- Contingency Fund: $7,000,000 – $21,000,000 for a large project. This fund provides a financial buffer to address unexpected challenges without disrupting the project’s progress.

- Benefits: Minimizing delays and additional costs, enhancing investor confidence, and supporting smoother project financing. Proper contingency planning ensures that the project can continue smoothly even when unexpected challenges arise, reducing stress for stakeholders.

Conclusion

Estimating the cost of building a modular multifamily building accurately is vital for the success of any construction project. By understanding the various factors that influence costs and using a detailed cost estimator, you can plan your project effectively and ensure it stays within budget. Whether you are undertaking a residential, commercial, or industrial project, careful planning and budgeting are key to achieving high-quality, timely, and cost-effective results. Investing in skilled professionals, quality materials, and effective project management will help you achieve a successful and sustainable building construction. The effort put into pre-construction planning lays a strong foundation for the entire project, leading to better outcomes and greater satisfaction for all stakeholders. Accurate cost estimation not only supports financial stability but also contributes to the overall success and quality of the construction project.

FAQs

Building a modular multifamily building can cost between $54,600,000 and $163,800,000 for a 100-unit building, depending on factors like building type, materials, project size, labor, location, and additional features.

Key factors include the type of building (low-rise, mid-rise), materials used (standard, premium, eco-friendly), project size and complexity, labor costs, location, and additional features such as amenities and landscaping.

The type of building significantly impacts costs. Low-rise buildings cost $273 – $455 per square foot, while mid-rise buildings cost $364 – $637 per square foot.

Standard materials cost $273 – $455 per square foot, premium materials cost $364 – $637 per square foot, and eco-friendly materials cost $455 – $819 per square foot. Higher quality and sustainable materials can increase initial costs but may reduce long-term maintenance and energy expenses.

Larger and more complex projects require more materials, labor, and specialized installation techniques, increasing costs. Small projects (up to 20 units) range from $5,460,000 – $10,920,000, medium projects (20 to 100 units) range from $10,920,000 – $54,600,000, and large projects (100 to 500 units) range from $54,600,000 – $273,000,000+.

Labor costs vary based on the complexity of the tasks and the location. Unskilled labor costs $63.70 – $101.92 per hour, skilled labor costs $127.40 – $191.10 per hour, and specialized labor costs $191.10 – $254.80 per hour.

Urban areas typically have higher labor costs and more stringent regulations, increasing overall expenses. Suburban areas offer a balance between cost and convenience, while rural areas have lower costs but potentially higher transportation expenses for materials.

Additional costs include amenities and landscaping, which can add $784,000 – $1,960,000 and $980,000 – $3,920,000, respectively, for a 100-unit building. Custom finishes can also add $392,000 – $1,568,000.

Effective project management involves detailed planning, regular monitoring, and coordination between teams to avoid delays, reduce waste, and ensure quality construction. Hiring a competent project manager can save money by preventing costly mistakes and rework.

Contingency planning is essential for managing unexpected issues during construction. Allocating around 10-15% of the total budget for contingencies helps cover unforeseen expenses, minimizing delays and additional costs.

Sustainable practices and eco-friendly materials can increase initial costs but offer long-term savings through durability and reduced maintenance. Implementing green building certifications can also enhance the property’s value and appeal to environmentally conscious buyers.

The total estimated cost ranges from $54,600,000 to $163,800,000 for a 100-unit building, considering costs for building type, materials, size and complexity, labor, and additional features.

Accurate cost estimation ensures financial stability, supports effective resource allocation, and helps in scheduling and resource management. It leads to better project outcomes, higher quality construction, and greater satisfaction for all stakeholders.

Google Reviews

Process To Get To Build a Modular Multifamily Building Estimate Report

Here I am going to share some steps to get your to build a modular multifamily building estimate report.

-

You need to send your plan to us.

You can send us your plan on info@estimatorflorida.com

-

You receive a quote for your project.

Before starting your project, we send you a quote for your service. That quote will have detailed information about your project. Here you will get information about the size, difficulty, complexity and bid date when determining pricing.

-

Get Estimate Report

Our team will takeoff and estimate your project. When we deliver you’ll receive a PDF and an Excel file of your estimate. We can also offer construction lead generation services for the jobs you’d like to pursue further.